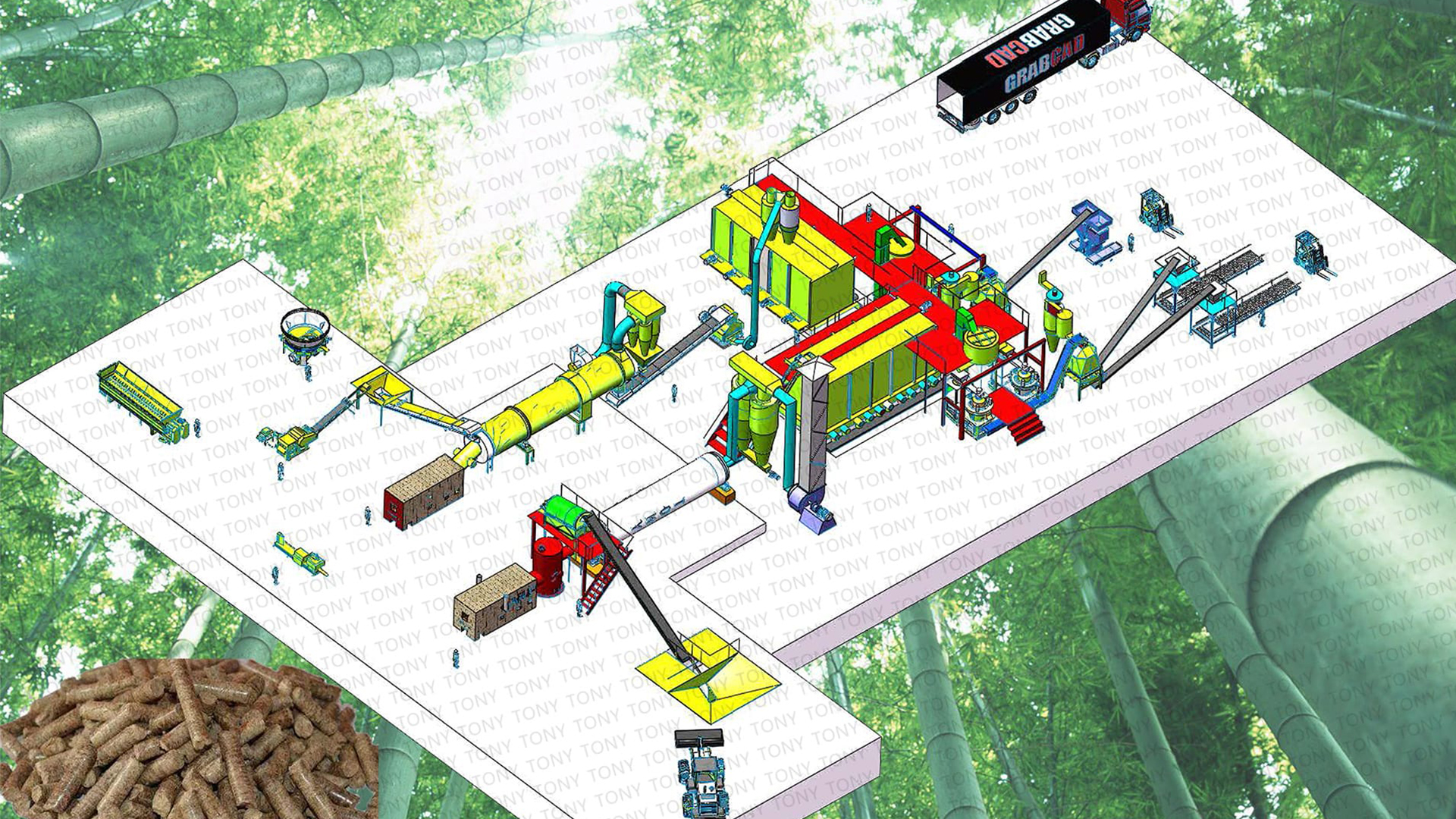

TONY Design Bamboo Production Line Specification

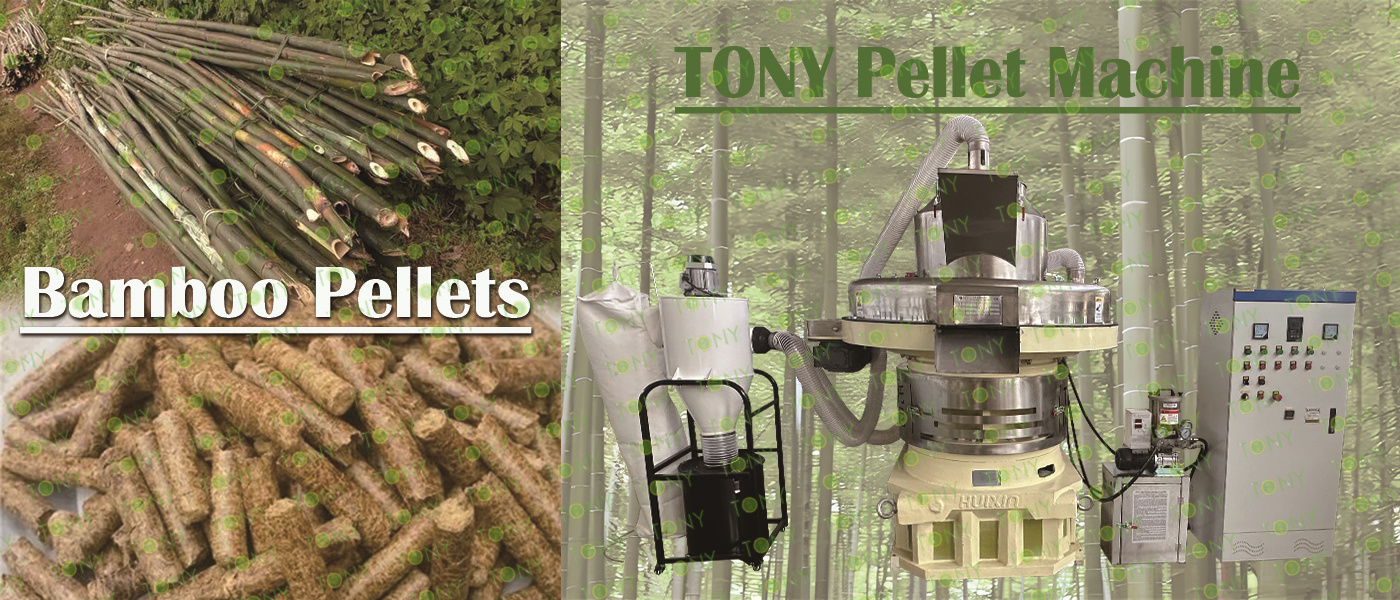

The biomass bamboo pellet production line technology is becoming more and more mature, and pellet fuel has entered the stage of industrial production and application.

Bamboo pellet production line is a good project for low-risk investment and entrepreneurship in many foreign countries. The investment can be large or small. It is suitable for both family workshops with low starting point and large-scale assembly lines. Can be customized according to customer needs.

Raw materials can be sourced locally according to customer conditions, and investors can produce qualified products as long as they follow the operating procedures. The product has high return on investment and broad application prospect. Especially for those owners with large bamboo forests, raw materials have no cost, and closed-loop production from raw materials to finished products can be achieved.

Biomass bamboo pellet production line can not only meet the huge demand for clean energy in ordinary families, but also apply to industrial energy. Large-scale production can also apply for state subsidies, which is the direction advocated by industrial policies in many countries.

The output of bamboo bio-granules varies depending on the type of raw materials, processing equipment and process. Generally speaking, one ton of bamboo can produce about 0.6 to 0.8 tons of bamboo powder particles, depending on the dry and wet moisture content of bamboo.

In the wave of sustainable development, biomass energy, as a green and environmentally friendly form of energy, is receiving more and more attention. Among them, bamboo, as a plant resource with rapid growth and strong regeneration ability, has become one of the important raw materials for biomass pellet production. So, what is the impact of bamboo, a specific raw material, on the processing of biomass pellets?

1. The Impact Of Raw Material Differences On Output

First, factors such as the type, growth age and harvesting season of bamboo will affect its quality as a raw material, and then affect the output of bio-granules. Generally speaking, bamboo with a moderate growth age and tough texture is more suitable for the production of bio-granules, and its output rate is relatively high. The choice of harvesting season is also crucial. The moisture content and cellulose content of bamboo in different seasons are different, which will directly affect the subsequent processing efficiency and output.

