TONY Design Feed Production Line Specification

1. Reduce Waste: Feed Pellet can be mixed with forage and other concentrated feed to reduce forage waste and improve utilization.

2. Easy To Store And Transport: Feed Pellet is small in size, easy to store and transport, and reduces space occupation.

3. Avoid Powder Stratification: Feed Pellet can avoid powder stratification and ensure the uniformity of feed.

4. Increase Fluidity: Feed Pellet is easier to flow than powder, which is convenient for automated feeding.

5. Improve Digestibility: Feed Pellet is easier to digest and has a high digestibility after being matured and made into pellets.

The process of making feed pellets usually includes the following steps:

1. Raw Material Preparation: Select raw materials suitable for making feed pellets, such as grains, beans, grass powder, etc., and ensure the quality and freshness of the raw materials.

2. Raw Material Crushing: Crush the raw materials to make them into a particle size suitable for processing. This helps to improve the mixing uniformity and digestion and absorption rate of the feed.

3. Ingredient Mixing: According to the feed formula, the crushed raw materials are accurately batched and mixed with other additives (such as vitamins, minerals, proteins, etc.). Ensure that the various ingredients are evenly distributed.

4. Modulation: Add an appropriate amount of water or steam to the mixed raw materials for modulation to improve the plasticity and adhesion of the raw materials.

5. Granulation: The modulated raw materials are extruded and cut through the feed pellet machine to make feed pellets of the required size and shape.

6. Cooling: The temperature of the newly made feed pellets is high and needs to be cooled to reduce the temperature and increase the hardness and stability of the pellets.

7. Screening: Screen the cooled feed pellets to remove oversized or undersized particles to ensure the quality and consistency of the product.

8. Packaging: The screened feed pellets are packaged for storage, transportation and sale.

It should be noted that the specific production process may vary depending on factors such as feed type, production scale and equipment conditions. In actual operation, adjustments and optimizations should be made according to specific circumstances to ensure the quality and production efficiency of feed pellets.

The working principle of making pellets from feed varies depending on the type of feed pellet machine. The following are the working principles of several common feed pellet machines:

Flat Die Pellet Machine: The main components of a flat die pellet machine are a flat round steel die and a set of (2-4) freely rotating grooved rollers. The raw material falls from top to bottom into the gap between the rollers, is pressed into the die hole by the rotating rollers, and the long cylindrical object is extruded from below the die hole and cut into pellets by the cutter. There are three drive modes: drive roller, drive flat die, and double drive.

Ring Die Pellet Machine: The die of the ring die pellet machine is a porous cylinder that rotates through the transmission. There are 2-4 grooved free-rotating or driven self-rotating rollers in the cylinder. The raw material enters the steel die, that is, it is pressed into the workshop by the rotating roller, embedded in the die hole, extruded from the outer wall of the steel die, and cut into cylindrical pellets by the cutter. The key point of the machine is: on the ring die and the pressure roller, the linear speed is equal everywhere. There is no additional friction, and all the pressure is used for pelletizing, so the efficiency is high.

1.Project Name: Feed Pellet Line

2.Raw Material: Straw, Soybean Meal, Alfalfa, Wheat Bran, Rice Bran.

3.Moisture Of Raw Material: 45%

4.Capcity: According to the customer's demand.

