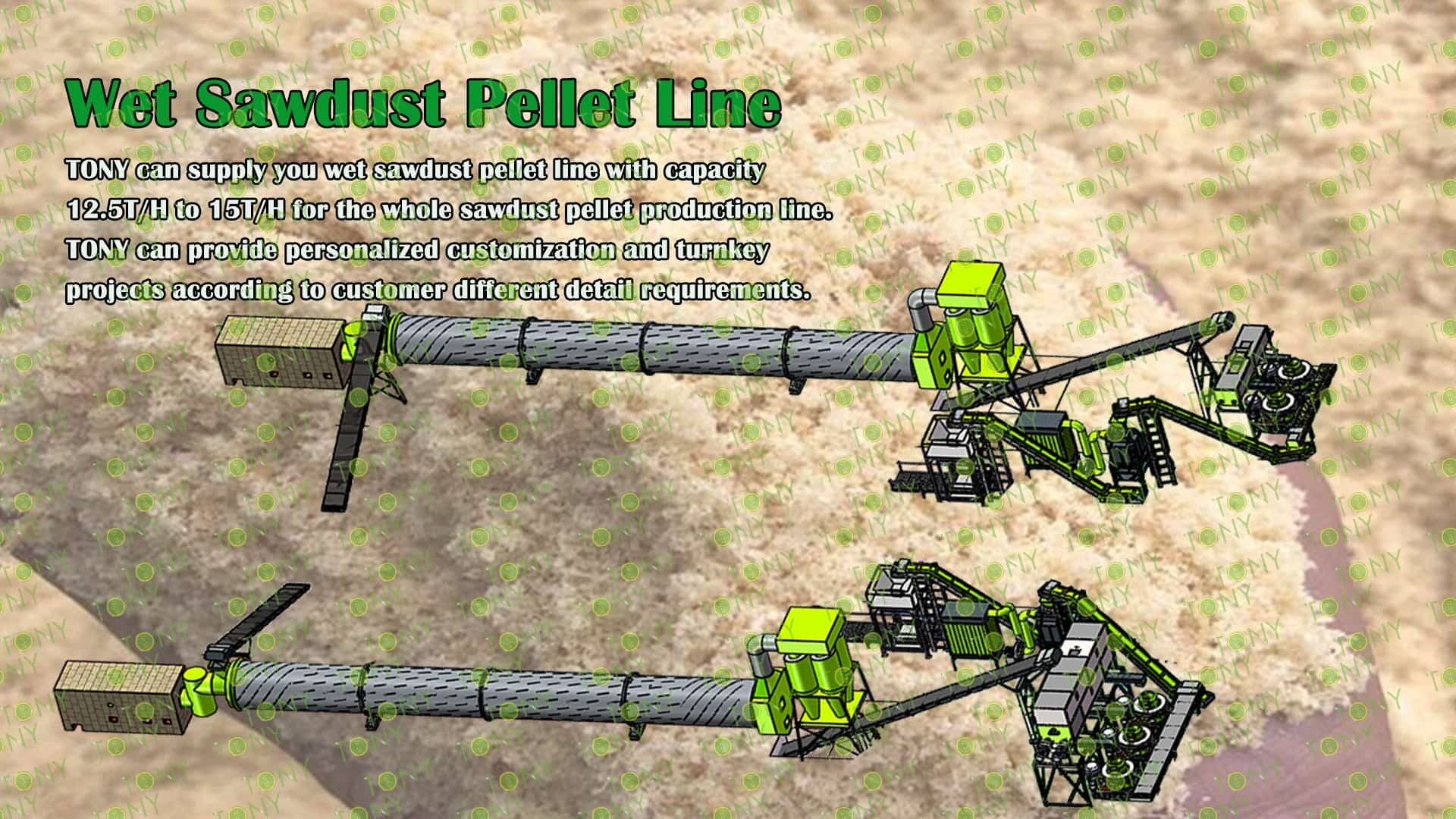

Project Brief Introduction:

1.Product:Wet Sawdust Pellet Line

2.Capacity: 12.5-15T/Hour

3.TONY Brand 12.5-15Ton /Hour Wet Sawdust Pellet Line Project Process

4.Main Machine: Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1040KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

1.The working principle of wet sawdust biomass pellet processing equipment

The pellet mill's main unit is the core equipment, operating based on the compression mechanism between rollers and a die. When material is fed into the pellet mill, an electric motor drives the main shaft through a gearbox or reducer, which in turn rotates the rollers. As the rollers rotate, they squeeze the material into the pores of the die. Under the influence of high temperature and pressure, the lignin in the sawdust softens, causing the cellulose molecules to dislocate, deform, and expand, allowing adjacent biomass particles to mesh with each other, automatically forming the pellets without any adhesive.

2.Characteristics of wet sawdust biomass pellet processing equipment

(1)The motor shaft is directly connected to the gear shaft, which provides stronger power transmission, greater torque resistance, greater stability and lower maintenance rate.