2. The Impact Of Processing Equipment And Technology

Secondly, the choice of processing equipment and technology plays a decisive role in the output of bio-granules. Modern biomass pellet production lines are usually equipped with efficient crushing, drying, pressing and other equipment, which can significantly improve the utilization rate of raw materials and the output of products. In addition, reasonable process settings and parameter adjustments are also the key to ensuring output. For example, appropriate drying temperature and time can reduce the moisture content in the raw materials and improve the forming rate and density of the pellets; while appropriate pressing pressure and speed can ensure the uniformity and stability of the pellets.

3. Output Range And Economic Benefit Analysis

Taking the above factors into consideration, the output of bamboo biomass pellets is roughly between 0.6 and 0.8 tons (calculated based on one ton of bamboo as raw material). Of course, this is only a rough range, and the actual output will be affected by specific conditions. Nevertheless, bamboo has significant economic advantages as a raw material for biomass pellets. On the one hand, bamboo has a fast growth rate and strong reproductive ability, and can provide a large amount of raw materials in a short time; on the other hand, bamboo biomass pellets have the characteristics of high calorific value and low pollution, which meets the needs of modern energy development.

Therefore, for biomass pellet production enterprises, choosing bamboo as raw material can not only ensure a stable supply of raw materials and product quality, but also obtain good economic and social benefits. Of course, in the actual production process, it is necessary to continuously optimize the process and equipment configuration to increase output and reduce costs.

Efficient Combustion Performance

Bamboo pellets are a high-quality biomass fuel. They are usually denser and have a higher energy density than logs or bamboo chips. For example, the bulk density of general wood may be 300-600 kg/m3, while the density of bamboo pellets after compression can reach about 1000-1300 kg/m3. This allows bamboo pellets to release more heat when burned, and the combustion process is more stable and lasting.

