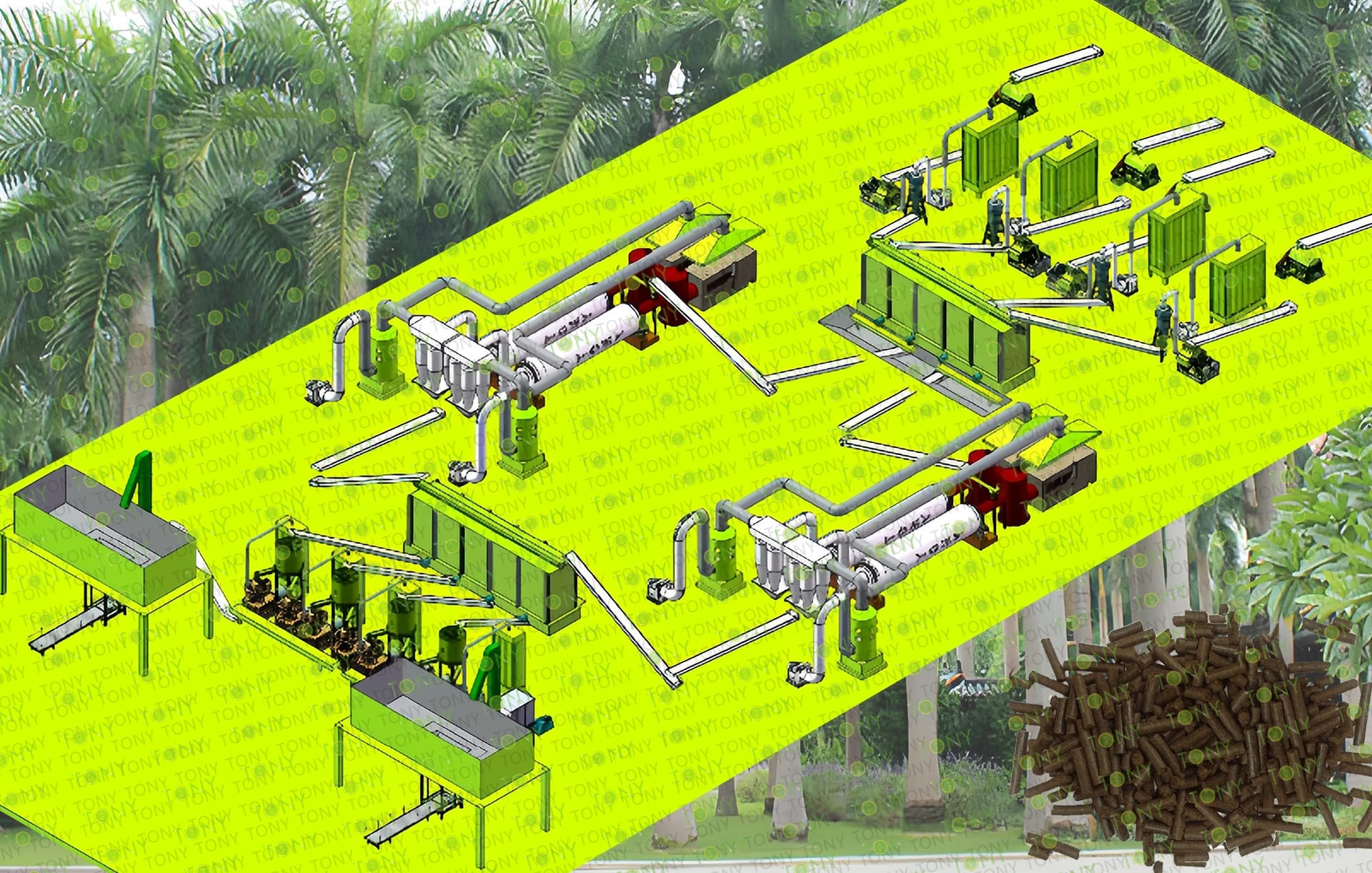

TONY Design EFB Pellet Production Line Specification

Empty Fruit Bunches (EFB) are waste products produced during the production of palm oil. When the palm fruit RIPS and separates from the stem, what is left is an empty cluster. This is a common agricultural waste in Southeast Asia, where millions of tons are produced each year

Palm empty fruit bunches( (EFB)) are an agricultural waste produced in the palm oil production process, which can be treated and utilized in a variety of ways. Although most of the empty palm fruit bunches are still processed by burning, with the improvement of environmental awareness and the development of technology, more sustainable utilization methods are being explored and implemented

Countries Suitable For Setting Up Complete EFB (Empty Fruit Bunches) Pellet Plant Include

The Use Of Palm Empty Fruit Bunches(EFB)

Empty Fruit Bunches (EFB) are one of the most important wastes in the palm oil industry. However, although it is waste, its potential uses are extensive. Here are some of the main uses of palm empty fruit bunches:

Pulp And Paper Making

Because of its rich cellulose and hemicellulose, palm hollow fruit skewer is considered as a potential non-wood fiber raw material, which is suitable for pulp and paper industry. Studies have shown that EFB has similar properties to hardwood, with good pulping and papermaking performance35. However, while laboratory studies have shown promising potential, these findings have yet to be commercialized on a large scale.

Biomass Energy

Because palm empty fruit bunches contain a large amount of organic matter, they can be used as a source of biomass energy. For example, EFBs can be burned to produce heat for electricity or heat. In addition, through advanced biotechnology, EFBs can also be converted into biofuels such as biodiesel and bioethanol

A Soil Conditioner

After proper treatment, palm empty fruit bunches can be used as a soil amendment. They are rich in organic matter that can help improve soil structure, increase the water retention capacity of the soil, and provide essential nutrients

Microbial Fermentation

The cellulose and hemicellulose in EFB can be converted into reducing sugar under certain conditions and used as carbon source for microbial fermentation. This allows EFB to be used as an inexpensive feedstock to produce a variety of biological products by microbial fermentation

