Project Brief Introduction:

1.Product:Dried Wood Log Pellet Line

2.Capacity:4-5T/Hour

3.TONY Brand 4-5Ton /Hour Dried Wood Log Pellet Line Project Process

4.Main Machine: Wood Chipper , Hammer Mill, TONY Pellet MachineTYJ860-Ⅲ-280KW, Pellet Cooler, Packing Machine And Belt Conveyors

5.Total Power: About 540KW

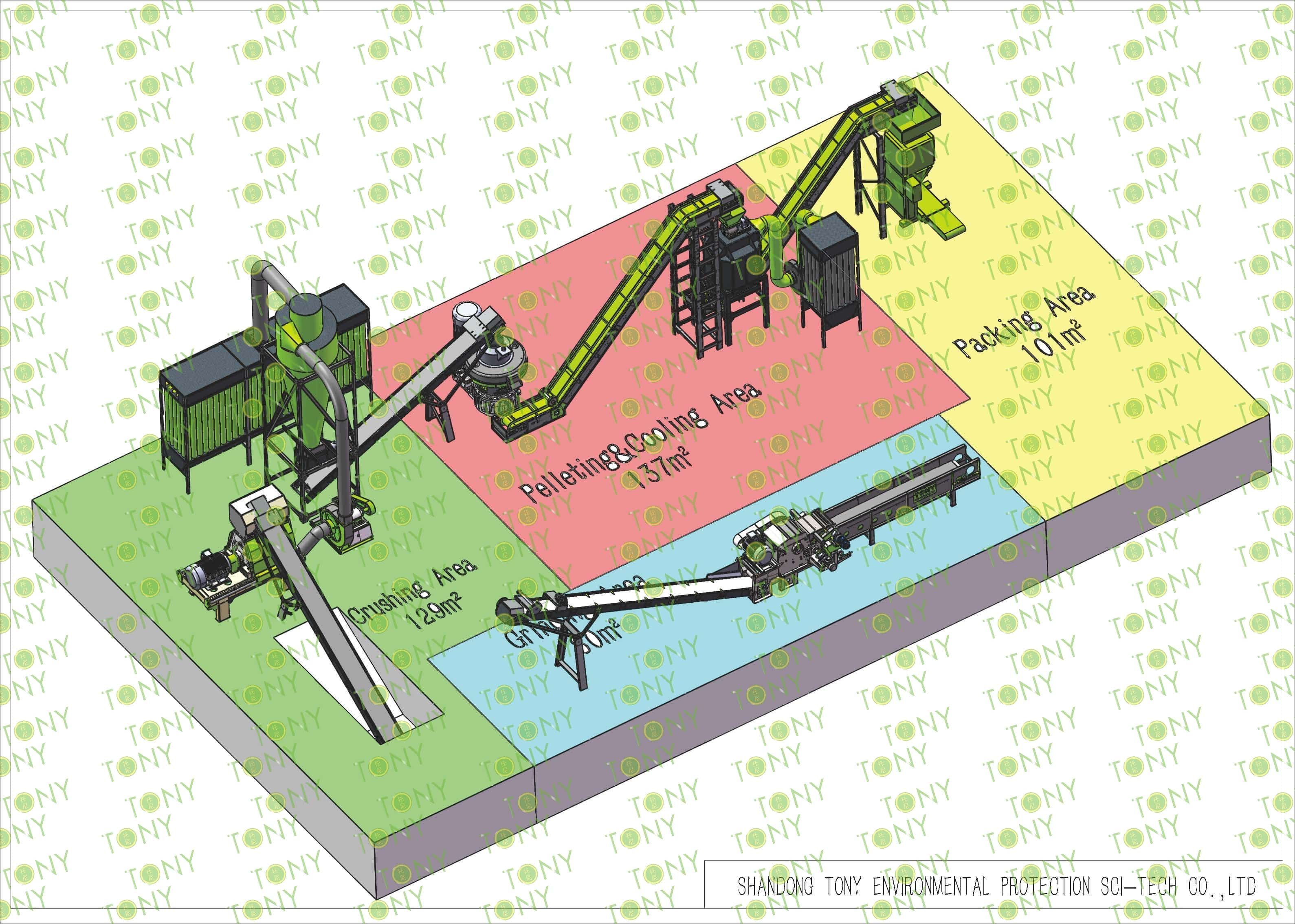

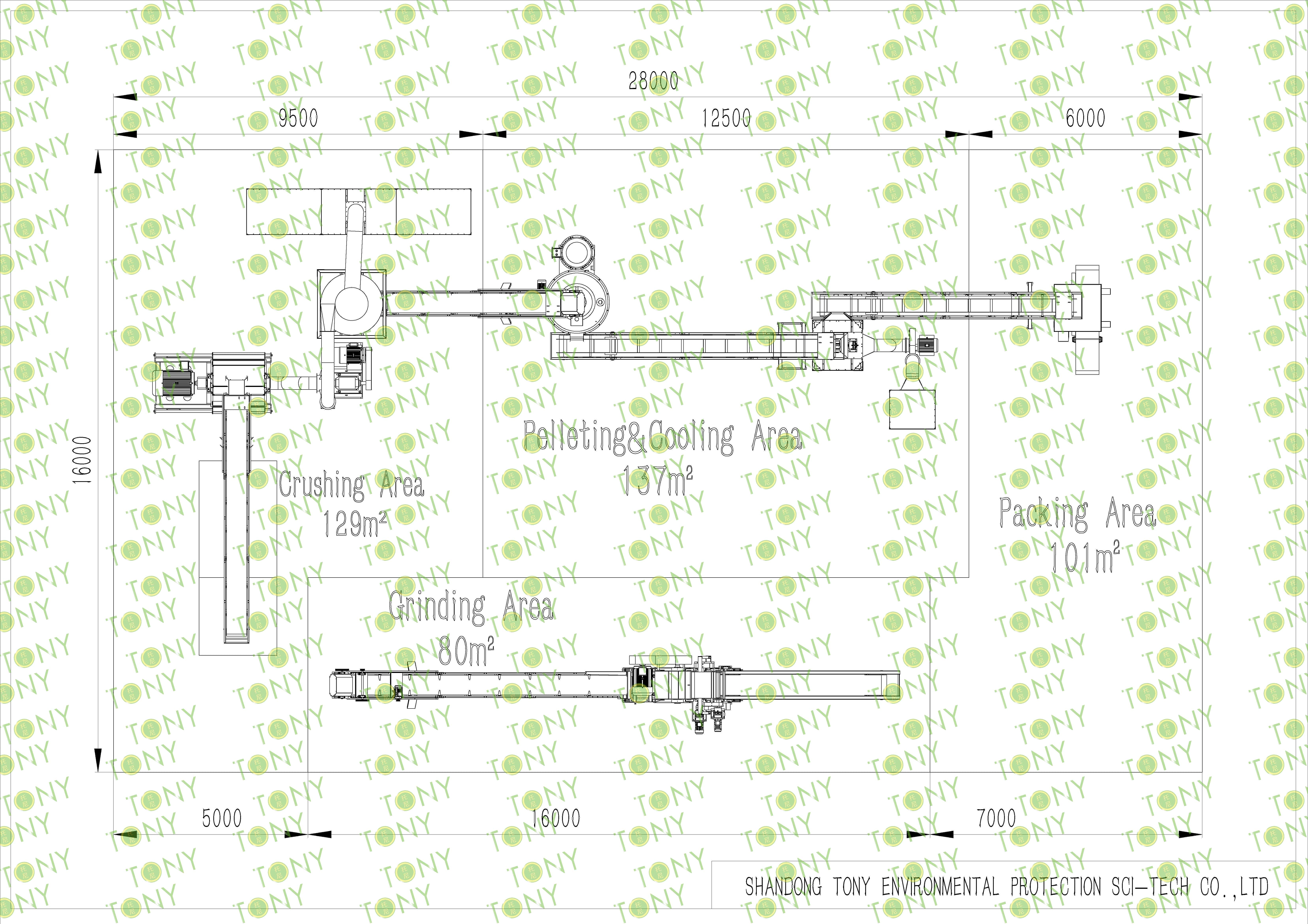

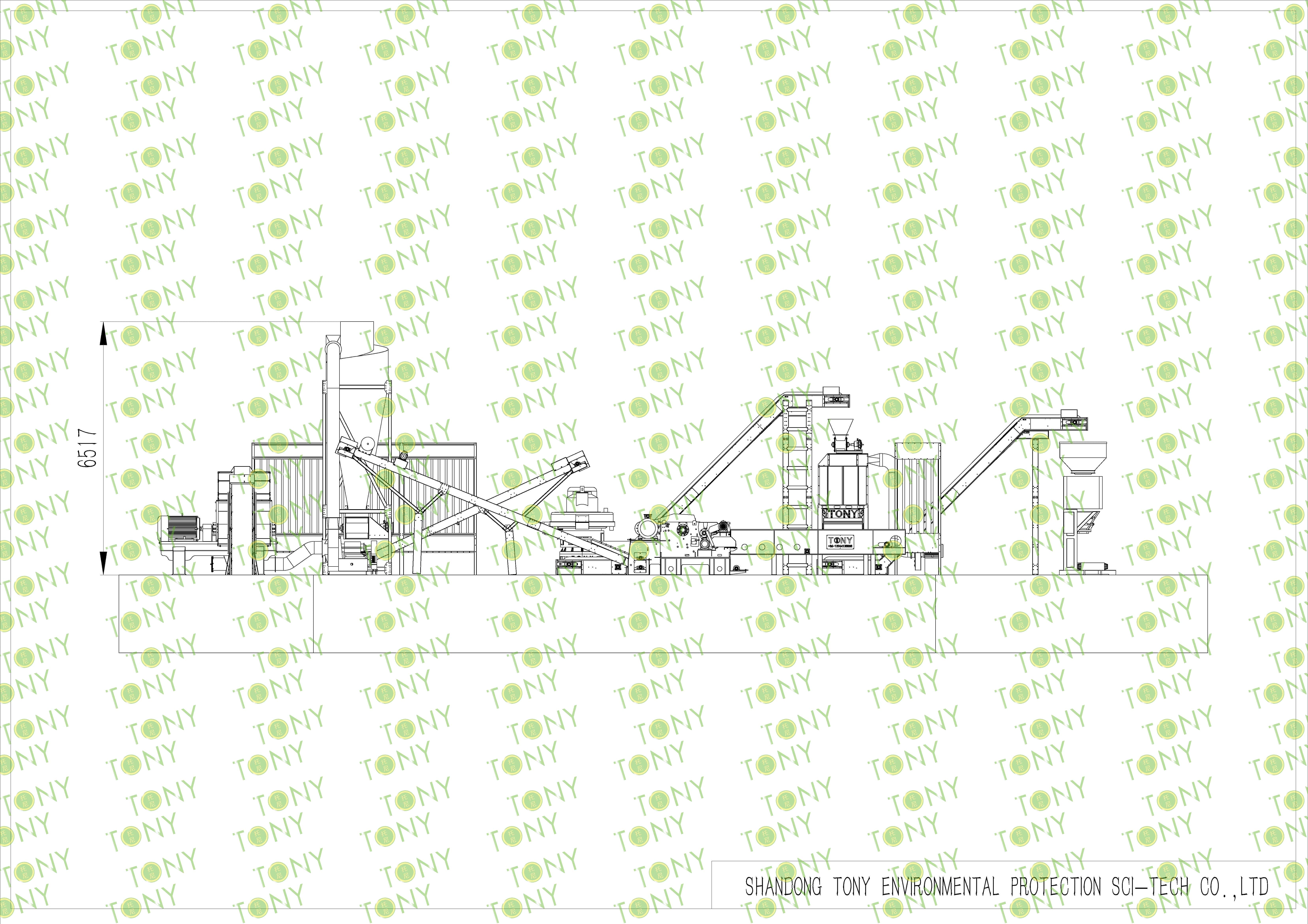

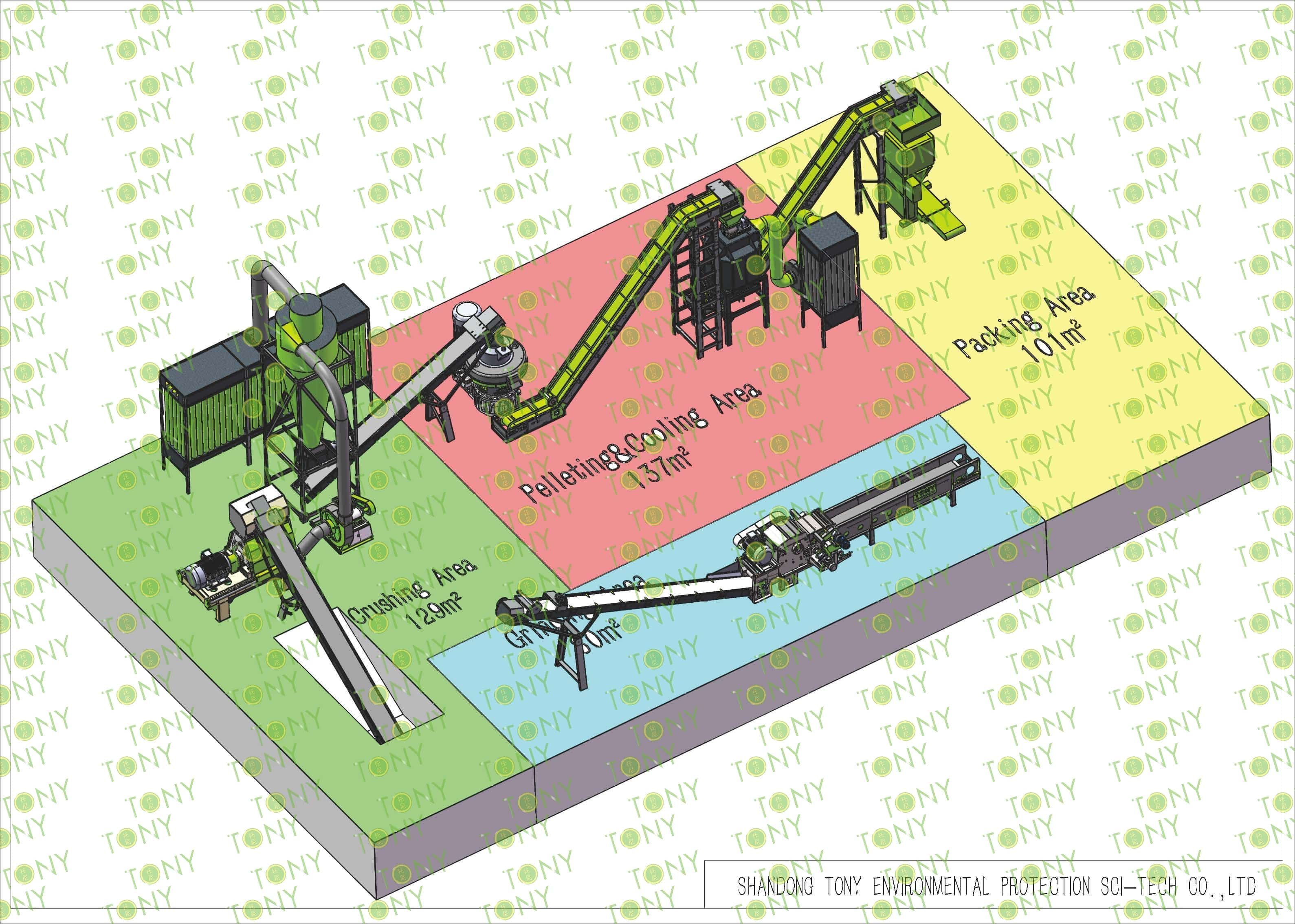

6.Need Area: About 448㎡ L: 28M W: 16M H: 6.517M

Project Layout For Customer:

1.The working principle of dried wood log biomass pellet processing equipment

The core principle of dry wood biomass pellet processing equipment is to use mechanical extrusion to densify dry wood chips. Frictional heat generated by extrusion activates the natural adhesive properties of lignin, achieving glue-free molding. The entire process relies on low moisture content in the raw material to ensure molding efficiency and pellet strength, appropriate particle size to ensure uniform force distribution, and precise coordination between the ring die and rollers to provide sufficient extrusion pressure and temperature. Ultimately, the loose wood waste is transformed into efficient and clean biomass pellet fuel.

