1.The working principle of dried wood log biomass pellet processing equipment

The processing of dry wood biomass pellets follows a core process of "raw material pretreatment → extrusion molding → post-processing." Because the raw material is dry wood with a low moisture content (typically 10%-15%), the process eliminates the energy-intensive deep drying step, focusing instead on the physical transformation of the material through mechanical forces. The specific process is as follows:

Raw material (dry wood waste) → crushing → fine crushing → pelletizing → cooling → packaging → finished pellets

2.Characteristics of dried wood log biomass pellet processing equipment

(1)Low unit energy consumption: It eliminates the deep drying step (drying energy consumption accounts for 40%-60% of the total energy consumption of biomass pellet processing), and the overall energy consumption is 30%-50% lower than that of equipment that processes wet materials; at the same time, the friction heat generated by dry materials during molding is more concentrated, which can reduce the need for external heating and further save energy.

(2)Strong production continuity: Dry materials are not easy to stick to the inner wall of the equipment (such as the feed pipe and ring die cavity), reducing the downtime and cleaning time caused by material blockage. The continuous operation time of a single pelletizer (1-5 tons per hour) can reach 8-12 hours, which is suitable for large-scale production.

(3)Intelligent control system: equipped with a PLC control system, which can monitor parameters such as raw material moisture content, feed rate, ring die temperature, and particle density in real time, and automatically adjust the feed speed, roller pressure, etc. to ensure the stability of the finished particle density (1.1-1.3g/cm³) and hardness (crushing strength ≥90%).

(4)Multiple safety protection: equipped with overload protection (automatic shutdown when the equipment is stuck), temperature warning (starting the cooling device when the ring die temperature is too high), metal detection (automatic discharge when metal impurities are detected in the screening process) and other functions to avoid equipment damage or production accidents.

(5)Low pollution emissions: The crushing and screening stages are equipped with dust removal devices (such as pulse bag dust collectors) to reduce the spread of sawdust dust; the pelletizing process does not generate waste gas or wastewater, which meets environmental protection standards.

(6)Finished product is compatible with combustion equipment: The pellets produced are of uniform size (6-8mm in diameter, 10-30mm in length), do not contain additives, have stable combustion power, and low ash content (≤3%). They can be directly adapted to combustion equipment such as biomass boilers and fireplaces, and are easy to store and transport (high bulk density and not easy to absorb moisture).

3.Application scenarios of dried wood log biomass pellet processing equipment

The core application scenario for wood pellet processing equipment is converting wood waste into environmentally friendly fuel.

Raw material sources: Sawdust and scraps from lumber processing plants, branches and trunks pruned from forestry farms, wood chips and shavings from furniture factories, and waste wood from building demolition.

Residential Heating: Produces clean pellet fuel for fireplaces and home heating stoves, replacing coal and natural gas and reducing pollutant emissions.

Industrial Heating: Provides boiler fuel for food processing plants, building materials factories (such as tile drying), textile mills, and other facilities, meeting steam and hot water needs for industrial production.

Power Generation: Used as fuel in biomass power plants, generating electricity that is fed into the grid through combustion, or provides electricity and heat to distributed energy stations (such as villages, towns, and industrial parks).

