Project Brief Introduction:

1.Product:Dried Wood Log Pellet Line

2.Capacity:6-7T/Hour

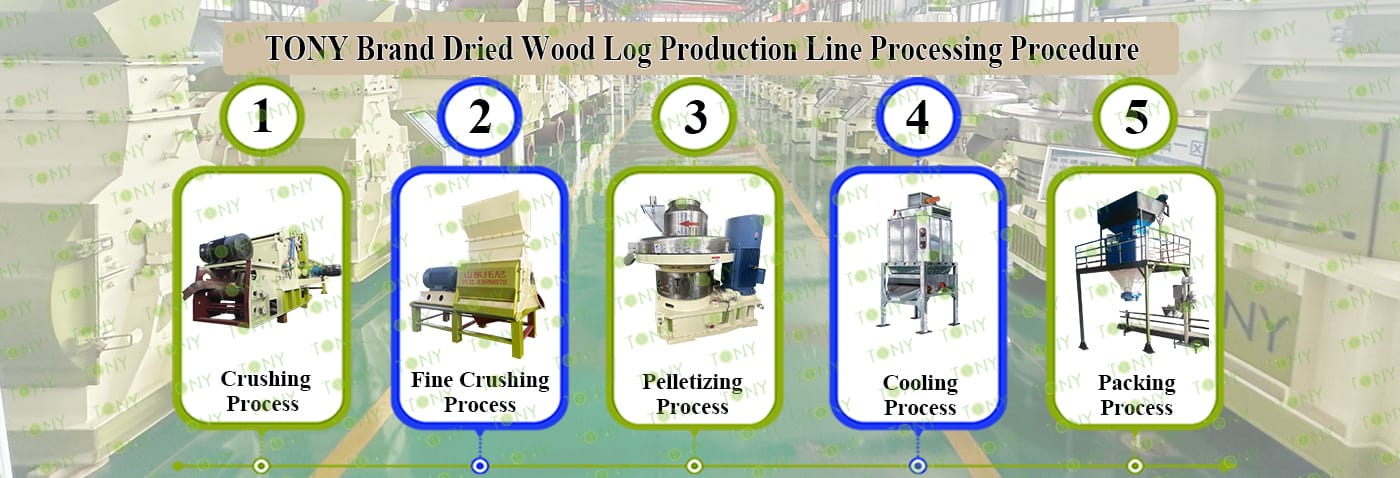

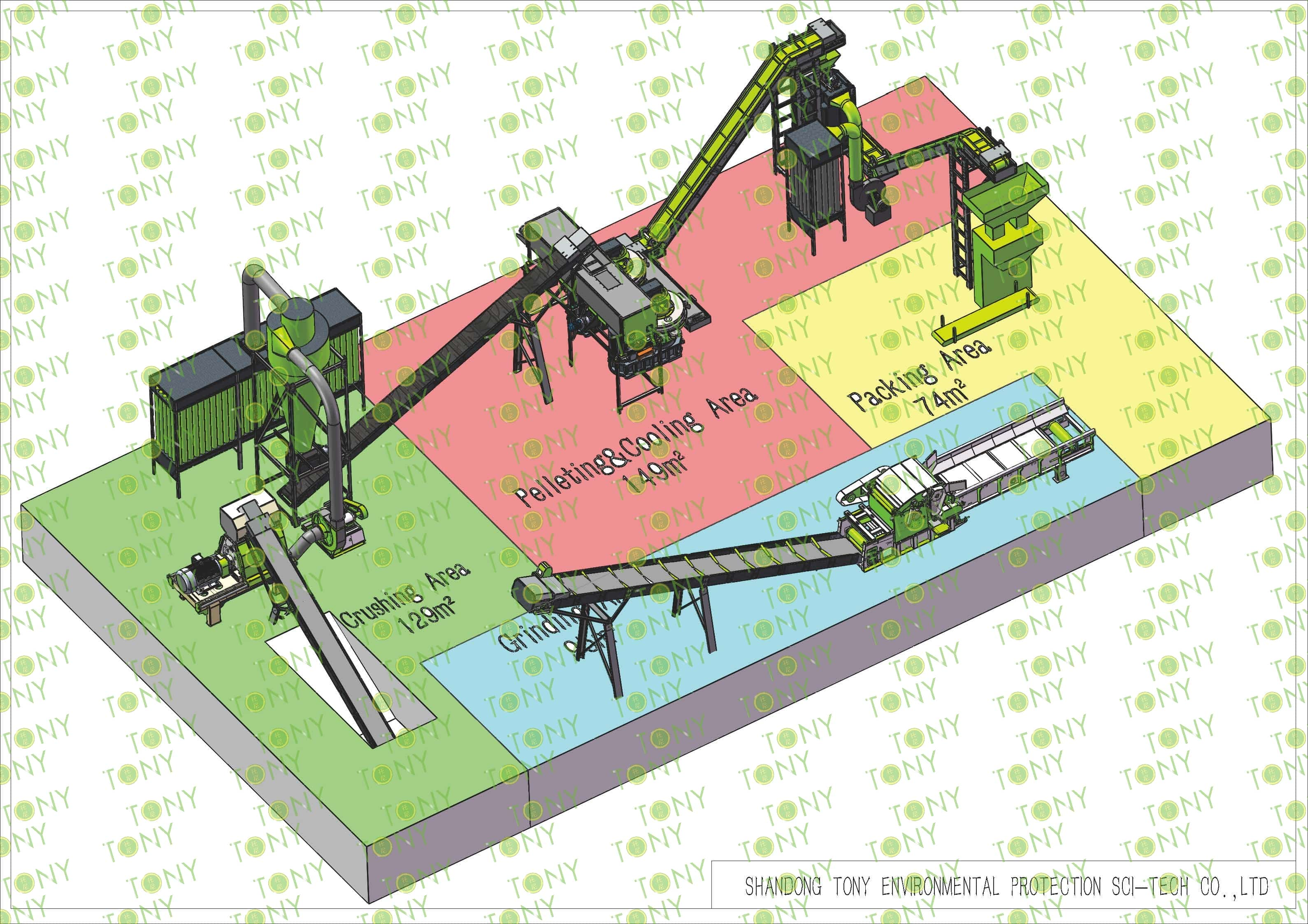

3.TONY Brand 6-7Ton /Hour Dried Wood Log Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill,TONY Pellet MachineTYJ860-Ⅲ-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 920KW

