Project Brief Introduction:

1.Product:Dried Wood Log Pellet Line

2.Capacity:2-2.5T/Hour

3.TONY Brand 2-2.5Ton /Hour Dried Wood Log Pellet Line Project Process

4.Main Machine: Wood Chipper,Hammer Mill,TONY Pellet MachineTYJ551-Ⅲ-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 280 kw

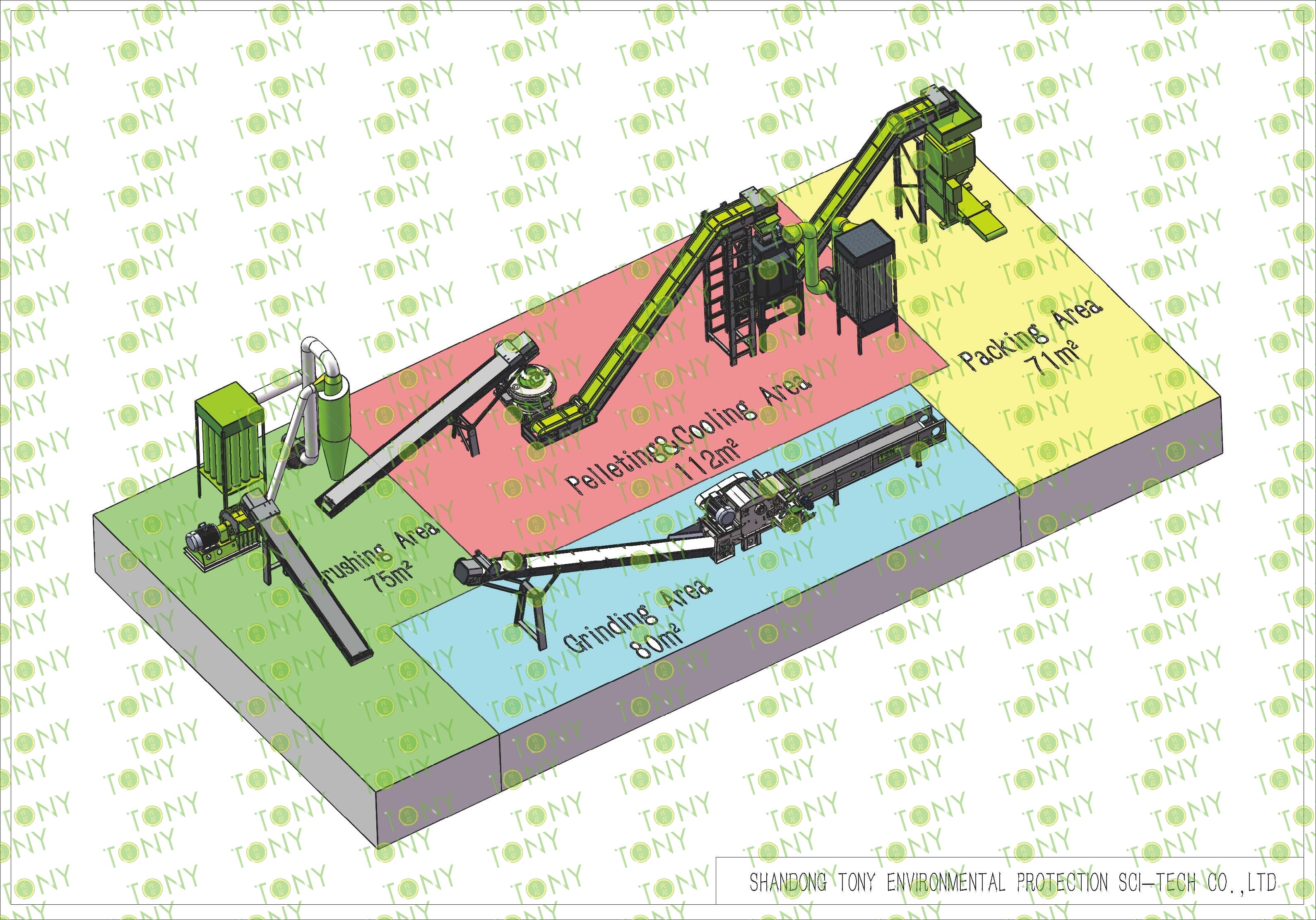

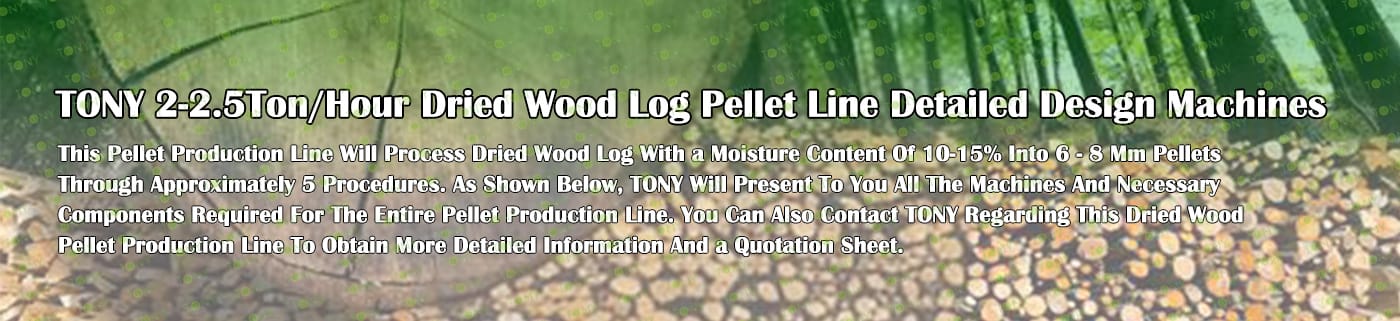

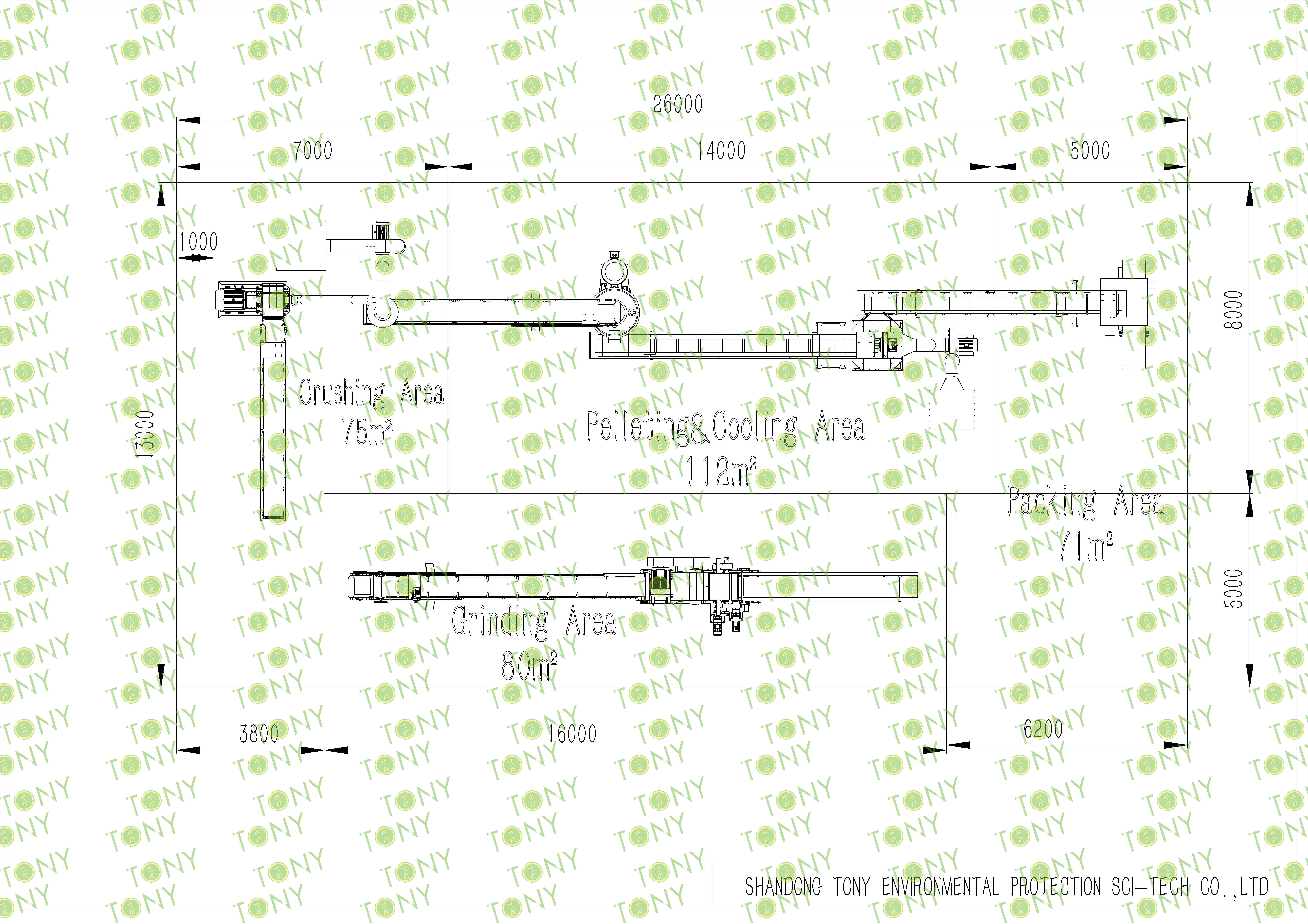

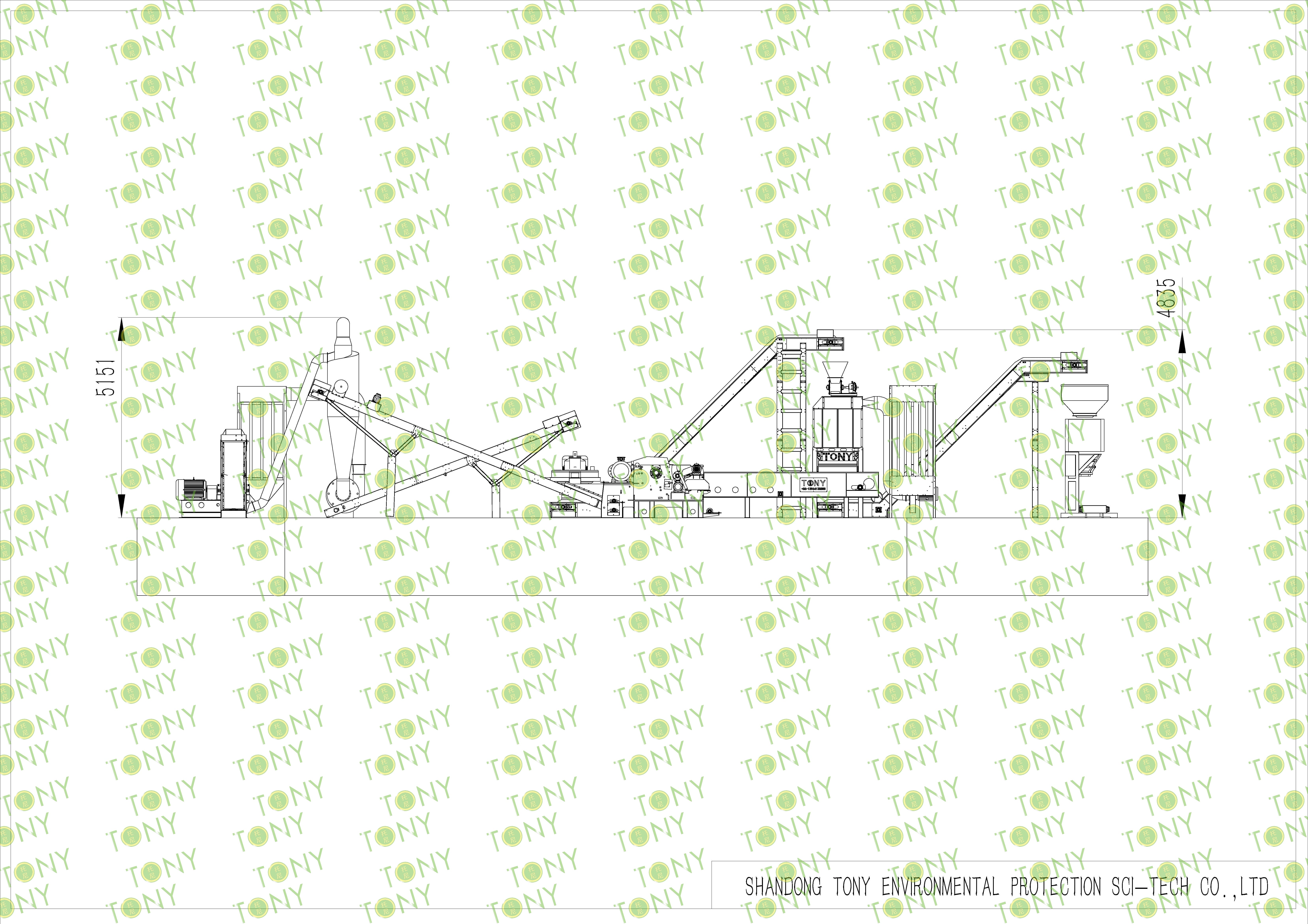

6.Need Area: About 338 ㎡ L: 26M W: 13M H: 5.151M

Project Layout For Customer:

1. The working principle of dried wood log biomass pellet processing equipment

The core principle of wood pellet processing equipment (such as wood chip pellet machines) is to convert biomass feedstock into high-density pellet fuel through mechanical extrusion. The basic process includes three steps: feedstock pretreatment (crushing, drying, and screening), mechanical pressing, and finished