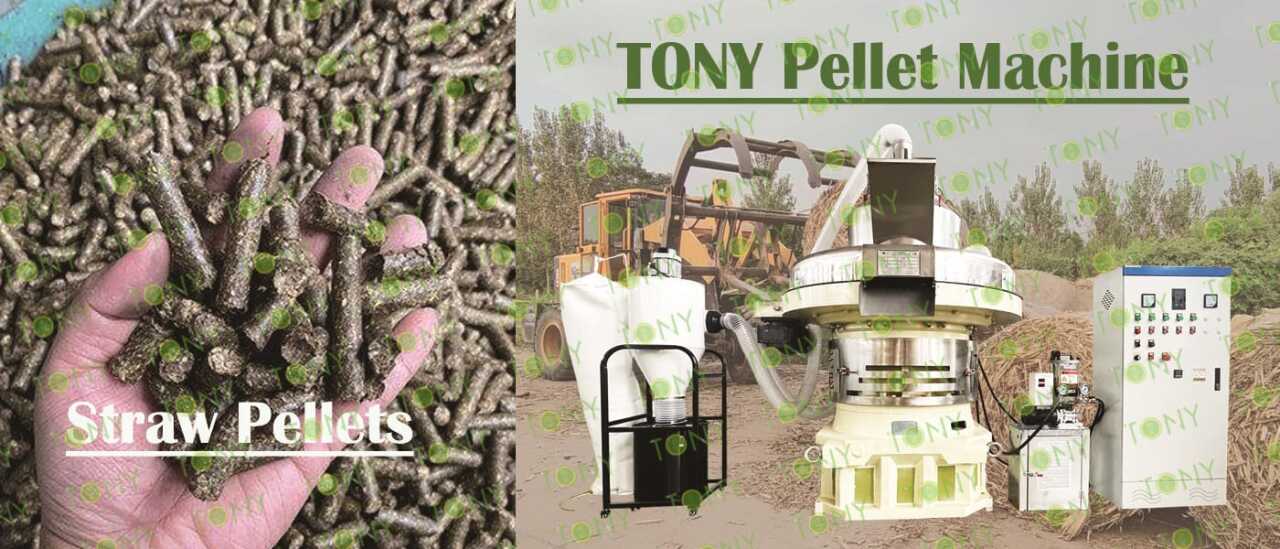

TONY Design Biomass Pellet Production Line Specification

Biomass mainly refers to the process of agricultural and forestry production in addition to grain, fruits, straw, trees and other lignocellulose (referred to as lignin), agricultural product processing industry waste, agricultural and forestry waste and livestock manure and waste in the production process. Biomass is the most widely existing substance on the earth, and the energy generated by biomass is biomass energy.

At present, in many countries in the world, through scientific and technological progress and innovation, the comprehensive development and utilization of crop straw has found a variety of uses, such as North America mainly planted corn and wheat. A large quantity of straw is produced every year. In the United States, there are 24 agricultural states, can collect about 45 million tons of straw every year, the United States also actively promote the cause of renewable energy, straw as an emerging alternative fuel, especially biofuels, so that the comprehensive recycling of straw has a new development.

The world's natural grassland can be divided into temperate grassland and tropical grassland. Temperate grasslands are distributed in the middle latitudes of the northern and southern hemispheres according to their composition and geographical distribution, such as the Eurasian steppe, the North American steppe, and the South American steppe. Stretching nearly 110 degrees of longitude from east to west, the Eurasian steppe forms the most extensive grassland on Earth. From the lower reaches of the Danube River in Europe in the west, it is distributed in a continuous band, passing through Romania, Ukraine, Russia, Kazakhstan, Turkmenistan and Uzbekistan in the east, traversing northeast Mongolia and China, forming the main body of the world's grasslands. Savannas are found in low-latitude regions such as tropical Africa, Oceania, South America and the tropical semi-arid regions of Southeast Asia.

Corylus belongs to the birch family, Corylus nut species, there are about 20 species in the world, widely distributed in Asia, Europe, North America temperate areas. Hazelnut in the processing process will produce a lot of hazelnut shell waste, the production of particles can realize the reuse of resources, reduce environmental pollution, but also reduce the cost of hazelnut industry waste treatment. Other nuts, such as walnuts, peanuts, coffee, sunflower seeds, etc., will produce a large number of biomass shells every year, if abandoned or incinerated, not only pollute the environment, but also cause a waste of resources, and these biomass shells after pretreatment, processing into biomass particles, will have a great use

Biomass energy is an important part of renewable energy. The efficient development and utilization of biomass energy will play a very positive role in solving the problems of energy and ecological environment. Since the 1970s, all countries in the world, especially economically developed countries, have attached great importance to this, actively carried out research on biomass energy application technology, and achieved many research results, reaching the scale of industrial application.

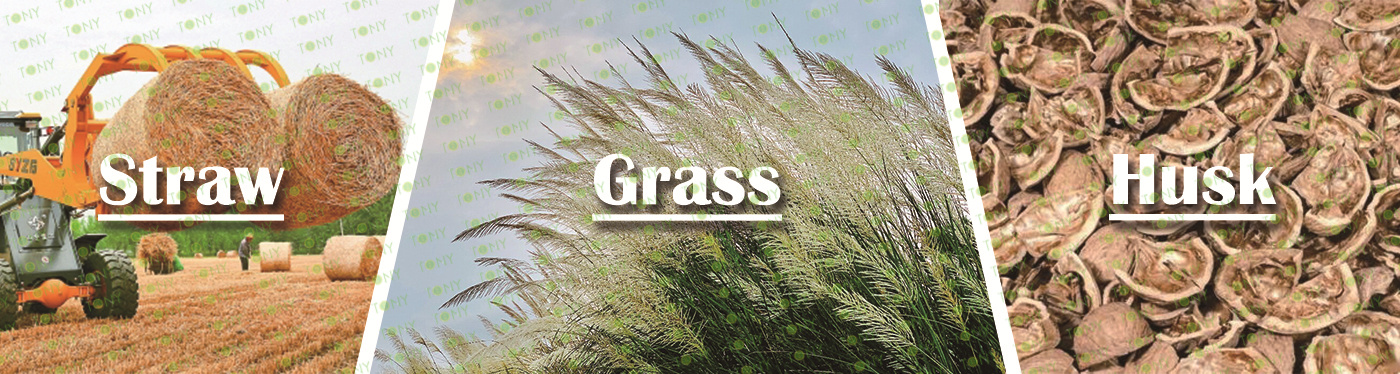

The prohibition of burning Straw/grass/husk is beneficial to the country and the people!

What are the hazards of burning straw/grass/husk?

Air Pollution: Burning will produce a large amount of nitrogen oxides, sulfur dioxide, hydrocarbons and smoke, which will cause serious pollution to the atmospheric environment. In addition, secondary pollutants such as ozone will be produced during the burning process, further exacerbating air pollution.

Human Health Hazards: Toxic chemicals produced by burning, such as polycyclic aromatic hydrocarbons, nitrogen oxides and sulfur oxides, will pose a threat to human health. These substances will irritate the eyes, nose and throat, causing symptoms such as coughing, chest tightness, and tears, and may cause bronchitis in severe cases.

Soil Damage: Burning straw will directly kill beneficial microorganisms in the soil, destroy soil structure, reduce humus and organic matter, cause soil compaction, and affect the yield and quality of farmland crops.

Traffic Safety Hazards: The smoke produced by burning will reduce air visibility, affect road traffic and aviation safety, and easily cause traffic accidents.

Fire Risk: It can easily ignite the surrounding flammable materials, causing fires, especially near forests. Fires are difficult to control and will cause serious economic losses.

In order to reduce the harm, the following measures can be taken:

Returning Straw/Grass/Husk To The Field: Crush and return them directly to the field to increase soil organic matter and improve soil structure.