The combustion value of bamboo pellets is high, and its low calorific value is generally 4000-4800 kcal/kg, which is close to the calorific value of medium-quality coal (about 5000 kcal/kg). It can be used as a substitute for coal in fields such as home heating and industrial boilers to reduce dependence on traditional fossil energy.

Clean Energy Attributes

Bamboo pellets are biomass energy. During the combustion process, they mainly produce carbon dioxide, water and a small amount of nitrogen oxides. Compared with fossil fuels, the amount of carbon dioxide released by its combustion is the recycling of the carbon dioxide absorbed by bamboo through photosynthesis during its growth. From the perspective of the entire life cycle, it is a relatively low-carbon energy source. Therefore, the use of bamboo pellets helps reduce net greenhouse gas emissions and has positive significance for mitigating climate change.

Energy Field:

Replacing Traditional Energy: With the increasing global demand for clean energy, bamboo pellets, as a biomass fuel, have the advantages of high calorific value, combustion resistance, and low pollution. They can replace traditional fossil energy such as coal and oil, and can be used for home heating, industrial boilers, power plants, etc. In some areas with energy shortages or high environmental protection requirements, the market demand for bamboo pellet fuel will continue to grow.

Policy Support: Many countries and regions have introduced policies to encourage the use of biomass energy, such as subsidies, tax incentives, etc., which will promote the production and sales of bamboo pellet fuel. For example, the Chinese government has vigorously promoted the development of biomass energy and provided a good policy environment for the bamboo pellet fuel market.

Agricultural Field:

Soil Conditioner: Bamboo pellets can be used as soil conditioners to increase the air permeability, water retention and fertility of the soil. In agricultural production, the use of bamboo pellets to improve soil can increase the yield and quality of crops, reduce the use of fertilizers and pesticides, and meet the development requirements of green agriculture.

Principle of biomass fuel pellet production:

Raw Material Pretreatment:

Bamboo selection and chopping: Select suitable bamboo, such as bamboo tubes, bamboo branches and bamboo processing residues, and cut them into smaller pieces for subsequent crushing. In this step, bamboo cutters and other equipment can be used to preliminarily process the bamboo into pieces of relatively uniform size.

Preliminary crushing: The chopped bamboo pieces are further crushed to obtain preliminary crushed pieces. This process usually uses a crusher to crush the bamboo pieces into smaller particles, increase the specific surface area of the bamboo, and prepare for subsequent drying and granulation steps.

Intermediate Processing Links:

Stacking: Stack the preliminary crushed pieces into piles, control their moisture content at 30-50%, and turn the pile every 5-9 days. The purpose of this is to allow the bamboo pieces to undergo natural fermentation and moisture adjustment during the stacking process, so that their internal structure undergoes certain changes and reaches a state suitable for granulation. When the pieces feel soft when pinched by hand, the stacking link ends.

Drying: A special dryer is used to dry the stacked crushed materials. The dryer is usually equipped with multiple spiral drying channels, such as three-way spiral drying channels, and the spiral rotation direction of the central spiral drying channel is opposite to that of the other two channels. The rotation of the drum forces the screened crushed materials to enter the central spiral drying channel from the innermost spiral drying channel, and then enter the outermost spiral drying channel. During the drying process, the moisture in the bamboo fragments is evaporated by heat transfer, so that its moisture content is reduced to a suitable range (generally around 10%) for subsequent granulation. At the same time, negative pressure is used to force the dried fragments to be sucked out of the spiral drying channel and discharged from the discharge port. This method can avoid sparks and carbonization and coking of bamboo fragments during the drying process, ensuring production safety.

Granulation: The dried bamboo fragments are input into the granulator. The granulator compresses the bamboo fragments into cylindrical or square particles under high temperature and high pressure by mechanical extrusion. During the pelletizing process, the lignin and other components in the bamboo fragments will soften and bond at high temperatures, giving the pellets a certain strength and stability. The bamboo biomass fuel pellets produced by the pelletizer are cooled and screened in turn to remove unqualified pellets, and finally qualified bamboo biomass fuel pellets are obtained.

TONY Brand bamboo pellet manufacturing plant can process bamboo,stlak,It is widely used in poultry feed, cattle, sheep and horse feed. It can also replace coal for burning.

1.Capacity: According to the customer's demand.

2.Raw materials: Bamboo.

3.Moisture Content: 45%

4.Application: All kinds of straw materials.