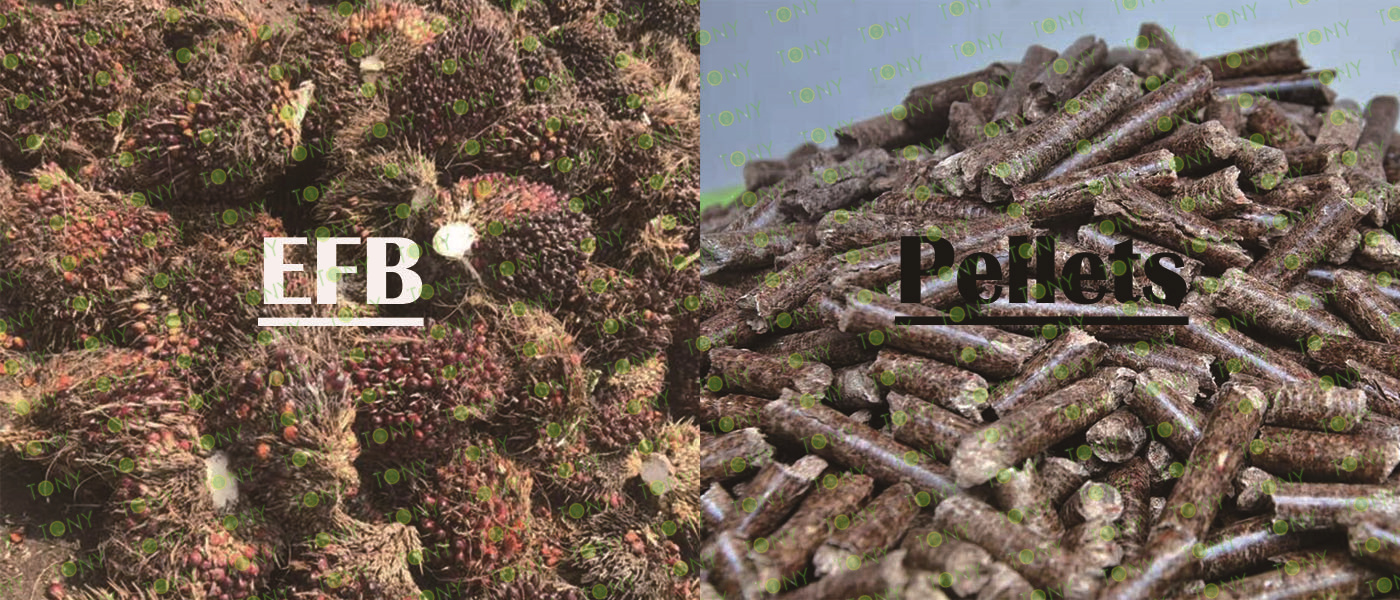

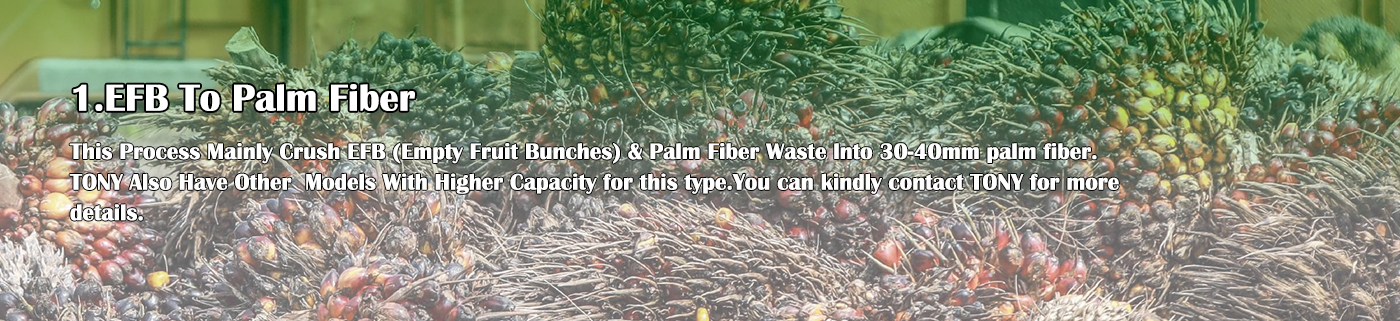

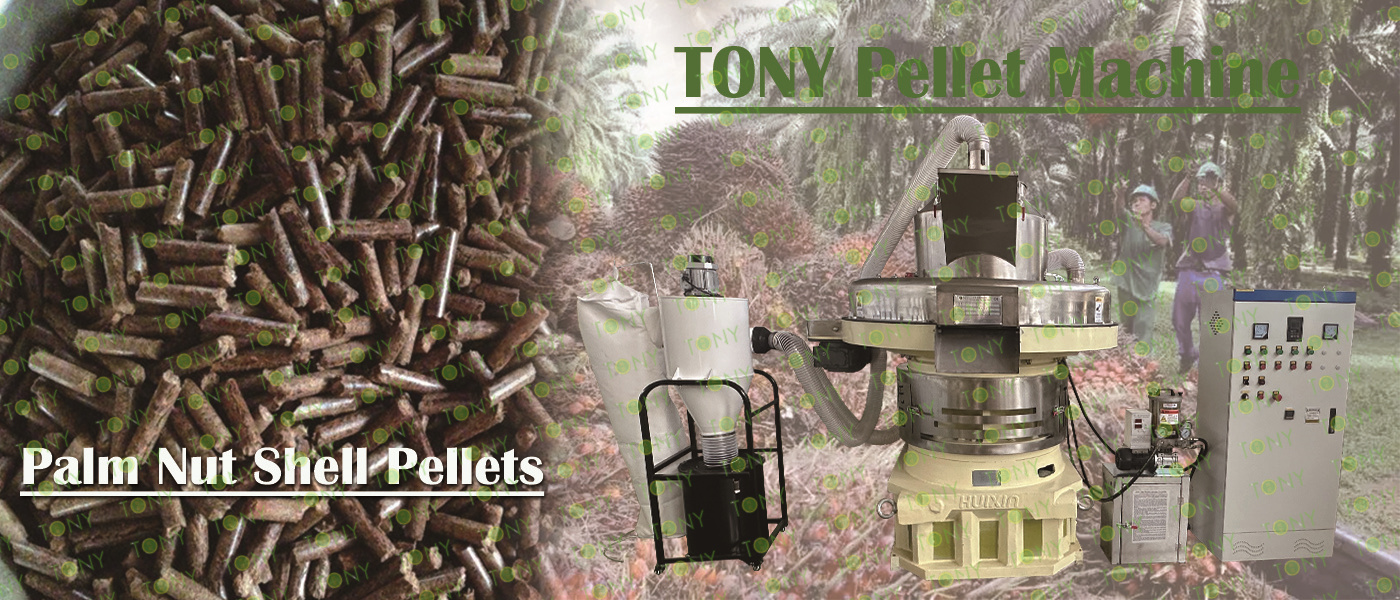

EFB (Empty Fruit Bunches) & Palm Fiber Waste

EFB (Empty Fruit Bunches) & Palm Fiber Waste Pellets

Palm oil production is a very important industry in Southeast Asia. After the palm ripens, the fruit separates from the stem, leaving an empty fruit bundle (EFB) that becomes waste. Millions of tons of EFB are produced every year, and research into the possibility of utilizing this waste is ongoing.

Most treatments for EFBs involve burning the ash and using it as fertilizer for plants, but combustion creates a lot of environmental pollution, so other treatments have to be found. EFB contains vascular bundles in its parenchyma, which is a material with good elasticity and low density. Several studies have shown that EFB can be used for paper, while EFB has a wide range of potential uses as a non-wood fiber feedstock as a boiler fuel.

1. Suitable Fiber Characteristics

EFB (empty fruit bundle fiber) has a certain fiber structure, which can form the skeleton structure of particles after treatment, which is conducive to the formation of particles. During extrusion, for example, the fibers interweave with each other, allowing the particles to maintain a stable shape6.

2. The Composition Is Favorable

Its own composition makes the prepared biomass particles have better combustion performance. It contains a certain proportion of carbon, volatiles and other components, can provide a stable calorific value, meet energy needs, in the combustion process can continue to release heat, can be used in a variety of combustion equipment such as power plant boilers, household furnaces and so on

If it is directly burned, it will pollute the environment, and EFB is generally made into biomass particles, which is conducive to storage and protection of the environment, and is currently a very good resource utilization method.

After being pressed and solidified, EFB becomes a biomass pellet fuel, which has the characteristics of high calorific value, complete combustion and no pollution. It is a kind of clean fuel that meets environmental protection requirements and can replace coal. In the wave of green development, EFB pellets are becoming more and more popular, the product can not only be used as a fuel specification, widely used in biomass power plants, biomass boilers, paper mills, food factories, etc., can also be used for home heating, home cleaning, as long as the need for heat sources, biomass particles can be used, then, What are the factors that affect the yield of EFB pellets?