(2)The bearing chamber has been modified, the sealing method has been changed, and the forged and tempered wear-resistant materials have been used to prevent dust from falling into the bearing chamber.

(3)The gearbox body is larger, the gears are larger, the output is higher, and the power consumption is lower.

(4)The bearings are made of genuine heavy-duty Ha shafts, which have a longer bearing life and a lower maintenance rate for the entire machine.

(5)The ring die is vertical and double layered, with dual use of upper and lower layers, improving utilization, reducing costs, and increasing efficiency.

(6)The pressure wheel rotates, the material is centrifuged, and the surrounding material is evenly distributed.

(7)Efficient and energy-saving, automatic timed oil lubrication, ensuring sufficient lubrication of bearings and safer and more reliable operation.

(8)High pressure filtration, clean and smooth independent frequency conversion device, ensuring the yield of pellets.

3.Application scenarios of wet sawdust biomass pellet processing equipment

Provides raw materials for biomass power plants, heating companies, and industrial boilers (such as those in food processing and textile mills). It converts dry wood into high-density pellet fuel, replacing traditional energy sources like coal and natural gas and reducing carbon emissions. It can also be used as fuel for household heating stoves and fireplaces, meeting clean heating needs.

(1)Wood Processing and Furniture Industry:Processes dry sawdust, scraps, shavings, and other waste generated by furniture and wood processing plants into pellets. These can be recycled as fuel for in-plant boilers or sold externally, transforming waste into a resource and reducing solid waste disposal costs.

(2)Agriculture and Animal Husbandry Support:First, it processes agricultural and forestry waste such as dry straw and branches into pellets for use as bedding for livestock and poultry (e.g., cowshed and chicken coop bedding, which is highly absorbent and easy to clean). Second, some equipment can process a mixture of dry sawdust and feed ingredients to produce simple biomass feed carrier pellets to aid animal husbandry production.

(3)Environmental Protection and Solid Waste Treatment:For forestry pruning waste, such as dry branches and wood processing waste, this equipment compresses loose waste into high-density pellets, reducing transportation and storage space while also preventing environmental pollution caused by indiscriminate waste stacking, effectively turning waste into treasure.

TONY Brand 12.5-15Ton/Hour Wet Sawdust Pellet Manufacturing Plant can take wet sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, wet sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 12.5-15Ton/Hour

2. Raw materials: Wet sawdust

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Sawdust Pellet Production Line