5.Finisheh pellets Markets: Fuel

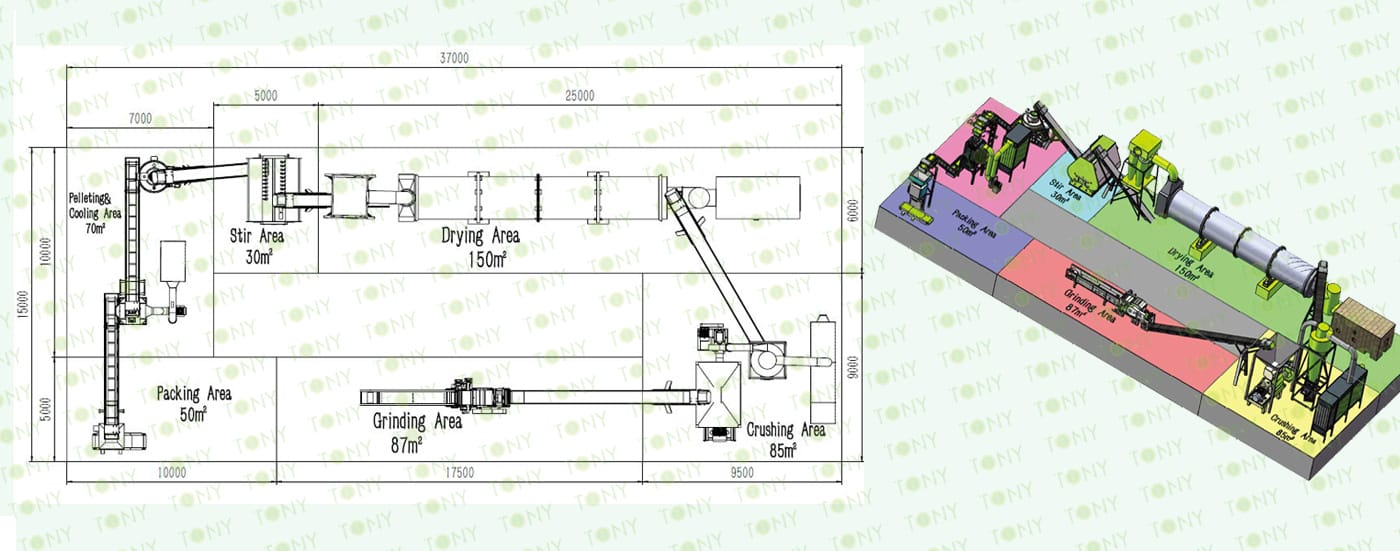

1.Project Name: Bamboo Pellet Line

2.Raw Materisl: Bamboo

3.Moisture Of Raw Material: 45%

4.Capacity: According to the customer's demand.

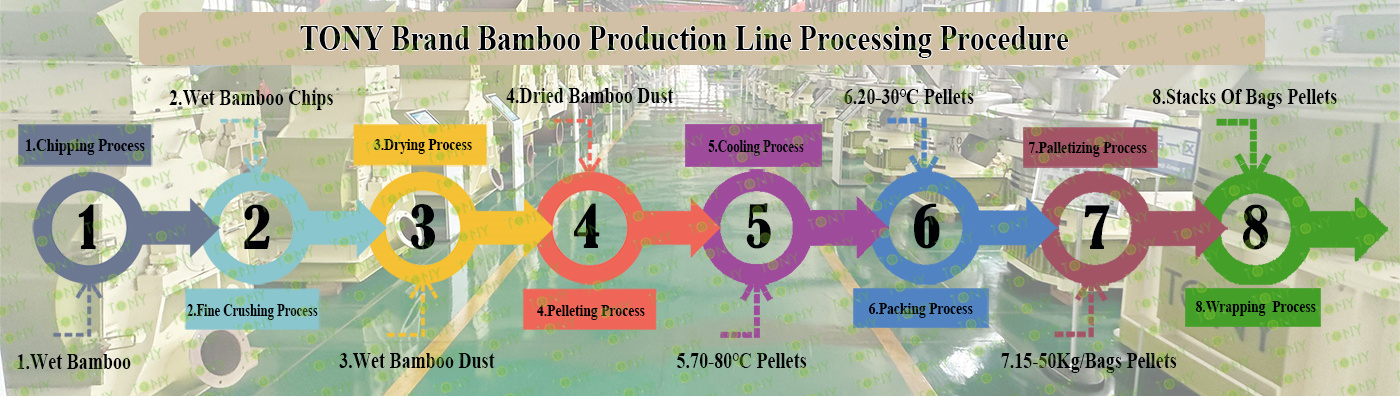

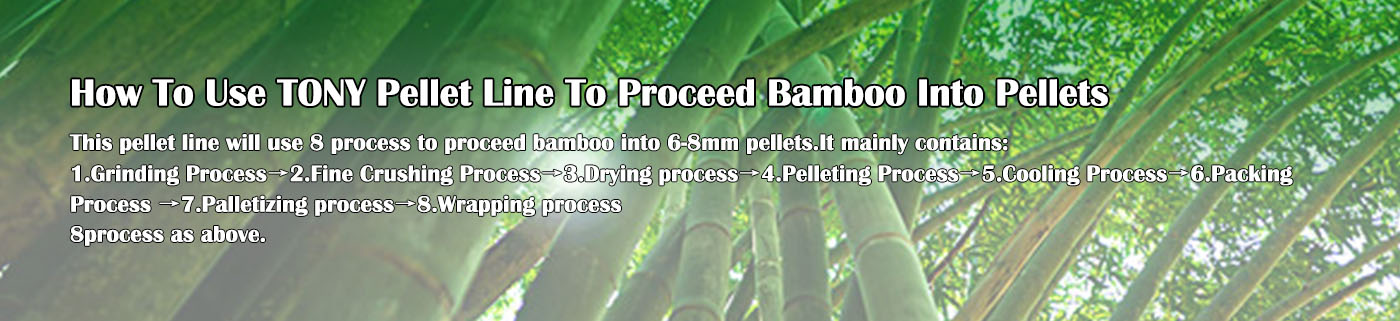

5.Process: 1.Grinding Process→2.Fine Crushing Process→3.Drying process→4.Pelleting Process→5.Cooling Process→6.Packing Process →7.Palletizing process→8.Wrapping process

6.Main Machine: Bamboo chipper, Hammer Mill, Rotary Drum Dryer, TONY Pellet Machine, Pellets Cooler, Packing Machine, Palletizer, Wrapping Machine And Belt Conveyors.

