1.The working principle of dried wood chips biomass pellet processing equipment

(1)Core forming mechanism: The equipment forms the material through the rotation and extrusion of the roller and the die. After pre-treatment, the dry wood chips enter the pelletizer and form a ring-shaped material layer under the action of centrifugal force. The material is extruded through the die hole under pressure without adding adhesives. The wood fiber's own softening properties are used to complete the bonding.

(2)Advantages of dry material processing: Some equipment supports the "dry in, dry out" mode. The moisture content of dry wood chips usually meets the processing standard of 10%-15%. The drying step can be omitted, reducing energy consumption and process complexity.

2.Characteristics of dried wood chips biomass pellet processing equipment

(1)Automatic lubrication and intelligent control: The pellet machine is equipped with an automatic lubrication system and variable frequency speed regulation function, which can adjust the speed according to the characteristics of the raw materials, avoid machine blockage problems, and reduce energy consumption.

(2)High efficiency and energy saving and cost control Dry-in and dry-out process: When the moisture content of the raw materials is 10-15%, there is no need to dry them and they can be processed directly, which significantly reduces energy consumption costs. Low maintenance design: The equipment's vulnerable parts (such as molds and rollers) are made of high-strength materials. Combined with regular lubrication and maintenance (such as gear oil replacement and metal impurity cleaning), they can extend their service life and reduce downtime.

(3)Environmental protection and resource recycling Zero additives and pollution-free: The processing process does not require adhesives and relies on the softening and bonding of lignin itself. When the finished product is burned, there is no harmful emission such as sulfur dioxide, which meets the requirements of energy conservation and emission reduction. Waste resource utilization: Agricultural and forestry waste such as dry wood chips and waste wood can be converted into high-value pellet fuel, realizing "waste to treasure" and contributing to the circular economy.

(4)Application scenarios and market adaptability The equipment is widely used in industrial boilers, biomass power plants, civil heating and other fields. With the advancement of environmental protection policies, equipment is extending from traditional energy replacement to diversified fields such as feed and fertilizer, and market demand continues to grow.

3.Application scenarios of dried wood chips biomass pellet processing equipment

(1)Energy production Biomass power generation: Processed pellet fuel can be directly used in biomass power plants as a boiler fuel, replacing traditional fossil energy and reducing carbon emissions. Heating and heating: Suitable for industrial boilers, commercial fireplaces and household heating equipment, providing clean and renewable heat.

(2)Industrial and manufacturing fields Board production: Crushed wood chips can be used as raw materials for particleboard, fiberboard, plywood and other boards, improving the utilization rate of wood resources. Paper and pulp: Crushed wood chips can be used for pulp production after processing, meeting the papermaking industry's demand for fiber raw materials.

(3)Environmental protection and resource recycling fields Agricultural and forestry waste treatment: Convert agricultural and forestry waste such as logs, branches, and straw into pellet fuel, reducing solid waste accumulation and promoting a circular economy. Fossil fuel replacement: Replace coal and oil in scenarios such as biomassdiesel production and power plant fuel, reducing environmental pollution.