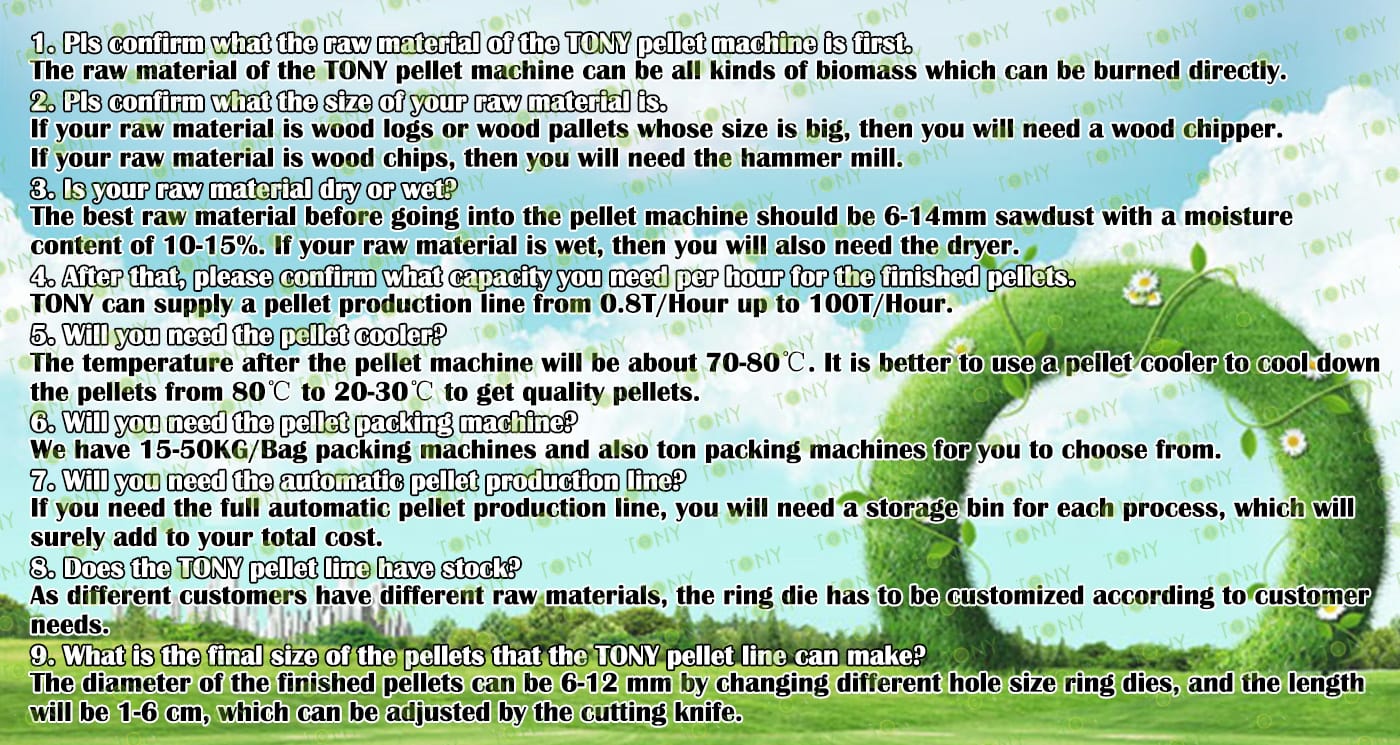

TONY Brand 80-100Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:80-100Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