2.Characteristics of dried wood log biomass pellet processing equipment

(1)Strong adaptability of the industrial chain and a wide range of application scenarios

Flexible production scale: The equipment can be configured with different production capacity models according to demand, ranging from small home workshops (less than 500kg per hour) to large industrial production lines (more than 10 tons per hour), to meet the needs of different investors.

Diverse product applications: The dry wood biomass pellets produced can not only be used as civilian heating and cooking fuel, but also in industrial boilers, power stations and other fields, replacing coal, natural gas and other energy sources, with stable market demand.

(2)Strong adaptability of raw materials, achieving efficient resource utilization

Wide range of raw material sources: It can process a variety of dry wood waste, including sawdust, shavings, scraps after wood processing, and forestry waste (such as branches, bark, etc.), and can be processed without complex pretreatment, effectively realizing "turning waste into treasure".

Clear requirements for raw material moisture content: Based on the characteristics of "dry wood", the equipment is more suitable for processing raw materials with low moisture content (usually 10%-15%), without the need for additional high-intensity drying (or only simple humidity adjustment), reducing energy consumption and processing costs.

3.Application scenarios of dried wood log biomass pellet processing equipment

(1)Professional Biomass Pellet Plants

These are core sites for large-scale wood pellet production, typically equipped with complete production lines, with daily output ranging from a few to dozens of tons. These products are supplied to industrial boilers, power plants, distributors, and other facilities.

(2)Wood Processing Plant Supporting Production

Furniture factories and wood-based panel factories generate large quantities of sawdust and scraps. These plants can be equipped with small-scale pellet processing equipment to convert these waste materials into pellets for their own use (e.g., factory heating and wood drying) or for external sale, thus realizing "waste resource utilization."

(3)Agricultural Cooperative/Forest Farm Ancillary Processing

Tree branches and wood waste from fruit tree pruning are crushed and processed into pellets for use in the cooperative's greenhouses, for heat preservation in livestock farms, and for heating nearby farmers.

(4)Home/Small Workshop Production

Rural areas or individual operators utilize local wood resources to produce pellets, primarily for heating nearby farmers or small commercial establishments (such as guesthouses). This approach is suitable for small-scale, localized sales.

TONY Brand 4-5Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 4-5Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