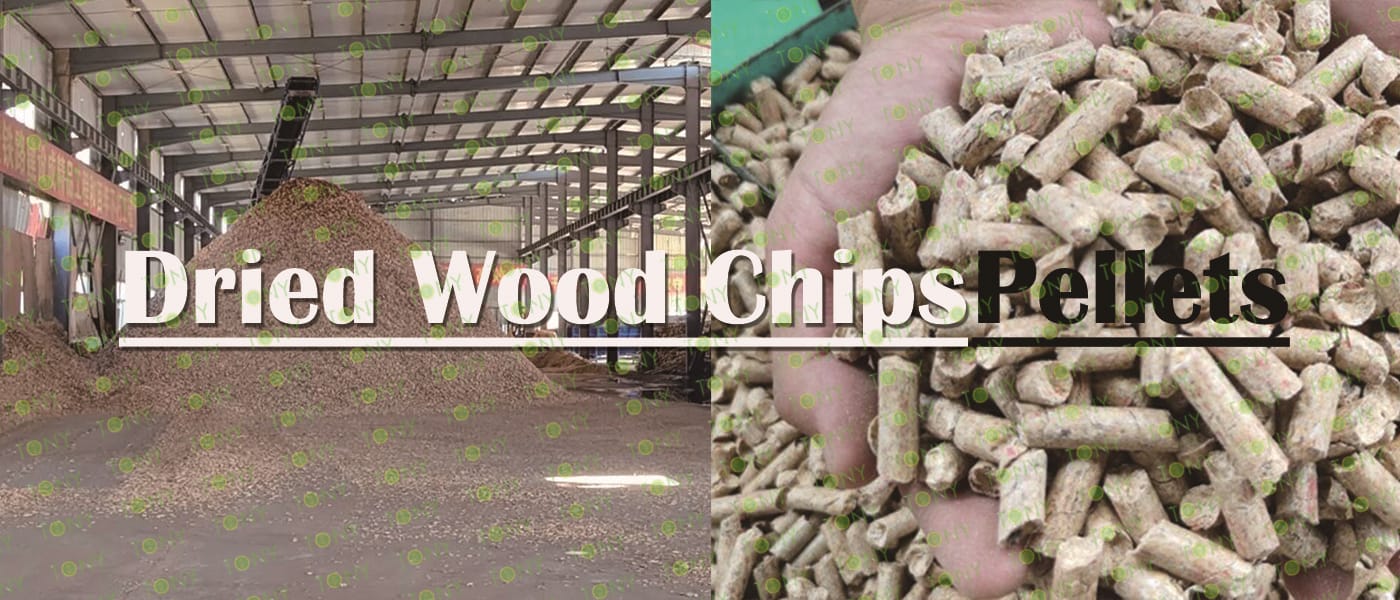

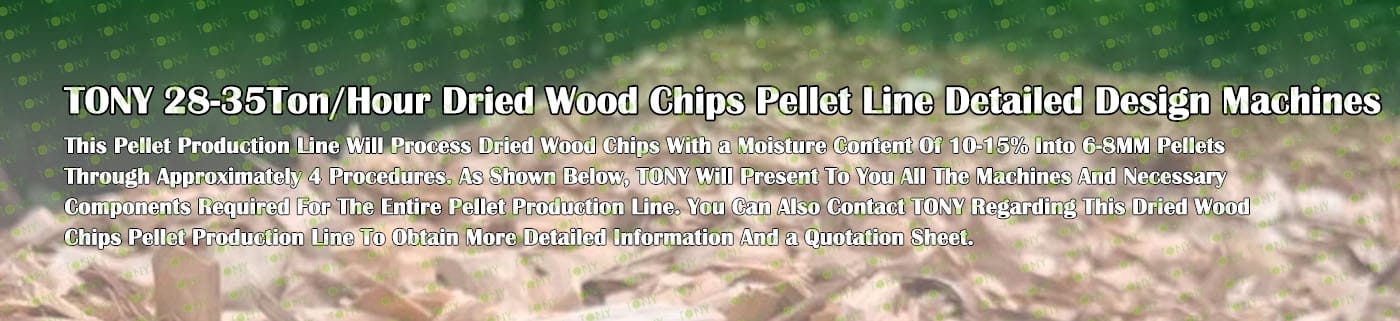

TONY Brand 28-35Ton/Hour Dried Wood Chips Pellet Manufacturing Plant can take dried wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 28-35Ton/Hour

2. Raw materials: Dried wood chips

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production.Where waste wood chip resources are advantageous.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Chips Pellet Production Line

