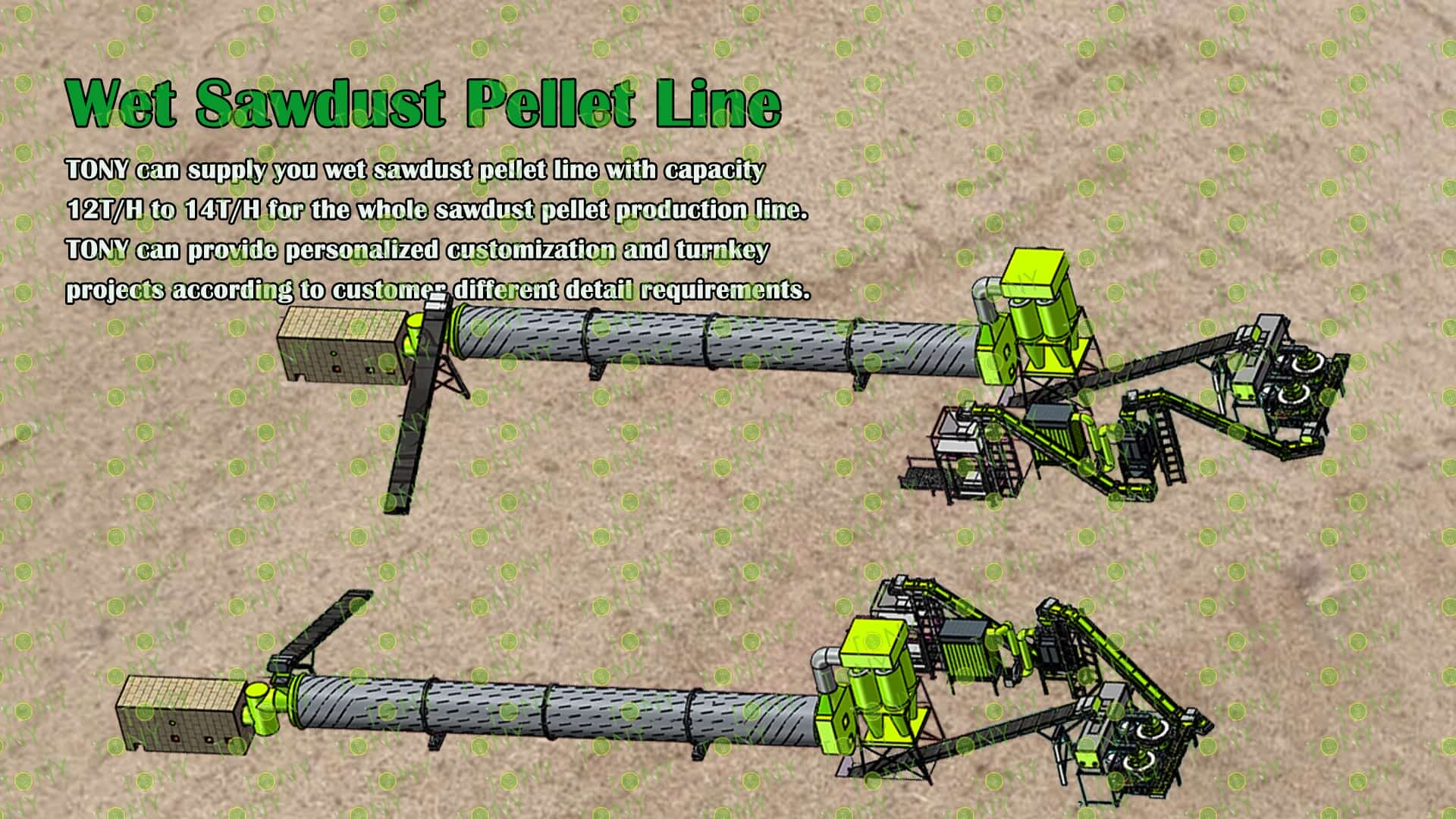

Project Brief Introduction:

1.Product:Wet Sawdust Pellet Line

2.Capacity: 12-14T/Hour

3.TONY Brand 12-14Ton /Hour Wet Sawdust Pellet Line Project Process

4.Main Machine: Rotary Drum Dryer,TONY Pellet Machine TYJ860-Ⅲ-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1110KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of wet sawdust biomass pellet processing equipment

The essence of wet sawdust pellet processing equipment is to "use mechanical high pressure as a driving force, with lignin (a natural binder) and water (an auxiliary bonding agent) as the bond, to transform loose wet sawdust into high-density, easily storable solid pellets through a continuous process of 'extrusion-cutting-cooling'." Its key advantage lies in its adaptability to wet materials. By optimizing die gaps, controlling frictional heat, and implementing a supporting cooling system, these equipment avoids mold sticking and clogging caused by wet materials during processing. Furthermore, the moisture in the wet material is used to reduce extrusion resistance and lower equipment energy consumption.

2.Characteristics of wet sawdust biomass pellet processing equipment

(1)Precise machining accuracy: The main housing is made of high-quality steel, with uniform thickness and compact structure; it is carefully machined by imported CNC machining centers, with zero machining accuracy, providing stronger support for normal operation.