1.Impact Of Production Environment:

(1) Because the humidity of EFB raw materials is different in different weather environments, the higher the humidity, the less ideal the crushing effect, and the lower the yield

(2) The instability of the power environment will also affect the normal operation of the equipment, and the high and low voltage will affect the equipment and the output, especially when the voltage is too high, it will damage the equipment.

2. Equipment Maintenance And Maintenance:

The good running condition of the equipment is an important premise to improve its work efficiency. In ordinary use, users must pay attention to the maintenance of the equipment, which can achieve the dual purpose of improving production efficiency and extending service life.

3. Operation Specifications:

The equipment operator of theEFB pellets production line must be professionally trained, have a comprehensive understanding of the performance of the equipment, and use the equipment reasonably according to the correct operation norms, which can not only ensure their personal safety but also ensure the production efficiency of the equipment.

4. Selection Of Production Line Equipment

EFB pellet production line requires multiple equipment to work together. In particular, the quality of the core equipment straw granulator plays a decisive role, and some poor quality granulator equipment is shoddy. The service life is generally not very long, and the failure rate is high, and the work is delayed, which seriously affects the normal production of customers.

TONY is more than 20 years of granular production line processing industry experience, the industry reputation is very good, you can visit the factory to buy

1. Environmental Benefits

(1) Reduce Waste Discharge

The use of EFB to produce biomass pellets is an effective utilization of waste from palm oil production. In palm oil production, EFB will become solid waste if not used, and after being made into biomass pellets, the waste emissions are reduced, contributing to environmental protection and sustainable use of resources.6

(2) The Combustion Is Relatively Clean

EFB biomass particles do not produce smoke during combustion, reducing air pollution. Compared with some traditional fuels, it emits less harmful gases during combustion, meets environmental protection requirements, and is a clean, environmentally friendly and sustainable new energy source.

2. Cost Effectiveness

For palm oil producers, EFB is originally a by-product of the production process, and it is made into biomass pellets, turning waste into treasure and increasing the source of economic income for enterprises. Without the need for a lot of additional input to obtain raw materials, valuable biomass pellet products can be produced, reducing production costs and improving economic benefits.

3. Adaptability To Market Demand

With the increasing demand for renewable energy and clean energy, the biomass pellet market has broad prospects. Biomass pellets made by EFB have the advantages of high calorific value, low humidity and so on, easy to handle, control and application, suitable for most feeding systems, can well adapt to market demand, have a certain competitiveness in the market, so as to promote its manufacturing

High Density:

EFB particles are made through a series of processes, including crushing, drying, extrusion and cooling. This high density of particles makes them easier to transport and store

Environmental Protection:

As a biomass fuel, EFB particles emit much less harmful gases such as carbon dioxide, nitrogen dioxide and sulfur dioxide after combustion than coal, which is in line with national emission standards and contributes to environmental protection

Renewable:

EFB particles use agricultural waste and belong to resource reuse. In addition, biomass fuel is a renewable energy, there will be a large number of agricultural and forestry waste recycling every year, so biomass fuel is not used up

Low Cost:

Because EFB particles use renewable waste resources, their use cost is much lower than gas, oil, electricity and other energy sources, with the advantage of low cost.

Clean combustion: Biomass particles in the combustion process, because the purity is high, so it will not cause harm to the boiler, and the combustion is stable, the period is long, and the pollutant content in the ash and flue gas is small

Versatility:

EFB particles can be used for a variety of purposes, such as home heating, supply of domestic hot water, small furnaces, small and medium boilers, and direct combustion for power generation or steam production

Waste Reduction:

By processing EFB fiber into pellet fuel, it can effectively reduce the accumulation of agricultural waste and avoid negative impacts on the environment.

Support Sustainable Development:

Using EFB pellets helps to promote the concept of sustainable development and promote the development of a circular economy, while also bringing economic benefits to businesses.

In summary, EFB biomass pellets not only have the advantages of environmental protection, low cost and multi-function, but also effectively promote the reuse of resources and waste treatment, which is a clean energy worthy of promotion and use.

1.The Working Principle Of EFB Pellet Processing Equipment

EFB (Empty Fruit Bunches, that is, bunch of oil palm fruit) as a specific biomass raw material, before processing biomass pellets, the biomass raw materials need to be prepared first, EFB needs to be pre-treated, such as crushing, drying, etc., to ensure that they are suitable for further processing. A device that solidifies it into a high-density pellet fuel

2.Characteristics Of EFB Pellet Processing Equipment

(1) Processing Efficiency

Efficient production capacity: EFB biomass pellet processing equipment has a certain production efficiency. Although the specific production rate may vary depending on the model and configuration of the equipment, it is possible to process EFB into pellet fuel stably.

(2) Product Quality

Good particle forming quality: The machine is able to process EFBs into regular shaped, high density particles. The formed particles have good physical properties, such as moderate hardness and are not easy to break, which helps to maintain the integrity of the particles during storage, transportation and combustion, and improve energy efficiency.

(3) Equipment Stability

Stable operation: During a long period of operation, EFB biomass pellet processing equipment shows good stability. This means that the equipment has a relatively low incidence of failure during continuous production, reducing production delays and cost increases caused by equipment downtime for maintenance.

3.Application Scenarios Of EFB Pellet Processing Equipment

(1) Domestic Solid Fuel:

Wheat straw pellet fuel has a high utilization rate, which is conducive to storage, use, health and safety, and can be used for home heating.

(2) The Main Solid Fuel For Industrial Boilers:

Replace raw coal, heavy oil and gas to reduce air pollution. Each 10,000 tons of biomass fuel ignited can replace 7,000 tons of standard coal, reduce so2 emissions by 165 tons, smoke and dust emissions by 80 tons, and carbon dioxide emissions by 14,400 tons

(3) Thermal Power Generation:

The fuel heat value can reach 3400~6000 kcal.

Simple words to describe biomass pellet fuel, that is, "environmental protection", "energy saving", "renewable", "zero carbon emissions". Biomass fuel is the best renewable energy to replace coal. From the point of view of cost, energy saving and environmental protection, biomass fuel is a better alternative to coal

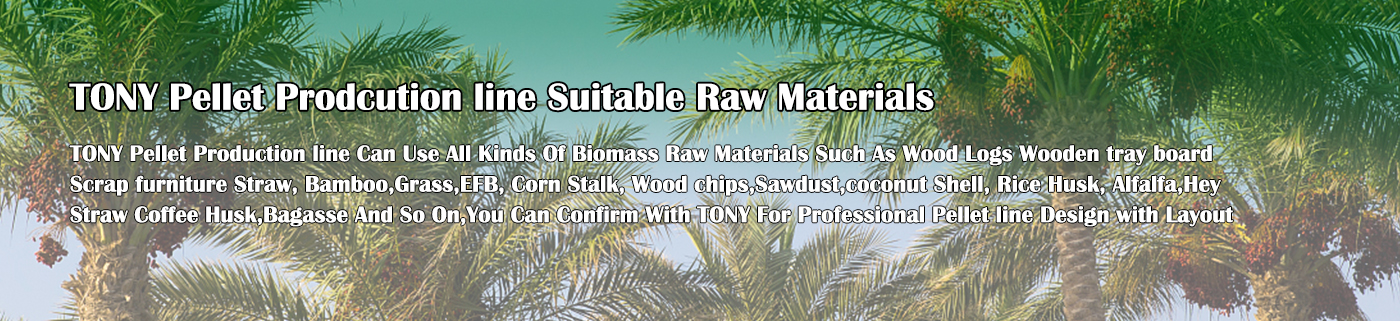

TONY Brand EFB pellet manufacturing plant can be with EFB as raw materials, after pretreatment and processing solidified into high-density pellet fuel, which is an ideal fuel to replace coal and oil, and has the role of energy saving and emission reduction. At present, it has been widely used in countries.