Biomass energy utilization: Use the straw/grass/husk for biomass power generation or heating to achieve resource recycling.

Feed Utilization: Use the straw/grass/husk as animal feed to increase their economic value.

Composting: Compost thestraw/grass/husk for agricultural production to reduce the use of chemical fertilizers.

Through these measures, the harm can be effectively reduced and sustainable resource utilization can be achieved.

1. Overview Of Global Straw Resources

Straw refers to the residue of the immature part of crops and is an important agricultural by-product. Straw can not only be used as animal feed and fertilizer, but also in biomass energy, pulp and paper, biomedicine and other fields. According to statistics, there are more than 100 plants in the world that can produce straw, among which the top 10 plants that account for straw production are corn, rice, wheat, soybeans, peanuts, cotton, potatoes, sugarcane, cranberries and wheat straw.

2. Distribution Of Straw Resources

1). Asia

Asia is one of the regions with the richest straw resources in the world, including China, India, Pakistan, Vietnam and other countries. China is one of the countries with the richest straw resources in Asia, with an annual straw production of more than 2 billion tons, most of which is used to produce biomass energy and organic fertilizers.

2). Europe

Europe is one of the regions with relatively rich straw resources in the world, including Russia, France, Germany, Poland and other countries. EU countries regard straw as a renewable energy source, and straw plays an important role in EU energy consumption.

3). North America

North American countries include the United States, Canada and Mexico. These countries have relatively rich straw resources, which are mainly used in power generation, paper production, biodiesel and other fields.

4). Africa

Africa is one of the regions with relatively scarce straw resources. Most of the straw is used as fuel, and a small amount is used for fertilizer and feed.

5). South America

South American countries have relatively scarce resources. Straw is mainly used in the production of pulp and paper, animal feed and fertilizer.

6). Australia

Australia has relatively limited straw resources, which are mainly used to produce biomass fuel and fertilizer.

3. Conclusion

Globally, Asia, Europe and North America have relatively rich straw resources, while South America, Africa and Australia have relatively scarce straw resources. Among them, China is one of the countries with the largest straw production. In the future, with the continuous enhancement of environmental awareness, the utilization value of straw resources will continue to be explored.

Biomass is the most abundant renewable resource on the earth, how to effectively use this resource is one of the problems that scientists have been trying to explore.

Taking agricultural straw as an example, China is a big country of grain production and straw resources, and the total amount of various crop straw produced in the country every year exceeds 700 million tons, ranking first in the world. Crop straw is a by-product of agricultural production, and about half of the products of crop photosynthesis exist in straw. Straw is an important biomass resource to do a good job of straw comprehensive utilization, not only can alleviate the rural fertilizer, feed, energy and industrial raw materials of the tense situation, but also can protect the rural ecological environment, promote the sustainable and coordinated development of rural economy. However, for a long time, affected by consumption concepts and lifestyles, and because of the large volume of straw, high collection and transportation costs, China's straw utilization rate is extremely low, the comprehensive utilization of straw is only about 33%, farmers have taken the way of burning straw in the field, not only a waste of precious resources, but also caused air pollution, seriously endangering people's health. Straw burning has become a big headache.

The use of straw to produce biomass particles, instead of traditional coal resources as fuel, has entered the industrialization stage, and the technology is gradually mature. Biomass pellets are a kind of clean energy. Compared with coal fuel, it is clean and clean, with less pollutant emission and high thermal efficiency. Another important aspect is that they can greatly improve the comprehensive utilization rate of crop straw resources and realize the transformation of waste into treasure. This is of great significance to increase farmers' income, protect environment, save resources and sustainable development of agricultural economy.

1. Moisture Content Of Biomass:

The moisture content of the raw material is an important factor. If the moisture is too high, the heat transfer rate in the body during granulation will be reduced, and the evaporated water will form high pressure steam in the hole of the molding mold, making the produced particles have low density, cracks on the surface and easy to break; If the moisture content is too low, it requires a high molding pressure, which not only increases the energy consumption of biomass during the drying process, but also prone to the phenomenon of boring and blocking, and even cause the spindle to bear too much torque and break. The moisture content of the raw material is too high or too low to make the pellet form well. Therefore, for the production of biomass particles, the industry recognized that the most suitable humidity is 10-15%.

2. Grain Size Of Corn Stalk Used For Granulation:

Generally, raw materials with small particle size are easy to be compressed, and raw materials with large particle size are difficult to be compressed. That is, the smaller the particle size, the easier it is to form. However, if the raw material is too small, it will lead to too much powder mixed in the finished product. Therefore, the particle size of the raw material should be controlled to ensure that the strength is small and easy to inhibit, and that the lignin that can fully release the wood chips can be fully released. For finished pellet fuel with a diameter of 8-10mm, the particle size of the raw material is usually required to be 3-5mm. The particle size of the raw material also affects the efficiency of the granulator and the quality of the molded product. For example, when the particle size of the raw material is large, the granulator will not work effectively, the energy consumption is large, the output is small, and the particle quality is not good.

The Following Is The Benefit Analysis Of Making Biomass Pellets:

1. Economic Benefits

(1) Raw material cost estimate granular fuel raw materials biomass energy, such as straw, grass, biomass shells and other resources, biomass resources in many countries are resources, many times the processing is burned on the spot, both a waste of resources and pollution of the environment, if the customer has enough biomass resources do not need to buy, if purchased, the cost is also very low

(2) Processed biomass pellets as fuel can be used for own use, but also can be sold, because with the global pursuit of green ecological environment, to abandon coal and other traditional fuels is the trend of The Times, the demand for biomass fuels is growing, and the benefits are more considerable

2. Environmental Benefits

Improper treatment of biomass will produce certain pollution to the environment. The biomass is made into pellet fuel, which is burned by a special gasification boiler, the thermal efficiency reaches 81%, and the CO2 and SO2 are close to zero emissions, which can replace non-renewable fuels such as coal and oil, and reduce the impact of waste on the environment.

3. Social Welfare

The completion of the biomass pellet production line project can not only increase farmers' income, but also expand employment and reduce social unemployment; Secondly, the product can replace non-renewable energy, solve the energy crisis, to establish a sustainable energy system, promote the development of national economy has certain social benefits.

4. Promotion And Application Prospects

"Biomass pellet fuel" to waste biomass resources as raw materials, local materials, local production, reduce the cost of agricultural waste transportation, and reduce pollution in the transportation process, its products have the characteristics of energy saving, environmental protection, saving non-renewable resources, alleviate the contradiction of power and oil shortage.

The demand for biomass pellet fuel is bound to increase significantly, and as a clean, renewable energy source, it has entered the stage of industrial production in many countrie