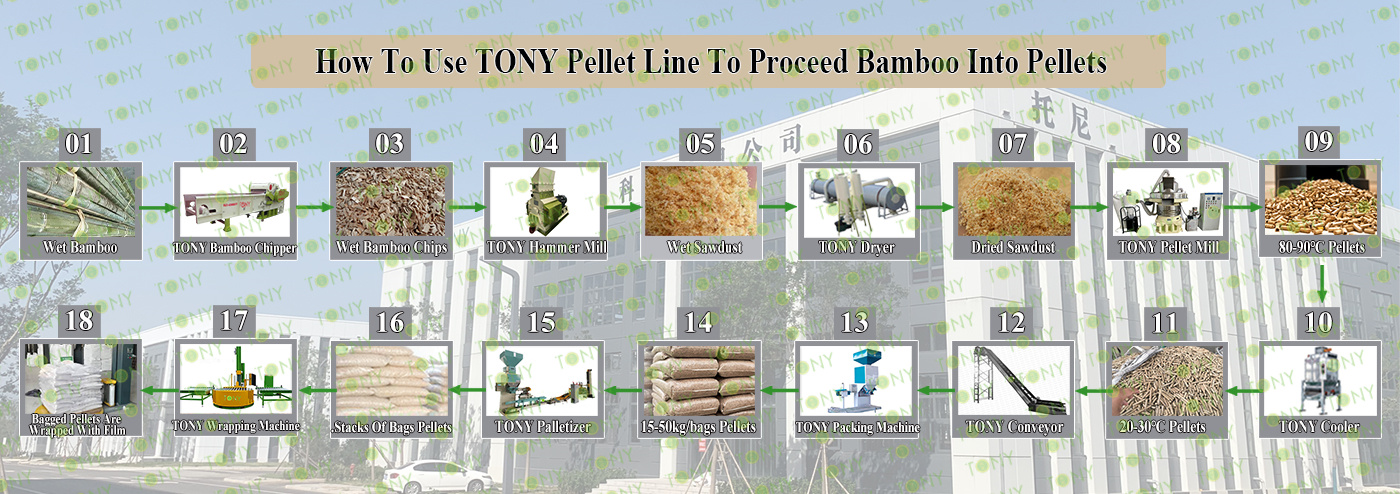

How to use TONY pellet line to proceed from bamboo into pellets?

It mainly contains the following steps and machines as following:

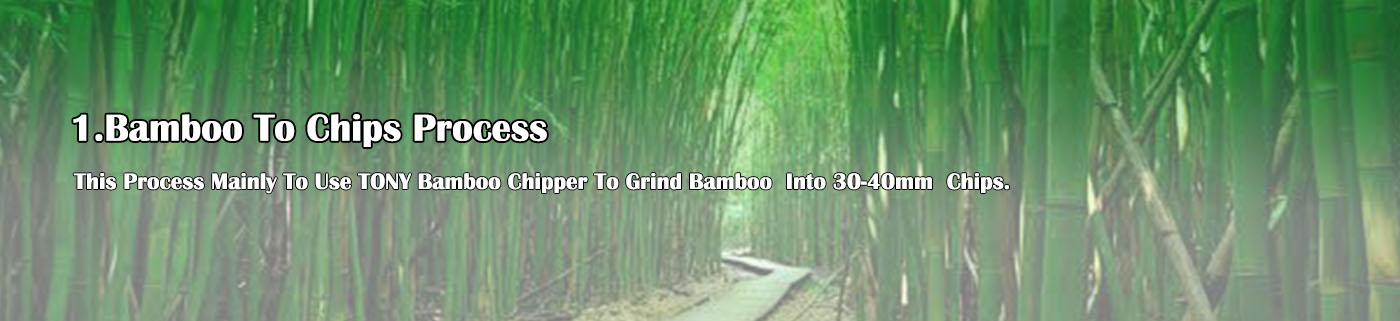

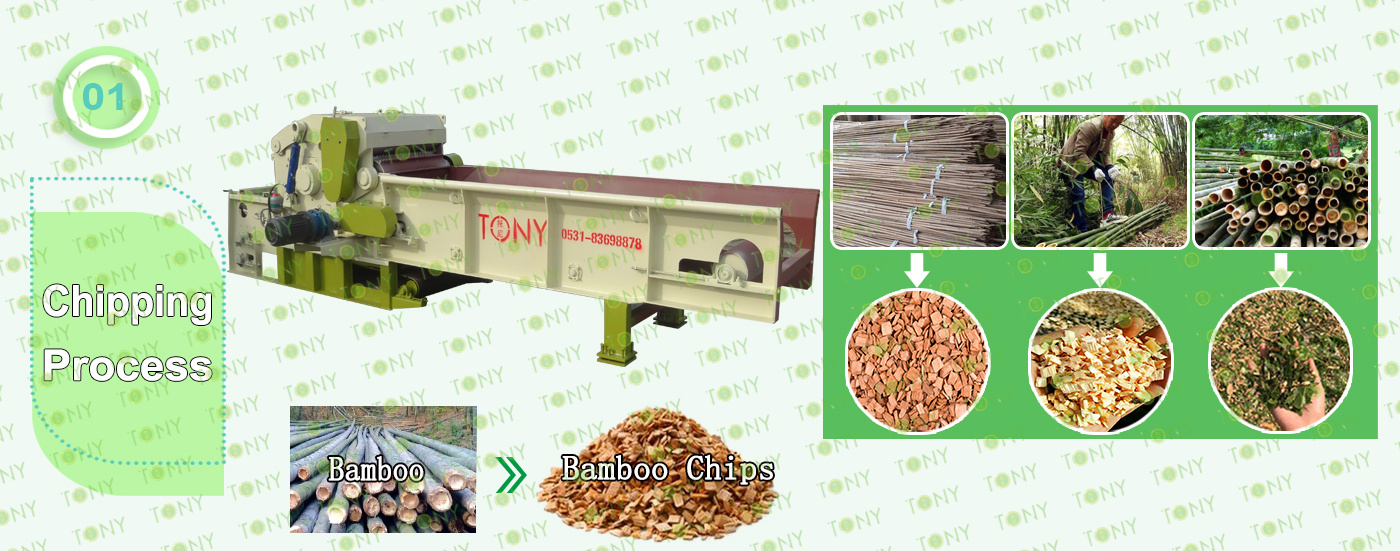

1.To Use TONY bamboo Chipper To Grind bambooWith Width 1M Into 30-40mm Chips.

2.To Use TONY Hammer Mill To Crush 30-40mm Chips Into 8-14mm Sawdust.

3.To Use TONY Drum Dryer To Dry The Raw Material From 45% Moisture Content Into 15% Moisture Content.

4.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm.

5.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ to 20-30℃.

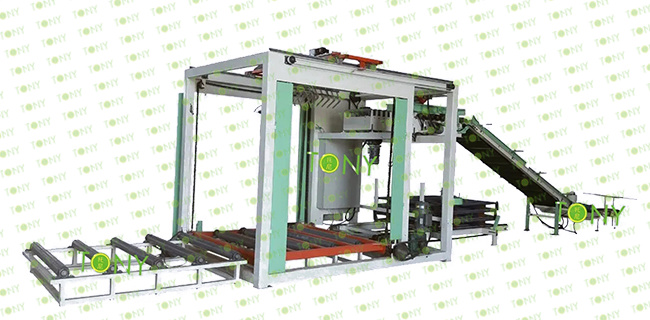

6.To Use TONY Semi-Auto Packing Machine To Packing Pellets To 15-50KG/Bags.

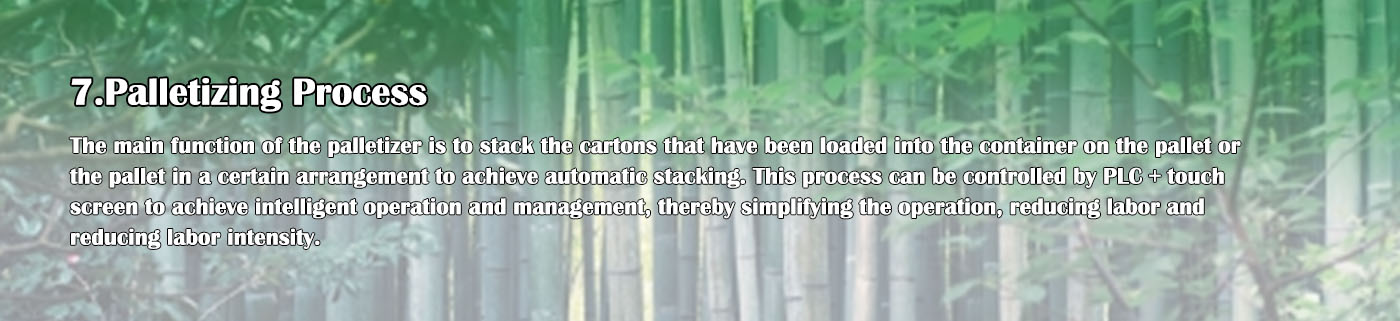

7.To Use TONY Palletizer To Place Product Packages On Pallets According To Certain Arrangement Codes And Stack Them Automatically.

8.To Use TONY Wrapping Mahince Wrap The Packaged Particles With Film.

You can contact TONY to get for more details information and quotation.