1. Capacity: Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the EFB pellet line customizes according to the actual production needs of customers

2. Raw materials:EFB

3. Humidity: Dry and wet materials can be used, wet materials need to be equipped with a dryer, in order to meet the requirements of the pellet machine

4. Uses: EFB

Suitable for customers: Green energy companies, large farms, private growers and other customers with advantages in straw raw materials.

5. Finished pellet market: Large power plants , home heating, industrial heating, combustion heating, heating, boiler room, school canteen

1.Project Name: EFB Pellet Line

2.Raw Materisl: EFB

3.Moisture Of Raw Material: Wet Type 45-55%

4.Capacity: Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the biomass pellet line customizes according to the actual production needs of customers.

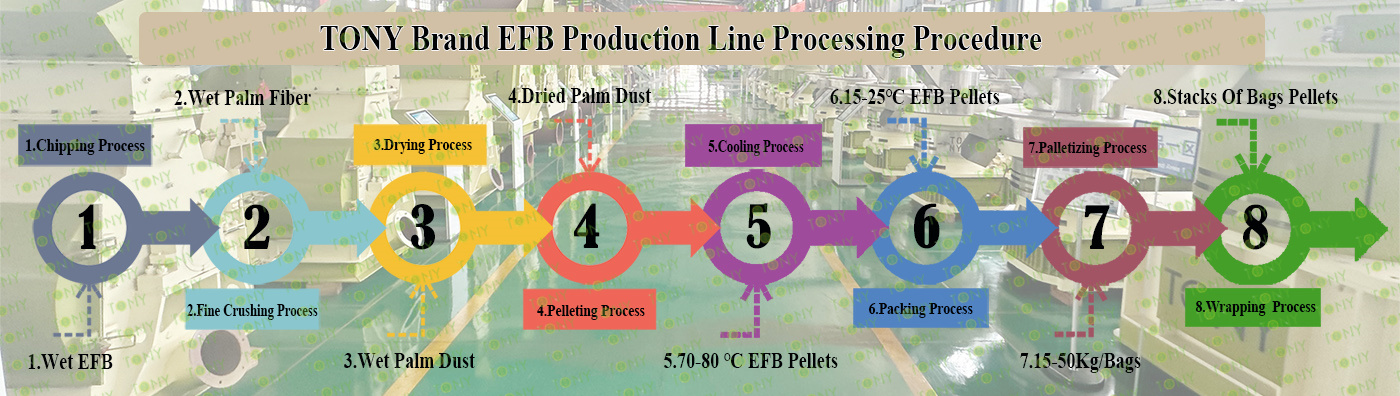

5.Proecss: Grinding Process→Fine Crushing Process→Drying Process→Pelleting Process→Cooling Process→Packing Process→Palletizing process→Wrapping process .

6.Main Machine: Palk Fiber Machine,Hammer Mill,Rotary Drum Dryer,TONY Pellet Machine,Pellets Cooler,Packing Machine,Palletize, Wrapping Machine And Belt Conveyors.

7.Total Power:Based on all selected equipment models,according to all the equipment models selected, different models have different power.

8.Need Area: Based on all selected equipment models,according to all the selected equipment models, different models of equipment sizes are different.

9.Project Country: Can be used in any country.

10.Voltage: The voltage standard of the country in which the equipment is used.

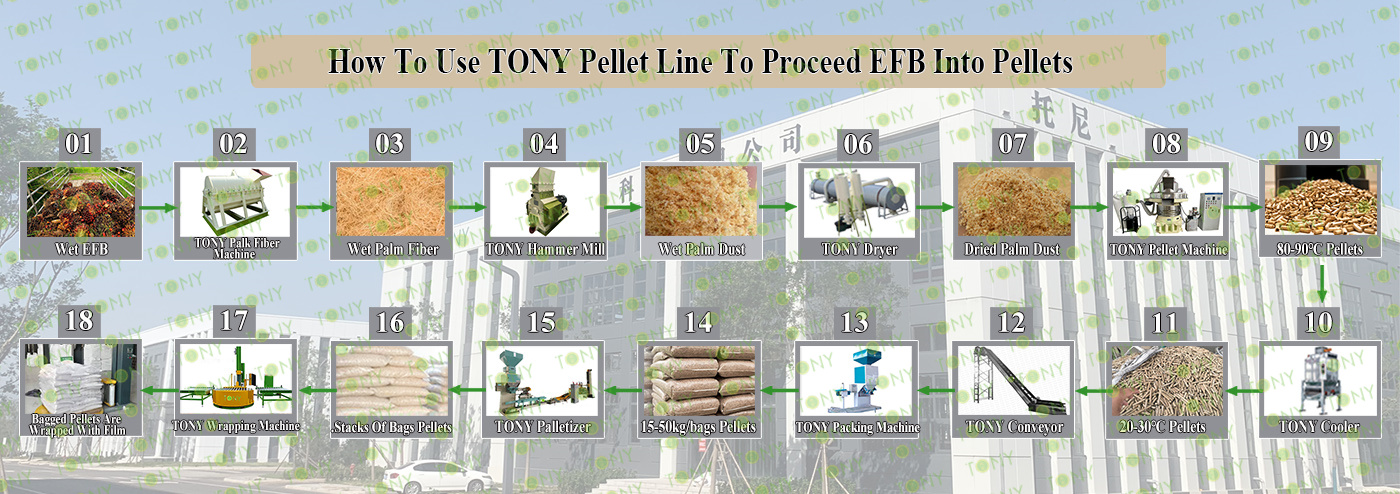

It mainly contains the following steps and machines as following:

1.To Use TONY Palk Fiber Machine To Grind EFB (Empty Fruit Bunches) Into 30-40mm Palm Fiber.

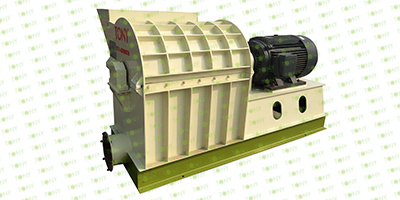

2.To Use TONY Hammer Mill To Crush 30-40mm Palm Fiber Into 8-14mm Sawdust. If customer has enough Investment budget,he can also choose TONY Special cutting machine for palm silk which will be more expensive than the hammer mill.

