Project Brief Introduction:

1.Product:Dried Wood Log Pellet Line

2.Capacity:3-4T/Hour

3.TONY Brand 3-4Ton /Hour Dried Wood Log Pellet Line Project Process

4.Main Machine: Wood Chipper,Hammer Mill,TONY Pellet MachineTYJ551-III-110KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 440KW

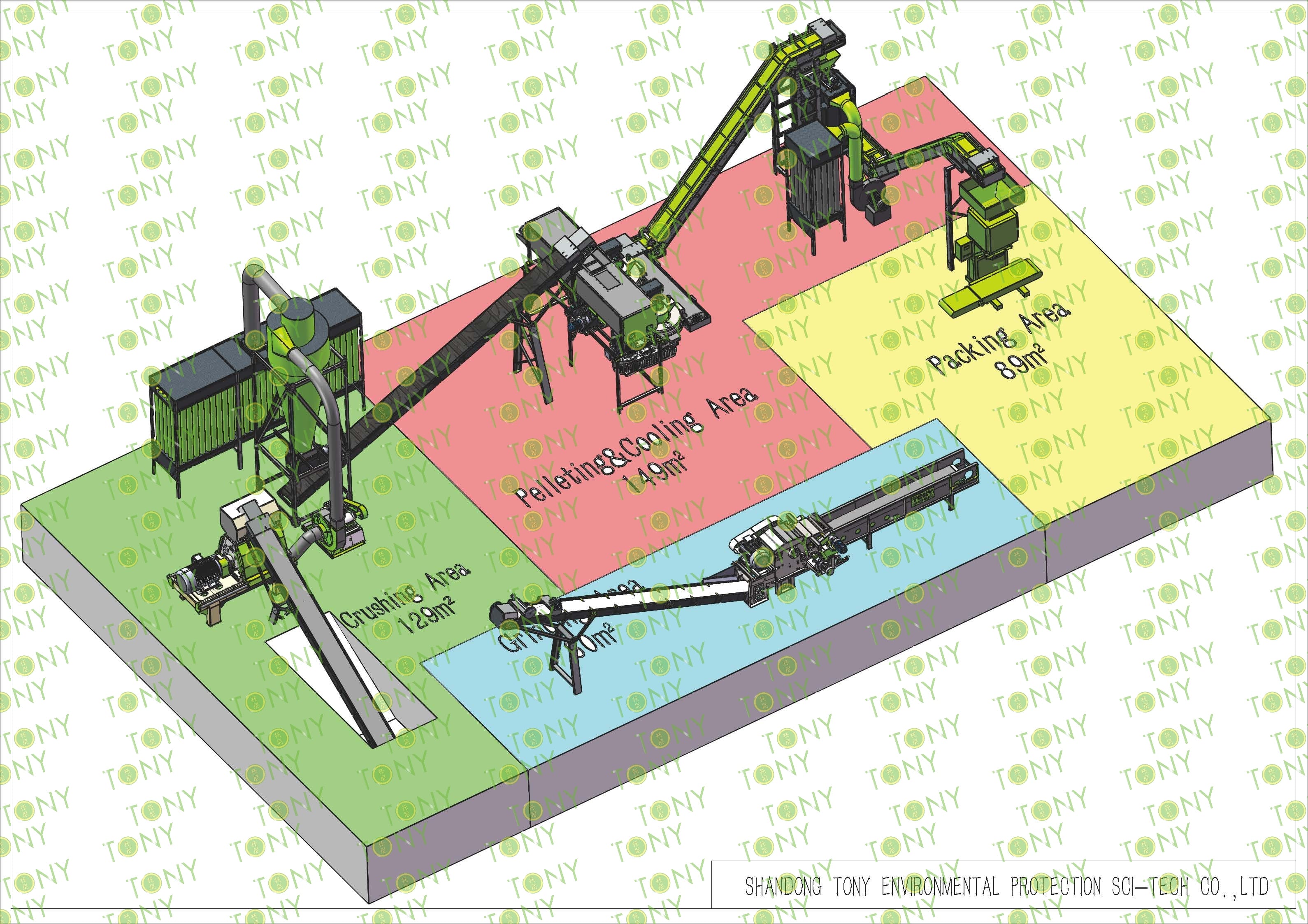

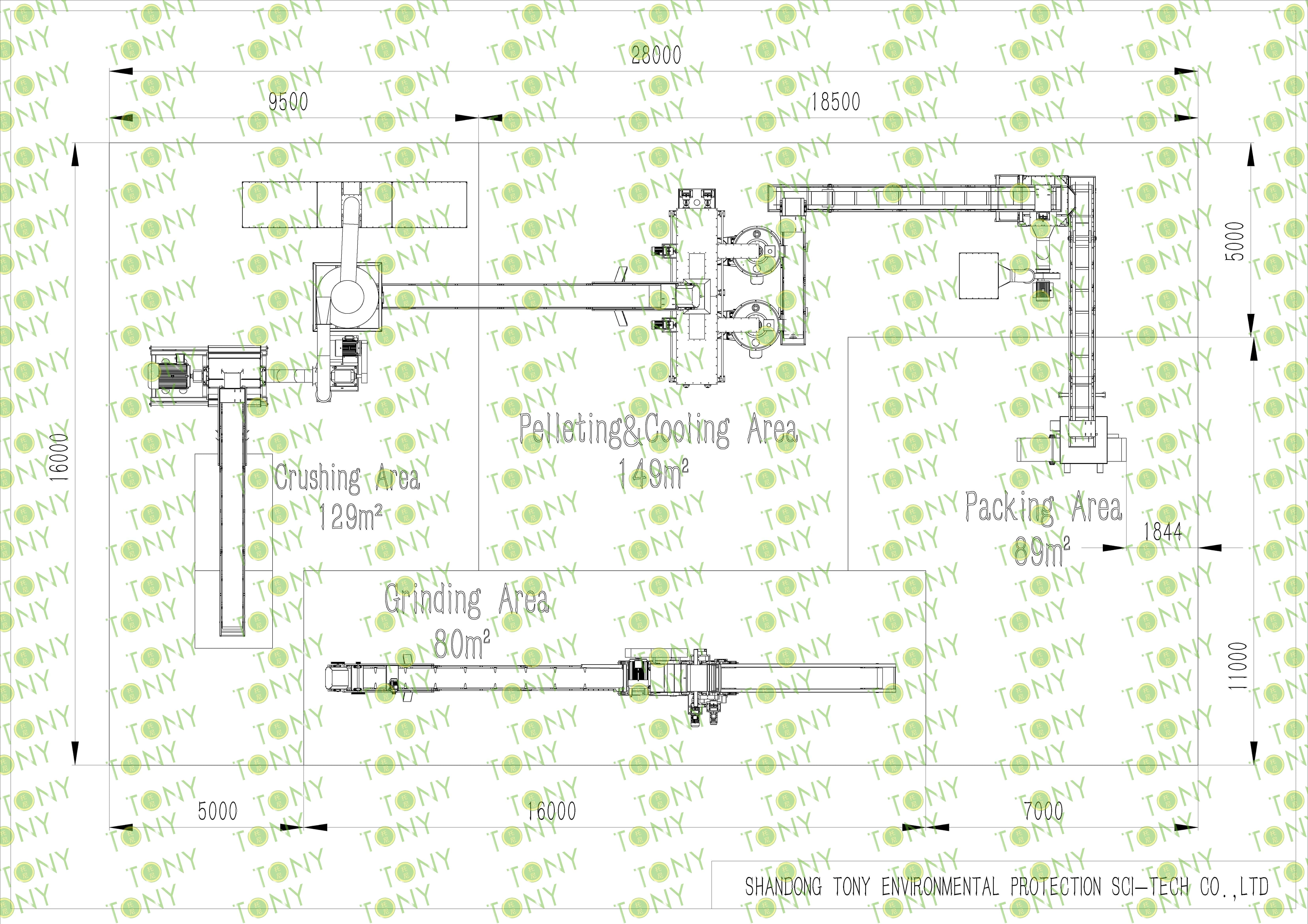

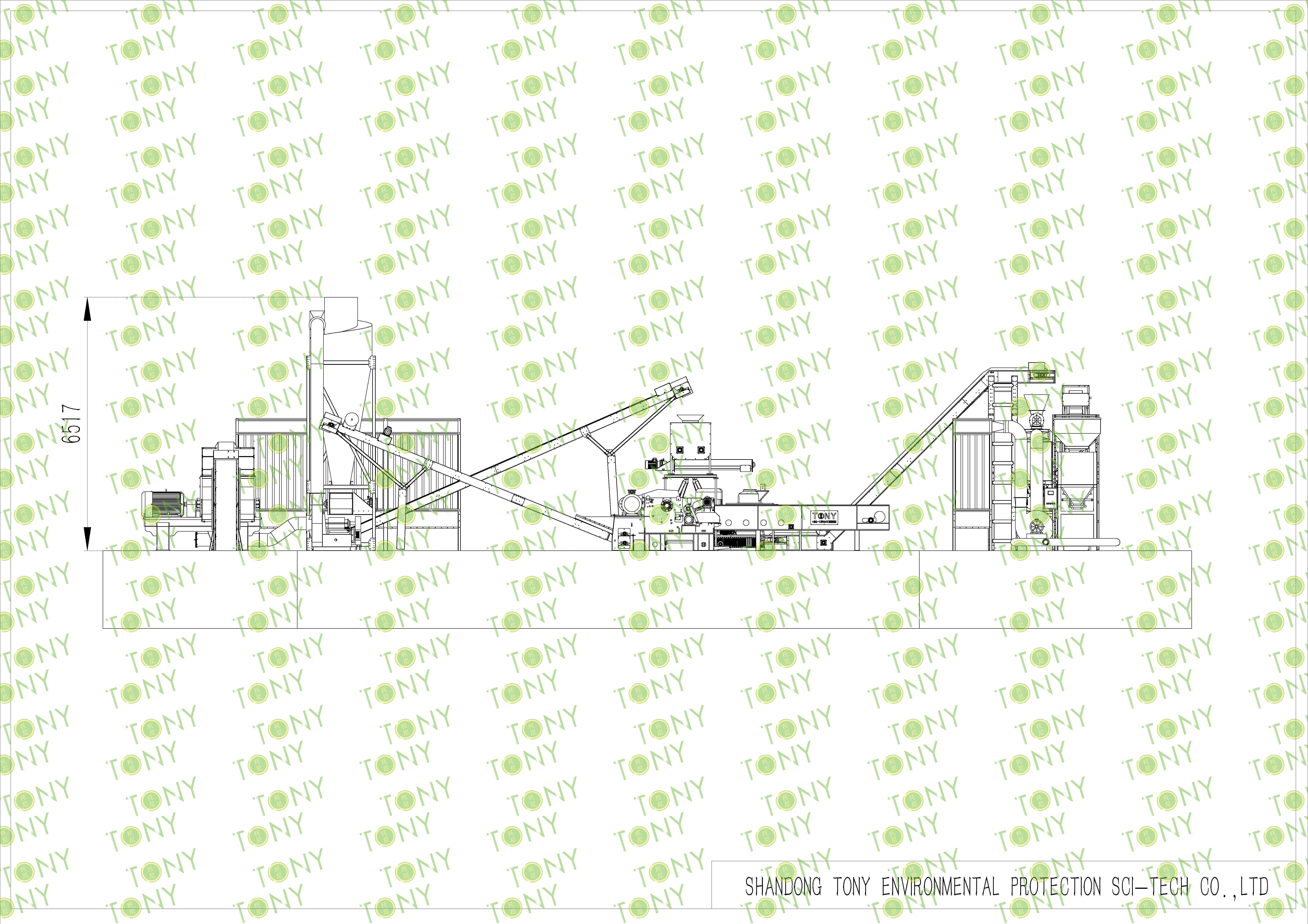

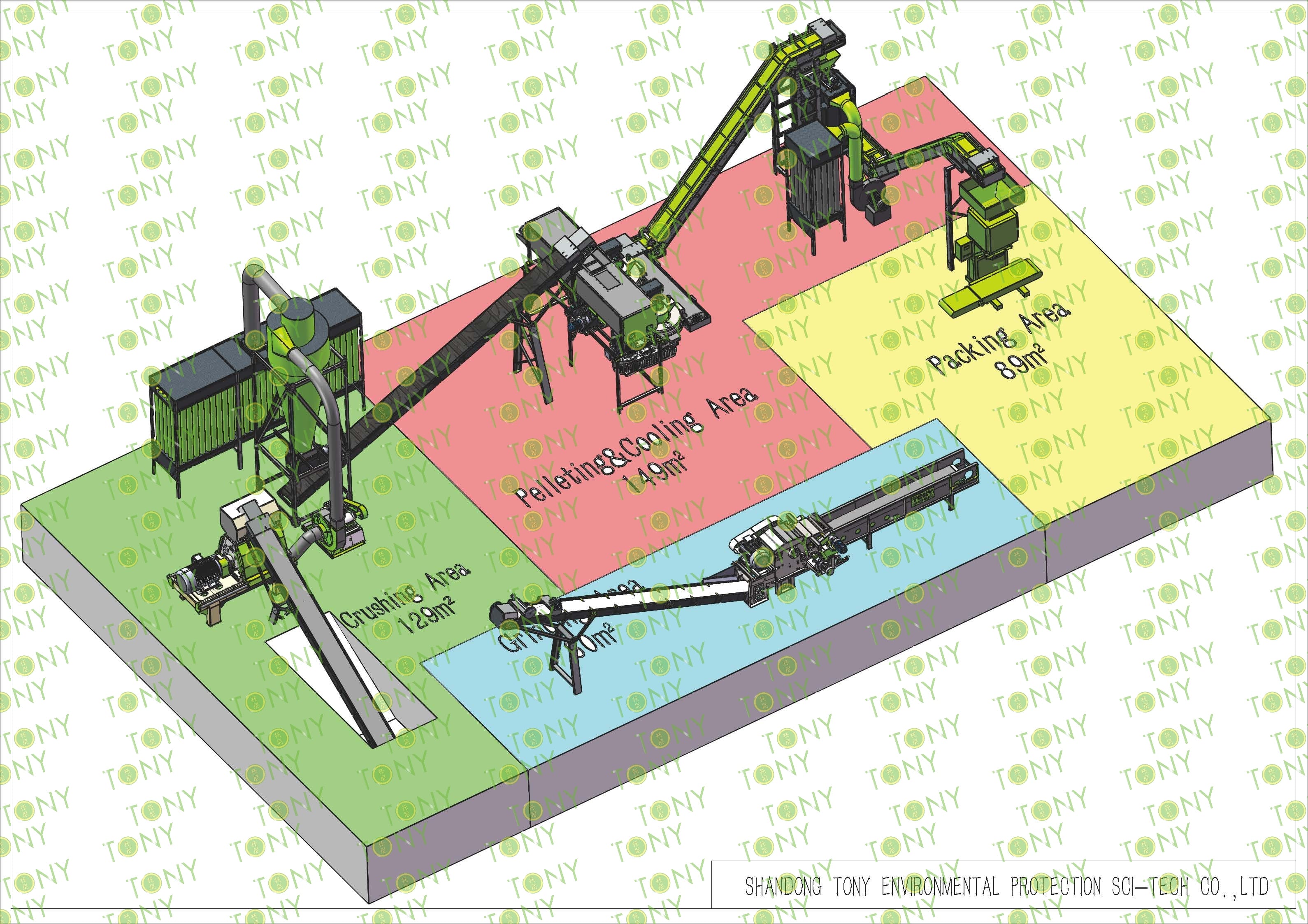

6.Need Area: About 448㎡ L: 28M W:16 M H:6.517 M

Project Layout For Customer:

1.The working principle of dried wood log biomass pellet processing equipment