(2)Reliable lubrication system: The bearings and oil seals used in the transmission part are all made of high-precision bearings and wear-resistant and temperature-resistant fluororubber oil seals, and a special automatic lubrication system is added, with oil circulation cooling and automatic timed lubrication to ensure that the bearings are fully lubricated and the operation is safer and more reliable.

(3)Durable ring die: The ring die is made of precision and has a unique compression ratio design, which makes the product quality better and the service life of the ring die longer, minimizing the production cost.

(4)Continuous operation capability: The new generation of biomass pellet mill can achieve 24-hour continuous operation

3.Application scenarios of wet sawdust biomass pellet processing equipment

(1)Building materials industry: Sawdust pellets can be used as raw materials for building materials and used to produce various boards and composite materials.

(2)Furniture factories: During the furniture manufacturing process, scraps and offal can be converted into sawdust pellets through wet sawdust pellet processing equipment. These pellets can be reused or used as fuel.

(3)Forest farms and board mills: Wood waste generated in these places can be processed into sawdust pellets for the production of biomass energy.

(4)Animal husbandry and feed industry: Sawdust pellets can also be used as raw materials for feed pellets. After proper drying and processing, they can meet the needs of animal feed.

TONY Brand 12-14Ton/Hour Wet Sawdust Pellet Manufacturing Plant can take wet sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets,branches, wood logs, and wood shavings. After pretreatment and processing, wet sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 12-14Ton/Hour

2. Raw materials: Wet sawdust

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Sawdust Pellet Production Line