2. Raw Material: All kinds of wet sawdust

3. Moisture Content of Raw Material: 40%

4. Capacity: 12.5-15 tons per hour

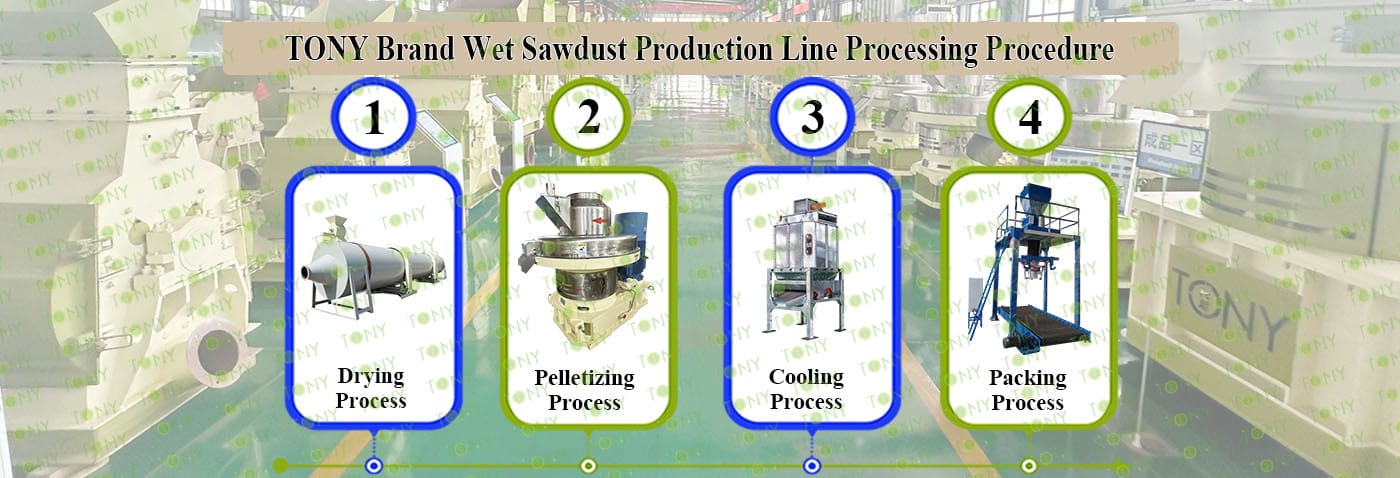

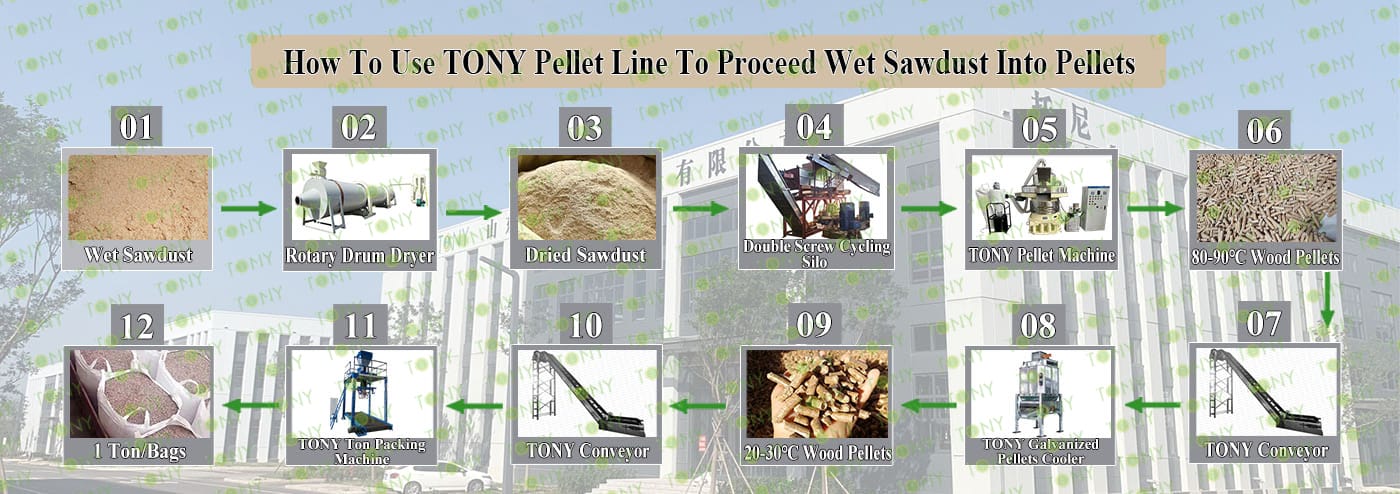

5. Process: Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Rotary Drum Dryer-2.2*24m, TONY Pellet Machine TYJ760-Ⅲ-160KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet sawdust? The process mainly includes the following steps and equipment: 1. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

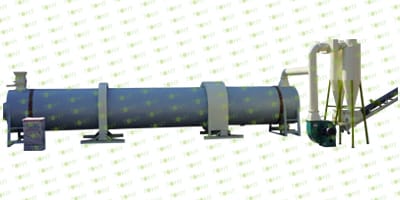

| Rotary Drum Dryer | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

|

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2.2*24*2sets 3.Capacity:6-7.5Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-15*1set 3.Capacity:12.5-15Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*5sets 3.Capacity:2.5-3Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

|

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:12.5-15Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*1set 3.Capacity:12.5-15Ton/Hour |

1.To Transport Sawdust,Pellets. 2.Width: 80cm*7sets 3.Capacity:Designed With The Whole Line |

三维图

1.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:12.5-15Ton/Hour.

C.TONY use 2 sets of 2.2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:12.5-15Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-160KW*5sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:12.5-15Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:12.5-15Ton/Hour.

C.TONY band ton packing machine*1set

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Biomass pellet fuel, due to its clean, environmentally friendly, high calorific value, and stable combustion, is widely used in industrial boilers, heating equipment, livestock farms, food processing, textile printing and dyeing, and the building materials industry. With the strict implementation of environmental protection policies and the gradual phase-out of traditional coal-fired boilers, market demand for biomass pellets continues to grow as a high-quality alternative to coal.

Biomass pellets are primarily made from agricultural and forestry waste, such as wood chips, rice husks, straw, and sawdust. These raw materials are abundant in rural areas and even free in some areas, reducing raw material costs while also enabling waste recycling.

Compared to traditional fuels like coal and firewood, sawdust pellets offer a superior user experience and require no major modifications to existing equipment:

1.Easy to ignite and stable combustion:

The pellets have a regular shape (typically 6-10mm in diameter and 20-30mm in length) and a controllable moisture content (10%-15%). Ignition requires only a small amount of combustion aid (such as paper or wood chips). Once ignited, the flame is stable and the calorific value is uniform (lower calorific value is approximately 4200-4800 kcal/kg, close to Class II bituminous coal). There are no problems with coal "coking and flameout" or firewood "smoking and fluctuating flames."

2.Compatible with existing equipment, low modification cost:

Industrial boilers, residential heating stoves, biomass burners, and other equipment require only a simple adjustment of the feed port (e.g., replacing the coal feed port with a pellet-specific feeder). The modification cost is typically only 5%-10% of the total equipment price, significantly lower than the cost of switching from coal to gas (which requires replacing the entire gas combustion system).

3.Strong adaptability to automated operations:

The particles have good fluidity and can be fed automatically and controlled automatically through pipes and screw conveyors. When combined with a temperature control system, unattended combustion can be achieved (such as 24-hour continuous operation of an industrial boiler), reducing manual operation costs.

2025 Tony Machinery - All Rights Reserved. Map