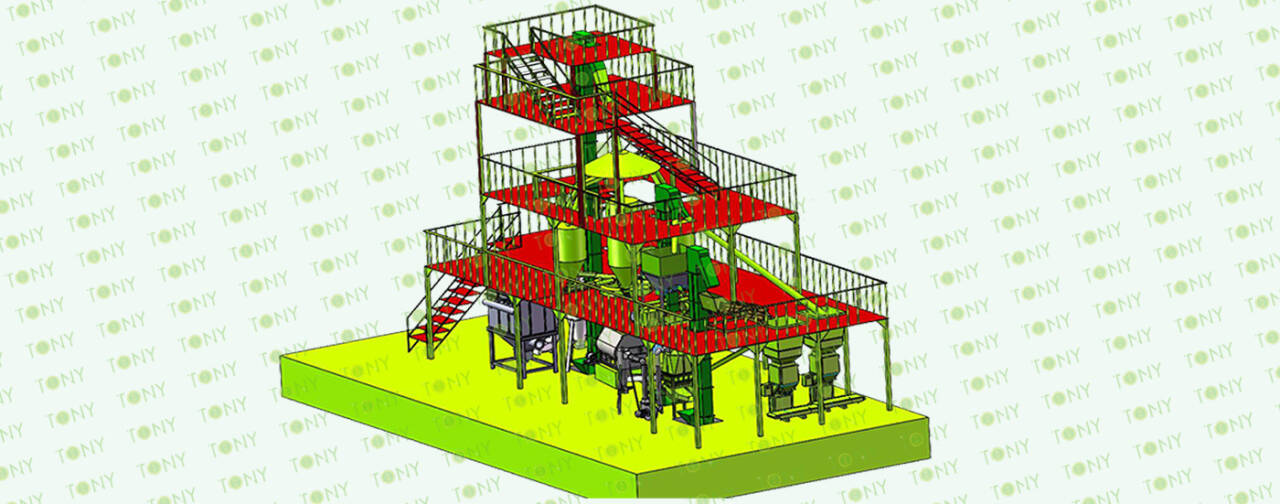

5.Proecss:1.Grinding Process→2.Fine Crushing Process→3.Drying process→4.Pelleting Process→5.Cooling Process→6.Packing Process →7.Palletizing process→8.Wrapping process

6.Main Machine: Feed Rotary Cutter, Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine,Pellets Cooler,Packing Machine,Palletizer,Wrapping Machine And Belt Conveyors.

TONY Brand Feed pellet manufacturing plant can process Straw, soybean meal, alfalfa, wheat bran, rice bran.It is widely used in poultry feed, cattle, sheep and horse feed.

1.Capacity: According to the customer's demand.

2.Raw materials: Straw, soybean meal, alfalfa, wheat bran, rice bran.

3.Moisture Content: 45%

4.Application: All kinds of feed materials.

5.Finished pellets Markets: Aquaculture, Animal Husbandry

How to use TONY pellet line to proceed from Feed into pellets?

It mainly contains the following steps and machines as following:

1.To Use TONY Feed Rotary Cutter To Grind Raw Materials Into 30-40mm Chips.

2.To Use TONY Hammer Mill To Crush 30-40mm Chips Into 8-14mm Sawdust.

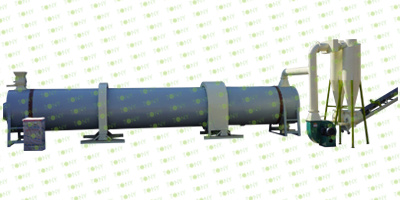

3.To Use TONY Drum Dryer To Dry The Sawdust From 45% Moisture Content Into 15% Moisture Content.

4.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm.

5.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ to 20-30℃.

6.To Use TONY Semi-Auto Packing Machine To Packing Pellets To 15-50KG/Bags.

7.To Use TONY Palletizer To Place Product Packages On Pallets According To Certain Arrangement Codes And Stack Them Automatically.

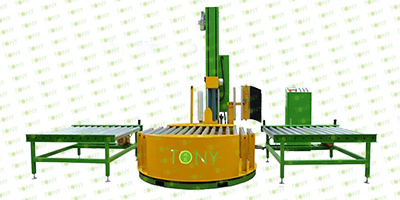

8.To Use TONY Wrapping Mahince Wrap The Packaged Particles With Film.

You can contact TONY to get for more details information and quoation.

