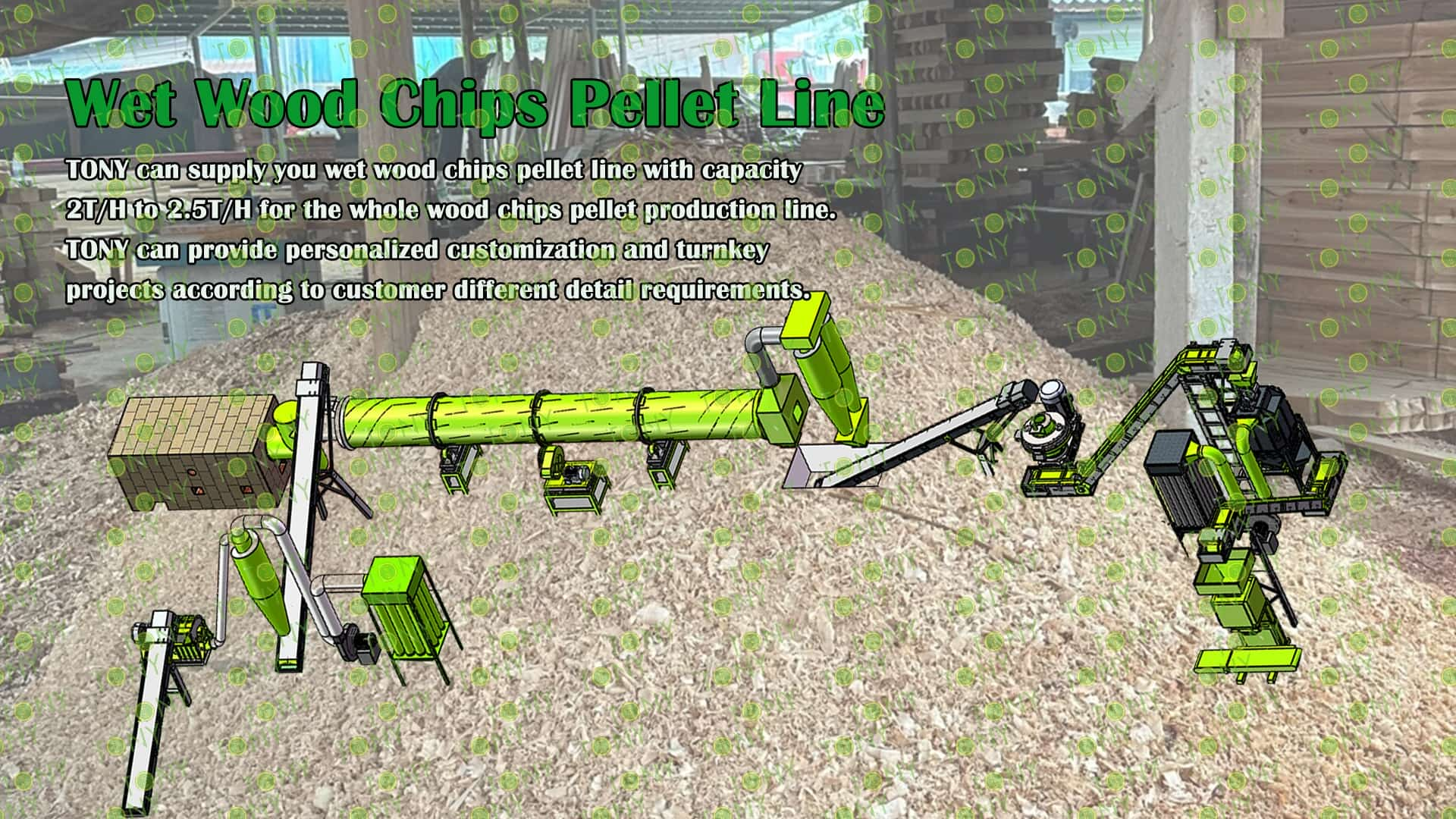

Project Brief Introduction:

1.Product:Wet Wood Chips Pellet Line

2.Capacity: 2-2.5T/Hour

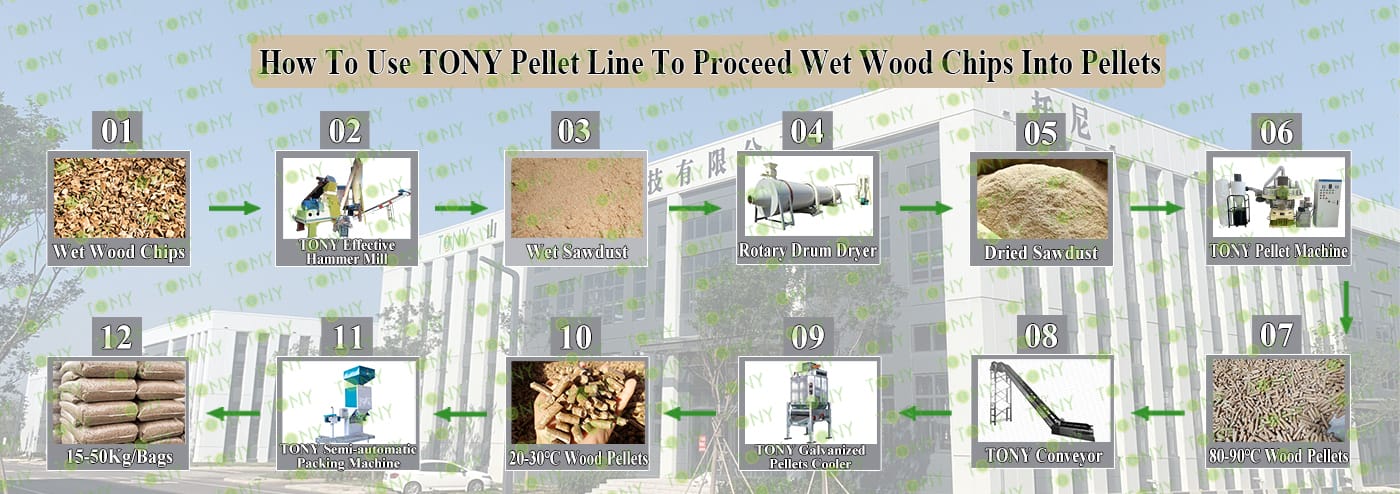

3.TONY Brand 2-2.5Ton /Hour Wet Wood Chips Pellet Line Project Process

4.Main Machine: Hammer Mill,Large Hydraulic Storage Silo, Rotary Drum Dryer,TONY Pellet Machine TYJ551-Ⅲ-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 270KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of wet wood chips biomass pellet processing equipment

(1)Pre-treatment: "Homogenization" of wet wood chips

Wet wood chips (such as wood processing waste, construction waste wood chips, etc.) usually have problems of uneven size and humidity fluctuations. They need to be adjusted to a state suitable for molding through pre-treatment to avoid subsequent blockage or molding failure.

(2)Core molding: "Fiber reorganization and densification" under mechanical extrusion

This is the key step in converting wet wood chips into pellets. The core principle is "high-pressure extrusion + wood fiber self-bonding" - the lignin in the wet wood chips (a natural adhesive that softens under pressure and frictional heat) works together with water to make the fibers tightly bonded to form pellets of fixed shape.

(3)Cutting and shaping: "Precise control" of pellet length

The wet wood chips squeezed out of the mold forming hole will form "continuous cylindrical strips" that need to be cut into pellets of uniform length by a cutting mechanism.

(4)Cooling and screening: the final checkpoint for pellet quality

(5)Auxiliary systems: ensuring stable operation of the equipment

Wet wood chip pellet processing equipment requires auxiliary systems to solve problems such as "blockage and overload" during wet material processing. The core systems include electronic control systems, dust removal systems, and lubrication systems.

2.Characteristics of wet wood chips biomass pellet processing equipment

(1)Precise machining accuracy: The main housing is made of high-quality steel, with uniform thickness and compact structure; it is carefully machined by imported CNC machining centers, with zero machining accuracy, providing stronger support for normal operation.