The core principle of dry wood biomass pellet processing equipment is to use mechanical extrusion to densify dry wood chips. Frictional heat generated by extrusion activates the natural adhesive properties of lignin, achieving glue-free molding. The entire process relies on low moisture content in the raw material to ensure molding efficiency and pellet strength, appropriate particle size to ensure uniform force distribution, and precise coordination between the ring die and rollers to provide sufficient extrusion pressure and temperature. Ultimately, the loose wood waste is transformed into efficient and clean biomass pellet fuel.

2.Characteristics of dried wood log biomass pellet processing equipment

(1)Environmental protection and energy saving, in line with the concept of green production

Low pollution emissions: No wastewater is generated during the processing process. Only a small amount of waste gas may be generated during the drying process (if necessary), but it can be effectively purified by the supporting dust removal equipment (such as cyclone separators, bag dust collectors), which meets environmental protection standards.

Relatively low energy consumption: Since the raw materials are already dried, the high-energy-consuming deep drying process is eliminated; and the pelletizing process uses extrusion friction to generate heat, without the need for additional heating (or only auxiliary heating), and the overall energy consumption is lower than that of wet material processing equipment.

Outstanding environmental attributes of the product: The biomass pellet fuel produced has low carbon emissions when burned (approximately "carbon neutral"), and the sulfur and nitrogen content is much lower than that of coal. It can replace fossil fuels, reduce environmental pollution, and contribute to the "dual carbon" goal.

