1.The working principle of dried wood log biomass pellet processing equipment

The core function of dry wood pellet processing equipment is to compress dried wood raw materials (such as sawdust, wood powder, and straw) into high-density pelletized fuel or material. Its operating principles primarily include the following key steps:

Raw material pretreatment: First, the dry wood is crushed to break down large pieces of wood into uniform sawdust or wood powder, ensuring a consistent particle size for subsequent compression.

Extrusion: The raw material is fed into the pelletizer's ring or flat die. The high-speed rotation of the rollers applies pressure, squeezing, rubbing, and heating the material within the die. The high temperature softens the wood fibers and allows them to bind tightly together, ultimately extruding them through the die to form cylindrical pellets.

Cooling and screening: The pellets, freshly extruded, are hot and need to be cooled to room temperature in a cooler to prevent mold. They are then screened to remove debris and impurities, resulting in a qualified product.

2.Characteristics of dried wood log biomass pellet processing equipment

Precisely matched to dry wood properties: Designed specifically for dry sawdust, wood scraps, dry branches, and other materials with a moisture content of 8%-15%, this machine eliminates the need for additional large-scale drying equipment (only a simple conditioning device is used to fine-tune the moisture content when the material moisture content is slightly lower). This avoids the high energy consumption and clumping associated with wet wood processing.

Compatible with a wide range of wood materials: It can process dry wood of varying hardness, including softwoods (pine and fir) and hardwoods (birch and oak). By flexibly adjusting the pulverizer blade material (high-carbon steel wear-resistant blades for hardwood) and the forming roller pressure, it ensures stable crushing efficiency and forming results, achieving a material utilization rate exceeding 95%.

3.Application scenarios of dried wood log biomass pellet processing equipment

Biomass Energy:Provides raw materials for biomass power plants, heating companies, and industrial boilers (such as those in food processing and textile mills). It converts dry wood into high-density pellet fuel, replacing traditional energy sources like coal and natural gas and reducing carbon emissions. It can also be used as fuel for household heating stoves and fireplaces, meeting clean heating needs.

Wood Processing and Furniture Industry:Processes dry sawdust, scraps, shavings, and other waste generated by furniture and wood processing plants into pellets. These can be recycled as fuel for in-plant boilers or sold externally, transforming waste into a resource and reducing solid waste disposal costs.

Agriculture and Animal Husbandry Support:First, it processes agricultural and forestry waste such as dry straw and branches into pellets for use as bedding for livestock and poultry (e.g., cowshed and chicken coop bedding, which is highly absorbent and easy to clean). Second, some equipment can process a mixture of dry sawdust and feed ingredients to produce simple biomass feed carrier pellets to aid animal husbandry production. Environmental Protection and Solid Waste Treatment:

For forestry pruning waste, such as dry branches and wood processing waste, this equipment compresses loose waste into high-density pellets, reducing transportation and storage space while also preventing environmental pollution caused by indiscriminate waste stacking, effectively turning waste into treasure.

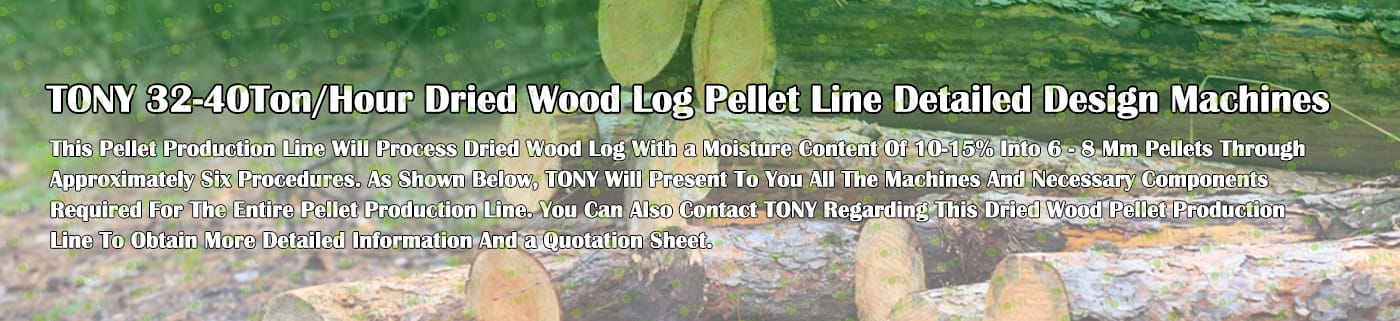

TONY Brand 32-40Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 32-40Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