2. Raw Material: All kinds of dried wood chips

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 28-35 tons per hour

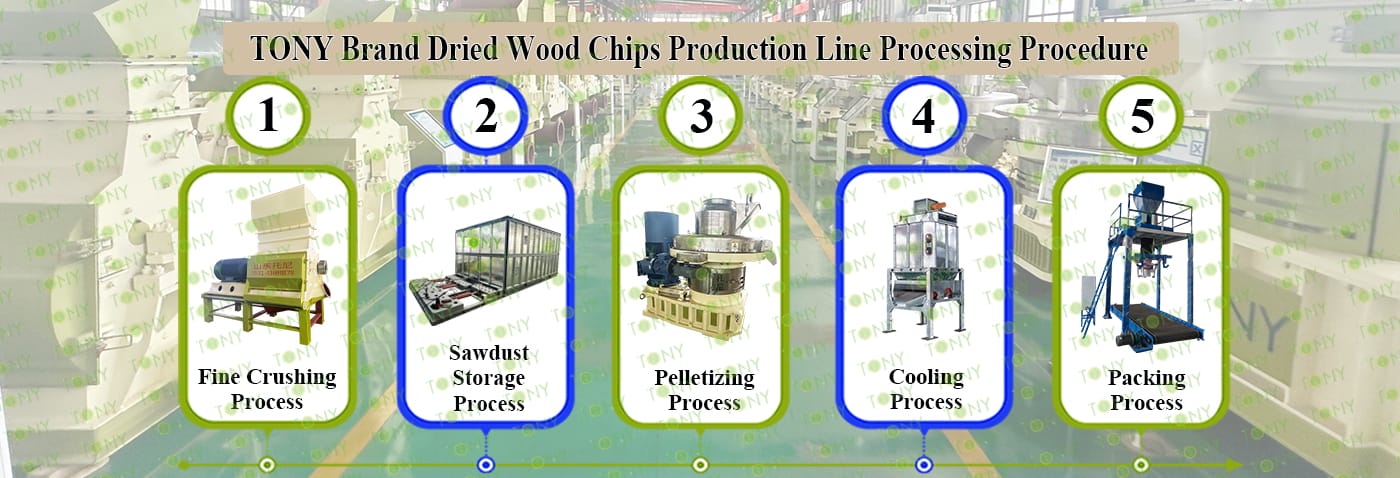

5. Process: Fine Crushing Process -Sawdust Storage Process- Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD85*250-250KW, TONY Large Hydraulic Storage Silo, TONY Pellet Machine TYJ860-Ⅲ-280KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

