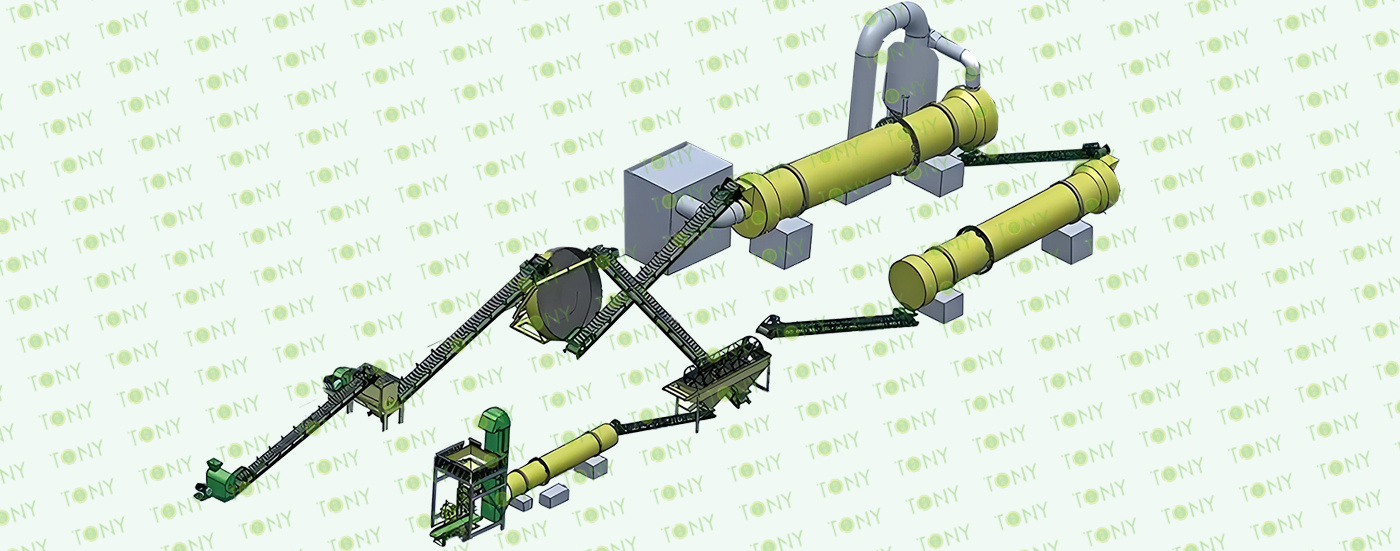

TONY Design Orignic Fertilizer Pellet Production Line Specification

The organic fertilizer production line is a set of modern production equipment integrating biotechnology and mechanical processing, designed to convert agricultural waste into valuable organic fertilizer. This production line not only helps reduce environmental pollution, but also improves soil fertility and crop yield and quality.

With the country's emphasis on the sustainable development and environmental protection of agriculture, the organic fertilizer production line has broad application prospects in the market. It can not only meet the market's demand for organic fertilizers, but also promote the resource utilization of agricultural waste and promote the development of ecological agriculture.

Organic fertilizer production line can not only provide comprehensive nutrition for crops, but also have long fertilizer efficiency, help to improve soil physical and chemical properties and biological activity, and is the main nutrient for green food production. In addition, the production line has the advantages of less investment, fast recovery, economic and environmental protection.

Countries Suitable For Setting Up Complete Orignic Fertilizer Pellet Plant Include:

Organic fertilizer is widely used in agricultural production and aquaculture, including the following aspects:

1. Improve The Soil And Cultivate Fertilizer

After the soil is applied by organic fertilizer, it can effectively improve the physical and chemical properties and biological characteristics of the soil, mature the soil, enhance the soil's fertilizer, fertilizer, supply and buffer ability, and create good soil conditions for the growth of crops

2. Increase Production And Improve Quality

Organic fertilizers are rich in organic matter and various nutrients, which can provide comprehensive nutrition for crops. In addition, microbial activity in organic fertilizers can promote the growth of crops and improve the quality of agricultural products

3. Improve The Utilization Of Fertilizers

The reasonable cooperation of organic fertilizer and fertilizer can be promoted to each other, which is conducive to crop absorption and improves the utilization rate of fertilizers. Organic acid in organic fertilizers can also promote the dissolution of mineral nutrients in soil and fertilizers

4. Promote The Improvement Of Water Quality And Fish Production Of Aquaculture

In aquaculture, the use of organic fertilizers scientifically and reasonably can promote the improvement of water quality and increase the production of fish. It should be noted that when using organic fertilizer, the amount of fertilization must be reasonably determined and ensured that organic fertilizer has been rotten and fermented.

