Project Brief Introduction:

1.Product:Dried Wood Log Pellet Line

2.Capacity:9-10.5T/Hour

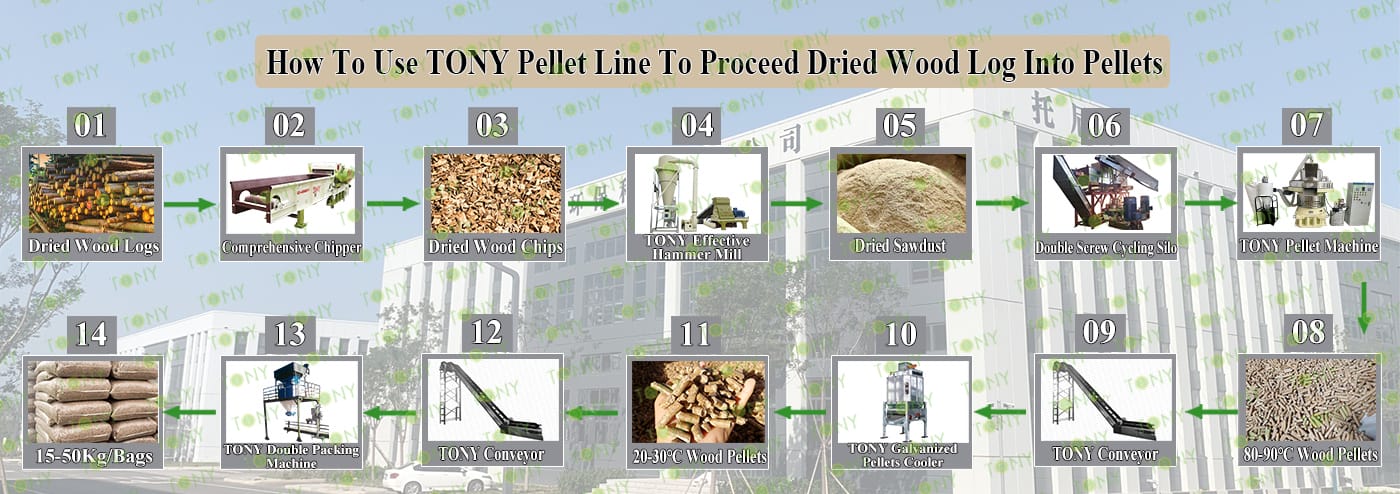

3.TONY Brand 9-10.5Ton /Hour Dried Wood Log Pellet Line Project Process

4.Main Machine: Comprehensive Chipper ,Hammer Mill, TONY Pellet Machine TYJ860-Ⅲ-220KW, Pellet Cooler, Packing Machine And Belt Conveyors