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some machines Can Be Custom Made By Customer According To Different Customer's Detailed Demand.Contact TONY For More

|

|

|

|

| Bamboo Chipper | High Efficient Hammer Mill | Drying Machine | Vertical Ring Die Pellet Machine |

|

|

|

|

| Cooler Separator | Semi-Auto Packing Machine | Palletizer | Wrapping Machine |

|

1.Chipping Process: A.This process is mainly used to grind the bamboo into bamboo chips with size 25-35mm. The finish bamboo chips size can be adjustable by changing different sizes of screeners. Main Parts: 1). TONY's new Comprehensive bamboo Chipper. 2). Feed and unload belt frequency control to prevent card material 3). Hydraulic system control for more thickness of raw materials 4). Electronic control system allows the equipment to be used normally 5). Contact TONY for more details with quotation. |

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal |

|

1. High dust removal efficiency 2. Large filter load,Low energy consumption 3. Low compressed air consumption 4.Simple circuit and strong adaptability |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure,Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

After The Gringding Process, About the Raw Materials, You Can Choose To Dump The Raw Materials On The Ground Or Add A Silo.

| The Pros and Cons of put the raw materials on the ground | 1. Low machine cost 2. Increased labor 3. Polluted the environment |

| The Pros and Cons of add a silo | 1. High machine cost 2. Reduce labor 3. Protect the environment |

If You Choose Increase A Storage Process, There Are Two Kinds Of Silo You Can Choose.

|

|

| Bamboo Chips Storage Bin | Large Galvanized Hydraulic Silo |

| Ordinary iron plate auger warehouse can accommodate 5-30 cubic meters. If it is larger than 30 cubic meters, it is easy to get stuck or blocked. | Large galvanized hydraulic silo, can hold 40-300 cubic meters, never blocked |

|

2.Bamboo Chips Fine Crushing Process: A. This process is mainly used to Crush 30-40mm bamboo Chips Into 8-14mm Sawdust. B. Capacity:According to the customer's demand.

Main Parts: 1). TONY High Effective Hammer Mill. 2). Galvanized Dust Collector. 3). Sawdust Transportation Fan Blower. 4). Cyclone With Airlock. 5). Electrical Cabinets. |

About Dust Collector

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal |

|

1. It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2. Automatic clearance mechanism. 3. Galvanized material, not easy to corrosion damage. 4. Limited by the temperature of the gas. |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure,Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

After The Crushing Process, About The Raw Materials,You Can Choose To Dump The Raw Materials On The Ground Or Add A Silo.

| The Pros and Cons of put the raw materials on the ground | 1. Low machine cost 2. Increased labor 3. Polluted the environment |

| The Pros and Cons of add a silo | 1. High machine cost 2. Reduce labor 3. Protect the environment |

If You Choose Increase A Storage Process,There Are Two Kinds Of Silo You Can Choose.

|

|

| Sawdust Auger Silo | Large Galvanized Hydraulic Silo |

| Ordinary iron plate auger warehouse can accommodate 5-30 cubic meters. If it is larger than 30 cubic meters, it is easy to get stuck or blocked. | Large galvanized hydraulic silo, can hold 40-300 cubic meters, never blocked |

|

3. Bamboo Sawdust Drying Process: A. This process is mainly used to dry the bamboo sawdust from 55% to 10-15%. B. Capacity:According to customer's demand. TONY Dryer use spiral tube material, which has higher heart rate and is not easy to deform. Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts: 1). TONY's Rotary Drum Dryer Main Body.(Reducers With Motors and Pips.) 2). TONY's Hot Stove. 3). Fan Blower+Cyclone With Airlock. |

Three Types Of Dust Removal Equipment

|

|

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal | Water Sray Dust Collector | Wet Electrostatic Precipitator |

|

1. It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2. Automatic clearance mechanism. 3. Galvanized material, not easy to corrosion damage. 4. Limited by the temperature of the gas. |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure,Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

1. Water Spray Dust Removal is suitable for high pressure and cooling process 2. Small resistance, easy to operate 3. Slightly larger volume 4. Large water consumption, power consumption |

1. Wet Electrostatic Precipitatoris the use of ionization effect 2. Steel structure is not easy to damage 3. Suitable for large-scale projects, the larger the amount of gas treated, the more obvious its economic role 4. High installation accuracy is required |

After The Drying Process,About The Raw Materials,You Can Choose To Dump The Raw Materials On The Ground Or Add A Silo.

| The Pros and Cons of put the raw materials on the ground | 1. Low machine cost 2. Increased labor 3. Polluted the environment |

| The Pros and Cons of add a silo | 1. High machine cost 2. Reduce labor 3. Protect the environment |

If You Choose Increase A Storage Process,There Are Two Kinds Of Silo You Can Choose.

|

|

| Ordinary Iron Silo | Large Galvanized Hydraulic Silo |

| Ordinary iron plate auger silo can accommodate 5-30 cubic meters. If it is larger than 30 cubic meters, it is easy to get stuck or blocked. | 1. High machine cost 2. Reduce labor 3. Protect the environment |

Before Pelleting Process, You Can Choose Two Kinds Of Silo On The Pellet Machine.

|

|

| Circulation Auger Bin | Galvanized Hydraulic Silo |

| Its performance advantage lies in the ability to dynamically operate materials, continuously convey materials, and achieve better conveying effects for materials with poor fluidity. | The performance characteristics of this silo are mainly its outstanding storage function, and the unloading process can be achieved through hydraulic control with more precise operation. |

|

4.Pelleting Process: A. This process is mainly used to product pellets with φ6-8mm. B. Capacity: According to customer's demand.