2. Raw Material: All kinds of wet sawdust

3. Moisture Content of Raw Material: 40%

4. Capacity: 12-14 tons per hour

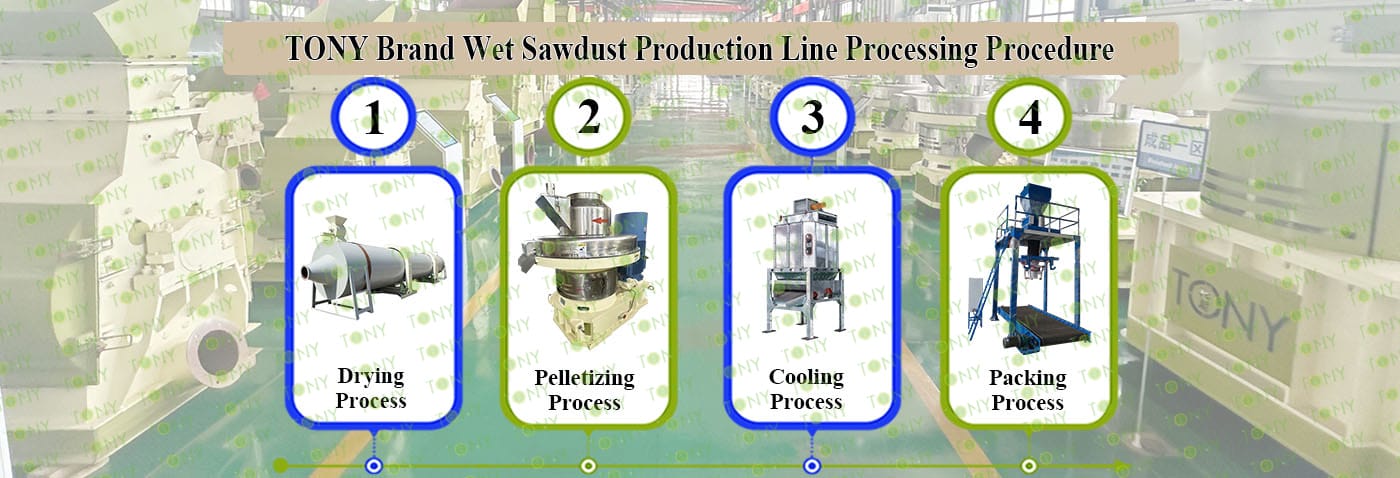

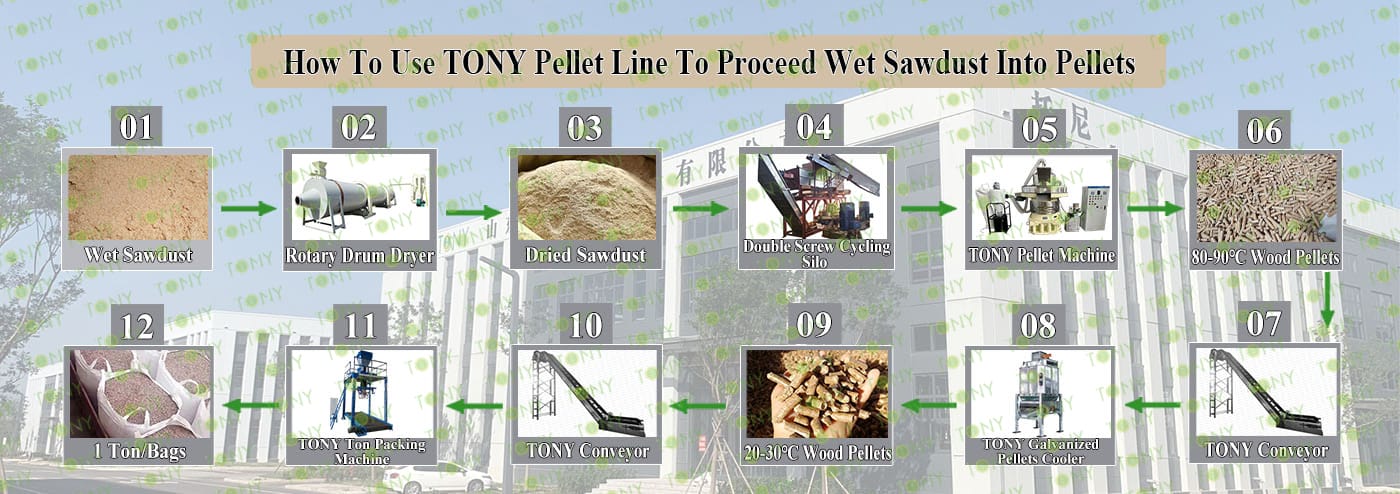

5. Process: Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Rotary Drum Dryer-2*24m, TONY Pellet Machine TYJ860-Ⅲ-220KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet sawdust? The process mainly includes the following steps and equipment: 1. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Rotary Drum Dryer | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

|

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2*24*2sets 3.Capacity:6-7Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-7*2sets 3.Capacity:6-7Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*4sets 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

|

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*2sets 3.Capacity:12-14Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*2sets 3.Capacity:12-14Ton/Hour |

1.To Transport Sawdust,Pellets. 2.Width: 80cm*10sets 3.Capacity:Designed With The Whole Line |

三维图

1.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:12-14Ton/Hour.

C.TONY use 2 sets of 2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:12-14Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*4sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:12-14Ton/Hour.

C.TONY brand galvanized pellets cooler *2sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:12-14Ton/Hour.

C.TONY band ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Benefit Analysis of Sawdust Processing Biomass Pellets Project

1.Economic Benefit Advantages:

Fast Return on Investment, Stable Profit Margin The project belongs to the “light asset, fast turnover” type, with flexible investment threshold, clear profit margin, and strong risk resistance. The price of raw materials (sawdust) fluctuates slightly (annual fluctuation is usually less than 10%), and the price of products (biomass pellets) is driven by the energy market (for example, when coal and natural gas prices rise, pellet prices rise simultaneously). “The cost side is stable, and the selling price side is linked to the energy price”, and the ability to resist market risks is better than most processing industries.

2.Environmental Protection and Social Benefit Advantages:

Taking into account both commercial value and social responsibility The project can not only bring economic benefits, but also generate significant environmental protection and social benefits, and enhance the brand value of enterprises:

(1)Significant environmental benefits:The carbon emissions of biomass pellets during combustion are much lower than those of traditional energy - compared with coal, burning 1 ton of pellets can reduce CO₂ emissions by about 1.5 tons and SO₂ emissions by about 0.08 tons, which is in line with the “dual carbon” goal. Enterprises can further obtain additional income through carbon trading (great potential in the future).

(2)Outstanding social benefits:The project can stimulate local employment (such as positions in raw material recycling, production operations, and logistics distribution), utilize local wood processing waste, contribute to rural revitalization, and easily obtain support from local governments, creating a good environment for the company's subsequent development.

In summary, the sawdust processing biomass pellet project is a high-quality investment direction with low risk and stable returns in the current new energy and environmental protection fields. It is particularly suitable for deployment in areas with concentrated wood processing industries and a large number of industrial boilers.

Sawdust itself is a waste product from wood processing (furniture, panel, and door factories, etc.). Processing it into pellets is essentially a "resource cycle," eliminating the issue of competing with grain crops for land or forest resources.

1.No additional raw material consumption and no productive resources are used:

No dedicated tree planting is required; existing industrial waste is directly utilized, eliminating the environmental pollution caused by sawdust incineration and landfills while also achieving "waste resource utilization."

2.Stable raw material supply, unrestricted by seasonality:

The wood processing industry operates year-round, resulting in a stable sawdust output (the furniture industry alone produces over 10 million tons annually). Sawdust can also be stored for long periods (dried sawdust has a low moisture content and is less susceptible to mold). This eliminates the risk of seasonal supply disruptions and ensures the continuity of pellet production.

3.High Cost-Effectiveness:

Amidst rising energy costs, sawdust pellets offer significantly better value for money than clean energy sources like natural gas and liquefied petroleum gas, and are even competitive with coal.

4.Long-Term Cost Stability and Strong Resistance to Fluctuations:

The raw material (sawdust) is an industrial waste product with minimal price fluctuations (annual fluctuations ≤10%). Coal and natural gas are significantly impacted by international energy markets and geopolitics. The cost stability of sawdust pellets makes them more suitable for long-term use by businesses and households.

2025 Tony Machinery - All Rights Reserved. Map