5.Total Power: About 1250KW

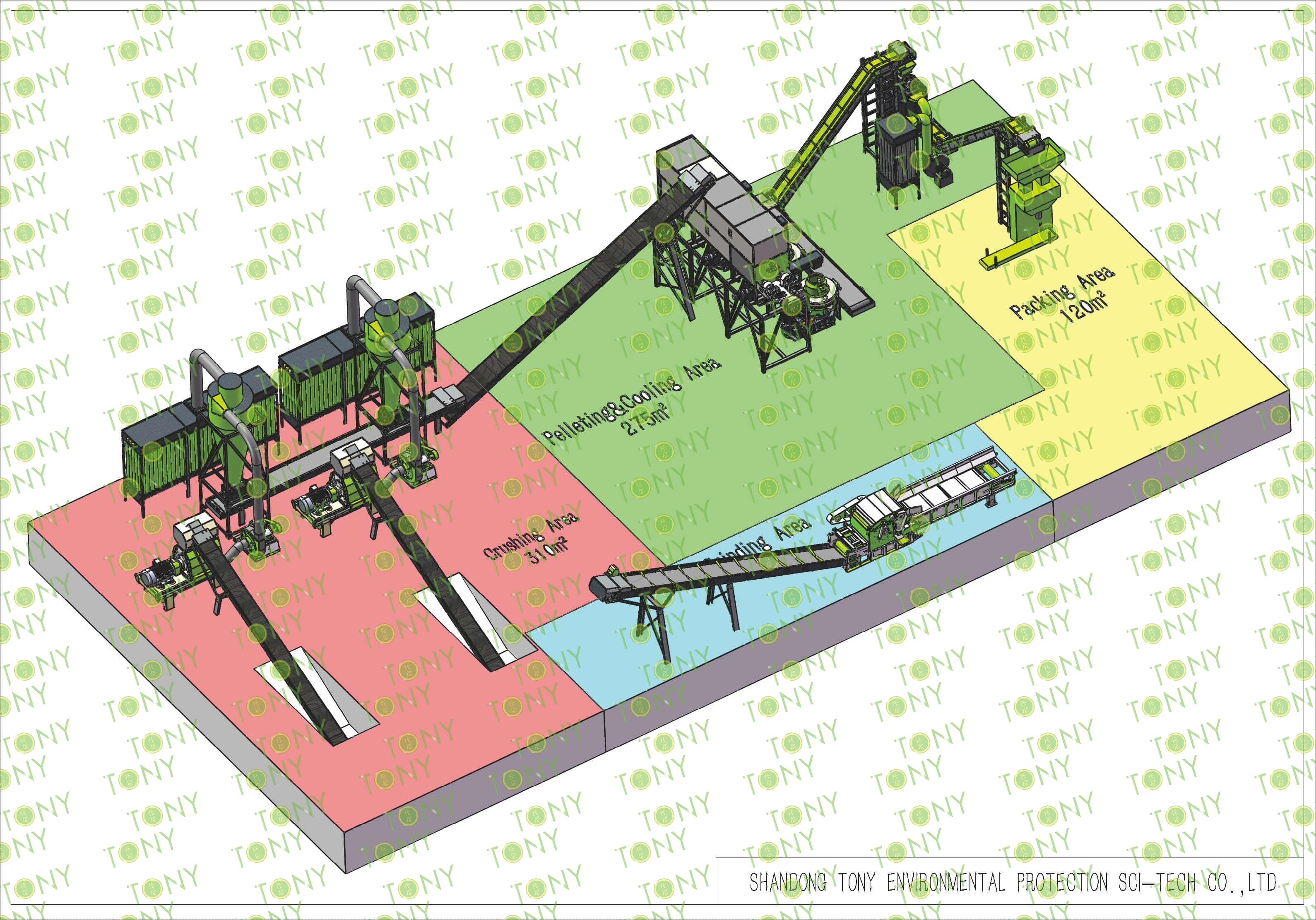

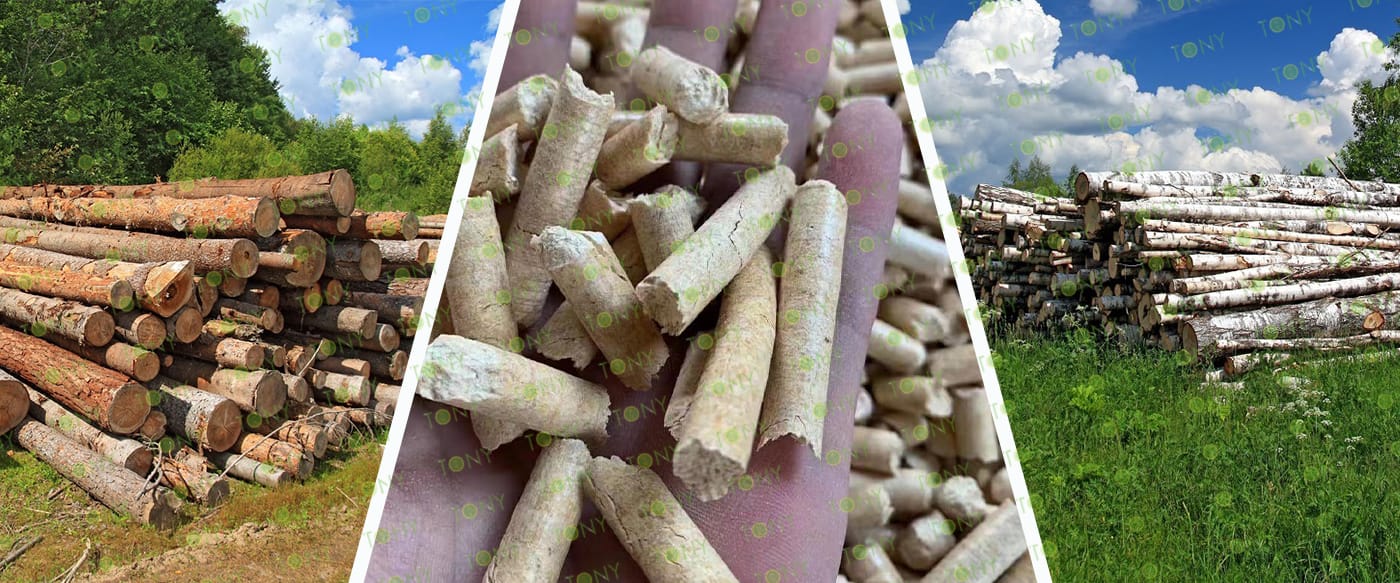

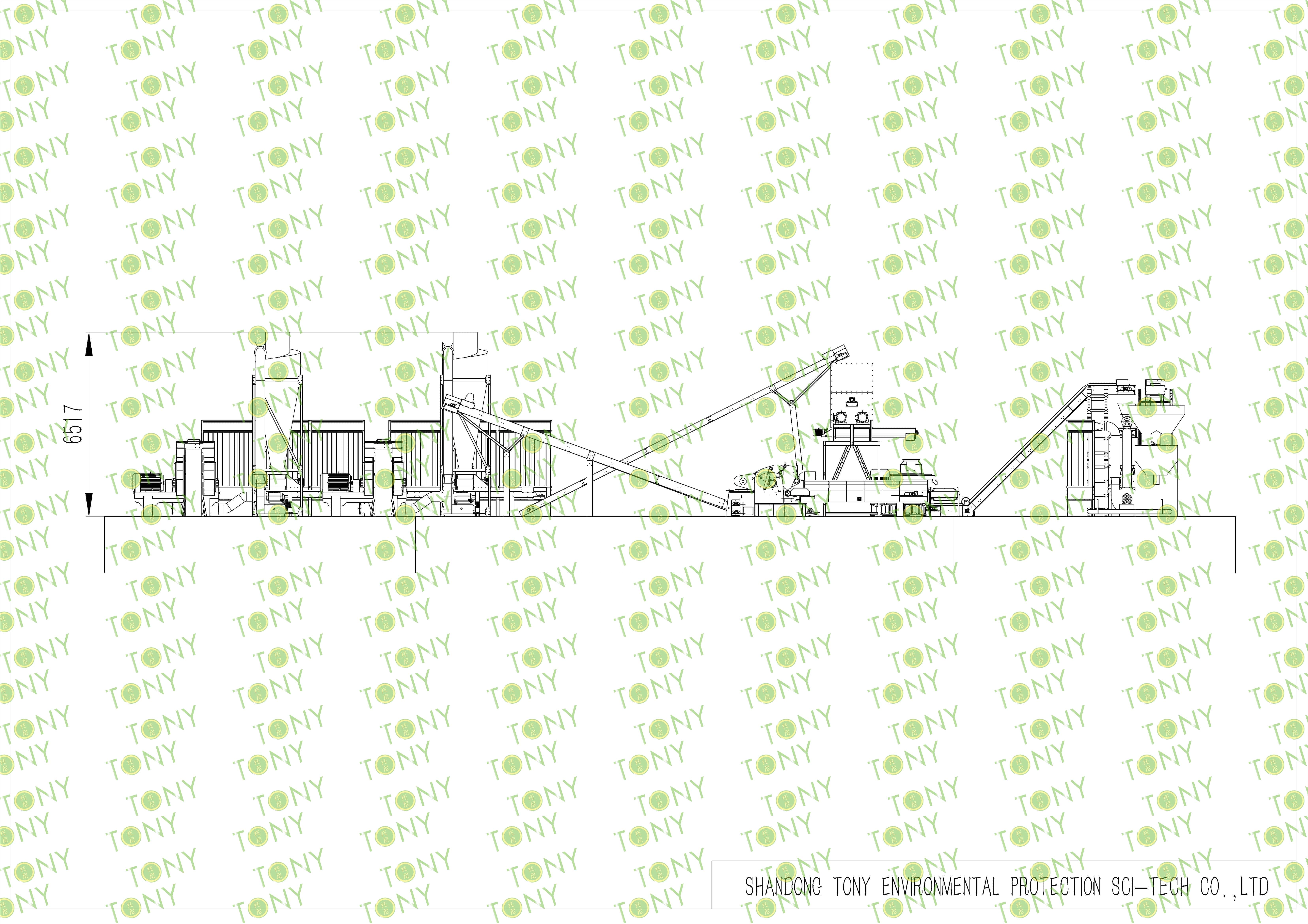

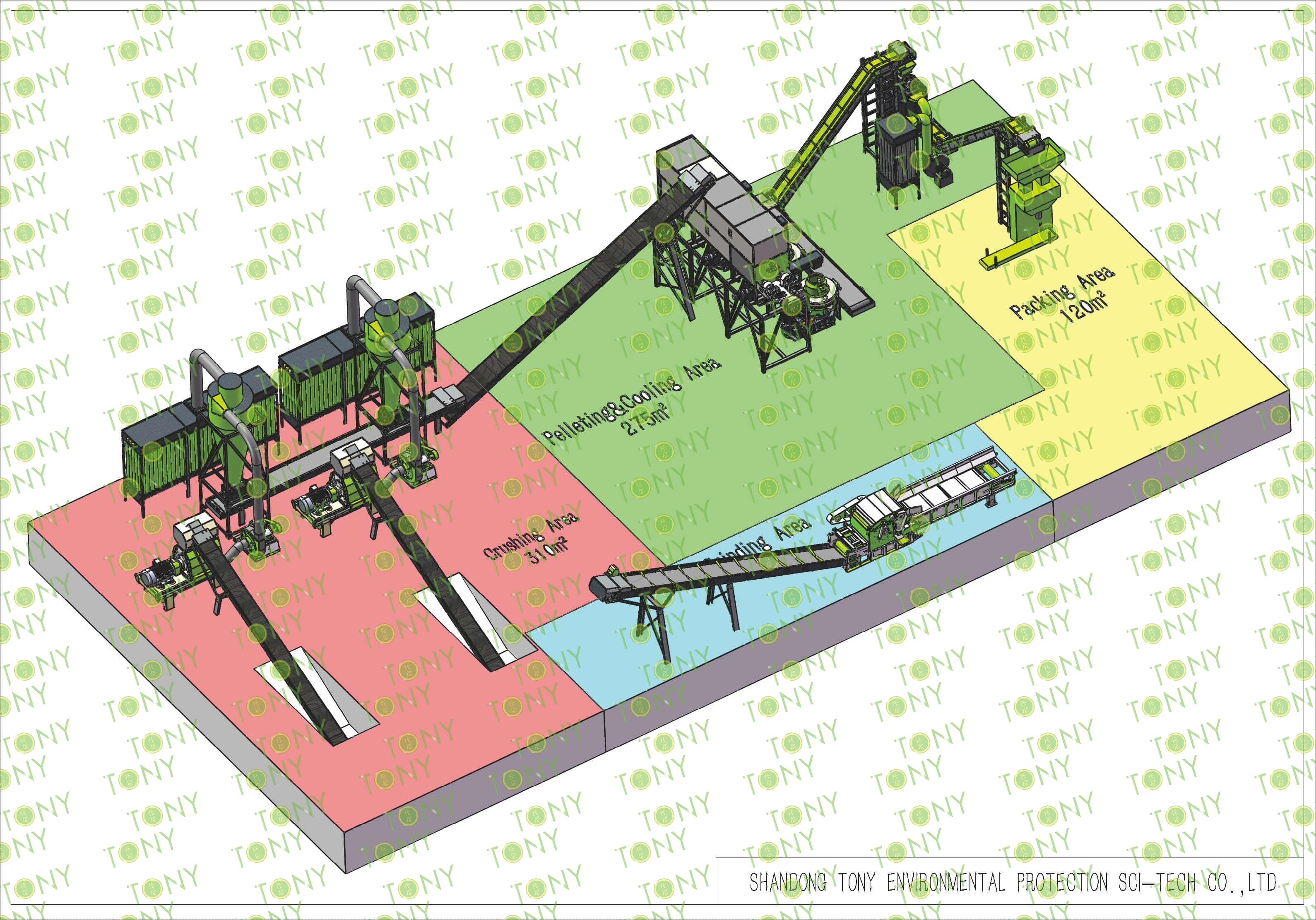

6.Need Area: About 800㎡ L: 40M W:20 M H: 6.517M

Project Layout For Customer:

1.The working principle of dried wood log biomass pellet processing equipment

The working principle of dry wood biomass pellet fuel processing equipment can be summarized as follows: qualified dry wood chips are obtained through crushing and screening pretreatment. The ring die and pressure rollers of the pelletizer apply high pressure, which densifies the wood chips and activates the natural adhesiveness of lignin under the action of frictional heat. Finally, high-density, regularly shaped pellet fuel is formed through cooling and screening. The entire process is mainly based on physical changes and does not require chemical additives. It not only realizes the resource utilization of wood waste, but also produces environmentally friendly and efficient renewable energy.