5. Reduce Environmental Pollution

Reasonable use of organic fertilizer can reduce environmental pollution and reduce investment in chemical fertilizer. For example, organic fertilizer can adsorb and chelate and toxic metal cations, increase the fixation of arsenic, thereby reducing soil and water pollution

It can be seen through the above analysis that organic fertilizer plays an important role in agricultural production and environmental protection. Reasonable use of organic fertilizers can not only improve crop yield and quality, but also improve the soil environment and promote the development of ecological agriculture.

1. Easy To Apply

(1) Easy To Apply: granular organic fertilizer application is more convenient, especially in the field operations, it is not easy to be blown by the wind, it is easier to sprinkle evenly

(2) Reduce Waste: granular fertilizer is not easy to be taken away during the application process, reducing the waste of fertilizer and increasing the utilization rate.

2. Improve Fertilizer Eeffect

(1) Add Inorganic Ingredients: In the process of making pellets organic fertilizer, some inorganic components can be added, such as trace elements, thereby improving the comprehensive effect of fertilizer.

(2) It Is Not Easy To Knot Mass: Granular organic fertilizer is not easy to be moisture and lumps, which makes fertilizer more stable during storage and transportation.

3. Production Process Advantage

(1) Simplify The Drying Process: Organic fertilizer is more difficult to remove during production, and dry treatment is needed. After the granular shape is made, high calories will be generated during the granular process. Just cool down and simplify the drying process.

(2) Improve Production Efficiency: The production process of pellets organic fertilizer is relatively complicated, but it can achieve large -scale production through the equipment and other equipment of the granulizer, improve production efficiency.

4. Use Flexibility

(1) Various Application Methods: Granular organic fertilizers can be used in various methods such as Sa Shi, Bida, Point, and Chong Shi. It is suitable for different crops and soil conditions.

(2) Adaptation To Large Field Crops: Granular organic fertilizer is widely used in large field crops due to its granular characteristics and lower investment costs, such as cotton, ginger, potatoes, yam, garlic, wheat, corn, etc.

5. Environmental Friendly

(1) Reduce Pollution: Granular organic fertilizer is not easy to fly during application, reducing pollution to the environment.

In summary, organic fertilizer into pellets not only improves the application efficiency and fertilizer effect of fertilizers, but also simplifies the production process, increases the flexibility of use, and is also more friendly to the environment. These advantages have widely used pellets organic fertilizers in modern agriculture.

1. You Can Add Inorganic Ingredients To Improve Fertilizer Effect

Some inorganic ingredients can be added to organic fertilizer pellets to improve the overall fertilizer effect of the fertilizer.

2. Easy To Use

The rules and large pellets size of organic fertilizer pellets make it more convenient during application. It is especially suitable for mechanical application, such as fertilizers, seeding machines, etc., which is convenient for control and quantitative application.

3. Adapt To Different Application Conditions

Organic fertilizer pellets are suitable for large -scale application, mechanical fertilization, and long -term fertilization.

4. Nutrition Release Speed Controlled

Due to the large pellets of organic fertilizer pellets and relatively slow internal nutrient release speed, plants need to be gradually decomposed and transformed in the soil. This makes the nutrient release more durable, which is conducive to the long -term growth of crops

5. Better Storage And Transportation

Organic fertilizer pellets have good liquidity and packaging stability due to the regular granules, and are more likely to store and transport.

6. Convenience In The Manufacturing Process

During the manufacturing process, organic fertilizer pellets can generate high calories by granularity. It can be completed by cooling, which is very convenient.

1. Equipment Investment And Cost Performance

The price of organic fertilizer pellets production line is determined by multiple factors, including equipment specifications and production capacity, high -quality steel and precision processing technology, brand and after -sales service. Although well -known brands may make the price slightly higher, they can provide better product quality and perfect after -sales service, and reduce the risk of later operation. The cost -effective consideration is not only the price of the equipment, but also the factors such as performance, durability, energy consumption and maintenance costs. Although an efficient, low -consuming, and easy -to -maintain equipment may have higher investment in the early stage, its long -term operating costs are lower and the production benefits are more significant, so it is more cost -effective.