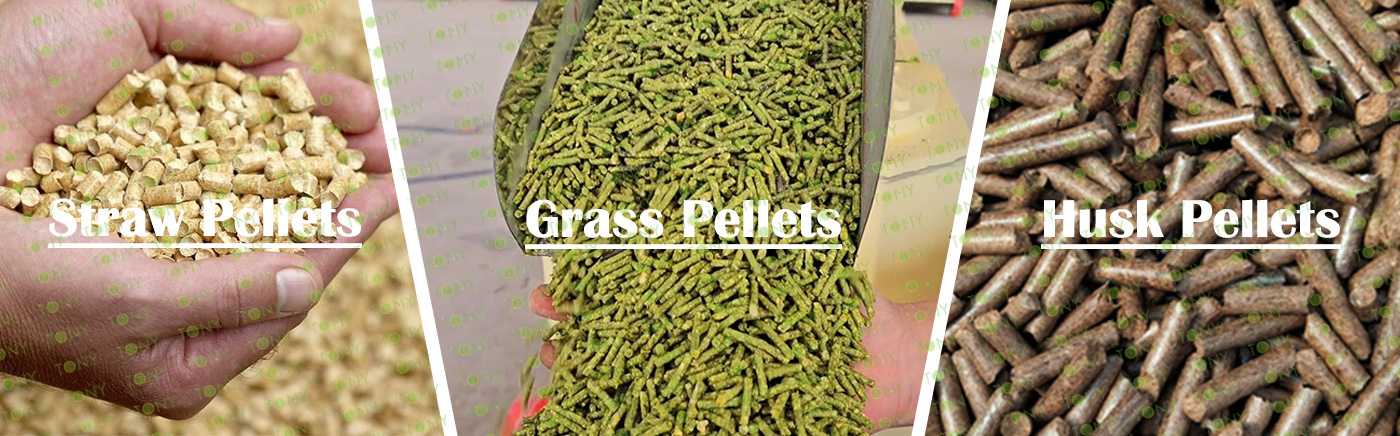

1. Renewable Energy

Biomass is a renewable energy, in theory, with biomass energy can achieve zero emissions of carbon dioxide, to control climate warming is very beneficial. Biomass energy raw materials such as straw, grass, all kinds of biomass husk ,etc can be deeply processed into granular fuels with higher heat and higher density, which can be used to replace fossil energy such as coal and oil, and is an internationally recognized clean energy. The biomass energy fuel itself contains very low S content, less than 1/10 of coal, and the sulfur dioxide generated by combustion is very small, which is a natural renewable energy suitable for sustainable development strategy, with the characteristics of inexhaustible and inexhaustible.

2. It Is A Low-Pollution Fuel

The pellet fuel made of straw, grass, all kinds of biomass husk etc as the main component is low pollution. The ash content of the fuel is 7.99%, the sulfur content is 0.07%, and the volatile content of combustible base is 83.61%. The ash content of the fuel is 70% lower than that of coal with similar low heating value, and the sulfur is about 90% lower than that of low-sulfur coal (1%). According to the test on the boiler burning straw fuel, the emission of sulfur dioxide is only 32m/m3, the smoke is less than 50mg/m3, and because the oxygen content of straw fuel is 3-4 times larger than that of coal, the heavy hydrocarbons are less, the combustion effect is good, and the blackness of the smoke is lower than Ringmann +1 level.

3. Economical And Reasonable, Wide Range Of Application

Processing straw, grass, all kinds of biomass husk etc into pellet fuel has a calorific value of 15,100 thousand 16,800 kJ/kg, which is significantly lower than the cost of coal, diesel and natural gas. Biomass energy particles have superior environmental performance and reproducibility. Because of the high volatile content and inflammability of straw, grass, all kinds of biomass husk fuel, it has a large application space. Such as less than 1t/h coal-fired boilers, tea bath furnaces, drying, heat treatment of low-temperature furnaces and other equipment, the furnace slightly improved, can be directly burned, for relatively large capacity of boilers and special purpose furnaces, after taking the corresponding measures, straw fuel can also be applied.

4.High Combustion Efficiency And Energy Saving

Due to the high volatile content of straw, grass, all kinds of biomass husk fuel, less ash, less moisture, flammable, mechanical, chemical, smoke exhaust incomplete combustion heat loss is small, combustion efficiency up to 95% or more. Under the same conditions, the thermal efficiency is more than 7% higher than that of coal-fired furnaces, and energy saving is about 10%.

1.The Working Principle Of Biomass Pellet Processing Equipment

Biomass pellets s processing equipment is a processing equipment that bundles or packets of crop straw, grass, or biomass husks is crushed and squeezed into granular fuel processing equipment. Make straw and grass. Biomass husks and other raw materials are chopped, and then suppressed by granulator, and finally the granular biomass fuel that meets quality standards.

2.Characteristics Of Biomass Pellet Processing Equipment

(1) Biomass pellet processing equipment has the characteristics of high efficiency and low energy consumption, which can rapidly process biomass raw materials into fuel pellets, improving production efficiency.

(2) Biomass pellet machine has a variety of specifications of the mold, according to different biomass raw materials to choose the corresponding mold for processing, improve the adaptability of processing.

(3) The processing equipment of biomass pellets has the characteristics of high automation and good safety, effectively reducing labor intensity and improving production efficiency.

(4) The quality and specifications of pellet biomass fuel processed by biomass pellet processing equipment are stable and meet the requirements of production standards.

3.Application Scenarios Of Biomass Pellet Processing Equipment

(1) Domestic Heating And Living Energy: Biomass pellets made from biomass straw, grass and biomass husks have a high combustion efficiency, are cleaner and easier to store,

(2) Biomass Industrial Boilers: In order to create a green ecological environment, many countries are gradually banning coal combustion. biomass straw, grass and biomass husks pellets can replace coal as the main fuel of industrial boilers, burning fully, low ash, to solve environmental pollution, environmental health

(3) Biomass Power Generation: Biomass straw, grass and biomass husks pellets are renewable resources that can be used as fuel for thermal power generation

In summary, biomass pellets have broad development prospects and can be used in various fields of production and life

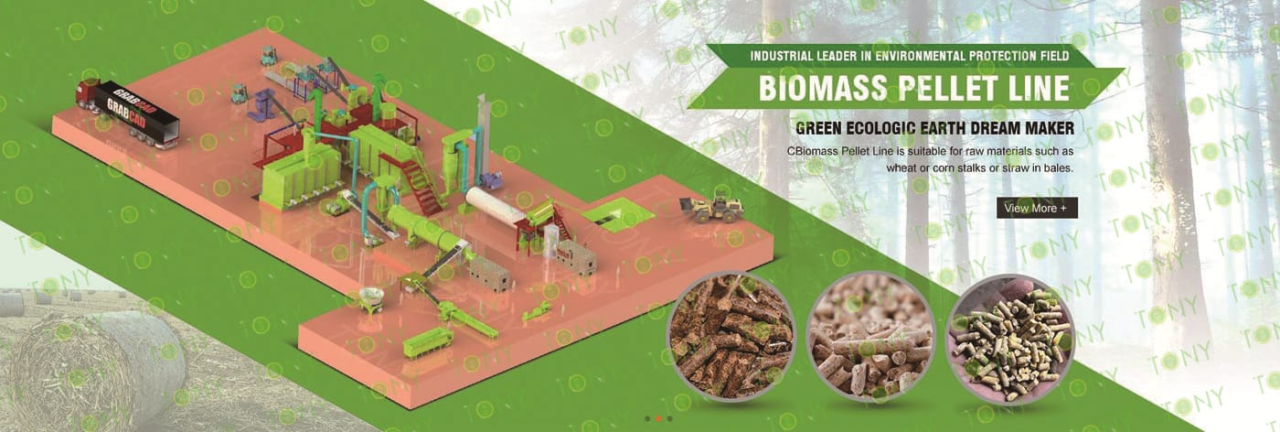

TONY brand can be a variety of crop straw, grass, a variety of husks, such as wheat straw, cotton straw, soybean straw hay, grass, miscanthus, alfalfa, peanut shell, hazelnut husk, walnut shell, sunflower husk, coffee husk and other biomass pressed pellets. Using biomass as raw material, after pretreatment and extrusion to make high-density biomass pellet fuel, which is an ideal fuel to replace coal and oil, and the role of energy saving and emission reduction. At present, it has been widely used in countries with various crop straws as raw materials.