2. Raw Material: All kinds of dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 32-40 tons per hour

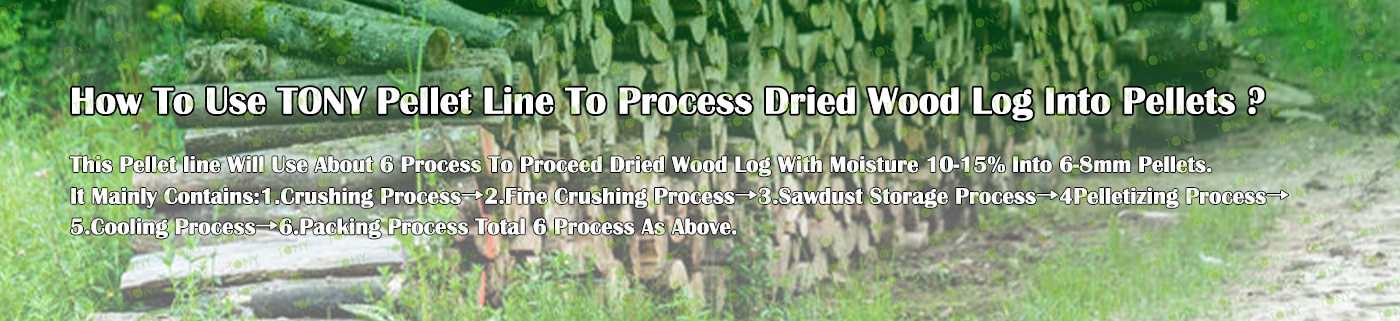

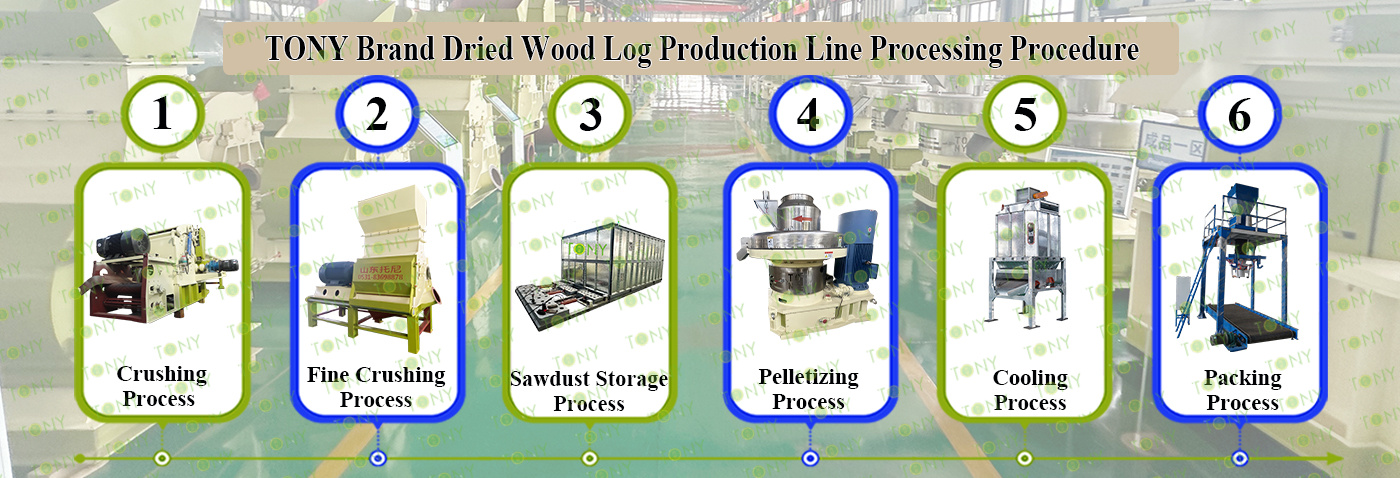

5. Process: Crushing Process - Fine Crushing Process -Sawdust Storage Process- Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1600-1000-315KW, Effective Hammer Mill-TFD100*200-315KW, TONY Large Hydraulic Storage Silo,TONY Pellet Machine TYJ860-Ⅲ-280KW, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