(2)High degree of automation and easy operation and maintenance

Automatic control system: The complete set of equipment is usually equipped with a PLC control system, which can realize the linkage control of raw material transportation, feeding, pelletizing, cooling, screening and other links, and automatically monitor parameters such as raw material moisture content, pellet temperature, equipment load, etc., reducing manual intervention.

Easy-to-maintain design: Core components (such as ring dies, rollers, and blades) are made of high-strength, wear-resistant materials (such as alloy steel) with a long service life. The modular structure makes it easy to disassemble, replace, and repair, reducing downtime and maintenance costs.

Complete safety protection: The equipment is equipped with safety devices such as overload protection, temperature alarm, and emergency stop button, which can effectively avoid damage caused by raw material impurities (such as metal blocks) or equipment failure, ensuring production safety.

3.Application scenarios of dried wood log biomass pellet processing equipment

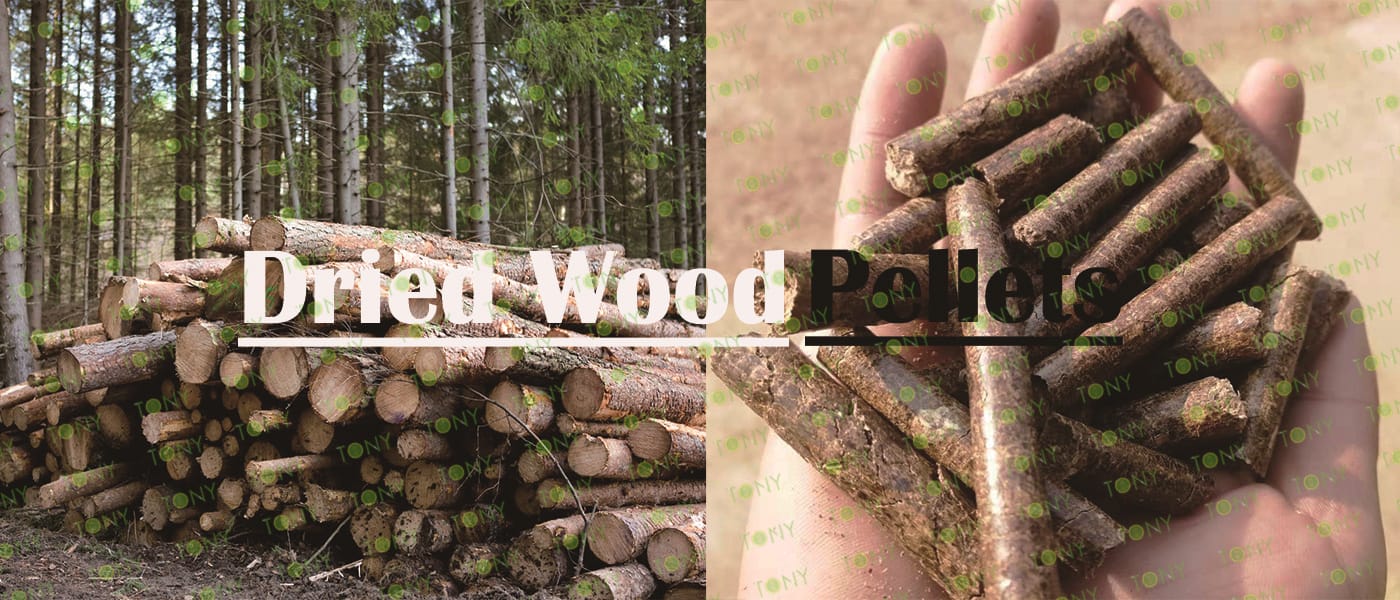

Dry wood processing biomass pellet equipment (hereinafter referred to as "dry wood pellet equipment") is mainly used to process dry wood waste (such as sawdust, shavings, wood scraps, branches, etc., with a moisture content of 10%-15%) into high-density biomass pellet fuel. Its application scenarios revolve around "wood waste resource utilization" and "clean energy substitution".

(1)Utilization of forestry waste: felled branches, trunk segments, dead wood, etc., after crushing (dry material state), can be processed into pellets by the equipment to solve the problem of scattered and difficult transportation of forest waste (pellet density reaches 1.1-1.3g/cm³, and transportation efficiency is increased by 5-8 times).