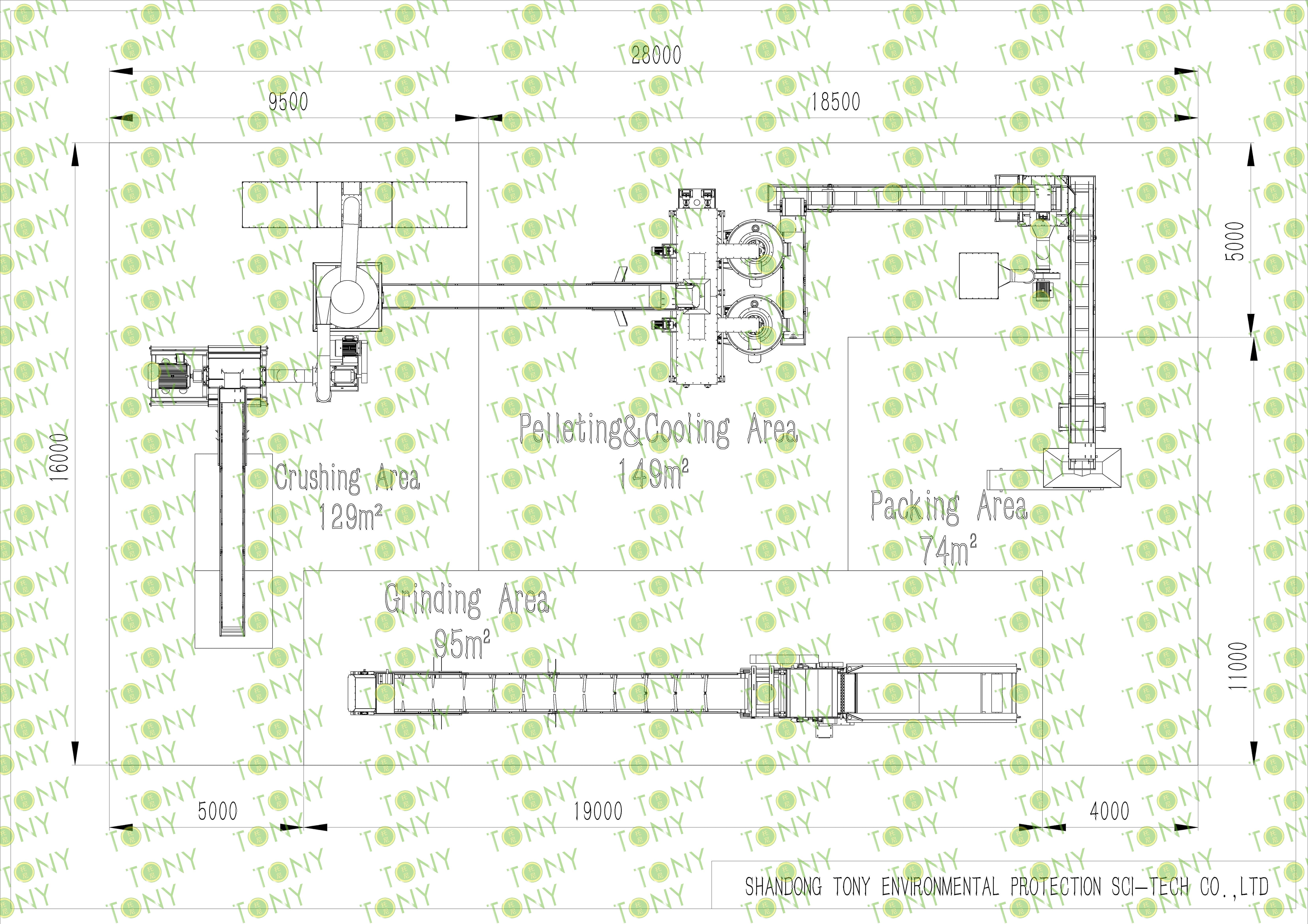

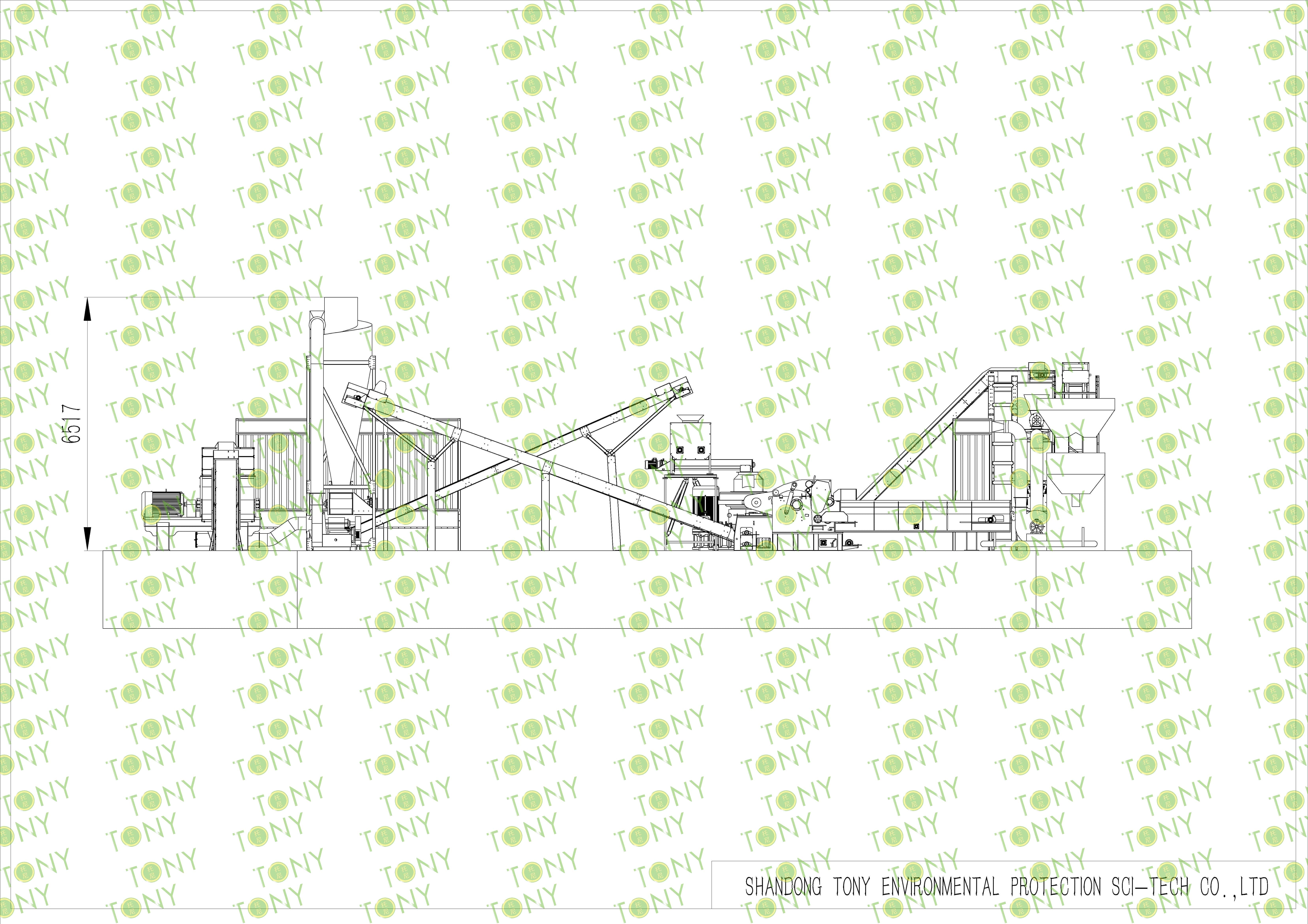