2.Characteristics of dried wood log biomass pellet processing equipment

Strong adaptability of raw materials, achieving efficient resource utilization

(1)Wide range of raw material sources: It can process a variety of dry wood waste, including sawdust, shavings, scraps after wood processing, and forestry waste (such as branches, bark, etc.), and can be processed without complex pretreatment, effectively realizing "turning waste into treasure".

(2)Clear requirements for raw material moisture content: Based on the characteristics of "dry wood", the equipment is more suitable for processing raw materials with low moisture content (usually 10%-15%), without the need for additional high-intensity drying (or only simple humidity adjustment), reducing energy consumption and processing costs.

The core equipment (pellet mill) has stable performance and high molding efficiency

(3)Relying on natural adhesives (lignin): The high temperature (100-120℃) generated by extrusion softens and melts the lignin in the wood, without the need to add artificial adhesives, which not only reduces costs but also ensures the environmental friendliness of pellet fuel (no harmful residues after combustion).

(4)High particle density and uniform quality: After high-intensity extrusion between the ring die and the roller, the particle density after forming can reach 1.1-1.3g/cm³. It has high hardness, is not easy to break, and has a regular shape (diameter 6-8mm, uniform length), which is convenient for storage and transportation.

(5)Strong continuous production capacity: Modern pellet mills mostly use automated feeding and speed control systems, which can adjust the speed and pressure according to the characteristics of the raw materials to achieve continuous and stable production. The output of a single device can reach hundreds of kilograms to several tons per hour, meeting the needs of different scales (from home workshops to industrial production).

3. Application scenarios of dried wood log biomass pellet processing equipment

Professional biomass pellet plants purchase dry wood waste (such as waste from wood processing plants and waste wood from building demolition), process it on a large scale through dry wood pellet equipment, and produce standardized pellet fuel (diameter 6-8mm, length 10-30mm), which is supplied to the following fields:

(1)Industrial heating: used for boiler heating in the textile, food, papermaking and other industries, replacing coal or oil, and meeting the environmental protection policy's requirements for "low sulfur and low nitrogen" emissions.

(2)Civil heating: In Europe, North America and other regions, biomass pellets are the mainstream fuel for home fireplaces and small heating stoves; some northern regions in China are also promoting "coal to biomass". Dry wood pellets have become an important choice for civil heating because of their clean combustion (ash content ≤3%) and easy storage.

(3)Power generation: Large biomass power plants purchase a large amount of pellet fuel, generate electricity through dedicated combustion equipment, achieve renewable energy grid connection, and enjoy national new energy subsidy policies.