(2)Treatment of fruit tree pruning waste: dry branches (such as apple wood and pear wood) produced by orchard pruning are crushed and processed into fuel through pellet equipment. Due to their high calorific value (about 4200-4500kcal/kg), they can be supplied as high-quality biomass fuel to farmers or small heating units.

TONY Brand 3-4Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 3-4Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

2. Raw Material: All kinds of dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 3-4 tons per hour

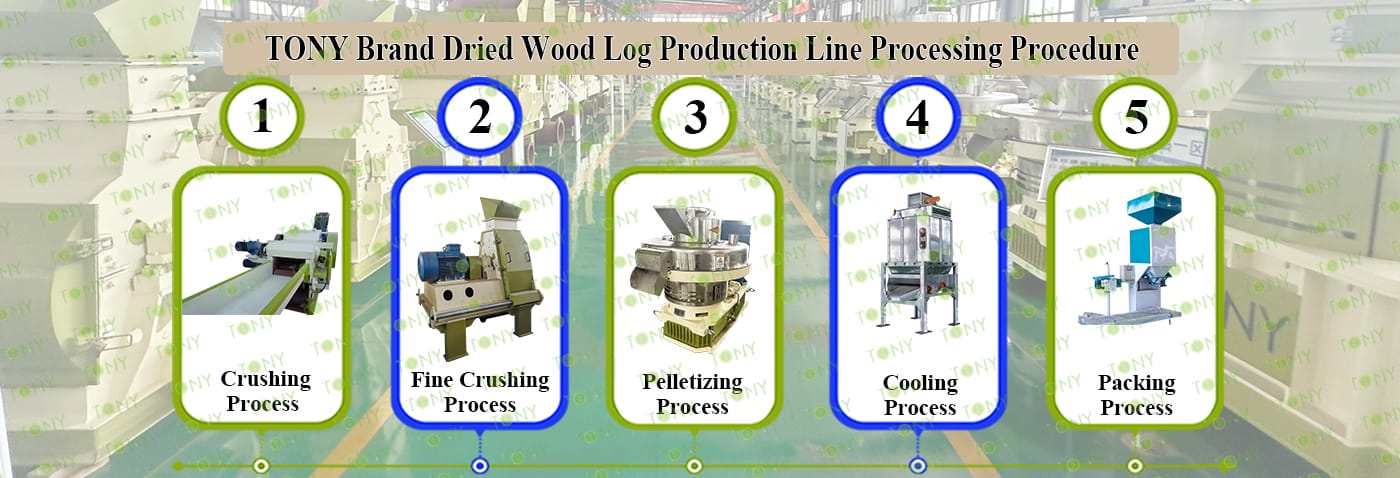

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Wood Chipper TPQ216 - 55KW, Effective Hammer Mill-TFD75*100-110KW, TONY Pellet Machine TYJ551-Ⅲ-110KW, Pellet Cooler, Small Packing Machine and Belt Conveyors