(2)Reliable lubrication system: The bearings and oil seals used in the transmission part are all made of high-precision bearings and wear-resistant and temperature-resistant fluororubber oil seals, and a special automatic lubrication system is added, with oil circulation cooling and automatic timed lubrication to ensure that the bearings are fully lubricated and the operation is safer and more reliable.

(3)Durable ring die: The ring die is made of precision and has a unique compression ratio design, which makes the product quality better and the service life of the ring die longer, minimizing the production cost.

(4)Continuous operation capability: The new generation of biomass pellet mill can achieve 24-hour continuous operation

3.Application scenarios of wet wood chips biomass pellet processing equipment

(1)Building materials industry: Wood chips can be used as raw materials for building materials and used to produce various boards and composite materials.

(2)Furniture factories: During the furniture manufacturing process, scraps and leftovers can be converted into wood chips through wet wood chip processing equipment. These pellets can be reused or used as fuel.

(3)Forestry and board mills: Wood waste generated in these places can be processed into wood chips for the production of biomass energy.

(4)Animal husbandry and feed industry: Wood chips can also be used as raw materials for feed pellets. After proper drying and processing, they can meet the needs of animal feed.

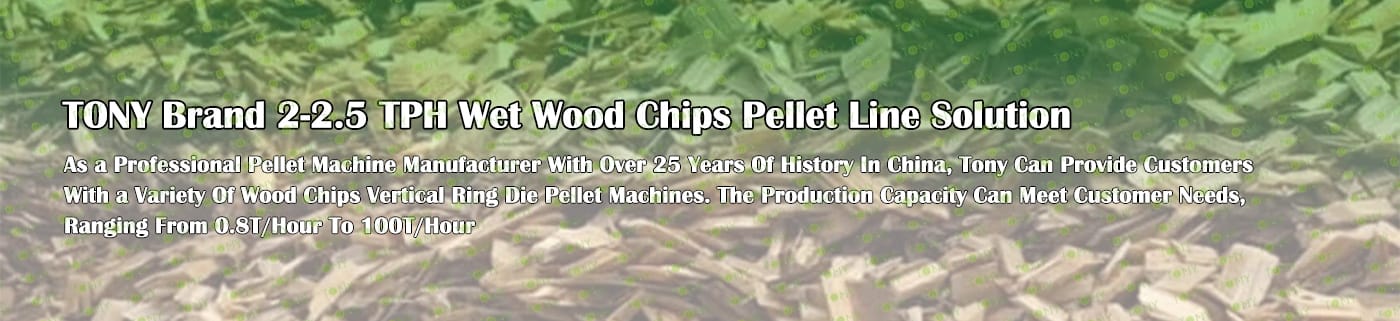

TONY Brand 2-2.5Ton/Hour Wet Wood Chips Pellet Manufacturing Plant can take wet wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, wet wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 2-2.5Ton/Hour

2. Raw materials: Wet wood chips

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production where waste wood chips have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