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some machines Can Be Custom Made By Customer According To Different Customer's Detailed Demand.Contact TONY For More Details With Quotation And Layout.

|

|

|

|

| Feed Rotary Cutter | High Effective Hammer Mill | Drying Machine | Vertical Ring Die Pellet Machine |

|

|

|

|

| Cooler Separator | Packing Machine | Palletizer | Wrapping Machine |

|

1.Chipping Process: A.This process is mainly used to grind the raw materiasl with size 25-35mm. The finish chips size can be adjustable by changing different sizes of screeners. Main Parts: (1). TONY's new Feed Rotary Cutter. (2). Feed and unload belt frequency control to prevent card material. (3). Hydraulic system control for more thickness of raw materials. (4). Electronic control system allows the equipment to be used normally. (5). Contact TONY for more details with quotation. |

| About Dust Collector | |

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal |

|

1. It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2. Automatic clearance mechanism. 3. Galvanized material, not easy to corrosion damage. 4. Limited by the temperature of the gas. |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure,Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

| After The Gringding Process,About The Raw Materials,You Can Choose To Dump The Raw Materials On The Ground Or Add A Silo. | |

| The Pros and Cons of put the raw materials on the ground | 1. Low machine cost 2. Increased labor 3. Polluted the environment |

| The Pros and Cons of add a silo | 1. High machine cost 2. Reduce labor 3. Protect the environment |

| If You Choose Increase A Storage Process,There Are Two Kinds Of Silo You Can Choose. | |

|

|

| Feed Chips Storage Bin | Large Galvanized Hydraulic Silo |

| Ordinary iron plate auger warehouse can accommodate 5-30 cubic meters. If it is larger than 30 cubic meters, it is easy to get stuck or blocked. | Large galvanized hydraulic silo, can hold 40-300 cubic meters, never blocked |

|

2.Chips Fine Crushing Process: A. This process is mainly used to crush 30-40mm chips into 8-14mm sawdust. B. Capacity: According to the customer's demand.

Main Parts: (1). TONY High Effective Hammer Mill. (2). Galvanized Dust Collector. (3). Sawdust Transportation Fan Blower. (4). Cyclone With Airlock. (5). Electrical Cabinets. |

| About Dust Collector | |

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal |

|

1. It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2. Automatic clearance mechanism. 3. Galvanized material, not easy to corrosion damage. 4. Limited by the temperature of the gas. |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure,Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

| After The Crushing Process,About The Raw Materials,You Can Choose To Dump The Raw Materials On The Ground Or Add A Silo. | |

| The Pros and Cons of put the raw materials on the ground | 1. Low machine cost 2. Increased labor 3. Polluted the environment |

| The Pros and Cons of add a silo | 1. High machine cost 2. Reduce labor 3. Protect the environment |

| If You Choose Increase A Storage Process, There Are Two Kinds Of Silo You Can Choose. | |

|

|

| Sawdust Auger Silo | Large Galvanized Hydraulic Silo |

| Ordinary iron plate auger warehouse can accommodate 5-30 cubic meters. If it is larger than 30 cubic meters, it is easy to get stuck or blocked. | Large galvanized hydraulic silo, can hold 40-300 cubic meters, never blocked |

|

3. Sawdust Drying Process: A. This process is mainly used to dry the sawdust from 55% to 10-15%. B. Capacity: According to customer's demand. TONY dryer use spiral tube material, which has higher heart rate and is not easy to deform. Unlike other manufacturers with iron plate splicing welding, very easy to deformation. Main Parts: (1). TONY's Rotary Drum Dryer Main Body.(Reducers With Motors and Pips.) (2). TONY's Hot Stove. (3). Fan Blower+Cyclone With Airlock. |

| Three Types Of Dust Removal Equipment | |||

|

|

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal | Water Sray Dust Collector | Wet Electrostatic Precipitator |

|

1. It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2. Automatic clearance mechanism. 3. Galvanized material, not easy to corrosion damage. 4. Limited by the temperature of the gas. |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure,Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

1. Water Spray Dust Removal is suitable for high pressure and cooling process 2. Small resistance, easy to operate 3. Slightly larger volume 4. Large water consumption, power consumption |