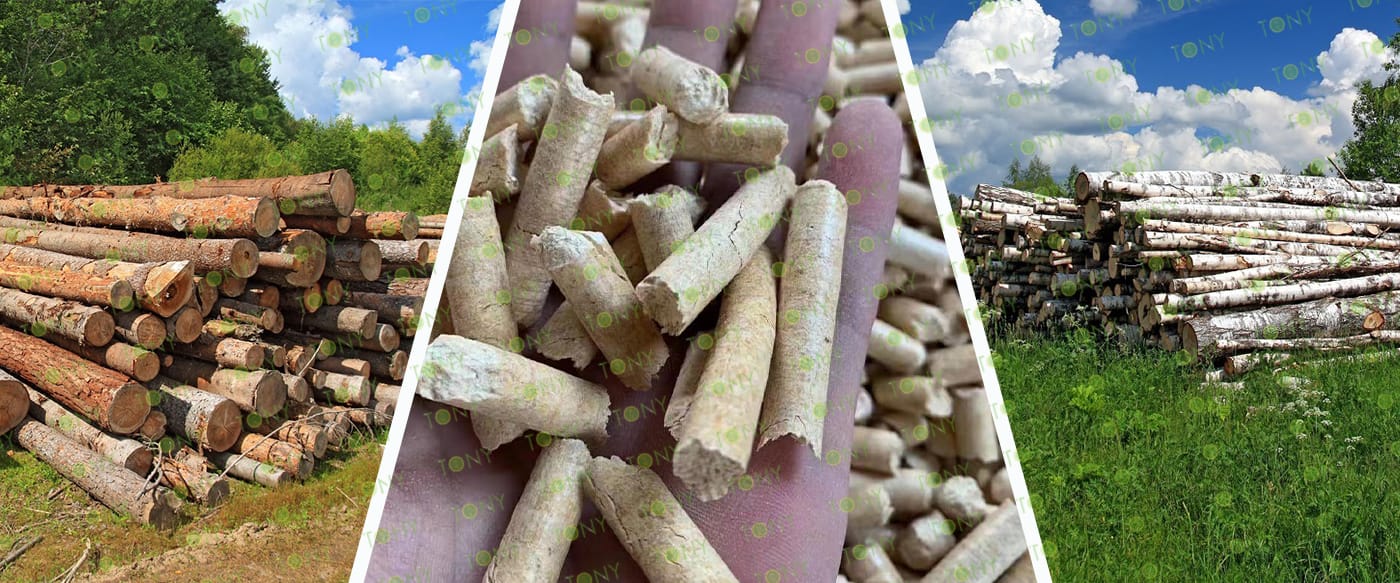

TONY Brand 9-10.5Ton/Hour Dried Wood Log Pellet Manufacturing Plant can take dried wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with dried wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 9-10.5Ton/Hour