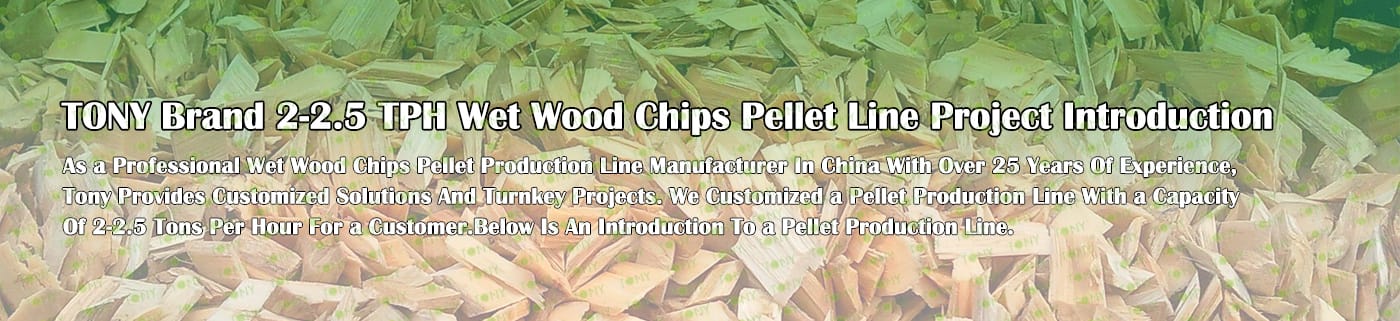

1. Project Name: Wet Wood Chips Pellet Production Line

2. Raw Material: All kinds of wet wood chips

3. Moisture Content of Raw Material: 40%

4. Capacity: 2-2.5 tons per hour

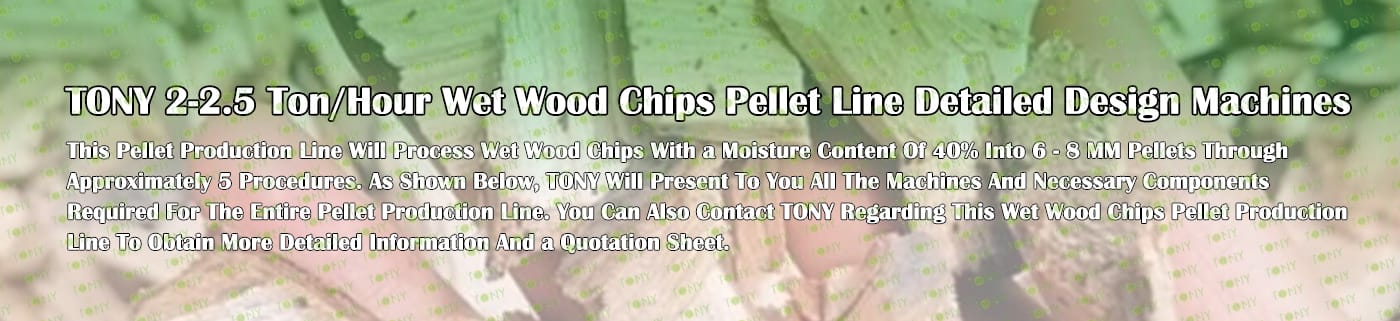

5. Process: Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD65*75-55KW, Rotary Drum Dryer-1.8*12m, TONY Pellet Machine TYJ551-Ⅲ-132KW, Pellet Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