2. Raw Material: All kinds of dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 80-100 tons per hour

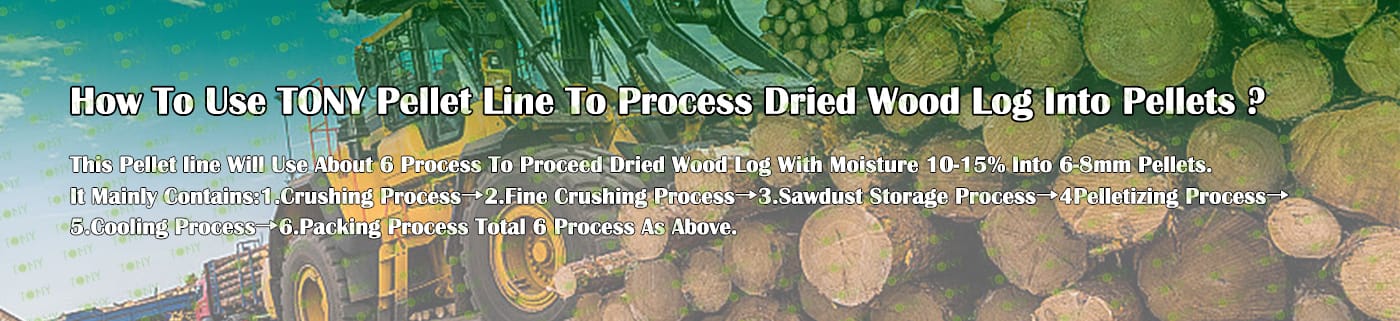

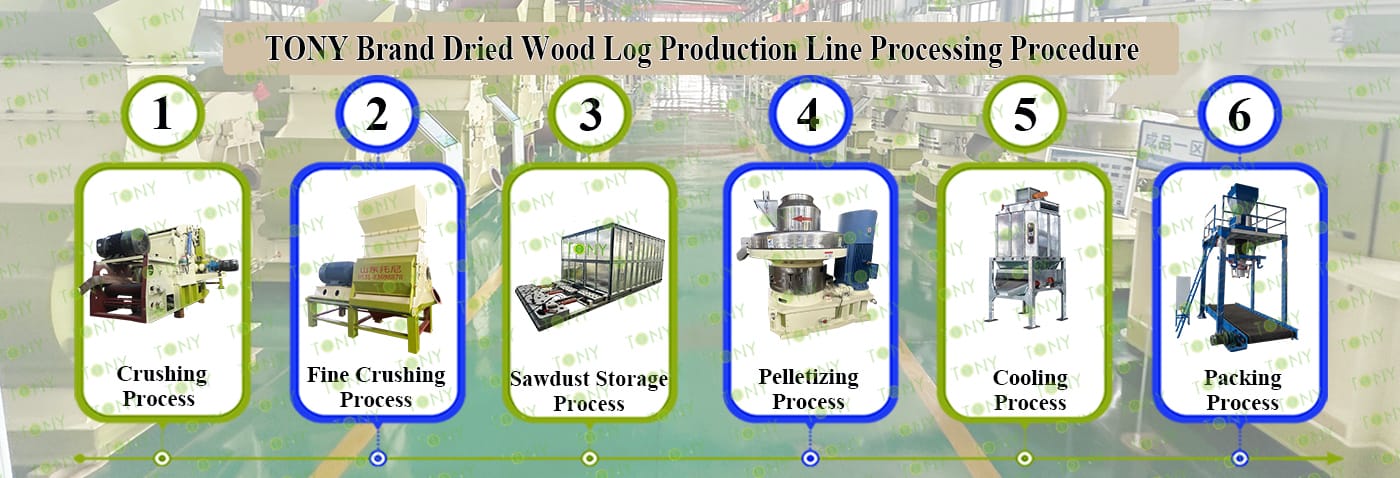

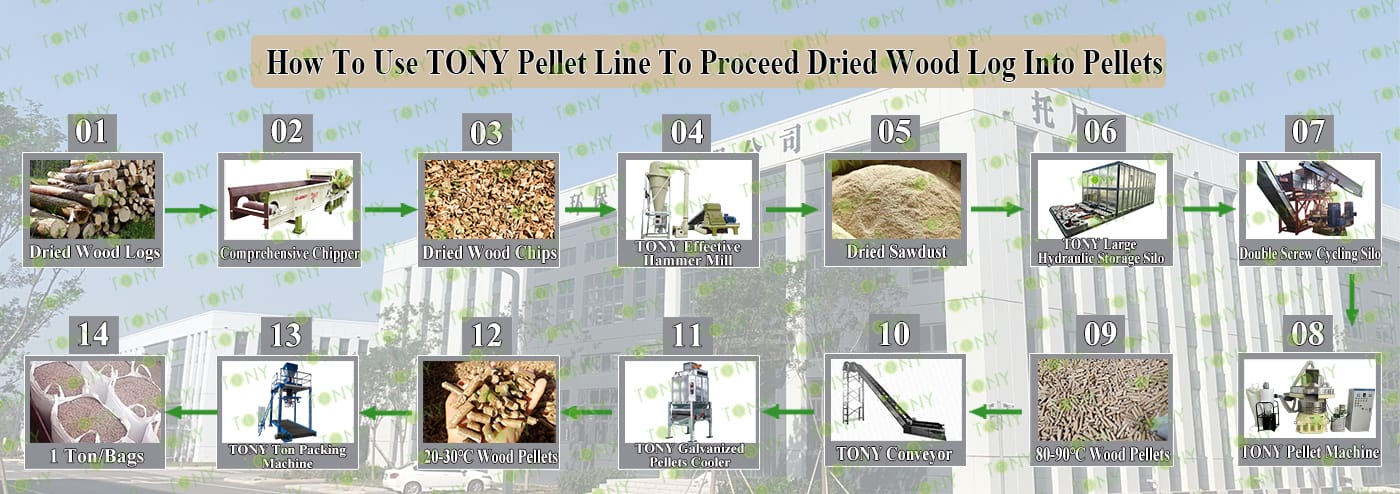

5. Process: Crushing Process - Fine Crushing Process -Sawdust Storage Process- Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1800-500KW, Effective Hammer Mill-TFD1600-500KW, TONY Large Hydraulic Storage Silo,TONY Pellet Machine TYJ860-Ⅲ-280KW, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut dried wood log with a diameter of less than 40cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Large Hydraulic Storage Silo |

|

1.To Grind Wood Logs φ ≤40cm Into25-55mm Wood Chips. 2.Model: TPC1800-500KW With 6 Blades*3sets 3.Capacity:80-100 Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD1600-500KW*6sets 3.Capacity: 14-17Ton/Hour/Set |