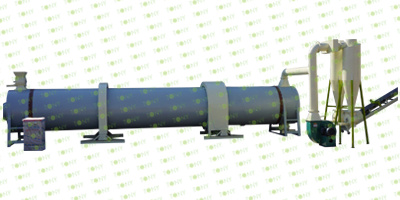

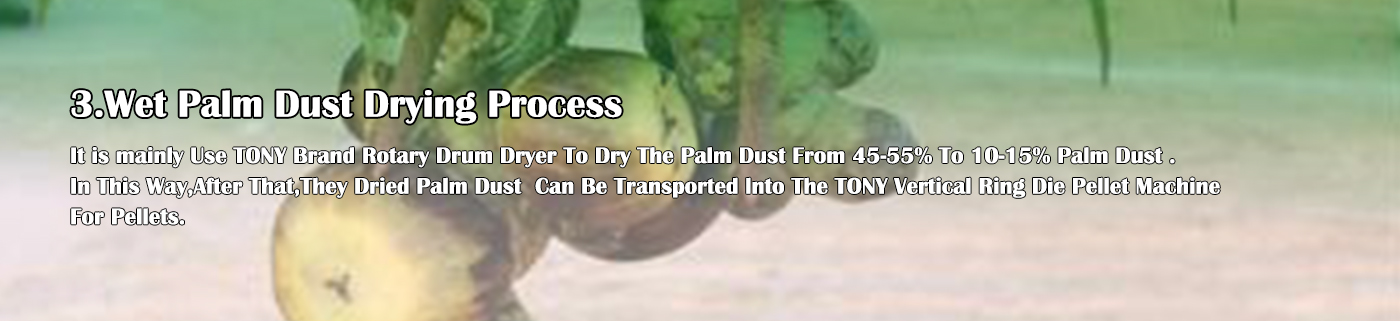

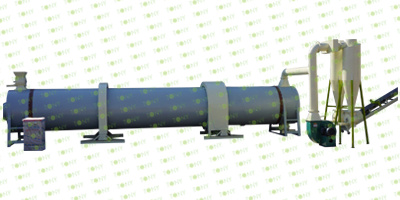

3.To Use TONY Rotary Drum Dryer To Dry The 45-55% Sawdust Into 10-15% Sawdust.

4.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm.

5.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ to 20-30℃.

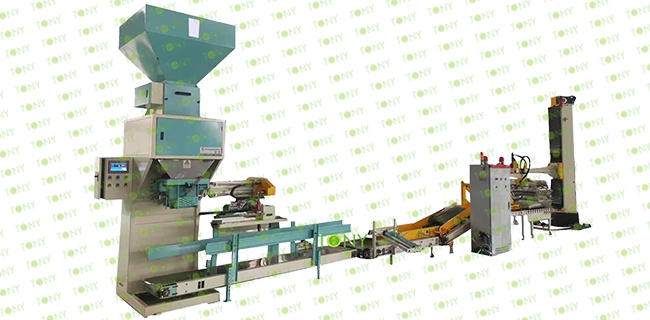

6.To Use TONY Packing Machine To Packing Pellets To 15-50KG/Bags.

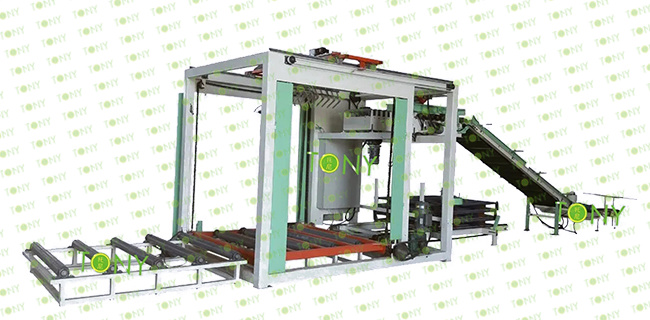

7.To Use TONY Palletizer To Palletizing 15-50Kg/Bags.

8.To Use TONY Wrapping Machine To Wrapping Palletized Biomass Pellet.

You can contact TONY to get for more details information and quotation.

TONY Can Supply You All The Products As Above With Competitive Price And Excellent Quality.

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some machines can be custom made by customer according to different customer's detailed demand.Contact TONY for more details with quotation and layout.

|

|

|

|

| Palk Fiber Machine | Hammer Mill | Rotary Drum Dryer | Vertical Ring Die Sawdust Pellet Machine |

|

1.To Grind EFB (Empty Fruit Bunches) Into 30-40mm Palm Fiber. 2.Models Can Be Selected Or Customized According To Production Needs |

1.Crush 30-40mm Palm Fiber Into 8-14mm Palm Dust. 2.Models Can Be Selected Or Customized According To Production Needs |

1.To Dry The 45-55% Palm Dust Into 10-15% Palm dust. 2.Models Can Be Selected Or Customized According To Production Needs |

1.To Press The Palm Sawdust Into Pellets 2.New 304SS Type 3.Models Can Be Selected Or Customized According To Production Needs |

|

|

|

|

| Galvanised Cooler Separator | Packing Machine | Palletizer | Wrapping Machine |

|

1. To Cool Pellets From 80-90℃ To 20-30℃ 2. Models Can Be Selected Or Customized According To Production Needs |

1. You Can Choose Semi-Automatic Or Automatic Packaging Machine To Pack Pellets Into 15-50kg/ Bag 2. You Can Also Choose To Pack The Pellets Into 1 Ton/Bag |

1. To Palletize Bagged Pellets 2. You Can Choose High Level Palletizer Or Column Palletizer According To Your Needs |

1. To Wrappe Film Palletized Bag Pellets 2. Wrapping Machine Can Be Equipped With Weighing System |

|

1.Grinding Process A.The process is mainly used to grind EFB into 30-40mm palm Fiber. Feed through the feed port of the machine. The knife in the machine spun quickly and crushed the palm skin. The crushed raw materials are rotated and stirred in the device and rubbed into filaments, and the finished products are transported through the discharge port. Main Parts: (1). TONY's new Palk Fiber Machine. (2). Feed and unload belt frequency control to prevent card material. (3). Electronic control system allows the equipment to be used normally. (4). Contact TONY for more details with quotation. |

2.Dust Removal Of Grinding Process

Dust removal of Grinding Process There are two kinds of dust removal equipment available.

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices.

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

3.Storage Of Palm Fiber

(1) How to store the 30-40mm palm fiber?

Option 1: The user can choose to pile the palm fiber on the ground.

Option 2: The user can also choose to put the palm fiber into the stock bin.

(2)What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Straw Pieces Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

(3)There are two types of silo:

Storage Bin and Large Hydraulic Storage Silo.

Please contact TONY for specific parameters and prices

|

|

| Auger Silo | Large Hydraulic Storage Silo |

|

1. Capacity :5-30m³,If the capacity is expanded, it is easy to block or stick the material 2. The material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3. Mainly for screw control,the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1. Capacity :40-300m³,If the capacity is expanded, there will be no clogging 2. The material is galvanized and corrosion-resistant 3. Mainly for hydraulic system control,The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4. Advantages: good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5. Disadvantages: Complex structure and high maintenance cost. |

|

1.Fine Crushing Process A. The process is mainly used to crush 30-40mm palm fiber into 8-14mm palm dust. B.There are three types of Fine Crushing Equipment,Multifunctional Hammer Mill Effective Hammer Mill ,Dual Shaft Hammer Mill, can be selected according to the actual situation Main parts: (1)TONY Fine Crushing Equipment (2)Galvanized Dust Collector. (3)Sawdust Conveying Fan. (4)Cyclone With Airlock. (5)Electrical Cabinet. |

|

|

|

| Multifunctional Hammer Mill | Effective Hammer Mill | Dual Shaft Hammer Mil |

|

1. Direct motor transmission, one motor, one spindle 2. The feed port is on the side of the machine, suitable for the raw materials that are difficult to feed 3. A piece of mesh screen 4. Spindle single direction rotation, limited output and crushing efficiency |

1. Direct motor transmission, one motor, one spindle 2. The feed port is on the upper side of the machine, suitable for raw materials that are easy to feed 3. Two screens 4. The spindle can rotate in the opposite direction, and the output and crushing efficiency are higher |

1. Direct motor transmission, two motors, two spindles 2. The feed port is on the upper side of the machine, suitable for raw materials that are easy to feed 3. Two screens 4. The same type of efficient crusher has a higher output than a single shaft |

2.Dust Removal Of Fine Crushing Process

Dust removal of Fine Crushing Process There are two kinds of dust removal equipment available

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag. |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

3.Storage Of Wet Palm Dust

(1)How to store the 8-14mm wet palm dust.?