2. Raw materials: Dried wood logs , branches, small - diameter logs, twigs, etc.

3. Moisture: Dried type, about 10-15%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Log Pellet Production Line

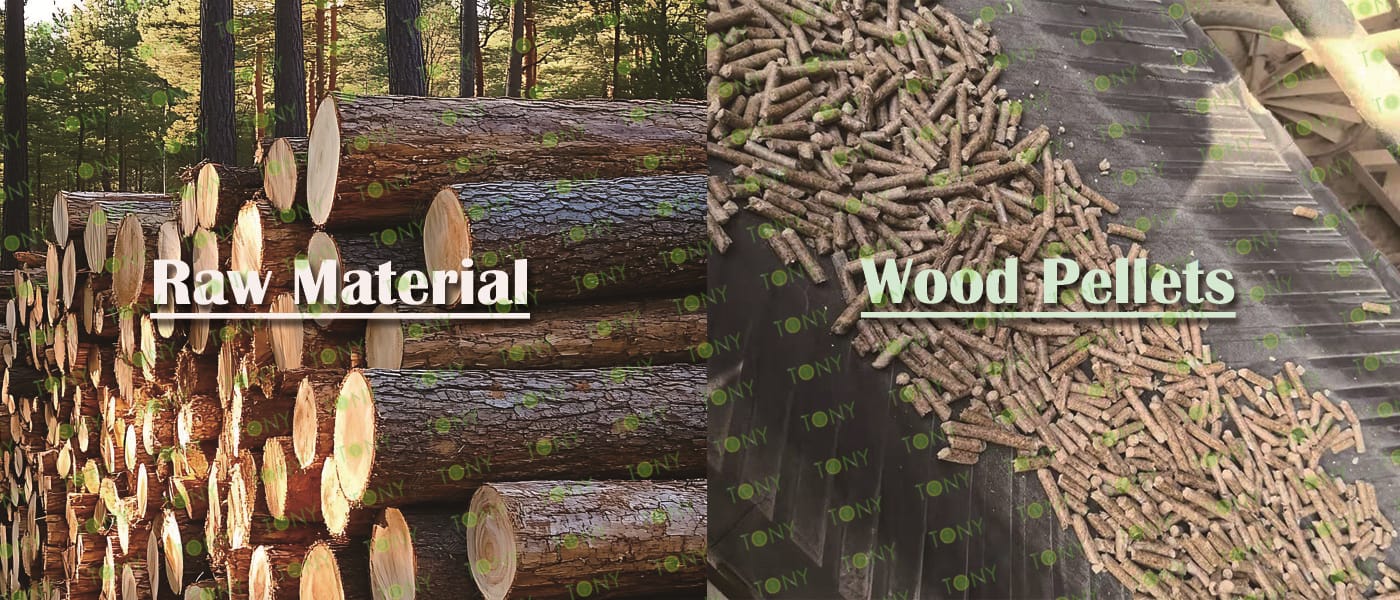

2. Raw Material: All kinds of dried wood log

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 9-10.5 tons per hour

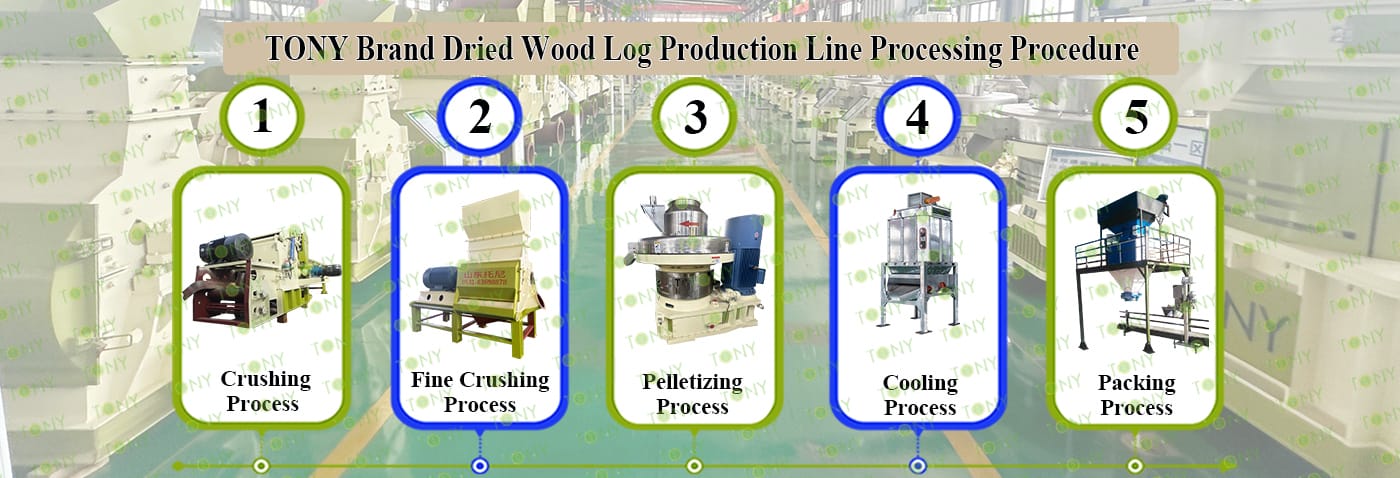

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment:Comprehensive Chipper TPC1300 -600-132KW,Effective Hammer Mill-TFD75*132-132KW, TONY Pellet Machine TYJ860- Ⅲ-220KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from dried wood log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut dried wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

| 1.To Grind Wood Logs φ ≤30cm Into25-55mm Wood Chips. 2.Model: TPC1300-600-132KW With 6 Baldes*1set 3.Capacity: 10-15Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*2sets 3.Capacity: 4-5Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-11*1set 3.Capacity:9-10.5Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*3sets 3.Capacity:3-4Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:9-10.5Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TPZ-50*1set 3.Capacity: 9-10.5Ton/Hour |

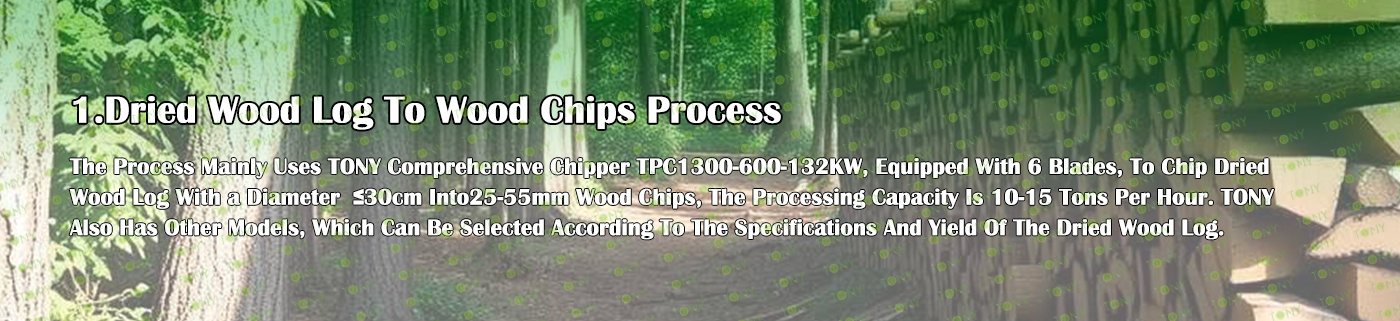

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 30cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPC1300-600 model with 6 flying blades type