|

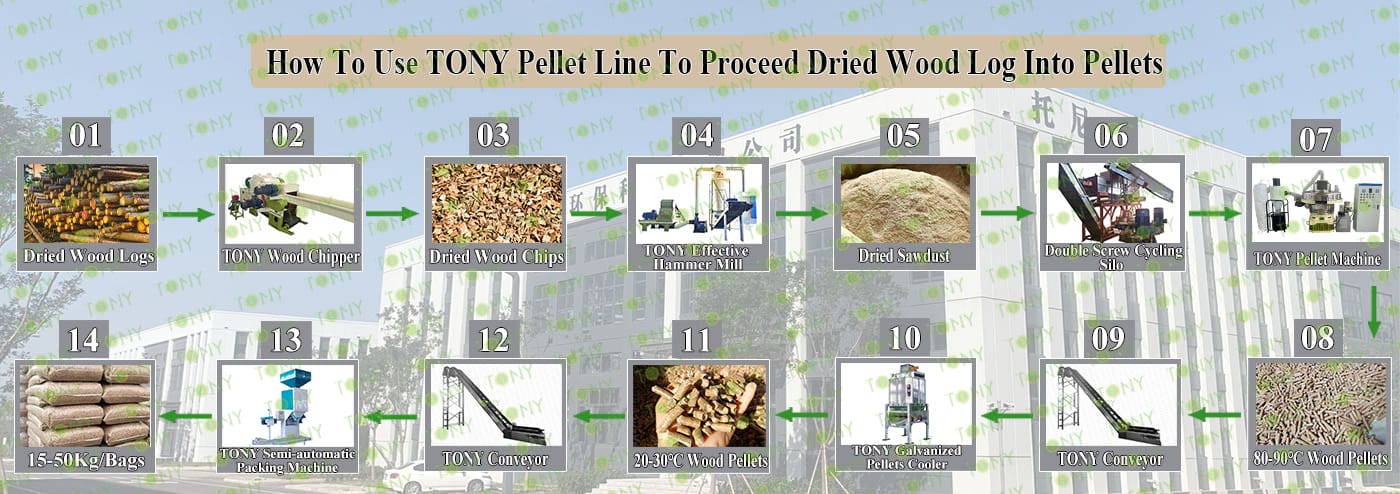

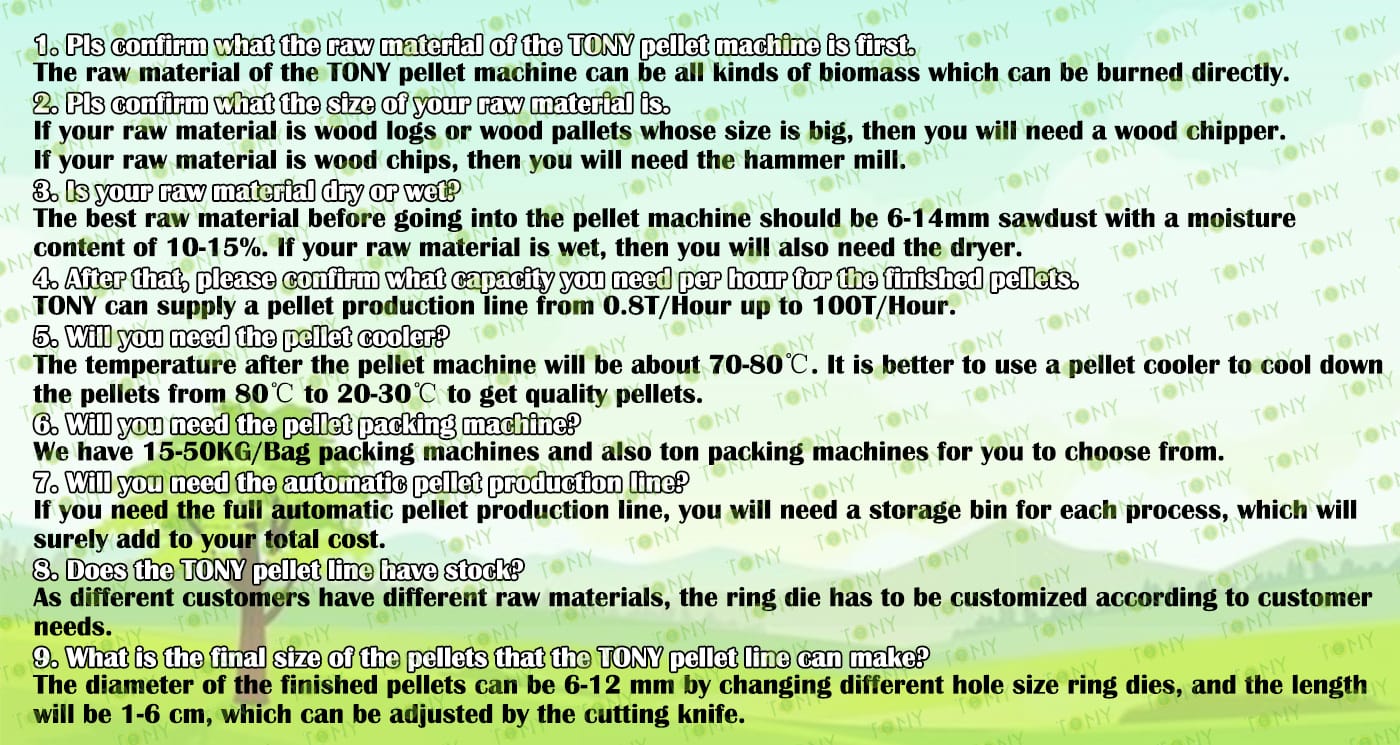

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY wood chipper to cut dried wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Wood Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

| 1.To Grind Wood Logs φ ≤20cm Into25-55mm Wood Chips. 2.Model: TPQ216-55KW With 2 Blades*1set 3.Capacity: 4-7Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*100-110KW*1set 3.Capacity: 3-4Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-4*1set 3.Capacity:3-4Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-110KW*2sets 3.Capacity:1.5-2Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3-4Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 3-4Ton/Hour |