Option 1:The user can choose to pile the wet palm dust on the ground.

Option 2:The user can also choose to put the wet palm dust into the stock bin.

(2) What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Palm Fiber Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

(3)There are two types of Silo: Palm Dust Storage Bin and Large Hydraulic Storage Silo.

Please contact TONY for specific parameters and prices

|

|

| Sawdust Auger Silo | Large Hydraulic Storage Silo |

|

1.Capacity: 5-30m³,If the capacity is expanded, it is easy to block or stick the material 2.The material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3.Mainly for screw control,the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: Simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1. Capacity: 40-300m³,If the capacity is expanded, there will be no clogging 2. The material is galvanized and corrosion-resistant 3. Mainly for hydraulic system control, the hydraulic system can precisely control the conveying amount and conveying speed of the material. 4. Advantages: Good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5. Disadvantages: Complex structure and high maintenance cost. |

|

1.Palm Dust Drying Process: A.This process is mainly used to dry the palm dust from45%- 55% to 10-15%. B.Capacity:According to raw material humidity and production requirements. C.According to the actual production process, you can choose to use Single-Layer Rotary Drum Dryer,Double-Layer Rotary Drum Dryer,Three-Layer Rotary Drum Dryer. It is necessary to provide heat source for Rotary Drum Dryer with Biomass Hot Stove. Waste wood, waste straw and Biomass particles can be used as fuel for Hot blast Stove. The models of Biomass Hot Stove are different and can also be customized. Main Parts: (1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.) (2)TONY's Hot Stove. (3)Fan Blower+Cyclone With Airlock. |

|

|

|

| Single-Layer Rotary Drum Dryer | Double-Layer Rotary Drum Dryer | Three-Layer Rotary Drum Dryer |

|

1. Structure: Only one drying layer. 2. Applicable materials: Usually used for drying light materials, such as sawdust, wood chipping, bean residue, cow dung, coal slime, etc. 3. Advantages: Simple structure, low cost, easy operation and maintenance. 4. Disadvantages: The drying efficiency is relatively low, which is suitable for scenes with small scale or low drying efficiency requirements. |

1. Structure: There are two drying layers, usually two concentric cylinders of different diameters. 2. Applicable materials: Suitable for drying granular materials with a certain humidity and particle size range, such as river sand, wood chips, sawdust, etc. 3. Advantages: Compared with single-layer dryer, it has higher thermal efficiency, faster drying speed and smaller footprint. 4. Disadvantages: The structure is complex, the cost is high, and the operation and maintenance are relatively complex. |

1. Structure: There are three drying layers, usually three concentric cylinders of different diameters. 2. Suitable materials: Suitable for drying materials that require higher thermal efficiency and faster drying speed, such as slag, clay, pulverized coal, etc. 4. Advantages: The highest thermal efficiency, the fastest drying speed, can handle larger scale material drying. 5. Disadvantages: The most complex structure, the highest cost, the most complex operation and maintenance. |

2.Dust Removal Of Drying Process

There are four kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Option 3: Water Spray Dust Removal

Option 4: Wet Electrostatic Precipitator

Please contact TONY for specific parameters and prices

|

|

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector | Water Spray Dust Removal | Wet Electrostatic Precipitator |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

1. The water film caused by a certain method on the inner wall of the dust collector or other special components is used to impact the dust, so that the dust is captured by the water film and the gas is purified. 2. Often used to deal with gas containing high humidity and sticky dust, suitable for boiler, chemical, spray paint, spray glaze, pigment and other industries. 3. Simple structure, small metal consumption, small water consumption. 4. It has higher dust removal efficiency for dust particles with larger particle size. 5. It is high and difficult to arrange. There may be water phenomenon in actual operation. |

1. The dust and liquid droplets in the flue gas are adsorbed to the surface of the anode and cathode using electric field load, and cleaned with water spray. 2. It usually used to deal with gas containing fine particles, which is suitable for boiler, chemical industry, waste incineration and other industries. 3. The dust removal efficiency of fine particles is high, up to 98%~99%. 4. It can remove some gaseous pollutants at the same time. 5. The structure is more complex, and the investment and operation cost are higher. Regular cleaning and maintenance is required. |

3.Storage Of Dried Palm Dust

(1)How to store the 8-14mm dried palm dust?

Option 1: The user can choose to pile the dried palm dust on the ground.

Option 2:The user can also choose to put the dried palm dust into the stock bin.

(2)What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Palm Dust Are Stored In The Stock Bin, |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

(3)There are two types of Silo:

Palm Dust Storage Bin and Large Hydraulic Storage Silo. Please contact TONY for specific parameters and prices

|

|

| Palm Dust Storage Bin | Large Hydraulic Storage Silo |

|

1.Capacity: 5-30m³, If the capacity is expanded, it is easy to block or stick the material 2.The material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3.Mainly for screw control,the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: Simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1.Capacity: 40-300m³, If the capacity is expanded, there will be no clogging 2.The material is galvanized and corrosion-resistant 3.Mainly for hydraulic system control, The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4.Advantages: Good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5.Disadvantages: Complex structure and high maintenance cost. |

|

1.Pelleting Process: A.This process is mainly used to product pellets with φ6-8mm. B.Biggest Capacity: The model of biomass pellet machine is different, the production capacity is different, the production capacity of a single pellet machine ranges from 0.8 tons/hour to 5 tons/hour, multiple pellet machines work together, the production capacity can reach up to 100 tons/hour Main Parts: (1). TONY's new Vertical Ring Die Pellet Machine. (2). Cyclone And Bags Dust Collectors. (3). Bearings Automatic Lubrication System. (4). Electrical Cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

2.Dust Removal Of Pelletizing Process

Dust removal of pelletizing process. There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices.

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

3.The way of palm dust entering pellet machine

(1)There Are Two Ways For Palm Dust To Enter The Biomass Pellet Machine

Option 1:Use the belt to transfer the palm dust directly into the pellet machine

Option 2:Add the silo on the side of biomass pellet machine and palm dust enter the biomass pellet machine from the silo

Please contact TONY for details and prices

(2)What Is The Difference Between Belt Transmission And Adding A bin To The Pellet Machine?

A. The Use Scenarios Of The Two Methods Are Different

The use of belt to directly transfer the sawdust to the biomass pellet machine inside, suitable for the number of pellet machines, biomass pellet production line 1-2 pellet machine, if the biomass pellet production line production capacity is large, the need for multiple biomass pellet machine work, you need to add silo above the pellet machine

B.The Advantage Of Adding Silo Above The Pellet Machine Is Greater

In the pellet machine above the bunker, the sawdust into the biomass pellet machine from the bunker, one can save the feed belt, the second can save the site, the third is the operation of personnel is relatively simple

Which method to use depends on the specific situation

(3)There Are Two Kinds Of Silo On The Biomass Pellet Machine, Screw Cycling Silo And Galvanized Hydraulic Silo.