2. The Advantages Of Organic Fertilizer Pellets

The advantage of organic fertilizer pellets is that its nutrients are comprehensive and contain a large amount of active substances such as and vitamin. It can increase the organic matter of the soil, improve the physical and chemical traits of the soil, and improve the ability of soil water storage, fertilizer, fertilizer, and drought -resistant waterlogging, thereby significantly increased production. Compared with chemical fertilizers, the fertilizer effect of organic fertilizers is more durable and rich in organic matter, which helps to cultivate fertilizer soil. Studies have shown that the combination of organic fertilizers and chemical fertilizers can achieve fertilizer and soil production, which can not only meet the crop's needs for nutrients, but also reduce the amount of chemical fertilizer and reduce environmental pollution.

3. Market Prospects And Development Trends

With the popularization of organic agriculture and the tightening of environmental protection policies, the demand for organic fertilizer pellets market will continue to expand. The development of organic fertilizer pellets production line has also been supported by national policies. It is expected that organic fertilizer pellets will gradually replace other fertilizers in the future and become an indispensable fertilizer in crop growth. Global organic fertilizer demand is expected to continue to grow, showing strong market potential and development prospects.

In summary, the organic fertilizer pellets production line not only has high cost performance in equipment investment, but also has a significant advantage in improving the quality of agricultural products, promoting soil health and environmental protection. With the continuous expansion of market demand and the advancement of technology, organic fertilizer pellets will play an increasingly important role in the sustainable agricultural development.

Here are some of the main benefits and advantages of organic fertilizer pellet:

1. Provide Comprehensive Nutrition:

Organic fertilizer pellets are rich in organic matter, humic acid, amino acids, nitrogen, phosphorus, potassium, calcium, sulfur, magnesium, zinc, copper, boron, manganese, iron and other nutrients, which can provide comprehensive nutrition for crops.

2. Improve Soil Structure:

Organic fertilizer pellets can improve soil physical properties, prevent soil compaction acidification and salinization, increase soil aggregate structure, thus making soil loose, which is conducive to water and fertilizer retention, ventilation and promote root development.

3. Enhance Plant Disease Resistance:

After the application of bio-organic fertilizer pellets, a variety of beneficial microorganisms produce and multiply in the roots of soil plants, compete with plant pathogens for nutrition, thus inhibiting the growth of plant pathogens and reducing the number of pathogens.

4. Improve Fertilizer Use Efficiency:

After application, organic fertilizer can improve the physical structure of the soil, and at the same time, it can release solidified nitrogen, phosphorus, potassium and other nutrients and then generate fertilizer easily absorbed by plants through coupling. It can also retain fertilizer in water while retaining water.

5. Promote Crop Growth:

Organic matter, humic acid and amino acid in organic fertilizer can continuously release nutrient elements and hormones required for plant growth through microbial activities, regulate plant growth, promote root development, help the absorption of nutrient elements, increase chlorophyll content, enhance photosynthesis, and achieve the purpose of combining quick effect and long-term effect and promoting stable agricultural yield and high yield.

6. Reduce Environmental Pollution:

Organic fertilizer will not cause environmental pollution, and the full use of change can play a role in protecting the environment.

7. Improve The Quality Of Agricultural Products:

Organic fertilizer contains a variety of trace elements, which can improve the quality of agricultural products.

1. Raw Material Pretreatment

Fermentation: Organic fertilizer raw materials usually include animal manure, crop residues, kitchen waste and other organic waste. These raw materials first need to be fermented to reduce pathogens and harmful substances, while improving the decomposition degree and fertilizer efficiency of organic matter. During fermentation, microbial activity generates heat that helps kill pathogens and weed seeds.

Crushing And Screening: The fermented raw material needs to be crushed and screened to remove large impurities and unevenpellet. This step ensures the smooth progress of subsequent processes and improves the uniformity and quality of the final product.

2. Mix With Ingredients

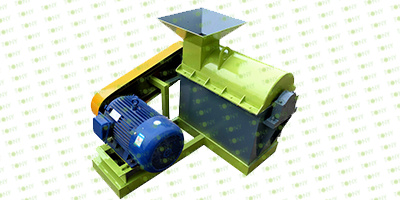

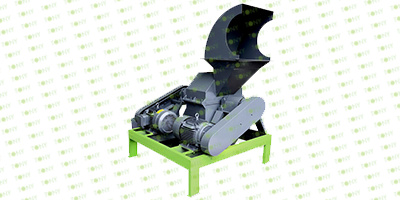

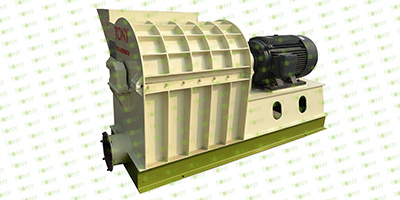

Mixing: The fermented raw materials and other necessary additives (such as inorganic components, trace elements, microbial agents, etc.) are mixed evenly in a certain proportion. The purpose of mixing is to ensure that the various ingredients are evenly distributed and improve the overall effect of the fertilizer.