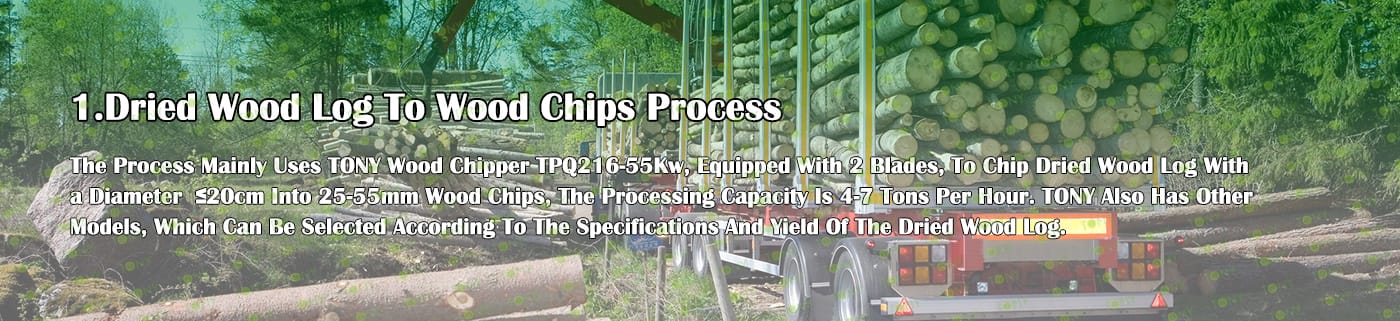

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPQ216 model with 2 flying blades type

C.Capacity:4-7Ton/Hour.

Main Parts:

(1)TONY's Wood Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:3-4Ton/Hour.

C.TONY brand effective hammer mill TFD75*100-110KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:1.5-2Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-110KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set of TONY galvanized cooler separator with capacity 3-4Ton/Hour

Main Parts:

(1)TONY's Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY semi-automatic packing machine.

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Processing dry wood into biomass pellets is a truly entrepreneurial venture that combines policy dividends, market potential, and environmental value, offering numerous feasibility and advantages.

1.Low technical barriers to entry

The production process is simple: dry wood crushing → extrusion pelletizing → cooling → packaging. The technology is mature and easy to master.

2.Diverse and robust market channels

Civilian use: The "coal-to-biomass" shift in rural areas of northern China has driven heating demand, with farms and greenhouses using biomass for insulation. Annual demand is growing with agricultural scale-up.

Industrial use: Biomass power plants, food factories, building materials factories, and other industries are using biomass pellets to replace coal/natural gas, resulting in high and stable demand.

3.Significant profit margins

After deducting costs such as site rental and labor, net profit still remains substantial.

4.Wide range of dry wood raw materials:

Wood processing plant scraps and sawdust (a long-term, stable supply, often free or at a low price);Tree branches and trunks from forestry pruning (which can be crushed and used, with forestry departments in some areas assisting in this connection);

Crop straw (if local wood resources are limited, this can be used in combination to further reduce raw material costs). The renewable nature of the raw materials ensures the long-term operation of the project without worrying about resource depletion.

Physical Properties of Wood Pellets

1.Regular Shape and High Density

The pellets are cylindrical (6-10mm in diameter, 20-30mm in length), compact, and have a density of 1.1-1.3 tons/cubic meter (4-5 times that of dry wood), significantly reducing storage space (for the same volume, the storage capacity is over 3 times that of loose wood chips).

2.Low Moisture Content, Resistant to Deterioration

Dry wood has a low moisture content (typically ≤15%, controlled at 8%-12% during processing). Once pelletized, they absorb little moisture and can be stored for 6-12 months in a ventilated, dry environment without deterioration, avoiding the mold and rot associated with wet wood.

3.Good flowability, facilitating automated handling

The pellets have a smooth, lumpy surface and can be transported automatically through pipes, conveyors, and other equipment. They are compatible with automated feed systems for boilers and fireplaces, reducing manual labor.

2025 Tony Machinery - All Rights Reserved. Map