1.To Storage Sawdust Before Pellet machine Model: TCY-45*6sets 2.TONY Uses Galvanized Material |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*20sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*6sets 3.Capacity:80-100Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*6sets 3.Capacity: 80-100Ton/Hour |

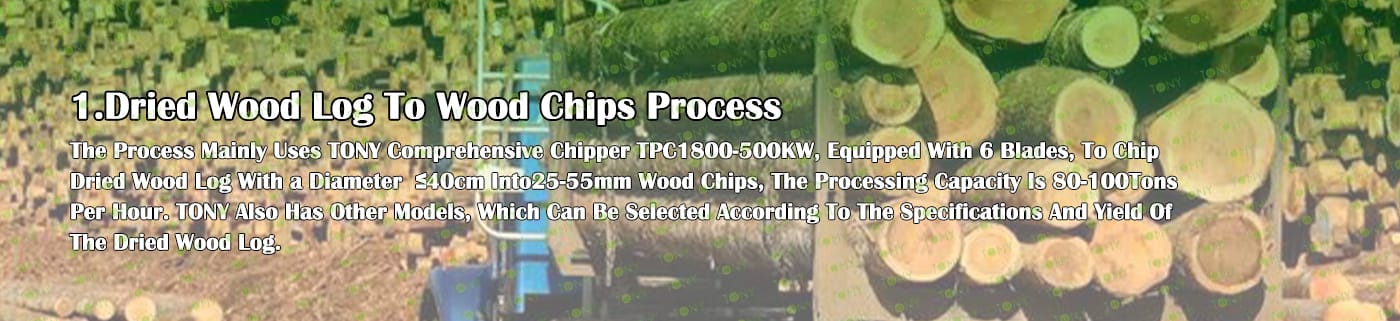

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 40cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPC1800-500KW model with 6 flying blades type*3sets

C.Capacity:80-100Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:80-100Ton/Hour.

C.TONY brand effective hammer mill TFD1600-500KW*6sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