Ingredients: According to the requirements of the formula, the proportion of each ingredient is precisely controlled to meet the national standard and market demand. The accuracy of the ingredients directly affects the quality and effect of the final product.

3. Granulation

Granulation Method: The granulation method of organic fertilizer mainly includes disk granulation, drum granulation, extrusion granulation and so on. The advantages of the disk granulator are uniform granulationpellet, stable performance, long service life, and suitable for the production of a variety of fertilizers.

Granulation Principle: In the process of granulation, raw materials are compressed intopellet under the action of mechanical forces. At the same time, the appropriate amount of water and the addition of the adhesive help to form a stablepellet structure. The granulatedpellet have a certain strength and shape, which is easy to transport and apply.

4. Dry

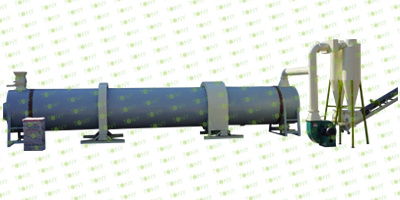

Drying Principle: The organic fertilizerpellet after granulation have a high water content (usually 50%-55%), and need to be dried to reduce the water content. During the drying process, hot air comes into contact with thepellet, causing the water to evaporate and be carried away. Drying equipment is usually a rotary dryer, through the interior is covered with lift sheet design, so that thepellet fully contact with the hot air, improve the drying efficiency.

Drying Requirements: According to different purposes of use, the moisture content requirements of dried organic fertilizerpellet are different. The moisture content of products for short-term sales should be less than 30%, and the moisture content of products for long-term storage or further processing should be less than 13%.

5. Cool

Cooling Principle: The temperature of dried organic fertilizerpellet is higher, and it is necessary to cool them to return to normal temperature. During the cooling process, thepellet are in contact with cold air, and the temperature is gradually reduced, while the strength and stability of thepellet are further improved.

Cooling Equipment: The rotary cooler is usually used, and the design of the lifting sheet is covered with the interior, so that thepellet are fully in contact with the cold air to achieve the cooling effect.

6. Sieve

Screening Purpose: The cooled organic fertilizerpellet may contain fine powder and largepellet, which need to be separated by the screening machine. The fine powder and largepellet are returned to the blender and crusher respectively for re-processing to ensure the uniformity and quality of the final product.

7. Packing

Packaging Requirements: Qualified organic fertilizerpellet need to be packaged after the above process. The packaging method can be manual weighing or automatic packaging machine to ensure that the weight and quality of each bag of products meet the standard.

The production of organic fertilizerpellet is a multi-step process, involving raw material pretreatment, mixing, granulation, drying, cooling and other links, with the attention to green ecological agriculture, the application prospect of organic fertilizerpellet will be more and more broad

1. Capacity: Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the Organic Fertilizer Pellet line customizes according to the actual production needs of customers

2. Raw Materials: Organic waste such as livestock and poultry feces, crops, kitchen waste and other organic waste

3. Humidity: The water content of organic fertilizers is high (usually 50%-55%), and dry treatment is required to reduce the moisture content

4. Uses: Various organic wastes

Suitable For Customers: Agricultural waste manufacturing enterprises such as livestock farms.

Food processing plants, industrial manufacturing enterprises such as paper mills, wood processing plants, tobacco processing plants, furfural plants, xylose plants, cotton processing plants, planting parks and fertilizer breeding parks, individual farmers and small farmers, professional organic fertilizer production enterprises

5. Finished Pellet Market: Use of field crops, Maintenance of flowers and lawns in landscaping, Soil improvement to improve the overall quality of the soil

1.Project Name: Organic Fertilizer Pellet Line

2.Raw Material: Organic waste such as livestock and poultry feces, crops, kitchen waste and other organic waste

3.Moisture Of Raw Material: Wet Type

4.Capacity: Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the organic fertilizer pellet line customizes according to the actual production needs of customers