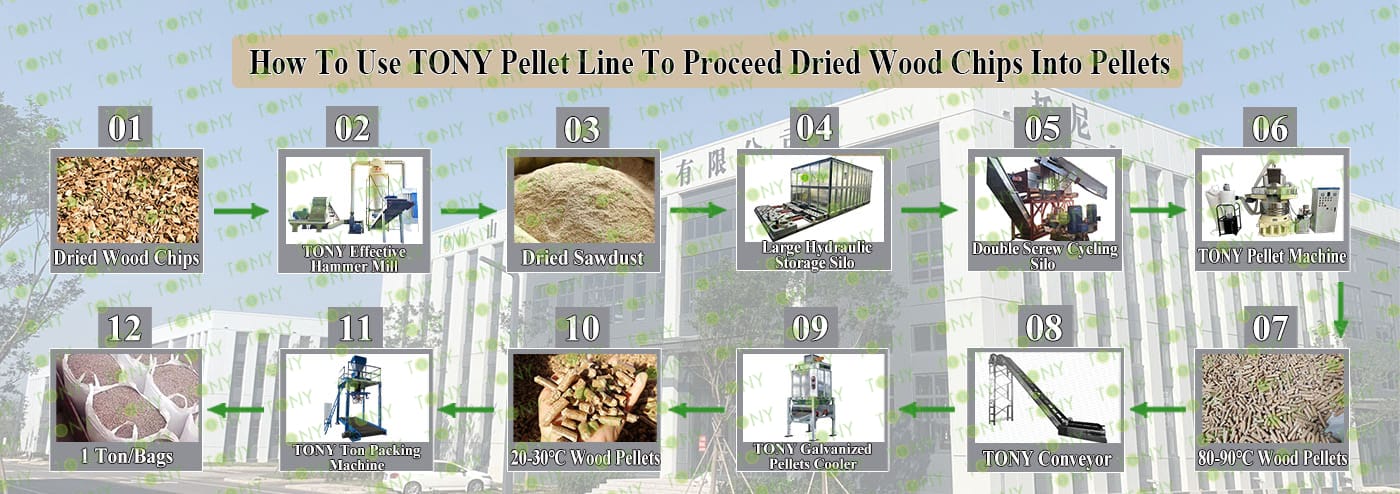

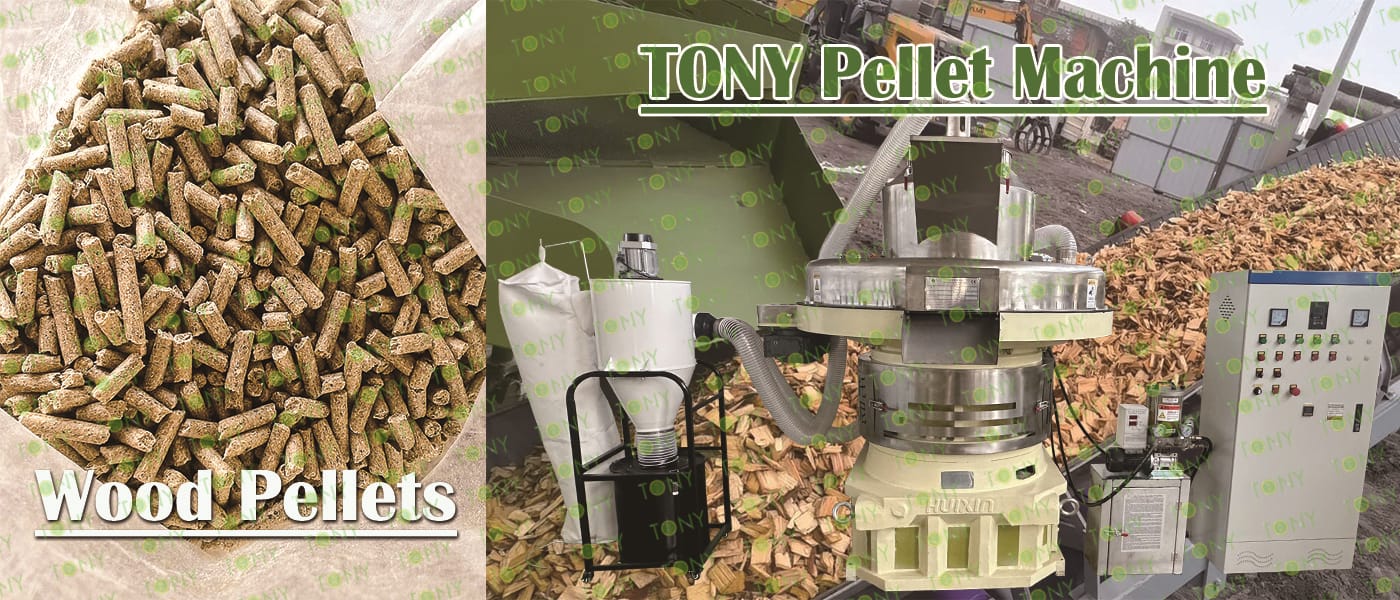

How to use the TONY pellet production line to make pellets from dried wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Effective Hammer Mill | Large Hydraulic Storage Silo | Vertical Ring Die Pellet Machine |

| 1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*5sets 3.Capacity: 5.5-7Ton/Hour/Set |

1.To Storage Sawdust Before Pellet machine 2.Model: TCY-45*2sets 3.TONY Uses Galvanized Material |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*7sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2sets 3.Capacity:28-35Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*2sets 3.Capacity: 28-35Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*22sets 3.Capacity:Designed With The Whole Line |

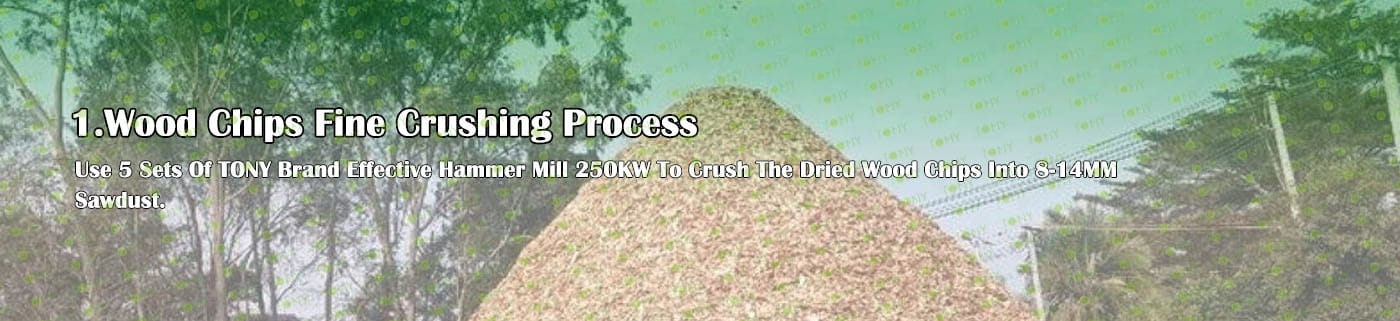

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:28-35Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*5sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

2.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:28-35Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-280KW*7sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:28-35Ton/Hour.