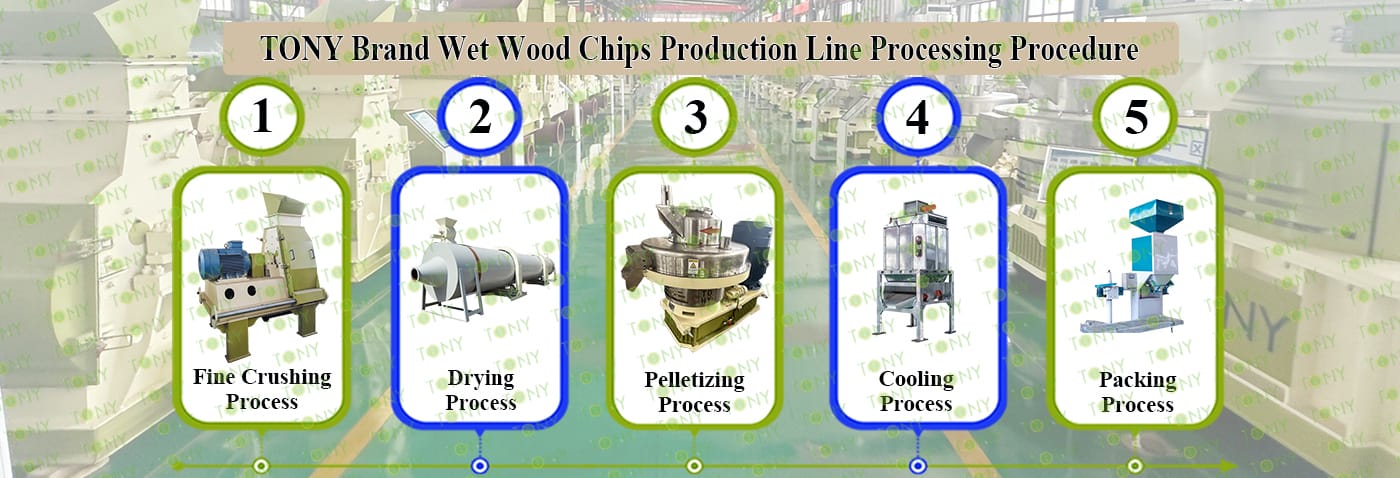

| Effective Hammer Mill | Rotary Drum Dryer | Vertical Ring Die Pellet Machine |

| 1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD65*75-55KW*1set 3.Capacity: 2-2.5Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.8*12*1set 3.Capacity:2-2.5Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-132KW*1set 3.Capacity:2-2.5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-1.5*1set 3.Capacity:2-2.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity:2-2.5Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 50cm*5sets 3.Capacity:Designed With The Whole Line |

三维图

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:2-2.5Ton/Hour.

C.TONY brand effective hammer mill TFD65*75-55KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

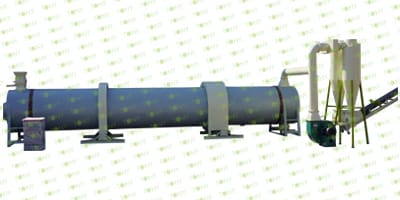

2.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:2-2.5Ton/Hour.

C.TONY use 1set of 1.8*12m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:2-2.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-132KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:2-2.5Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:2-2.5Ton/Hour.

C.TONY semi-automatic packing machine*1set

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

The wet wood chip pellet project is a promising biomass energy utilization project.

1.Project Overview:

The wet wood chip pellet project converts wet wood chips generated during wood processing into high-density, high-calorific value wood pellet fuel or biomass pellet products through a series of processes, including crushing, drying, and pelletizing. These pellets can be widely used in biomass power generation, industrial boiler fuel, and residential heating.

2.Market Demand:

(1)Energy Sector:

With the increasing global demand for clean energy, wood pellets, as a renewable biomass fuel, are increasingly being used in biomass power generation and industrial boilers. For example, in Europe, wood pellets have become a key fuel for power generation. The German wood pellet market has an annual demand of over one million tons and is growing at approximately 5% annually.

(2)Construction and Furniture Industry:

Wood pellets can also be used as a filler in new building materials and furniture production. They are environmentally friendly, energy-efficient, and offer excellent performance. With the development of the construction industry and growing consumer demand for eco-friendly furniture, market demand is also expanding.

Biomass pellets processed from wood chips offer the following advantages:

1.Renewable Energy:

Biomass pellets are derived from waste wood and agricultural residues, resulting in minimal environmental impact and a renewable energy source.

2.Low CO2 Emissions:

Compared to fossil fuels, the combustion of biomass pellets produces lower CO2 emissions, contributing to global climate change mitigation.

3.High Calorific Value:

Pine wood pellets have a calorific value of 4200-5000 kcal/kg, making them one of the highest calorific biomass fuels.

4.Low Ash Content:

Pine wood pellets have a low ash content, typically 1-3. Compared to coal, this ash content leaves very little ash and residual ash. This low ash content significantly increases the fuel's utilization rate, saving fuel.

5.Environmental Advantages:

The main components of the combustible gases released after pyrolysis of pine wood pellets are H2, CH4, CmHn, and CO. Emissions of SO2, CO, and NO after full combustion are negligible. Therefore, pine wood pellets offer significant environmental advantages compared to coal.

6.Economical:

The utilization rate and unit price of pine wood pellet fuel are high. Compared with fuel oil, gas, electricity and other energy sources, pine wood pellet fuel is a relatively cost-effective energy source. It can generally save 50% compared with fuel oil and gas, and 80% compared with electricity. It is 10% cheaper than anthracite and about 20-30% more expensive than low-quality polluting coal.

2025 Tony Machinery - All Rights Reserved. Map