product processing (cooling and packaging). For example, in a ring die pellet machine, a motor connected to a reducer via a coupling drives the ring die to rotate. Gravity forces the feedstock into the pressing zone, where the pressing rollers squeeze the material into the ring die holes. After being formed in the die, the pellets are cut into pellets of a fixed length by a cutter.

2. Characteristics of dried wood log biomass pellet processing equipment

Wood pellet processing equipment (i.e., wood biomass pellet machines and supporting production lines) is specifically designed to process wood materials such as sawdust, wood chips, and branches into high-density pellets.

It is compatible with a wide range of wood materials: sawdust, wood chips, shavings, wood chaff, shredded branches, and waste wood. Both softwoods (such as pine and fir) and hardwoods (such as oak and birch) can be efficiently processed after pretreatment (crushing and pulverization).

To address raw material moisture fluctuations: Dedicated drying equipment (such as drum dryers) can control the moisture content of wood raw materials to 10%-15% (the optimal moisture range for wood pellet production), avoiding problems such as clogging and loose pellets caused by excessive moisture.

Flexible particle size control: The accompanying pulverizer can crush wood raw materials to the size of sawdust, meeting the pellet machine's fineness requirements and ensuring uniform pellets.

3. Application scenarios of dried wood log biomass pellet processing equipment

Processing equipment provides fuel for factory boilers and kilns (replacing coal and oil), such as steam boilers in textile and food processing plants, and heating kilns in the ceramics and building materials industries. Stable pellet production ensures a secure energy supply.

Power Generation:Biomass power plants require large quantities of standardized pellets as fuel. Large-scale processing equipment can meet the power plants' stringent requirements for pellet calorific value and density, ensuring efficient combustion and stable power generation.

Residential Heating:For pellets used in home fireplaces and space heaters, processing equipment must control pellet size and hardness to accommodate residential combustion equipment. The equipment's refined production capabilities directly impact the user experience of these pellets.

TONY Brand 2-2.5Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:2-2.5Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

2. Raw Material: All kinds of Dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 2-2.5 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Wood Chipper TPQ216 - 55KW, Effective Hammer mill-TFD65*75-55KW, TONY Pellet Machine TYJ551-Ⅲ-132KW, Pellet Cooler, Small Packing Machine and Belt Conveyors