C.TONY brand galvanized pellets cooler separator*2sets

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:28-35Ton/Hour.

C.TONY brand ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Risk Control and Operation Recommendations for Dry Wood Chip Processing Biomass Pellets Project

1.Core Risks and Countermeasures

(1)Raw Material Risk: Raw material shortage and price increase

Sign long-term agreements with 3-5 suppliers to lock in price and supply;

Expand raw material sources (e.g., cooperate with forestry departments to recycle logging residues);

Reserve 15-30 days of raw material inventory

(2)Quality Risk: Pellet density does not meet standards and yield is low

Establish a raw material testing system (measure moisture and impurities for each batch);

Regularly maintain the pellet machine (clean the ring die weekly and check the rollers monthly);

Train operators and familiarize them with parameter adjustments (e.g., pressure, temperature)

(3)Market Risk: Pellet price drop and demand reduction

Binding long-term customers (e.g., signing a 1-3 year supply agreement with a power plant);

Expanding multi-scenario customers (industrial + civil + export);

Improving product quality (entering the high-end market)

(4)Environmental Risk: Exceeding dust emission standards and failing environmental inspections

Maintain the dust removal system regularly (replace filter bags monthly);

Install online monitoring equipment (real-time monitoring of dust concentration);

Reserve environmental emergency funds (to cope with unexpected inspections)

2.Operational optimization suggestions

(1)Optimize raw material pretreatment:

For dry wood chips containing impurities (such as scrap wood with nails), add a "magnetic separation + manual sorting" step to avoid damage to the equipment;

(2)Equipment maintenance plan:

Establish a "daily inspection (check screws, lubrication), weekly inspection (clean mold holes, filter bags), monthly inspection (replace wearing parts)" system to extend the life of the equipment;

(3)Cost control details:

Reuse of scrap materials (can reduce raw material loss by 5%-10%), staggered electricity use (use off-peak electricity hours for production to reduce electricity costs), and recycling packaging materials (woven bags can be reused 2-3 times).

1.Outstanding environmental value: renewable, low-carbon, and contribute to "dual carbon"

(1)100% renewable, recycling resources

The raw materials mainly come from wood processing waste (such as wood chips, sawdust, scraps), forestry residues (such as branches, bark), without consuming natural timber, realizing the "waste-to-treasure" of agricultural and forestry waste, avoiding the methane (strong greenhouse gas) generated by the accumulation and decay of waste or the pollution caused by incineration, and promoting the recycling of resources.

(2)"Carbon neutral" emissions, in line with low-carbon goals

The carbon dioxide released by the combustion of wood pellets is basically balanced with the amount of carbon dioxide absorbed during the growth of trees. From the perspective of the life cycle, it is a "carbon neutral" energy source and can replace fossil energy such as coal and oil, helping to reduce carbon emissions in industries such as industry and heating, and is in line with the global "dual carbon" strategy and the environmental protection policy orientation of various countries.

2.Good economic efficiency: controllable costs and policy support

(1)Low raw material costs and stable supply

The raw materials are wood processing waste or forestry residues. The procurement cost is much lower than coal and natural gas. The raw materials are widely sourced (furniture factories, wood processing plants, forest farms, etc.). The supply chain is stable and there is no need to worry about raw material shortages.

(2)Obvious production and use cost advantages

Although the pelletizing process requires equipment and energy consumption, the high calorific value and high transportation efficiency of the pellet products can offset some of the costs. For example, under the same heat demand, the cost of using wood pellets is 20%-30% lower than natural gas and 40%-50% lower than electric heating, which is attractive to both businesses and households.

2025 Tony Machinery - All Rights Reserved. Map