1. Wet Electrostatic Precipitatoris the use of ionization effect 2. Steel structure is not easy to damage 3. Suitable for large-scale projects, the larger the amount of gas treated, the more obvious its economic role 4. High installation accuracy is required |

| After The Drying Process, About The Raw Materials,You Can Choose To Dump The Raw Materials On The Ground Or Add A Silo. | |

| The Pros and Cons of put the raw materials on the ground | 1. Low machine cost 2. Increased labor 3. Polluted the environment |

|

The Pros and Cons of add a silo |

1. High machine cost 2. Reduce labor 3. Protect the environment |

| If You Choose Increase A Storage Process, There Are Two Kinds Of Silo You Can Choose. | |

|

|

| Ordinary Iron Silo | Large Galvanized Hydraulic Silo |

| Ordinary iron plate auger silo can accommodate 5-30 cubic meters. If it is larger than 30 cubic meters, it is easy to get stuck or blocked. | 1. High machine cost 2. Reduce labor 3. Protect the environment |

| Before Pelleting Process,You Can Choose Two Kinds Of Silo On The Pellet Machine. | |

|

|

| Circulation Auger Bin | Galvanized Hydraulic Silo |

| Its performance advantage lies in the ability to dynamically operate materials, continuously convey materials, and achieve better conveying effects for materials with poor fluidity. | The performance characteristics of this silo are mainly its outstanding storage function, and the unloading process can be achieved through hydraulic control with more precise operation. |

|

4.Pelleting Process: A. This process is mainly used to product pellets with φ6-8mm. B. Capacity:According to customer's demand.

Main Parts: (1). TONY's new Vertical Ring Die Pellet Machine. (2). Cyclone And Bags Dust Collectors. (3). Bearings Automatic Lubrication System. (4). Electrical Cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

| About Dust Collector | |

|

|

| Galvanized Pulsed Dust Collector | Bag Dust Removal |

|

1. It is more suitable for dealing with large air volume, high dust concentration and complex dust properties. 2. Automatic clearance mechanism. 3. Galvanized material, not easy to corrosion damage. 4. Limited by the temperature of the gas. |

1. Suitable for dealing with moderate air volume, low dust concentration occasions. 2. Simple structure, Physical filtration. 3. The maintenance is complicated, and the bag needs to be cleaned regularly. 4. High dust removal resistance. |

5.Cooling Process:

This process is mainly used to cool pellets from 80-90℃ to 20-30℃

Main Parts:

(1). TONY's new Galvanized Cooler Separator With Vibrating Screen.

(2). Cyclone And Bags Dust Collectors.

(3). Fan Blower.

(4). Connect Pipes.

| After Cooling Process,You Can Choose Packing Machine To Pack Or Put The Pellets Into Large Galvanized Hydraulic Silo For Temporary Storage. | ||

| There are three kinds of packing machine you can choose. | ||

| Semi-Automatic Packing Machine | Automatic Packing Machine | Ton Packing Machine |

|

|

|

| Generally speaking, a Automatic packaging machine packaging scale refers to a Automatic packaging scale, that is, manual bagging, and after weighing, the material falls into the packaging bag and is folded and sealed or directly sealed or heat-sealed. The characteristics of a Automatic packaging scale are generally that weighing is automatic and bagging is manual, so it is called a Automatic packaging scale. | Different from semi-automatic packaging scales, fully automatic packaging scales are usually also called fully automatic packaging machines or fully automatic packaging scales. All process steps are completed automatically by machines and equipment: automatic sorting of packaging bags, automatic bagging by the Column, automatic weighing of materials, automatic error detection and correction during the process, automatic filling of materials into packaging bags, automatic folding and sealing of packaging bags. The entire process is automatically controlled by PLC and no human intervention is required. | If the output is relatively large, you should choose our ton packing machine, which can carry out packaging operations continuously and stably. The packaging speed of a ton packing machine is much higher than manual packaging, which can greatly shorten the packaging time and improve production efficiency. |

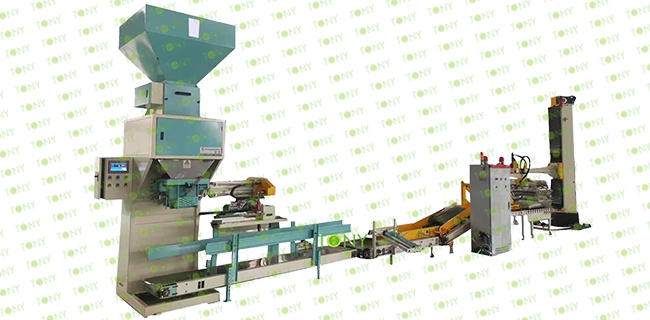

6.Packing Process:

This process is mainly used to pack pellets

Main Parts:

(1). TONY's new Packing Machine.