|

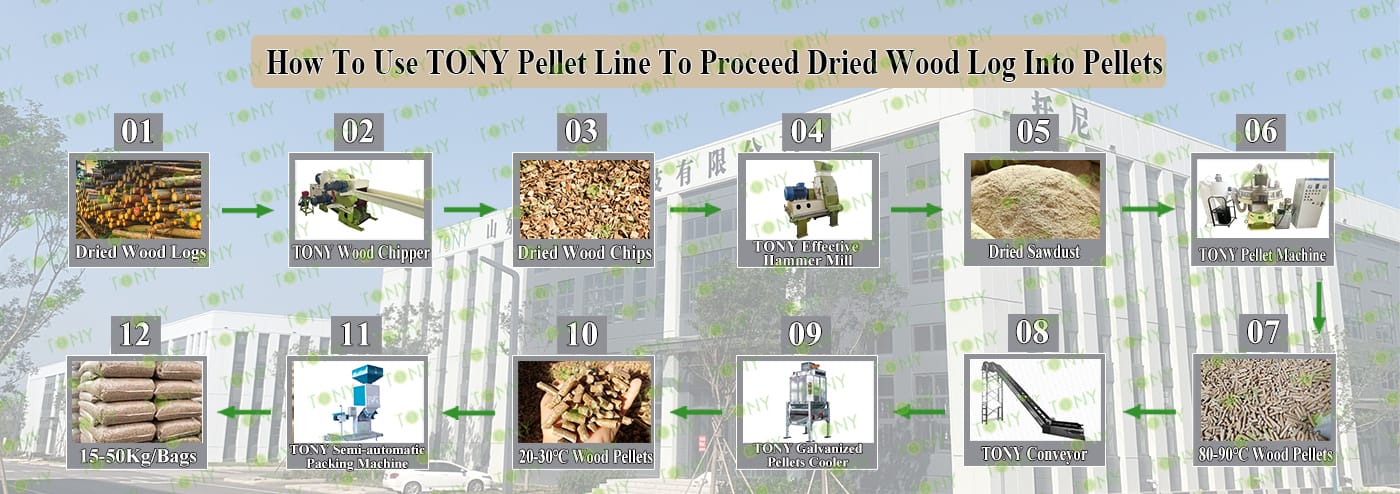

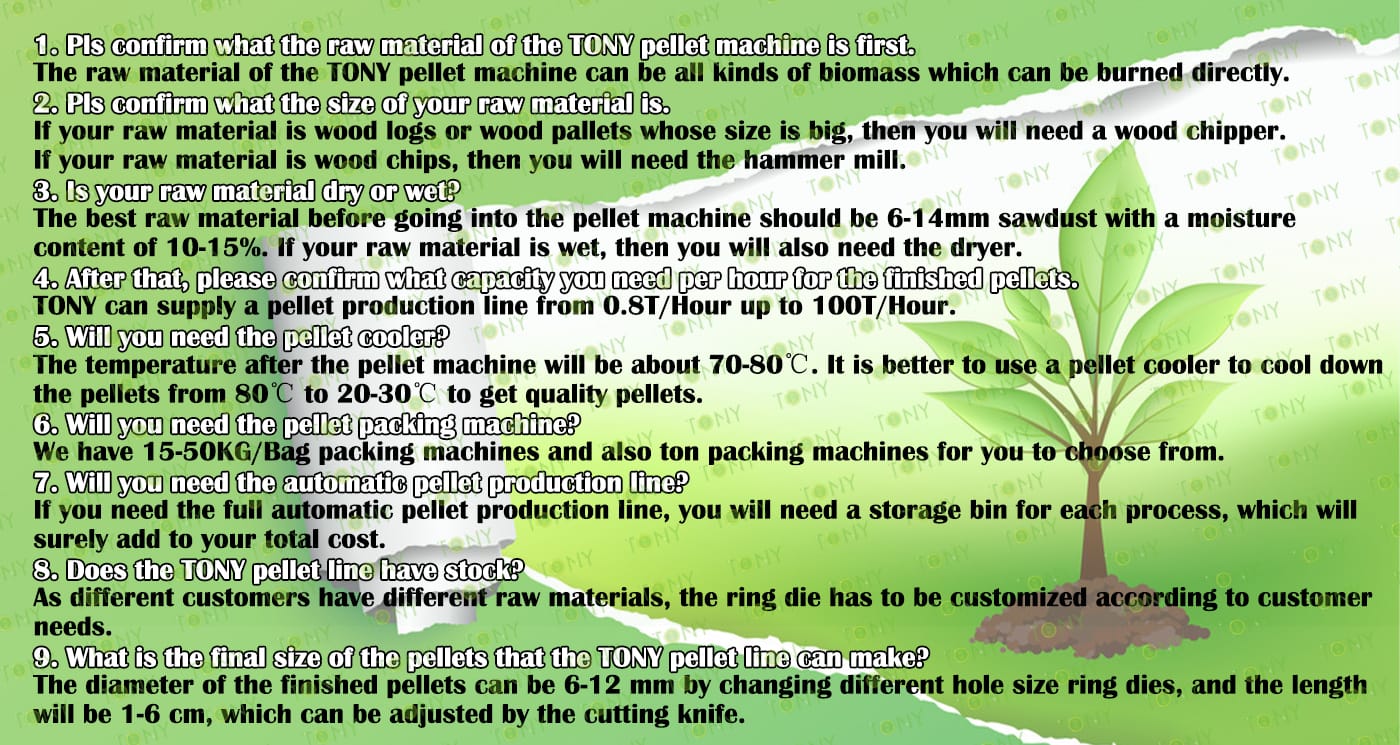

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY wood chipper to cut dried wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY Effective Hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. |

||

|

|

|

| Wood Chipper | Effective Hammer mill | Vertical Ring Die Sawdust Pellet Machine |

| 1.To Grind Wood Logs φ ≤20cm Into25-55mm Wood Chips. 2.Model: TPQ216-55KW With 2 Blades*1set 3.Capacity: 4-7Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD65*75-55KW*1set 3.Capacity: 2-2.5Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-132KW*1set 3.Capacity:2-2.5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-1.5*1set 3.Capacity:2-2.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 2-2.5Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 50cm*4sets 3.Capacity:Designed With The Whole Line |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPQ216 model with 2 flying blades type

C.Capacity:4-7Ton/Hour.

Main Parts:

(1)TONY's Wood Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:2-2.5Ton/Hour.

C.TONY brand effective hammer mill TFD65*75-55KW*1set

Main Parts:

(1)TONY Effective Hammer mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:2-2.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-132KW

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set of TONY galvanized cooler separator with capacity 2-2.5ton/hour

Main Parts:

(1)TONY's Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY semi-automatic packing machine.

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

1. With the increasingly severe energy and environmental crises, biomass energy, as a renewable and clean energy source, is gaining increasing attention. Wood, for example, has enormous potential for further development. Biomass can be utilized in a variety of ways, and processing it into compressed pellet fuel is a leading approach. The sulfur content in biomass pellet fuel is less than