Main Parts: 1). TONY's new Vertical Ring Die Pellet Machine. 2). Cyclone And Bags Dust Collectors. 3). Bearings Automatic Lubrication System. 4). Electrical Cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

About Dust Collector

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal |

|

1.It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2.Automatic clearance mechanism. 3.Galvanized material, not easy to corrosion damage. 4.Limited by the temperature of the gas. |

1.Suitable for dealing with moderate air volume, low dust concentration occasions. 2.Simple structure, Physical filtration. 3.The maintenance is complicated, and the bag needs to be cleaned regularly. 4.High dust removal resistance. |

5.Cooling Process:

This process is mainly used to cool pellets from 80-90℃ to 20-30℃

Main Parts:

(1). TONY's new Galvanized Cooler Separator With Vibrating Screen.

(2). Cyclone And Bags Dust Collectors.

(3). Fan Blower.

(4). Connect Pipes.

After Cooling Process,You Can Choose Packing Machine To Pack Or Put The Pellets Into Large Galvanized Hydraulic Silo For Temporary Storage.

| There Are Three Kinds Of Packing Machine You Can Choose |

||

| Semi-Automatic Packing Machine | Automatic Packing Machine | Ton Packing Machine |

|

|

|

|

Generally speaking, a Automatic packaging machine packaging scale refers to a Automatic packaging scale, that is, manual bagging, and after weighing, the material falls into the packaging bag and is folded and sealed or directly sealed or heat-sealed. The characteristics of a Automatic packaging scale are generally that weighing is automatic and bagging is manual, so it is called a Automatic packaging scale. |

Different from semi-automatic packaging scales, fully automatic packaging scales are usually also called fully automatic packaging machines or fully automatic packaging scales. All process steps are completed automatically by machines and equipment: automatic sorting of packaging bags, automatic bagging by the Column, automatic weighing of materials, automatic error detection and correction during the process, automatic filling of materials into packaging bags, automatic folding and sealing of packaging bags. The entire process is automatically controlled by PLC and no human intervention is required. |

If the output is relatively large, you should choose our ton packing machine, which can carry out packaging operations continuously and stably. The packaging speed of a ton packing machine is much higher than manual packaging, which can greatly shorten the packaging time and improve production efficiency. |

6.Packing Process:

This process is mainly used to pack pellets to 1Ton/Bags.

Main Parts:

(1). TONY's new Packing Machine.

(2). Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen.

(3). Bags Transportation Conveyors.

(4). Feeding Inlet Silo .

(5). Electrical Cabinets.

In addition to packaging the pellets, you can also choose to store the biomass pellets in Large Galvanized Hydraulic Silo. When there is an order for biomass pellets, they can be transported directly from the pellet silo to a vehicle or container.

|

Advantages and disadvantages of placing in large silos Advantages: 1. Large Storage Capacity: Large silos can store a large amount of biomass pellets, suitable for large-scale production and storage. 2. Convenient Management: Large silos can be centrally managed, which is convenient for fuel use and scheduling. 3. Reduce the number of transportations: Large-scale storage can reduce the number of transportations and reduce logistics costs. Disadvantages: 1. Large Investment: The construction and management of large silos require large fixed equipment and site investments. 2. Complex Management: Scientific and rigorous management and protection are required to ensure the storage and control performance of fuel. 3. High Environmental Requirements: Large silos need to have good ventilation, moisture-proof, waterproof and other conditions. |

|

|

| High Level Palletizer | Column Palletizer |

Comparison of two palletizers

Compared with the two types of palletizers, the Column palletizer is more convenient and flexible to install. It can stack finished packaging bags (packaging boxes) of several specifications and varieties at the same time, reaching the finished products from 3 conveyor lines. The high-level palletizer can only stack packaging bags of one specification or one conveyor line.

In terms of stacking effect, the high-level palletizer has great advantages, and the stacking shape is neat and beautiful, and the packaging bags are not easy to slide. One weakness of the Column palletizer's manipulator is that if the level and posture of the incoming packaging bags are not very accurate, it is easy to scratch them.

|

1. During the arduous process of storage and transportation, goods are extremely highly susceptible to being contaminated by dust. This situation truly poses a remarkably significant challenge. Dust has a tendency to firmly adhere to the surface of the goods, which can potentially have a substantial impact on both their quality and appearance. For instance, in the case of delicate electronic components, dust contamination can lead to malfunctions and a diminished aesthetic appeal. 2. However, thankfully, the film wrapping machine comes to the rescue by offering a highly practical and effective solution. By meticulously wrapping film on the surface of the goods, it is capable of effectively blocking dust from reaching the goods. This action ensures that the goods remain impeccably clean. 3. This is of utmost importance as it not only helps maintain the integrity of the goods in a comprehensive manner but also significantly enhances their presentation. A well-presented product is more likely to attract customers and thereby enhances its marketability. |

|

2025 Tony Machinery - All Rights Reserved. Map