Please contact TONY for specific parameters and prices

|

|

| Screw Cycling Silo | Galvanized Hydraulic Silo |

|

1. It is composed of a large bunker and a screw conveyor (skein) inside. The silo is used to store the material, while the screw conveyor is used to transport the material from the bottom of the silo to other places. 2. Push the material along the direction of the spiral axis through the rotation of the spiral blade. Materials are usually stored open in the warehouse. 3. Relatively simple structure and easy maintenance. 4. Suitable for conveying most dry bulk materials. 5. Materials are stored open in the warehouse and may be affected by environmental factors, such as dust, humidity, etc. 6. In some cases, there may be a problem of material bridging (that is, material forming an arch in the bin and obstructing the flow of material). 7. The use of general iron plate material processing, compared with galvanized material, corrosion resistance is slightly poor |

1. It is usually composed of gantry frame, sliding main beam, moving plucking wing, fixed plucking wing, hydraulic cylinder, hydraulic station, Hank dragon discharge and silo body. The hydraulic system is used to drive the movement of the various components. 2. The expansion and expansion of the hydraulic cylinder is controlled by the hydraulic system to push the material from the warehouse to the discharge port. The discharge port is usually connected with a winch conveyor to further transport the material. 3. Materials are sealed in the warehouse to avoid the impact of environmental factors. 4. The bottom adopts the power to push the material, which effectively prevents the phenomenon of material bridging. 5. Galvanized material, corrosion resistance, durable 6. The structure is more complex and the maintenance is relatively difficult. 7. The cost is relatively high, because the hydraulic system needs to be equipped. |

1.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

Main Parts:

(1). TONY's new Galvanized Cooler Separator With Vibrating Screen.

(2). Cyclone and bags dust collectors.

(3). Fan Blower.

(4). Connect Pipes.

2.Dust Removal Of Cooling Process

There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

1.Packing Process:

A. This process is mainly used to pack pellets.

B. The main equipment: Semi-automatic Packing, Machine Automatic Packing Machine, Ton Packing Machine, High Level Palletizer, Column Palletizer, Wrapping Machine

|

|

|

| Semi-Automatic Packing Machine | Automatic Packing Machine | Ton Packing Machine |

|

1. Packing Pellets To 15-50kg/bags 2. Manual assistance is required to complete some operations, such as bagging. 3. Production efficiency: Compared with the automatic packaging machine, the production efficiency of the semi-automatic packaging machine is lower, but it is still higher than the complete manual operation. 4. Cost: Usually the price is relatively close to the people, suitable for small enterprises with limited budgets. 5. Flexibility: Due to the need for manual intervention, semi-automatic packaging machines have a certain degree of flexibility when dealing with products of different specifications and shapes. 6. Sew Machine,Buyer Can Also Chose Hot Seal Machine For Chosen |

1. Packing Pellets To 15-50kg/bags 2. All steps from feeding, metering, bagging to sealing are automatically completed by the machine. 3. Production efficiency: The production efficiency is significantly higher than the semi-automatic packaging machine, which can greatly reduce labor costs. 4. Cost: The price is higher, but the investment can be recovered in the long run by improving efficiency and reducing labor costs. 5. Accuracy and consistency: It can provide high-precision packaging to ensure that the weight of each bag of products is consistent. 6.Sew Machine,Buyer Can Also Chose Hot Seal Machine For Chosen |

1. Packing Pellets To 1Ton/bags 2. Packaging capacity: Specially used for large bag (ton bag) packaging, usually used for packaging bulk materials. 3. Degree of automation: Most tonnage charter machines have a high degree of automation, which can automatically complete a series of operations such as loading, metering, bagging and so on. 4. Special functions: Usually equipped with dust removal system, dust prevention device, etc., to ensure safety and environmental protection. 5. Suitable for applications requiring efficient, high-volume packaging with special requirements for packaging capacity and safety |

2.Palletizing Machine

It is a kind of high-efficiency palletizing equipment with high degree of automation and good integration. The palletizer groups the bags according to the predetermined way, and then puts the whole layer of bags on the tray layer by layer. Usually used as a follow-up equipment to the packaging line to improve production capacity and transfer capacity, TONY has two types of column palletizer and high palletizer to choose from, you can contact TONY for more product details and price differences

|

|

| High Level Palletizer | Column Palletizer |

|

1. Gantry type structure, the entire mechanical system is located above the production line, through horizontal and vertical movement to move items from the production line to the pallet. The structure of the high palletizer makes it suitable for efficient palletizing at the end of the production line. 2. Mainly used in packaging bag palletizing production line, such as feed, fertilizer, flour, cement and other industries. The high palletizer can realize efficient packaging bag palletizing, and the palletizing shape is neat and beautiful. 3. High degree of automation, can achieve automatic flattening, automatic bag, automatic stratification and other functions. 4. Installation requires large space and is usually fixed at the end of the production line. The operation of the high palletizer requires professional technical personnel to maintain and operate. 5. The cost of use is low and maintenance is relatively simple, but in some cases a higher initial investment may be required. |

1. With a vertical column, the robot arm moves up and down the column, and can rotate or move on the horizontal plane at the same time. This design allows the post palletizer to have high stability and accuracy when handling heavy and large items. 2. It is suitable for high-speed and stable palletizing of large and heavy goods, which is commonly used in chemical industry, building materials and other industries. Due to its stable structure, it can ensure the accuracy and quality of palletizing when handling heavy items. 3. It has high flexibility and adaptability, and can adapt to items of different sizes and shapes by adjusting parameters. Its intelligent design makes it possible to handle many types of items. 4. The installation is relatively flexible and can adapt to different production line layouts. Due to its compact structure and relatively small occupation space, it is suitable for the use of small production workshops. 5. The initial investment is high, but in the long run, due to its stability and efficiency, the overall operating cost can be reduced. |

3. Wrapping Machine

Wrapping machine the use of stretch film (also called winding film) as consumables, and pallet baler, pallet wrapping machine and other titles. People's requirements for logistics efficiency continue to improve, in order to reduce labor, save packaging costs, to achieve economical handling and the emergence of a packaging machine. It has gradually become a necessary packaging machine for large enterprises, especially export-oriented enterprises

|

The Characteristics Of The Wrapping Machine 1.Various Operation Modes: Including manual operation and automatic operation of two modes, can be changed at any time 2. Automatic Sensing Function: Automatic sensing cargo height, equipped with top pressing device 3. Versatility: Suitable for single or multiple cylindrical combination packaging requirements and general packaging 4. Control Panel Is Convenient: Touch control panel, fool type and intelligent control design, easy operation 5. Parameters Can Be Adjusted: Winding specifications, winding film lifting speed, tightness can be adjusted at any time, convenient and rapid 6. Smooth Operation: Slow start, slow stop, fixed stop 7. Automatic Film Breaking: When the packaging is completed, the film will be automatically pulled and broken without cutting knife 8. Easy Maintenance: Easy parts replacement, low failure 9. Safety Guarantee: With self-protection switch device and emergency safety shutdown device, electromagnetic pre-drawing device, different from the general mechanical, safer for operators |