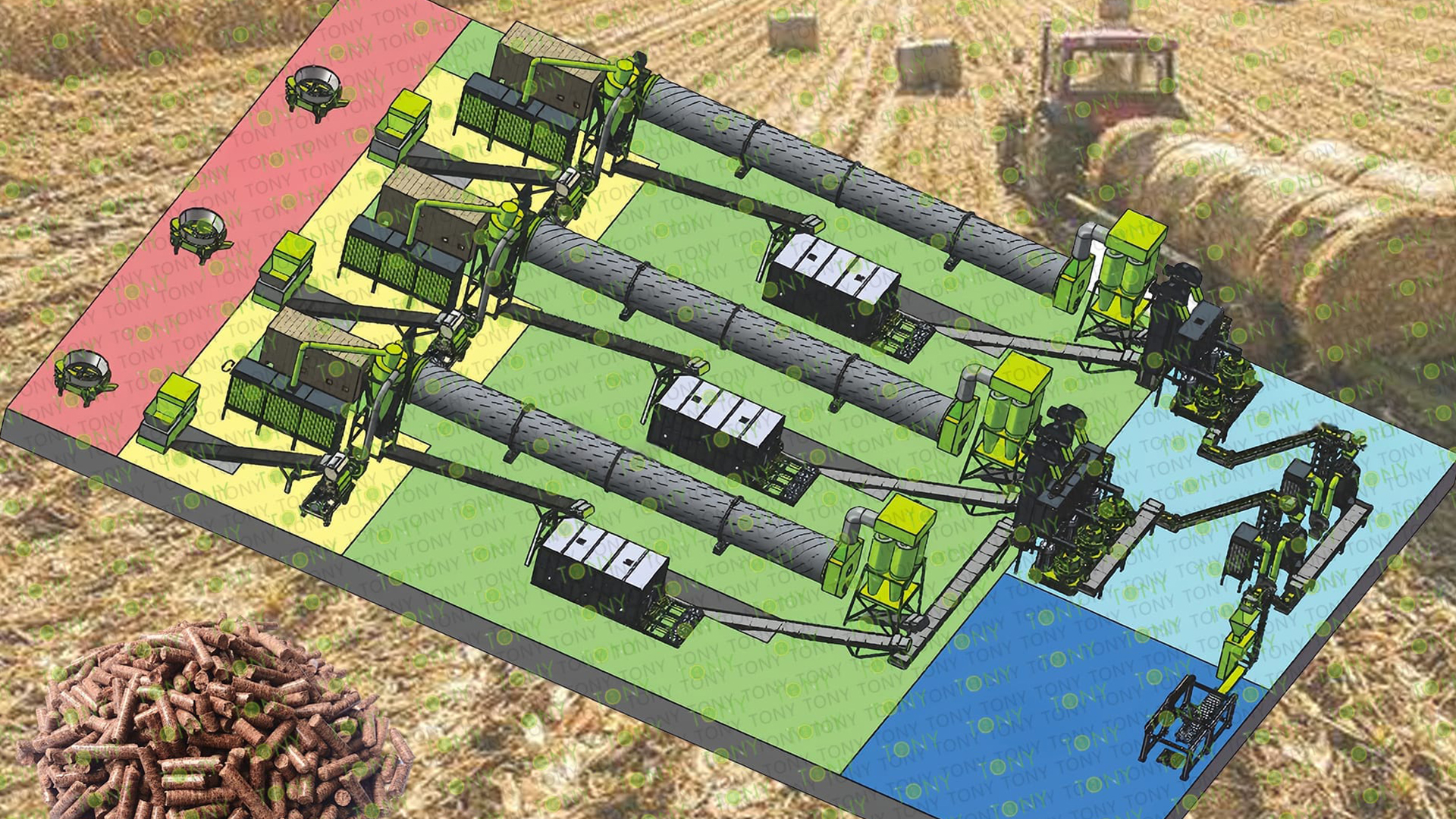

1. Capacity: Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the biomass pellet line customizes according to the actual production needs of customers.

2. Raw Materials: All kinds of crop stalks, grasses, all kinds of husks.

3. Humidity: Dry and wet materials can be used, wet materials need to be equipped with a dryer, in order to meet the requirements of the pellet machine.

4. Uses: Various biomass.

5. Suitable For Customers: Green energy companies, large farms, private growers and other customers with advantages in straw raw materials.

6. Finished Pellet Market: Large power plants, home heating, industrial heating, combustion heating, heating, boiler room, school canteen.

In order to fully introduce the entire production line process, we take straw with humidity of 45%-55% as an example.

(If the humidity of the raw material is below 15%, it is not necessary to dry it, if it is a shell or other raw material with a small size, directly start the fine crushing process or pellet process) Contact TONY for more information

1. Project Name: Biomass Pellet Line

2. Raw Materisl: Biomass straw

3. Moisture Of Raw Material: Wet Type 45-55%

4. Capacity:Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the biomass pellet line customizes according to the actual production needs of customers.

5. Raw Materials: All kinds of straw

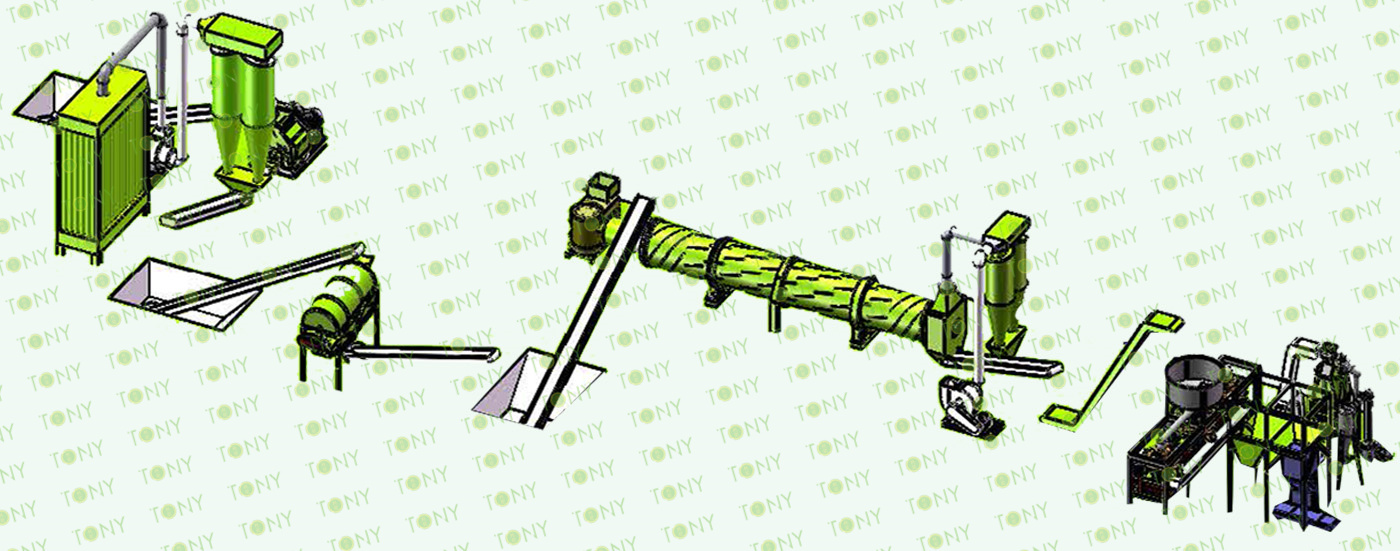

6. Process:Grinding Process→Fine Crushing Process→Drying Process→Pelleting Process→Cooling Process→Packing Process→Palletizing process→Wrapping process

7. Main Machine: Straw Cutter,Hammer Mill,Rotary Drum Dryer,TONY Pellet Machine,Pellets Cooler,Packing Machine,Palletizer, Wrapping Machine And Belt Conveyors

8. Total Power:Based on all selected equipment models,according to all the equipment models selected, different models have different power

9. Need Area:Based on all selected equipment models,according to all the selected equipment models, different models of equipment sizes are different

10. Project Country:Can be used in any country

11. Voltage:The voltage standard of the country in which the equipment is used

How to use TONY Biomass pellet line to proceed from straw into pellets?