one-tenth that of coal. Using it as a substitute for coal effectively reduces atmospheric sulfur dioxide emissions, and the ash produced after combustion serves as an excellent natural fertilizer. Currently, gasification of biomass pellets is a clean and environmentally friendly combustion method, playing a significant role in reducing pollution emissions and protecting the atmospheric environment.

2. Biomass fuel is not only environmentally friendly but also provides an alternative to meet national energy needs. Market demand for biomass fuel continues to grow, and the price of biomass pellets made from straw is steadily rising. For entrepreneurial projects, the profit margins are considerable. Therefore, using straw to produce biomass pellets offers numerous benefits. Besides protecting the environment and helping to solve employment problems, it also brings significant economic benefits and ensures energy sustainability.

As a biomass energy source, wood pellets have significant environmental protection characteristics and energy benefits. In terms of environmental protection, its production process does not contain any chemical additives, and it is smokeless and odorless when burned, has no pollution to the environment, and meets environmental protection requirements.

Compared with traditional coal, its carbon dioxide emissions are 97.91% less than coal, sulfur dioxide emissions are 99.15% lower than coal, and nitrogen dioxide emissions are 72.09% less than coal, almost achieving zero pollution emissions. At the same time, its raw materials are mainly agricultural and forestry waste, such as branches, sawdust, straw, etc., which are renewable energy sources and effectively realize the recycling of resources. In terms of energy efficiency, the calorific value of wood pellet fuel can reach 3600-4200 kcal/kg, and the thermal efficiency can reach more than 85% when using a special biomass heating furnace, which has a high energy density.

2025 Tony Machinery - All Rights Reserved. Map