C.Capacity:10-15Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:9-10.5Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity: 9-10.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set of TONY galvanized cooler separator with capacity 9-10.5Ton/Hour

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

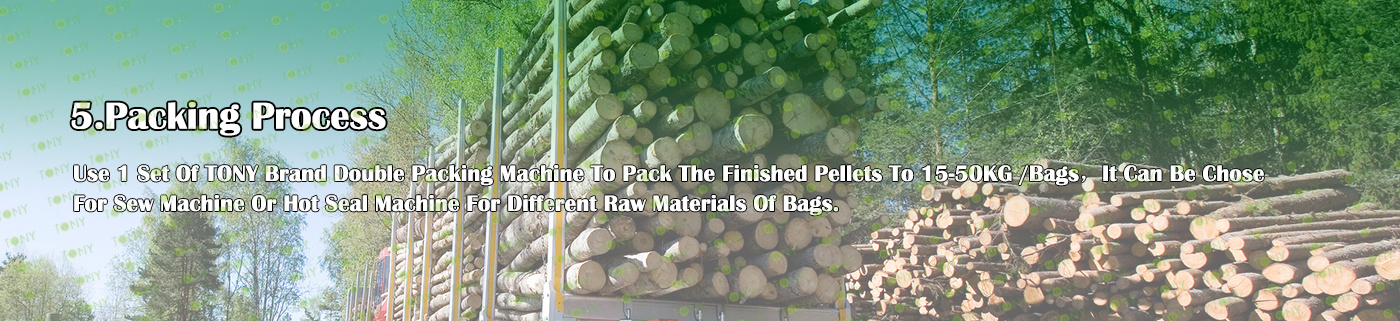

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY double packing machine.

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Project Advantages

Processing dry wood into biomass pellets is a promising entrepreneurial venture. Here are its advantages and some key considerations:

1.Low Raw Material Cost:

Dry wood is widely available. Furniture factories, panel mills, sawmills, and other industries generate large quantities of scraps, shavings, and wood chips. In some areas, discarded wood can be obtained free of charge, effectively reducing raw material costs.

2.Stable Market Demand:

Biomass pellet fuel is environmentally friendly and renewable. In the residential sector, it can be used for home heating and is particularly popular in areas with high winter heating demand. Industrially, it can also be used as boiler fuel in factories, farms, and greenhouses. There is also significant demand for biomass pellets in some export markets.

3.Large Profit Margin:

The equipment pays for itself within 3-5 months, significantly increasing the added value compared to directly recycling dry wood.

4.Highly intelligent equipment:

Nowadays, some advanced pellet machines support PLC intelligent control and have the function of starting the entire line with one button. They have a high degree of automation and can generally be operated by two people. The difficulty and cost of human management are relatively low.

1.Environmental friendliness:

Dry wood pellets are typically made from wood waste and sawdust. This utilization method reduces wood waste and aligns with modern green production concepts. Furthermore, using dry wood pellets as fuel reduces dependence on fossil fuels, thereby reducing environmental pollution.

2.Energy-efficiency:

The production process for dry wood pellets typically requires low energy consumption and is highly efficient.

3.High combustion efficiency:

Dry wood pellets have a high combustion rate, with a calorific value of approximately 3,900 to 4,800 kcal/kg. After carbonization, the calorific value can even reach 7,000 to 8,000 kcal/kg. This makes them a highly efficient fuel option in the biomass energy sector.

4.Cleanliness:

Dry wood pellets contain no sulfur or phosphorus, are non-corrosive to boilers, and do not produce sulfur dioxide or phosphorus pentoxide. Therefore, they do not contribute to acid rain and pollute the atmosphere or the environment. Furthermore, their combustion produces minimal ash, reducing the space required for ash storage and the cost of ash removal.

5.Widely applicable:

Dry wood pellets can be used in a variety of applications. In the biomass energy sector, they can be used for power generation and heating. Dimensional stability: Dry wood particles are dried and hot-pressed during the production process, so they have good dimensional stability and strength and are not easy to warp or deform.

2025 Tony Machinery - All Rights Reserved. Map