It mainly contains the following steps and machines as following:

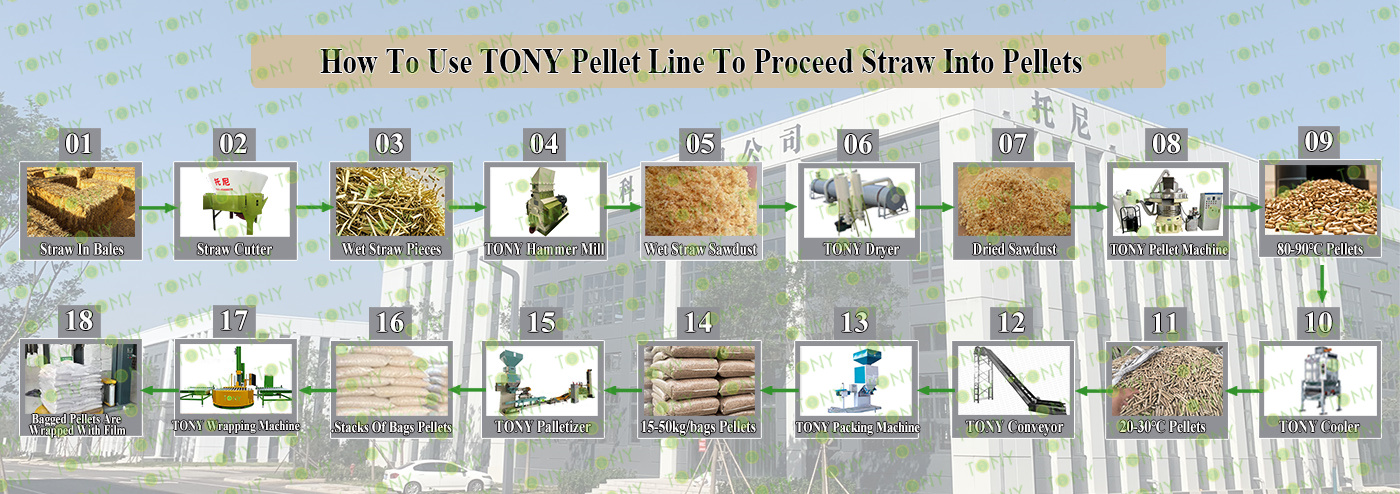

1.To Use TONY Straw Cutter To Grind Straw Bales Into 60-70mm Pieces.

2.To Use TONY Hammer Mill To Crush 60-70mm Straw Pieces Into 8-14mm Sawdust.

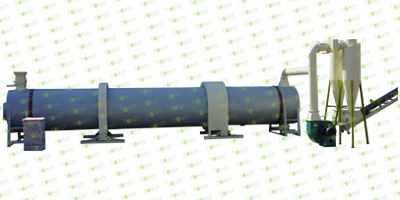

3.To Use TONY Rotary Drum Dryer To Dry The 45-55% Straw Sawdust Into 10-15% Straw Sawdust

4.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm.

5.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ To 20-30℃.

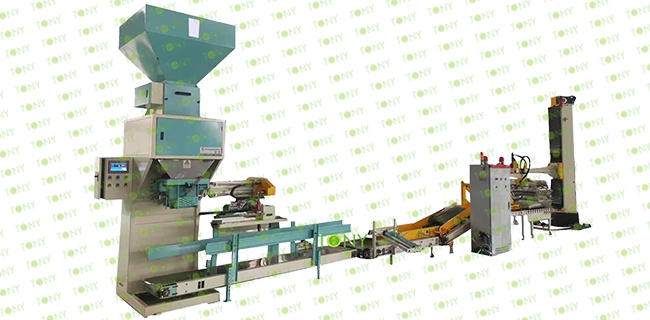

6.To Use TONY Packing Machine To Packing Pellets To 15-50Kg/Bags

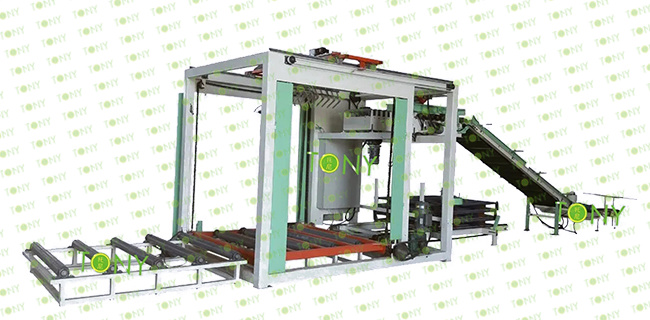

7.To Use TONY Palletizer To Palletizing 15-50Kg/Bags

8.To Use TONY Wrapping Machine To Wrapping Palletized Biomass Pellet

You Can Contact TONY To Get For More Details Information And Quotation.

TONY Can Supply You All The Products As Above With Competitive Price And Excellent Quality.

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom Made By Customer According To Different Customer's Detailed Demand.Contact TONY For More Details With Quotation And Layout.

|

|

|

|

| Straw Cutter | Hammer Mill | Rotary Drum Dryer | Vertical Ring Die Sawdust Pellet Machine |

|

1.To Grind Straw In Bales Diameter Into 60-70mm Pieces 2.Models Can Be Selected Or Customized According To Raw Materials And Production Needs |

1.Crush 60-70mm Straw Pieces Into 8-14mm Sawdust. 2.Models Can Be Selected Or Customized According To Raw Materials And Production Needs |

1.To Dry The 45-55% Sawdust Into 10-15% Sawdust. 2.Models Can Be Selected Or Customized According To Raw Materials And Production Needs |

1.To Press The Straw Sawdust Into Pellets 2.New 304SS Type 3.Models Can Be Selected Or Customized According To Production Needs |

|

|

|

|

| Galvanised Cooler Separator | Packing Machine | Palletizer | Wrapping Machine |

|

1.To Cool Pellets From 80-90℃ to 20-30℃ 2.Models Can Be Selected Or Customized According To Production Needs. |

1. You Can Choose Semi-Automatic Or Automatic Packaging Machine To Pack Pellets Into 15-50kg/ Bag 2. You Can Also Choose To Pack The Pellets Into 1Ton/Bag |

1.To Palletize bagged pellets 2.You Can Choose High Level Palletizer Or Column Palletizer According To Your Needs |

1.To Wrappe film palletized bag pellets 2. Wrapping Machine Can Be Equipped With Weighing System |

|

1.Grinding Process A. The process is mainly used to grind straw in bales into straw pieces. The rotary cutting mode of the outer chain of the gear, the rotary cutting rotor blade is sharp, and the blade types are various, which can be rotated to cut various bundles of straw with different diameters, different thicknesses, different lengths and different water contents B. There are three types of Straw Grinding Equipment, Straw Cutter, Straw Finely Cutter,Mobile Rotary Cutters,which can be selected according to the specifications and yield of the straw,Please contact TONY for specific parameters and prices Main Parts: (1) TONY's new rotary cutting machine (2) Turntables that can store large quantities of materials (3) High-quality brand motor, strong power (4) Electronic control system allows the equipment to be used normally (5) Contact TONY for more details with quotatio |

|

|

|

| Straw Cutter | Straw Finely Cutter | Mobile Rotary Cutter |

|

1. One of the most widely used straw grinding equipment 2. The finished product is 60-70mm straw pieces 3. Wide Application Range: Can handle a variety of materials, such as corn straw, wheat straw, straw and so on 4. Good Safety: Good safety: the breaking rate is high and the throwing distance is 10 meters away, which avoids injury and other accidents and can ensure the personal safety of the operator |

1. It is a straw grinding and fine grinding machine 2. Finished product is straw sawdust 3. Wide Application Range: Can handle a variety of materials, such as corn straw, wheat straw, straw and so on 4. Reduce Equipment And labor Input: If it is to deal with bundles of materials, it can directly enter the granulation process after crushing, without additional equipment for pretreatment, saving equipment costs and labor costs |

1. It is a straw grinding and fine grinding machine 2. Finished product is straw sawdust 3. Wide application range: Can handle a variety of materials, such as corn straw, wheat straw, straw and so on 4. Reduce equipment and labor input: If it is to deal with bundles of materials, it can directly enter the granulation process after crushing, without additional equipment for pretreatment, saving equipment costs and labor costs |

2.Dust Removal Of Grinding Process

Dust removal of Grinding Process There are two kinds of dust removal equipment available

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

3.Storage Of Straw Pieces

(1) How to store the 60-70mm straw pieces?