6.Need Area: About 448㎡ L: 28M W: 16M H: 6.517M

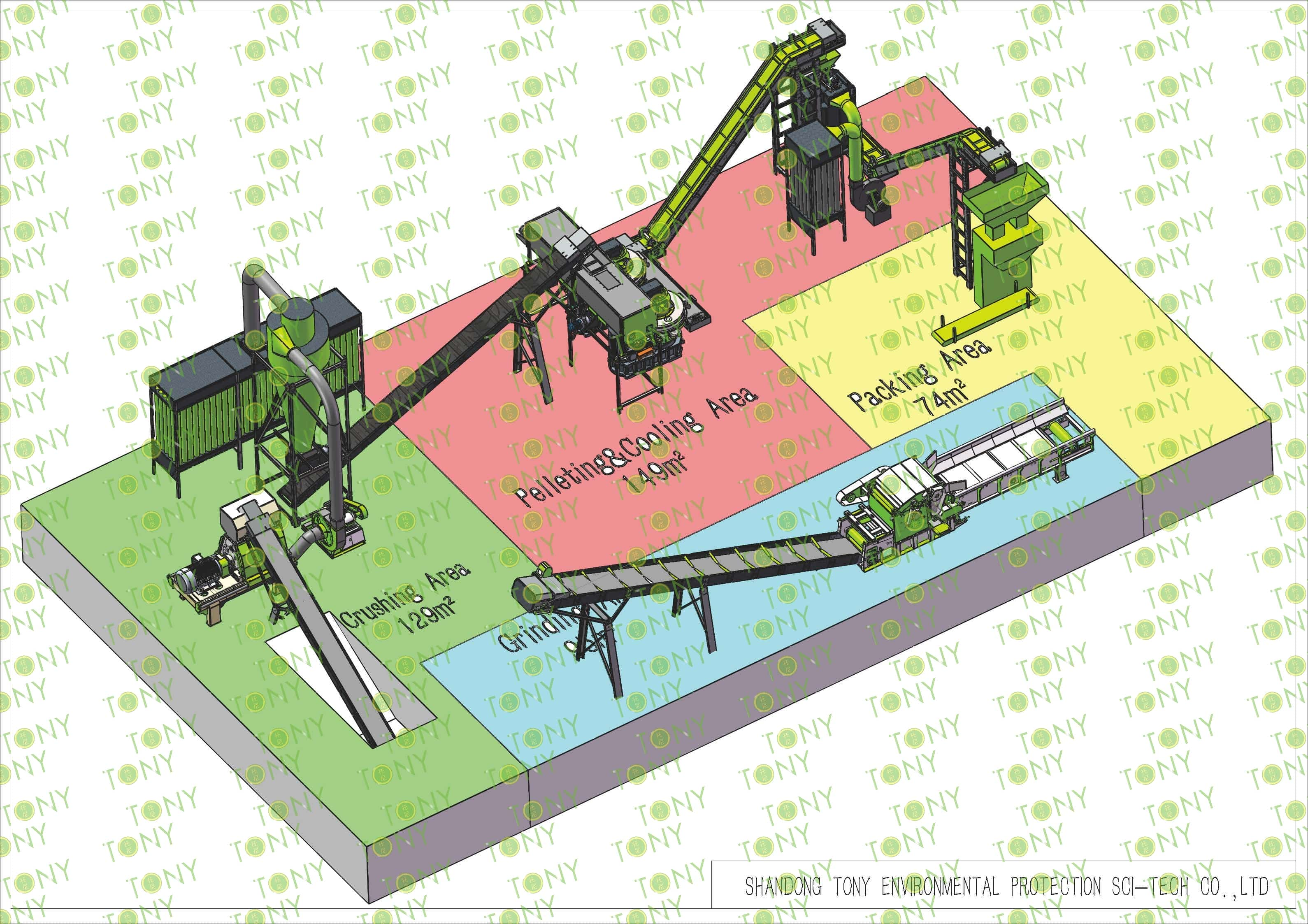

Project Layout For Customer:

1.The working principle of dried wood log biomass pellet processing equipment

The equipment uses a pressure wheel to roll the inner surface of the mold, causing the dry wood chips to undergo physical changes under high pressure and high temperature (some materials may undergo appropriate chemical changes). They pass through the mold hole to form a cylindrical solid body, and are then cut into particles of a certain size by a cutter. This process does not require the addition of adhesives, and only relies on the physical properties of the raw materials themselves to achieve the desired shape.

2.Characteristics of dried wood log biomass pellet processing equipment

As key equipment for biomass energy conversion, dry wood chip pellet processing equipment possesses several notable features, giving it a significant position in the environmental protection and energy sectors. First, the equipment is highly efficient and energy-efficient, converting wood chips into high-calorific value pellet fuel. Compared to traditional incineration or landfill disposal, this maximizes resource utilization, and the processing process emits no harmful gases such as carbon dioxide, thus meeting environmental protection requirements. Second, it is easy to operate, safe, and reliable. Its automated control system allows for flexible parameter adjustments based on demand, while also featuring multiple safety safeguards to ensure operator safety. 1 Furthermore, its pellet forming is excellent, using mechanical extrusion principles to create full, uniform pellets with a moderate density under high temperature and pressure. These pellets are easy to store and transport, and support adjustable pellet length, demonstrating strong adaptability.

3.Application scenarios of dried wood log biomass pellet processing equipment

(1)The pellet fuel processed by the equipment can meet the needs of multiple fields, including home heating, industrial boilers, power generation, etc. At the same time, it can process a variety of biomass raw materials such as crop straw and forestry waste, and promote the comprehensive utilization of renewable energy1. In addition, it has also expanded its application in feed processing, food industry (such as candy mixture processing) and ceramic, plastic and other mixture molding fields.

(2)With the improvement of environmental awareness and the growth of demand for renewable energy, the market demand for dry wood chip pellet processing equipment will continue to expand. By optimizing energy consumption, improving automation level and raw material adaptability, the equipment is expected to play a more important role in the industrialization of biomass energy in the future and help achieve the "dual carbon" goal.

TONY Brand 6-7Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 6-7Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

2. Raw Material: All kinds of Dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 6-7 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment:Comprehensive Chipper TPC1000 - 90KW,Effective Hammer Mill-TFD85*250-250KW, TONY Pellet Machine TYJ860-Ⅲ-220KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