2. Raw Material: All kinds of Dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 4-5 tons per hour

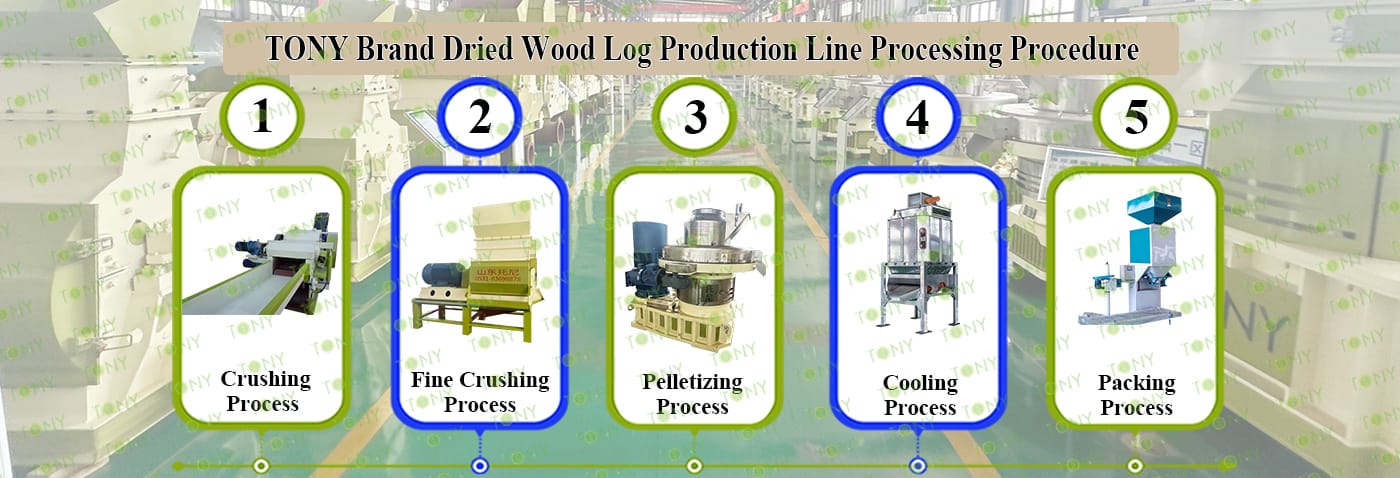

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Wood Chipper TPQ216 - 55KW, Effective Hammer Mill-TFD75*132-132KW, TONY Pellet Machine TYJ860-Ⅲ-280KW, Pellet Cooler, Small Packing Machine and Belt Conveyors

|

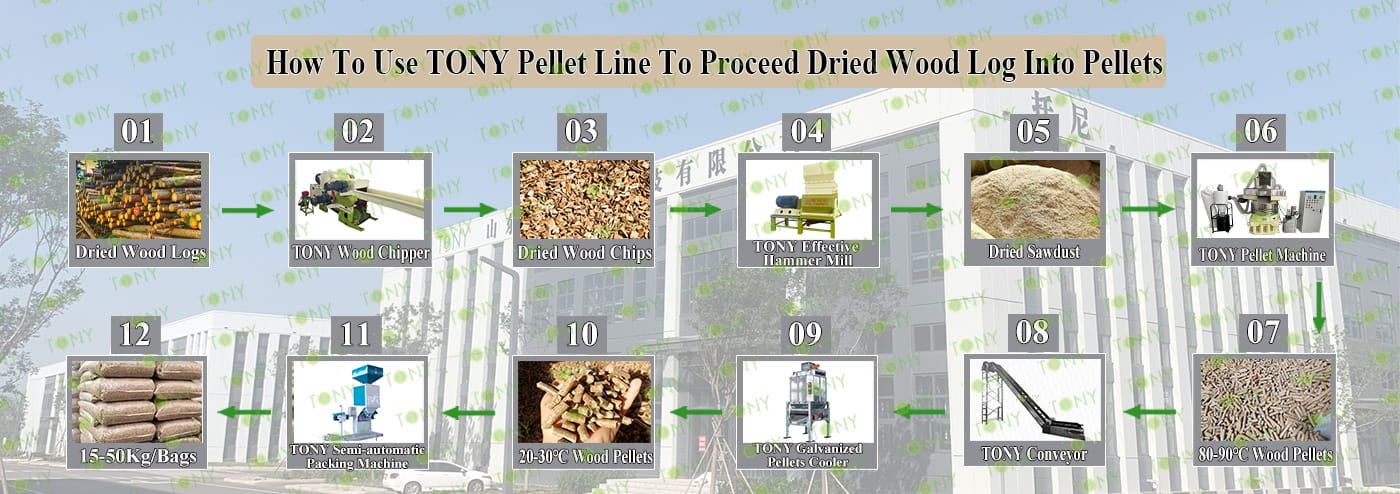

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY wood chipper to cut dried wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Wood Chipper | Effective Hammer Mill | Vertical Ring Die Sawdust Pellet Machine |

| 1.To Grind Wood Logs φ ≤20cm Into25-55mm Wood Chips. 2.Model: TPQ216-55KW With 2 Blades*1set 3.Capacity: 4-7Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*1set 3.Capacity: 4-5 Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*1set 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:4-5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 4-5Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*4sets 3.Capacity:Designed With The Whole Line |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPQ216 model with 2 flying blades type

C.Capacity:4-7Ton/Hour.

Main Parts:

(1)TONY's Wood Chipper.

(2) Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4) Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:4-5Ton/Hour.

C.TONY brand effective hammer mill TFD75*132*132KW*1set

Main Parts:

(1)TONY Effectivel Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5) Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:4-5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set of TONY galvanized cooler separator with capacity 4-5ton/hour

Main Parts:

(1)TONY's Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY semi-automatic packing machine.