Option 1: The user can choose to pile the straw pieces on the ground.

Option 2: The user can also choose to put the straw pieces into the stock bin.

(2)What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Straw Pieces Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

(3)There are two types of Silo: Storage Bin and Large Hydraulic Storage Silo. Please contact TONY for specific parameters and prices

|

|

| Straw Pieces Storage Bin | Large Hydraulic Storage Silo |

|

1.Capacity: 5-30m³,If the capacity is expanded, it is easy to block or stick the material 2.The material is ordinary iron plate, compared with galvanized materials, corrosion resistance is lower 3.Mainly for screw control, the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: Simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1.Capacity: 40-300m³,If the capacity is expanded, there will be no clogging 2.The material is galvanized and corrosion-resistant 3.Mainly for hydraulic system control, The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4.Advantages: Good sealing can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5.Disadvantages: Complex structure and high maintenance cost. |

|

1.Fine Crushing Process A.The process is mainly used to crush 60-70mm straw pieces into 8-14mm sawdust. B.There are three types of Fine Crushing Equipment,Multifunctional Hammer Mill. Effective Hammer Mill, Dual Shaft Hammer Mill can be selected according to the actual situation. Main parts: (1) TONY Fine Crushing Equipment (2) Galvanized Dust Collector. (3) Sawdust Conveying Fan. (4) Cyclone With Airlock. (5) Electrical Cabinet. |

|

|

|

| Multifunctional Hammer Mill | Effective Hammer Mill | Dual Shaft Hammer Mil |

|

1. Direct motor transmission, one motor, one spindle 2. The feed port is on the side of the machine, suitable for the raw materials that are difficult to feed 3. A piece of mesh screen 4. Spindle single direction rotation, limited output and crushing efficiency |

1. Direct motor transmission, one motor, one spindle 2. The feed port is on the upper side of the machine, suitable for raw materials that are easy to feed 3. Two screens 4. The spindle can rotate in the opposite direction, and the output and crushing efficiency are higher |

1. Direct motor transmission, two motors, two spindles 2. The feed port is on the upper side of the machine, suitable for raw materials that are easy to feed 3. Two screens 4. The same type of efficient crusher has a higher output than a single shaft |

2.Dust Removal Of Fine Crushing Process

There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please Contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

3.Storage Of Wet Straw Sawdust

(1) How to store the 8-14mm wet straw sawdust?

Option 1:The user can choose to pile the wet straw sawdust on the ground.

Option 2:The user can also choose to put the wet straw sawdust into the stock bin.

(2)What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Straw Pieces Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

(3)There are two types of Silo: Sawdust Storage Bin and Large Hydraulic Storage Silo. Please contact TONY for specific parameters and prices

|

|

| Straw Sawdust Storage Bin | Large Hydraulic Storage Silo |

|

1. Capacity: 5-30m³,If the capacity is expanded, it is easy to block or stick the material 2. The Material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3. Mainly for screw control,the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1. Capacity: 40-300m³,If the capacity is expanded, there will be no clogging 2. The Material is galvanized and corrosion-resistant 3. Mainly for hydraulic system control,The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4. Advantages: good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5. Disadvantages: Complex structure and high maintenance cost. |

|

1.Sawdust Drying Process: A. This process is mainly used to dry the sawdust from 45%-55% to 10-15%. B. Capacity:According to raw material humidity and production requirements C. According to the actual production process, you can choose to use Single-Layer Rotary Drum Dryer,Double-Layer Rotary Drum Dryer,Three-Layer Rotary Drum Dryer It is necessary to provide heat source for Rotary Drum Dryer with Biomass Hot Stove. Waste wood, waste straw and Biomass particles can be used as fuel for Hot blast Stove. The models of Biomass Hot Stove are different and can also be customized Main Parts: (1). TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.) (2). TONY's Hot Stove. (3). Fan Blower+Cyclone With Airlock. |

|

|

|

|

Single-Layer Rotary Drum Dryer |

Double-Layer Rotary Drum Dryer | Three-Layer Rotary Drum Dryer |

|

1. Structure: Only one drying layer. 2. Applicable Materials: Usually used for drying light materials, such as sawdust, wood chipping, bean residue, cow dung, coal slime, etc. 3. Advantages: simple structure, low cost, easy operation and maintenance. 4. Disadvantages: The drying efficiency is relatively low, which is suitable for scenes with small scale or low drying efficiency requirements. |

1. Structure: There are two drying layers, usually two concentric cylinders of different diameters. 2. Applicable Materials: Suitable for drying granular materials with a certain humidity and particle size range, such as river sand, wood chips, sawdust, etc. 3. Advantages: Compared with single-layer dryer, it has higher thermal efficiency, faster drying speed and smaller footprint. 4. Disadvantages: The structure is complex, the cost is high, and the operation and maintenance are relatively complex. |

1. Structure: There are three drying layers, usually three concentric cylinders of different diameters. 2. Suitable Materials: suitable for drying materials that require higher thermal efficiency and faster drying speed, such as slag, clay, pulverized coal, etc. 4. Advantages: the highest thermal efficiency, the fastest drying speed, can handle larger scale material drying. 5. Disadvantages: The most complex structure, the highest cost, the most complex operation and maintenance. |

2.Dust Removal Of Drying Process

There are four kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Option 3:Water Spray Dust Removal

Option 4:Wet Electrostatic Precipitator

Please contact TONY for specific parameters and prices

|

|

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector | Water Spray Dust Removal | Wet Electrostatic Precipitator |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

1. The water film caused by a certain method on the inner wall of the dust collector or other special components is used to impact the dust, so that the dust is captured by the water film and the gas is purified. 2. Often used to deal with gas containing high humidity and sticky dust, suitable for boiler, chemical, spray paint, spray glaze, pigment and other industries. 3. Simple structure, small metal consumption, small water consumption. 4. It has higher dust removal efficiency for dust particles with larger particle size. 5. It is high and difficult to arrange. There may be water phenomenon in actual operation. |

1. The dust and liquid droplets in the flue gas are adsorbed to the surface of the anode and cathode using electric field load, and cleaned with water spray. 2. It usually used to deal with gas containing fine particles, which is suitable for boiler, chemical industry, waste incineration and other industries. 3. The dust removal efficiency of fine particles is high, up to 98%~99%. 4. It can remove some gaseous pollutants at the same time. 5. The structure is more complex, and the investment and operation cost are higher. Regular cleaning and maintenance is required. |

3.Storage Of Dried Straw Sawdust

(1) How to store the 8-14mm dried straw sawdust?

Option 1:The user can choose to pile the dried straw sawdust on the ground.

Option 2: The user can also choose to put the dried straw sawdust into the stock bin.