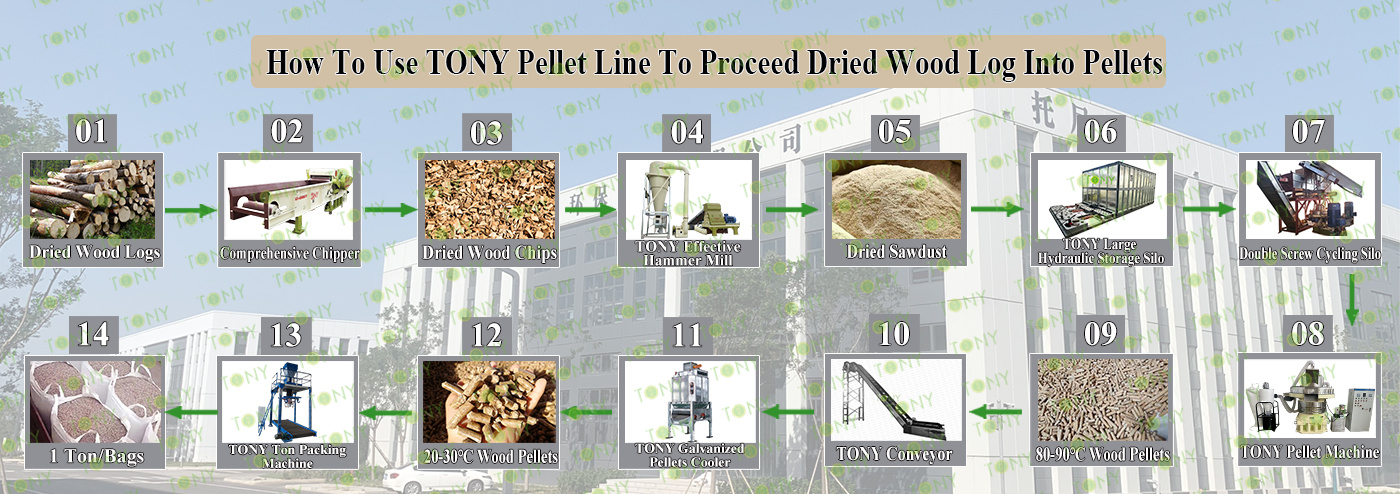

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut dried wood log with a diameter of less than 40cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Large Hydraulic Storage Silo |

| 1.To Grind Wood Logs φ ≤40cm Into25-55mm Wood Chips. 2.Model: TPC1600-1000-315KW With 6 Blades*2sets 3.Capacity:32-40Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD100*200-315KW*3sets 3.Capacity: 12-14Ton/Hour/Set |

1.To Storage Sawdust Before Pellet machine Model: TCY-35*3sets 2.TONY Uses Galvanized Material |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*8sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2sets 3.Capacity:32-40Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags 2.Model: TBD*2sets 3.Capacity: 32-40Ton/Hour |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 40cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPC1600-1000 model with 6 flying blades type

C.Capacity:32-40Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:32-40Ton/Hour.

C.TONY brand effective hammer mill TFD100-200-315KW*3sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:32-40Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*8sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.2 set of TONY galvanized cooler separator with capacity 32-40Ton/Hour

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.2 sets of TONY ton packing machine

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

1.Strong policy support:

With the ongoing advancement of the "Dual Carbon" strategy, China has introduced a series of policies to encourage the development and application of biomass energy. For example, the "14th Five-Year Plan for Renewable Energy Development" explicitly supports this sector, creating a favorable policy environment for biomass pellet processing projects.

2.Abundant raw material resources:

The raw materials for biomass pellets primarily consist of agricultural and forestry waste, such as straw, sawdust, rice husks, and peanut shells. These sources are widespread, and in some areas, these raw materials are even available free of charge, effectively reducing procurement costs.

3.Strong market demand:

Biomass pellets can be used for industrial heating, residential heating, power generation, animal husbandry, and other applications. With increasing environmental protection requirements, traditional coal-fired boilers are gradually being phased out. Demand for biomass pellets is rapidly growing in areas such as industrial boiler renovation, biomass heating, and power plants.

1.Wide range of sources and low cost:

The raw materials are mainly forestry waste such as wood chips, scraps, branches, and bark generated by wood processing. These materials are available in large quantities in wood processing plants, furniture factories, and other places. Some can be obtained at low prices or even for free, which can effectively control the cost of raw materials.

2.Strong sustainability:

It is a renewable resource. As long as trees are harvested and planted reasonably, a continuous supply of raw materials can be achieved, which is in line with the concept of green development.

3.High and stable calorific value:

The calorific value of wood chip pellets is usually 4000-5000 kcal/kg, and the combustion efficiency can reach more than 90%. It can provide heat stably to meet the needs of industrial heating and household heating.

4.Complete combustion and low pollution:

The pollutants such as sulfur dioxide and nitrogen oxides produced during combustion are much lower than those of coal, and the amount of ash is small, which has little impact on the environment and meets environmental protection standards.

2025 Tony Machinery - All Rights Reserved. Map