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Processing dry wood into biomass pellets is indeed a high-quality investment project with both economic benefits and ecological value.

1.Controllable costs throughout the entire chain, with a short investment return cycle.

(1)Significant raw material cost advantages.

By signing long-term agreements with forest farms and wood processing plants, a stable and low-priced raw material supply can be locked in.

(2)High cost-effectiveness of equipment investment.

The eighth-generation TONY centrifugal high-efficiency pelletizer can achieve an electricity consumption of less than 60 degrees per ton of material, saving 20% energy compared to traditional equipment.

2.A sound risk prevention and control system and a clear sustainable development path.

(1)Diversified raw material supply.

Investors can use this to build a "mixed pelletizing of agricultural and forestry waste" model to reduce the risk of fluctuations in a single raw material.

(2)Environmentally compliant operations.

It is recommended to build a closed raw material warehouse to achieve zero dust overflow and zero sewage discharge.

(3)Vertical extension of the industrial chain:

Combining biomass pellet production with forest tending and forest economy: increasing forest stock through thinning and obtaining residual raw materials from forest tending; using the sawdust ash after pelleting to produce biochar-based fertilizer, achieving the triple benefits of "forestry carbon sink + biomass energy + circular agriculture"

1.High Energy Efficiency

High calorific value and stable combustion: After compression molding, wood pellets significantly increase their density (typically 1.1-1.3 tons/cubic meter), resulting in a significantly higher energy density than raw wood chips. They also offer stable combustion and high thermal efficiency. Their low calorific value is typically 4200-4800 kcal/kg, close to that of coal (5000-6000 kcal/kg), meeting the heat requirements of industrial boilers and home heating applications.

Full combustion and low ash content: Compared to loose wood chips or straw, wood pellets burn more completely, with ash content typically below 5% (high-quality pellets can even be below 1%), reducing ash removal costs and equipment wear.

2.Outstanding Environmental Benefits

Low Carbon Emissions: Wood pellets are a biomass energy source. The carbon dioxide produced by their combustion comes from carbon absorbed by plants during growth, theoretically achieving a "carbon cycle." Compared to fossil fuels like coal and oil, they can significantly reduce greenhouse gas emissions (such as carbon dioxide and sulfur dioxide), contributing to carbon neutrality goals.

Renewable Raw Materials: The raw materials are derived from wood processing waste (such as scraps from furniture and lumber mills), transforming waste into treasure, reducing environmental pollution caused by waste incineration or landfills, and avoiding the need for deliberate tree felling, thus aligning with the concept of sustainable development.

3.Convenient Storage and Transportation

Regular Shape and High Density: The wood chip pellets are uniformly cylindrical (typically 6-8 mm in diameter and 20-30 mm in length), with a volume only 1/5-1/10 of the original wood chip, saving storage space. They can be stored efficiently in bags or bulk, and are resistant to moisture (moisture content is generally controlled at 8%-12%).

Low Transportation Costs: The high density reduces transportation costs, making it suitable for long-distance transport and facilitating large-scale supply.

4.Wide Range of Applications

Energy: It can be used as a coal-replacing fuel in industrial boilers and biomass power plants. It is also suitable for use in residential heating systems such as fireplaces and stoves, ensuring ease of use and cleanliness.

Agriculture and Environmental Protection: After crushing, wood pellets can be used as organic fertilizer or as a culture medium for mushroom cultivation. Some modified wood pellets can also be used as adsorbents to treat industrial wastewater, offering low cost and excellent results.

Industrial Auxiliary: They can be used as raw materials for biomass plastics and artificial boards, achieving diversified resource utilization.

5.Economic Efficiency and Policy Support

Low Raw Material Cost: Biomass pellets primarily utilize wood processing waste, which is widely available and inexpensive, making them particularly suitable for areas near forestry and furniture industries.

Policy Support: As a clean energy source, many governments provide subsidies for the production and use of biomass pellets (such as electricity and equipment subsidies), reducing investment and operating costs.

2025 Tony Machinery - All Rights Reserved. Map