(2)What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Straw Pieces Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

(3)There are two types of Silo: Straw Sawdust Storage Bin and Large Hydraulic Storage Silo. Please contact TONY for specific parameters and prices.

|

|

| Straw Sawdust Storage Bin | Large Hydraulic Storage Silo |

|

1. Capacity: 5-30m³,If the capacity is expanded, it is easy to block or stick the material 2. The material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3. Mainly for screw control, the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1. Capacity :40-300m³,If the capacity is expanded, there will be no clogging 2. The material is galvanized and corrosion-resistant 3. Mainly for hydraulic system control,The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4. Advantages: good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5. Disadvantages: Complex structure and high maintenance cost. |

|

1.Pelleting Process: A. This process is mainly used to product pellets with φ6-8mm. B. Biggest Capacity: The model of biomass pellet machine is different, the production capacity is different, the production capacity of a single pellet machine ranges from 0.8 tons/hour to 5 tons/hour, multiple pellet machines work together, the production capacity can reach up to 100 tons/hour Main Parts: (1). TONY's New Vertical Ring Die Pellet Machine. (2). Cyclone And Bags Dust Collectors. (3). Bearings Automatic Lubrication System. (4). Electrical Cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

2.Dust Removal Of Pelletizing Process

There are two kinds of dust removal equipment available

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

3.The Way Of Straw Sawdust Entering Pellet Machine

(1)There are two ways for straw sawdust to enter the biomass pellet machine

Option 1: Use the belt to transfer the straw sawdust directly into the gpellet machine

Option 2: Add the silo on the side of biomass pellet machine and sawdust enter the biomass pellet machine from the silo

Please contact TONY for details and prices

(2)What is the difference between belt transmission and adding a bin to the pellet machine?

A.The use scenarios of the two methods are different

The use of belt to directly transfer the sawdust to the biomass pellet machine inside, suitable for the number of pellet machines, biomass pellet production line 1-2 pellet machine, if the biomass pellet production line production capacity is large, the need for multiple biomass pellet machine work, you need to add silo above the pellet machine

B.The advantage of adding silo above the pellet machine is greater

In the pellet machine above the bunker, the sawdust into the biomass pellet machine from the bunker, one can save the feed belt, the second can save the site, the third is the operation of personnel is relatively simple

Which method to use depends on the specific situation

(3)There are two kinds of Silo on the biomass pellet machine, Screw Cycling Silo and Galvanized Hydraulic Silo.

Please contact TONY for specific parameters and prices

|

|

| Screw Cycling Silo | Galvanized Hydraulic Silo |

|

1. It is composed of a large bunker and a screw conveyor (skein) inside. The silo is used to store the material, while the screw conveyor is used to transport the material from the bottom of the silo to other places. 2. Push the material along the direction of the spiral axis through the rotation of the spiral blade. Materials are usually stored open in the warehouse. 3. Relatively simple structure and easy maintenance. 4. Suitable for conveying most dry bulk materials. 5. Materials are stored open in the warehouse and may be affected by environmental factors, such as dust, humidity, etc. 6. In some cases, there may be a problem of material bridging (that is material forming an arch in the bin and obstructing the flow of material). 7. The use of general iron plate material processing, compared with galvanized material, corrosion resistance is slightly poor |

1. It is usually composed of gantry frame, sliding main beam, moving plucking wing, fixed plucking wing, hydraulic cylinder, hydraulic station, Hank dragon discharge and silo body. The hydraulic system is used to drive the movement of the various components. 2. The expansion and expansion of the hydraulic cylinder is controlled by the hydraulic system to push the material from the warehouse to the discharge port. The discharge port is usually connected with a winch conveyor to further transport the material. 3. Materials are sealed in the warehouse to avoid the impact of environmental factors. 4. The bottom adopts the power to push the material, which effectively prevents the phenomenon of material bridging. 5. Galvanized material, corrosion resistance, durable 6. The structure is more complex and the maintenance is relatively difficult. 7. The cost is relatively high, because the hydraulic system needs to be equipped. |

1.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

Main Parts:

(1) TONY's new Galvanized Cooler Separator With Vibrating Screen.

(2) Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4) Connect Pipes.

2.Dust Removal Of Cooling Process

There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

1.Packing Process:

A.This process is mainly used to pack pellets.

B.The main equipment: Semi-automatic Packing,Machine Automatic Packing Machine,Ton Packing Machine,High Level Palletizer,Column Palletizer,Wrapping Machine

|

|

|

| Semi-Automatic Packing Machine | Automatic Packing Machine | Ton Packing Machine |

|

1. Packing Pellets To 15-50kg/bags 2. Manual assistance is required to complete some operations, such as bagging. 3. Production Efficiency: Compared with the automatic packaging machine, the production efficiency of the semi-automatic packaging machine is lower, but it is still higher than the complete manual operation. 4. Cost: Usually the price is relatively close to the people, suitable for small enterprises with limited budgets. 5. Flexibility: Due to the need for manual intervention, semi-automatic packaging machines have a certain degree of flexibility when dealing with products of different specifications and shapes. 6. Sew Machine,Buyer Can Also Chose Hot Seal Machine For Chosen |

1. Packing Pellets To 15-50kg/bags 2. All steps from feeding, metering, bagging to sealing are automatically completed by the machine. 3. Production Efficiency: The production efficiency is significantly higher than the semi-automatic packaging machine, which can greatly reduce labor costs. 4. Cost: The price is higher, but the investment can be recovered in the long run by improving efficiency and reducing labor costs. 4. Accuracy And Consistency: It can provide high-precision packaging to ensure that the weight of each bag of products is consistent. 5. Sew Machine,Buyer Can Also Chose Hot Seal Machine For Chosen |

1.Packing Pellets To 1Ton/bags 2. Packaging Capacity: Specially used for large bag (ton bag) packaging, usually used for packaging bulk materials. 3. Degree Of Automation: Most tonnage charter machines have a high degree of automation, which can automatically complete a series of operations such as loading, metering, bagging and so on. 4. Special Functions: Usually equipped with dust removal system, dust prevention device, etc., to ensure safety and environmental protection. 5.Suitable for applications requiring efficient, high-volume packaging with special requirements for packaging capacity and safety |

2.Palletizing Machine

It is a kind of high-efficiency palletizing equipment with high degree of automation and good integration. The palletizer groups the bags according to the predetermined way, and then puts the whole layer of bags on the tray layer by layer. Usually used as a follow-up equipment to the packaging line to improve production capacity and transfer capacity, TONY has two types of column palletizer and high palletizer to choose from, you can contact TONY for more product details and price differences

|

|

| High Level Palletizer | Column Palletizer |

|

1. Gantry type structure, the entire mechanical system is located above the production line, through horizontal and vertical movement to move items from the production line to the pallet. The structure of the high palletizer makes it suitable for efficient palletizing at the end of the production line. 2. Mainly used in packaging bag palletizing production line, such as feed, fertilizer, flour, cement and other industries. The high palletizer can realize efficient packaging bag palletizing, and the palletizing shape is neat and beautiful. 3. High degree of automation, can achieve automatic flattening, automatic bag, automatic stratification and other functions. 4. Installation requires large space and is usually fixed at the end of the production line. The operation of the high palletizer requires professional technical personnel to maintain and operate. 5. The cost of use is low and maintenance is relatively simple, but in some cases a higher initial investment may be required. |

1. With a vertical column, the robot arm moves up and down the column, and can rotate or move on the horizontal plane at the same time. This design allows the post palletizer to have high stability and accuracy when handling heavy and large items. 2. It is suitable for high-speed and stable palletizing of large and heavy goods, which is commonly used in chemical industry, building materials and other industries. Due to its stable structure, it can ensure the accuracy and quality of palletizing when handling heavy items. 3. It has high flexibility and adaptability, and can adapt to items of different sizes and shapes by adjusting parameters. Its intelligent design makes it possible to handle many types of items. 4. The installation is relatively flexible and can adapt to different production line layouts. Due to its compact structure and relatively small occupation space, it is suitable for the use of small production workshops. 5. The initial investment is high, but in the long run, due to its stability and efficiency, the overall operating cost can be reduced. |