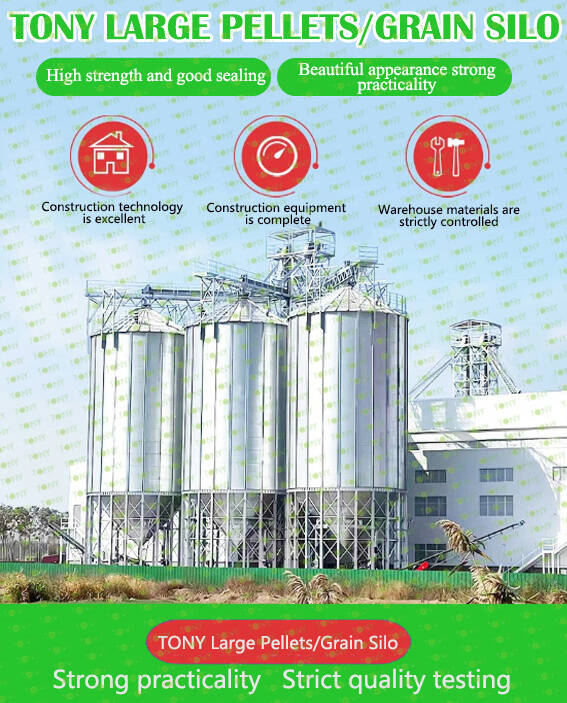

4.Large Pellets Silo:

After processing the biomass pellets, the customer has no need for bagging and packaging, and can choose to store the biomass pellets in the Large Pellets Silo. When there is an order for biomass particles, it can be directly transported from the particle bin to the vehicle or container

|

TONY Large Pellets/Grain Silo Advantages 1. Cost: TONY Large Pellets/Grain Silo light weight, less consumables, so reduce the basic cost. 2. Standardization : TONY Large Pellets/Grain Silo standardization degree is high, can be made into standard parts according to domestic materials, so as to achieve standardization, general serialization production, arbitrary combination into a variety of warehouse types required by users. 3. Installation: TONY Large Pellets/Grain Silo is simple and fast, all steel bin components, are bolted connection, fast installation, short construction period. 4. Storage: TONY Large Pellets/Grain Silo is easy to achieve automation, steel silo has supporting equipment, can be configured according to the use of requirements into the warehouse, out of the warehouse, ventilation, drying, temperature measurement, measuring full and other equipment, to achieve the purpose of safe grain storage. 5. Disassembly: TONY Large Pellets/Grain Silo simple disassembly, easy maintenance, local board damage can be replaced. 6. Life: TONY Large Pellets/Grain Silo low cost, suitable service life. Generally, it is only 35% to 50% of the reinforced cement warehouse, and the service life can reach more than 30 years. |

|

EFB (Palm silk) can be processed into pellets. Traditional pelleting machines cannot produce EFB pellets in large quantities because palm silk fibers are tough and easily twisted. However, through a customized granulator, palm empty fruit bunches can be directly chopped and dried to make biomass pellet fuel, whose caloric value can be up to more than 5000 kcal.

In the processing process, it is first necessary to chop the empty palm fruit bunches and then dry them. Due to the fibrous properties of palm silk, drying is a key step to ensure the formation and quality of the particles. Customized granulators are able to process the tough material, and the resulting particles can be used in energy production and are exported in large quantities to Japan, South Korea and other places.

EFB particles have a wide range of applications, mainly for energy production. Because of its high calorific value, EFB particles have important applications in the energy field as a biomass fuel. In addition, due to its characteristics of resource utilization, EFB particles also promote the effective treatment and reuse of waste.

Advantages Of EFB Biomass Pellets:

1. High Density: EFB particles are manufactured through a series of processes such as crushing, drying, extrusion and cooling, and have the characteristics of high density.

2. Environmental Protection: As a biomass fuel, EFB particles produce less pollutants during combustion, helping to reduce environmental pollution.

3. Renewable: EFB particles use agricultural waste as raw material, which is a renewable energy source and contributes to sustainable development.

4. Economic Benefits: The use of agricultural waste to produce biomass pellets can reduce the cost of waste treatment and create new economic value.

5. Strong Applicability: EFB particles are suitable for many types of biomass boilers and can be used as an alternative to traditional fuels.

6. Moderate Calorific Value: Although the calorific value of EFB particles may not be as high as some other types of biomass particles, it is still sufficient to meet the needs of many application scenarios.

7. Easy Storage And Transportation: Due to its granular form, EFB particles are easy to store and transport, reducing logistics costs.

8. Drive Economic Development: The production and use of EFB pellets promote economic development and provide employment opportunities.

1. Market Opportunities Brought By Environmental Advantages

In line with environmental protection needs: EFB biomass pellet fuel has environmental protection characteristics, and the harmful gas content is very low when burning, which can effectively reduce harmful gas emissions, such as carbon dioxide, which is in line with the growing global environmental protection needs. With the increasing concern for environmental protection and the emphasis of countries on emission reduction targets, the demand for this environmentally friendly fuel in the market is expected to increase. For example, in combating climate change and improving air quality, EFB biomass pellet fuel can be an ideal alternative to traditional fossil fuels to meet the clean energy needs of all types of businesses and households.

2. Energy Substitution Potential

Alternative to traditional energy: it can replace traditional fossil fuels, such as coal, oil, natural gas and other non-renewable resources. In the field of energy, traditional energy is facing problems such as resource depletion and price fluctuations, while EFB biomass pellet fuel as a renewable energy, its supply is relatively stable. For the industrial sector, many industrial boilers can directly use EFB biomass pellet fuel, reducing dependence on traditional energy, reducing energy costs, and improving energy security.

3. Policy Support To Promote Market Development

Favorable policy orientation: From the policy level, many countries are actively promoting the development of renewable energy. The government has introduced a series of incentive policies, such as subsidies, tax incentives and other measures to support the renewable energy industry, including biomass energy. These policies help to reduce the production cost of EFB biomass pellet fuel and improve its competitiveness in the market, thus promoting the expansion of its market size.

4. Wide Range Of Applications

(1) Industrial Applications: In industry, EFB biomass pellet fuel can be used for boiler heating, power generation, etc. Many factories require a lot of heat energy for the production process, and EFB biomass pellet fuel can meet this demand and is relatively clean during combustion, helping companies to meet environmental requirements.

(2) Home Applications: In the family field, it can be used for heating, cooking and other daily life purposes. For some rural areas or remote areas, the use of EFB biomass pellet fuel is convenient and environmentally friendly, which can solve the problem of inconvenient traditional energy supply, but also save energy costs for families.

5. Raw Material Supply And Cost Advantage

(1) Rich Raw Materials: EFB (Empty Fruit Bunches, oil palm empty fruit bunches) as a raw material for the production of EFB biomass pellet fuel, the source is relatively rich. The oil palm industry is widespread in many tropical regions and produces large amounts of EFB, which provides sufficient feedstock for the large-scale production of EFB biomass pellet fuel and reduces the risk of price fluctuations due to raw material shortages.

(2) Cost-Effectiveness: The relatively low raw material cost helps control the production cost of EFB biomass pellet fuel, making it a certain price competitiveness in the market. Compared with some other biomass pellet fuels, in the case of sufficient supply of raw materials, it can be provided to consumers at a more favorable price, thus attracting more users to choose this fuel.

2025 Tony Machinery - All Rights Reserved. Map