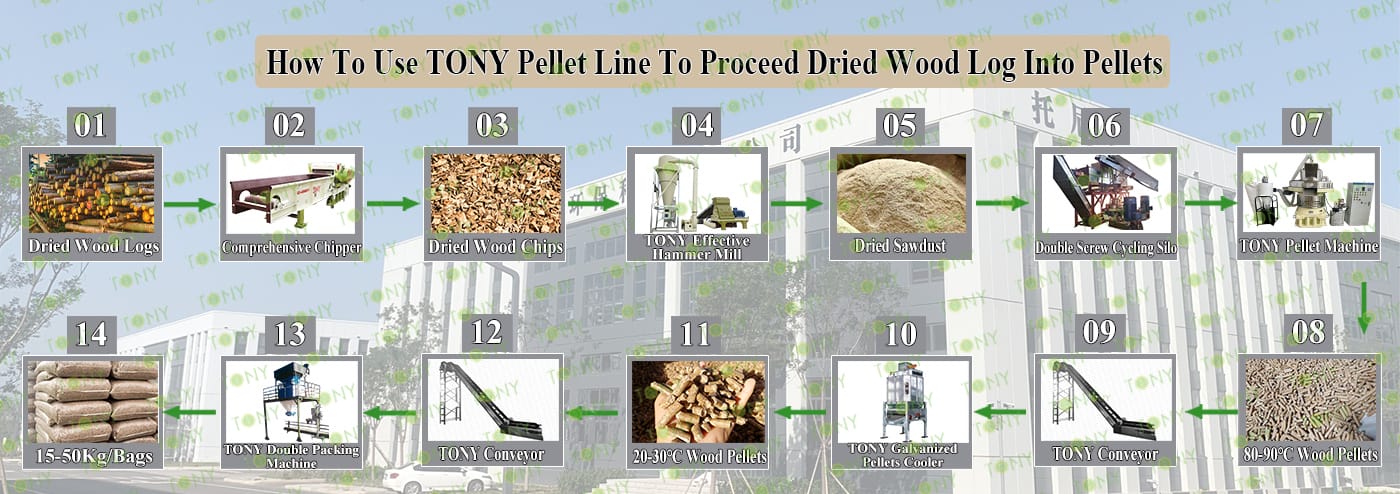

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut dried wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

| 1.To Grind Wood Logs φ ≤20cm Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 6 Baldes*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*1set 3.Capacity: 6-7Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-6*1set 3.Capacity6-7Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*2 sets 3.Capacity:3-4Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1set 3.Capacity:6-7Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6-7Ton/Hour |

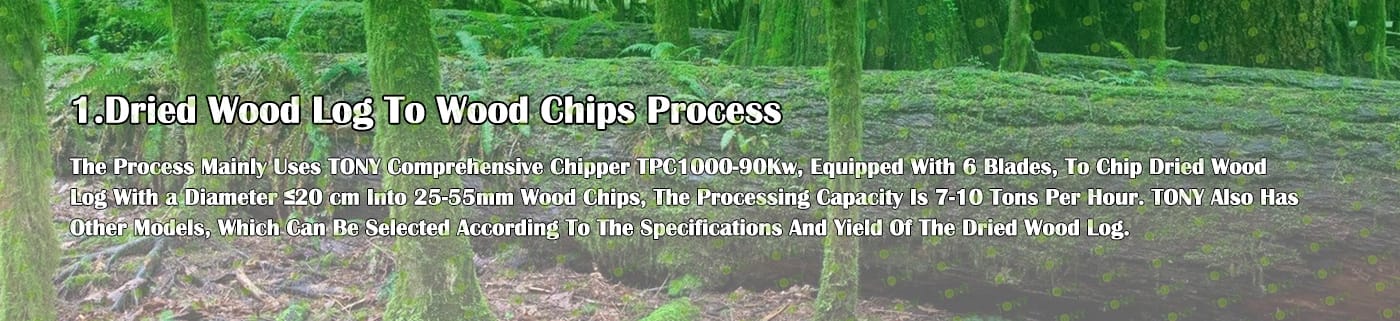

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY Brand TPC1000-90 model with 6flying blades type

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6-7Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*1set

Main Parts:

(1)TONY Effective hammer mill

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6-7Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set of TONY galvanized cooler separator with capacity 6-7Ton/Hour

Main Parts:

(1)TONY's Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY double packing machine.

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Biomass pellet processing is a startup that converts agricultural waste such as wood chips, straw, and rice husks into environmentally friendly fuel pellets. With the advancement of environmental protection policies and the growing demand for alternatives to traditional energy sources, this project has become a popular choice for rural entrepreneurs due to its large market potential and clear policy support.

Its core advantages lie in its low raw material costs, wide range of applications, and flexible equipment investment requirements, making it suitable for startups of all sizes. As the "coal to biomass" policy drives the elimination of traditional coal-fired boilers, biomass pellets, as a clean alternative, are experiencing a surge in demand in industrial boilers, heating, and livestock farming.

As a biomass energy source, wood pellets have significant environmental protection characteristics and energy benefits. In terms of environmental protection, its production process does not contain any chemical additives, and it is smokeless and odorless when burned, has no pollution to the environment, and meets environmental protection requirements.

Compared with traditional coal, its carbon dioxide emissions are 97.91% less than coal, sulfur dioxide emissions are 99.15% lower than coal, and nitrogen dioxide emissions are 72.09% less than coal, almost achieving zero pollution emissions. At the same time, its raw materials are mainly agricultural and forestry waste, such as branches, sawdust, straw, etc., which are renewable energy sources and effectively realize the recycling of resources. In terms of energy efficiency, the calorific value of wood pellet fuel can reach 3600-4200 kcal/kg, and the thermal efficiency can reach more than 85% when using a special biomass heating furnace, which has a high energy density.

2025 Tony Machinery - All Rights Reserved. Map