3. Wrapping Machine

The use of stretch film (also called winding film) as consumables, and pallet baler, pallet wrapping machine and other titles. People's requirements for logistics efficiency continue to improve, in order to reduce labor, save packaging costs, to achieve economical handling and the emergence of a packaging machine. It has gradually become a necessary packaging machine for large enterprises, especially export-oriented enterprises

|

The Characteristics Of the Wrapping Machine 1. Various Operation Modes: Including manual operation and automatic operation of two modes, can be changed at any time 2. Automatic Sensing Function: Automatic sensing cargo height, equipped with top pressing device 3. Versatility: Suitable for single or multiple cylindrical combination packaging requirements and general packaging 4. Control Panel Is Convenient: Touch control panel, fool type and intelligent control design, easy operation 5. Parameters Can Be Adjusted: Winding specifications, winding film lifting speed, tightness can be adjusted at any time, convenient and rapid 6. Smooth Operation: Slow start, slow stop, fixed stop 7. Automatic Film Breaking: When the packaging is completed, the film will be automatically pulled and broken without cutting knife 8. Easy Maintenance: Easy parts replacement, low failure 9. Safety Guarantee: With self-protection switch device and emergency safety shutdown device, electromagnetic pre-drawing device, different from the general mechanical, safer for operators |

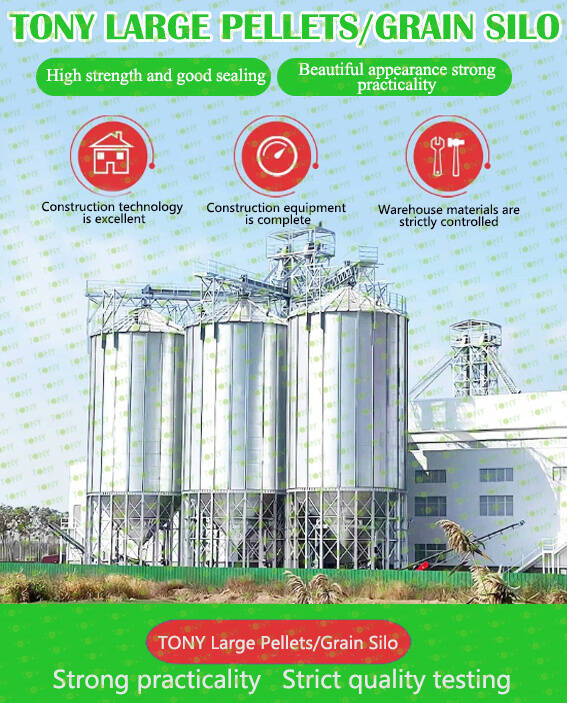

4.Large Pellets Silo:

After processing the biomass pellets, the customer has no need for bagging and packaging, and can choose to store the biomass pellets in the Large Pellets Silo. When there is an order for biomass particles, it can be directly transported from the particle bin to the vehicle or container

|

TONY Large Pellets/Grain Silo Advantages 1. Cost: TONY Large Pellets/Grain Silo light weight, less consumables, so reduce the basic cost. 2. Standardization : TONY Large Pellets/Grain Silo standardization degree is high, can be made into standard parts according to domestic materials, so as to achieve standardization, general serialization production, arbitrary combination into a variety of warehouse types required by users. 3. Installation: TONY Large Pellets/Grain Silo is simple and fast, all steel bin components, are bolted connection, fast installation, short construction period. 4. Storage: TONY Large Pellets/Grain Silo is easy to achieve automation, steel silo has supporting equipment, can be configured according to the use of requirements into the warehouse, out of the warehouse, ventilation, drying, temperature measurement, measuring full and other equipment, to achieve the purpose of safe grain storage. 5. Disassembly: TONY Large Pellets/Grain Silo simple disassembly, easy maintenance, local board damage can be replaced. 6. Life: TONY Large Pellets/Grain Silo low cost, suitable service life. Generally, it is only 35% to 50% of the reinforced cement warehouse, and the service life can reach more than 30 years. |

|

1. In some agricultural countries, a large number of corn stalk resources are being made into biomass pellets for comprehensive utilization. At present, with the increasing demand for energy and the depletion of coal resources, countries all over the world pay more and more attention to biomass energy and have formulated and implemented corresponding development plans. At present, all countries in the world are trying to develop bio-alternative fuels

2. The benefits of biomass processing pellet business are many. First of all, biomass energy, such as various straw, grass, biomass shells, is rich in resources, and the cost of raw materials is very low. This means you can get a return in a shorter period of time and have a greater advantage in terms of cost control. Secondly, biomass energy processing pellets, the current market competition is relatively small, which provides entrepreneurs with more opportunities and space.

3. Of course, professionalism is essential for success in this industry. You need to understand the habits, processes, market demand and trends of biomass energy.

Only by continuous learning and practice, and constantly improve their professional skills and market acumen, can they stand out in the competitive market.

4. If you are a visionary entrepreneur, you may wish to consider entrepreneurial opportunities in biomass processing. This will not only bring you huge profits, but also protect the environment and promote sustainable development. Make a contribution. In this era full of opportunities and challenges, let's seize the opportunity to make money by processing biomass into pellets and create a better future together!

Compared To Traditional Fossil Fuels, Biomass Pellets Have The Following Advantages:

1. Clean and environmental protection, green energy: After testing, the sulfur content of biomass particles is 0.16% ~ 0.22%, far lower than the sulfur content of coal 1% ~ 3%, is an environmentally friendly clean energy.

2. Low cost, high added value: very low raw materials, low cost of use. The ash after combustion, rich in calcium, magnesium, phosphorus, potassium, sodium and other elements, is the best inorganic fertilizer.

3. High density, easy storage and transportation: The density of biomass pellet fuel is large, the density is above 1.2, the area is small, easy to transport and storage. Easy access in bag.

4. Application: Biomass particles are easy to ignite, high heat value, strong firepower, suitable for rural, urban, units and families, is the ideal fuel for heating, bathing, canteen cooking, boiler combustion and straw power plants.

1. Characteristics And Application Range Of Biomass Pellet Fuel

Biomass pellet fuel is a renewable fuel made of various straw, grasses and biomass shells as raw materials through crushing, screening, drying and pressing processes. It is characterized by high energy density, easy storage, easy processing, non-toxic and harmless, smokeless and odorless combustion process. Biomass pellet fuel is widely used, mainly including home heating, industrial heating, power machinery fuel and so on.

2. Market Demand Status Of Biomass Pellet Fuel

Biomass pellet is not only an environmental protection project, but also a new energy industry, is a new way to effectively use surplus resources, with huge potential market demand.

At present, farmers do not know enough about biomass. Processing enterprises lack confidence in the comprehensive production benefits and effective utilization of biomass; Relevant departments are developing industrial support and technology promotion support policies to promote the comprehensive utilization of biomass, the production of biomass particles to form a complete comprehensive utilization industry chain, can form a new economic growth point, increase farmers' income, effectively reduce carbon emissions, but also help the government to solve part of the employment problem.

3. Market Prospect Analysis Of Biomass Pellet Fuel

If the biological material resources can be used comprehensively, rationally and scientifically, it will have great economic value. Recycle, turn waste into treasure, and transform into new energy fuels. At present, natural energy resources are decreasing, but people's lives are inseparable from energy, in order to live better and better, society can develop healthily, we only develop new energy, is the best new way out.

Biomass pellet fuel, a modern clean dye, is suitable for urban coal-fired boiler equipment, can replace coal carbon, can be used in power plants. Straw granulation value is high, combustible, less ash, less pollution, more fuel saving, reduce the cost of use, molding straw particles are small, dye burning resistance, high density, convenient storage and transportation. With the continuous development of society, small and medium-sized enterprises can survive well only by keeping up with the pace of The Times. The function of corn straw pelleting enables the harmonious development of enterprises and environmental protection. As a new era of environmental protection and energy-saving equipment, investing in a corn stalk pellet machine has great prospects for young people who are interested in entrepreneurship.

2025 Tony Machinery - All Rights Reserved. Map