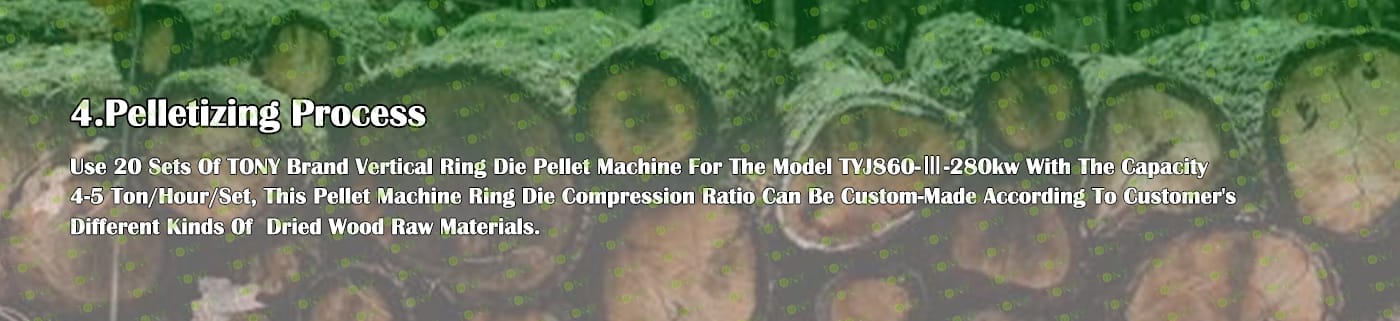

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:80-100Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*20sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.6 sets of TONY galvanized cooler separator with capacity 80-100ton/hour

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.6 sets of TONY ton packing machine

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Processing dry wood into biomass pellets is a promising entrepreneurial venture. Here are its advantages and some key considerations:

1.Low Raw Material Cost:

Dry wood is widely available. Furniture factories, panel mills, sawmills, and other industries generate large quantities of scraps, shavings, and wood chips. In some areas, discarded wood can be obtained free of charge, effectively reducing raw material costs.

2.Stable Market Demand:

Biomass pellet fuel is environmentally friendly and renewable. In the residential sector, it can be used for home heating and is particularly popular in areas with high winter heating demand. Industrially, it can also be used as boiler fuel in factories, farms, and greenhouses. There is also significant demand for biomass pellets in some export markets.

3.Large Profit Margin:

The equipment pays for itself within 3-5 months, significantly increasing the added value compared to directly recycling dry wood.

4.Highly intelligent equipment:

Nowadays, some advanced pellet machines support PLC intelligent control and have the function of starting the entire line with one button. They have a high degree of automation and can generally be operated by two people. The difficulty and cost of human management are relatively low.

Wood pellets offer outstanding combustion performance and environmental advantages.

1.High and Stable Calorific Value

The calorific value of dry wood pellets is typically 4,000-4,500 kcal/kg (depending on the wood type; hardwoods like oak can reach 4,500 kcal, while softwoods like pine reach approximately 4,200 kcal). This is close to high-quality bituminous coal (4,500-5,500 kcal) and significantly higher than straw pellets (3,000-3,500 kcal).

2.Complete Combustion, Low Ash

Due to their high density and uniform structure, they provide ample air contact during combustion, achieving a complete burnout rate exceeding 95%. Residual ash is only 1%-3% (compared to approximately 5%-10% for straw pellets), reducing the need for frequent cleaning (industrial boilers can be cleaned every 10-15 days of continuous operation).

3.Easy to ignite, stable flame

Compared to raw coal, dry wood pellets are highly flammable (can be ignited with an open flame) and produce no deflagration or black smoke (high-quality pellets burn virtually smokelessly). Flame temperatures can reach 800-1000°C, making them suitable for applications requiring a stable heat source (such as food drying and industrial steam generation).

4.Low carbon emissions, nearly "carbon neutral"

The carbon dioxide absorbed during wood growth is roughly balanced by the amount released during combustion. Lifecycle carbon emissions are only 1/10 of those from coal, and nitrogen oxide emissions are over 50% lower than coal, meeting the requirements of the "dual carbon" policy.

5.Low pollutants

Sulfur content is ≤ 0.05% (compared to the typical 0.5%-3% for coal), and dust can be treated with simple collection devices.

6.Recyclable waste

The ash from combustion is rich in potassium, calcium, and other elements and can be returned to the fields as organic fertilizer, completing a closed "fuel-ash-fertilizer" cycle. It is particularly suitable for use in agricultural production areas.

2025 Tony Machinery - All Rights Reserved. Map