(2). Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen.

(3). Bags Transportation Conveyors.

(4). Feeding Inlet Silo .

(5). Electrical Cabinets.

In addition to packaging the pellets, you can also choose to store the biomass pellets in Large Galvanized Hydraulic Silo. When there is an order for biomass pellets, they can be transported directly from the pellet silo to a vehicle or container.

|

Advantages and disadvantages of placing in large silos Advantages: 1. Large Storage Capacity: Large silos can store a large amount of biomass pellets, suitable for large-scale production and storage. 2. Convenient Management: Large silos can be centrally managed, which is convenient for fuel use and scheduling. 3. Reduce The Number Of Transportations: Large-scale storage can reduce the number of transportations and reduce logistics costs. Disadvantages: 1. Large Investment: The construction and management of large silos require large fixed equipment and site investments. 2. Complex Management: Scientific and rigorous management and protection are required to ensure the storage and control performance of fuel. 3. High Environmental Requirements: Large silos need to have good ventilation, moisture-proof, waterproof and other conditions. |

|

|

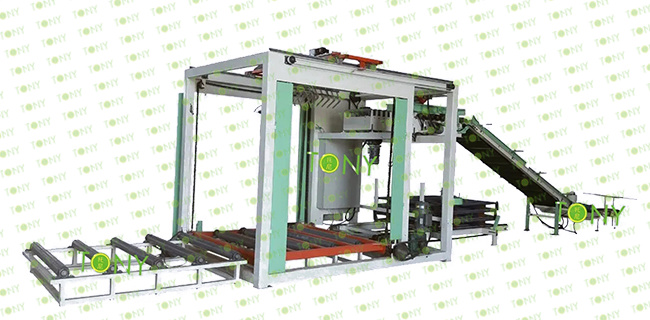

| High Level Palletizer | Column Palletizer |

Comparison Of Two Palletizers

Compared with the two types of palletizers, the Column palletizer is more convenient and flexible to install. It can stack finished packaging bags (packaging boxes) of several specifications and varieties at the same time, reaching the finished products from 3 conveyor lines. The high-level palletizer can only stack packaging bags of one specification or one conveyor line.

In terms of stacking effect, the high-level palletizer has great advantages, and the stacking shape is neat and beautiful, and the packaging bags are not easy to slide. One weakness of the Column palletizer's manipulator is that if the level and posture of the incoming packaging bags are not very accurate, it is easy to scratch them.

|

1. During storage and transportation, goods are highly vulnerable to dust. It's a significant challenge as dust sticking to the goods can harm both quality and appearance. For delicate electronic components, it may even cause malfunctions and reduce aesthetics. 2. Fortunately, the film wrapping machine provides an effective solution. Wrapping film carefully around the goods can block dust, keeping them clean. 3. This is crucial as it safeguards the goods' integrity and boosts their appearance. Attractive products draw more customers and enhance market competitiveness. |

|

SHANDONG TONY ENVIRONMENTAL PROTECTION SCI-TECH CO.,LTD is an integrated enterprise specializing in developing, anufac-turing and international trade of pellet equipments for over 20 years.

Main products are biomass ring die and flat die pellet machine,biomass pellet line, feed pellet machine, drying, crushing equipments,cooling and ton packing machine.

Looking to the future, we sincerely hope to establish a long-term reliable cooperation relationship with clients all over the world!

TONY is a professional manufacture for biomass pellet machine,pellet production line in China for over twenty years.Main products are biomass ring die and flat die pellet machine,biomass pellet line, feed pellet machine, drying, crushing equipments,cooling and ton packing machine.

The new pellet machine adopts stainless steel material ,with high capacity and lower consumption ,which is highly pressed by domestic and abroad all over the world.

2025 Tony Machinery - All Rights Reserved. Map