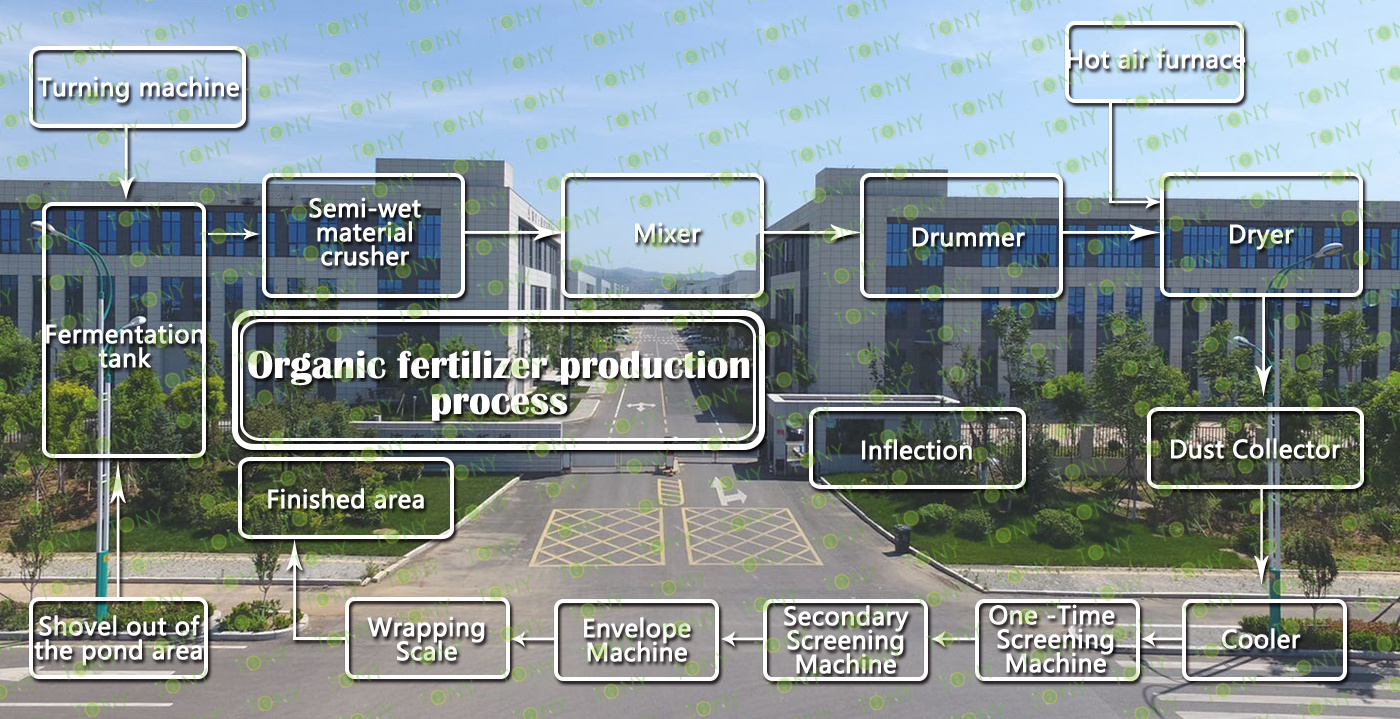

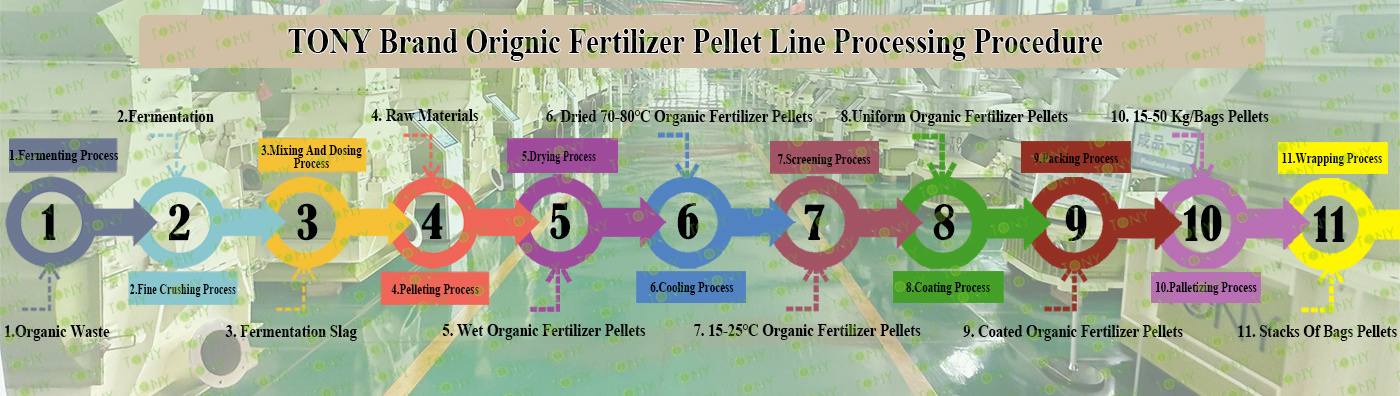

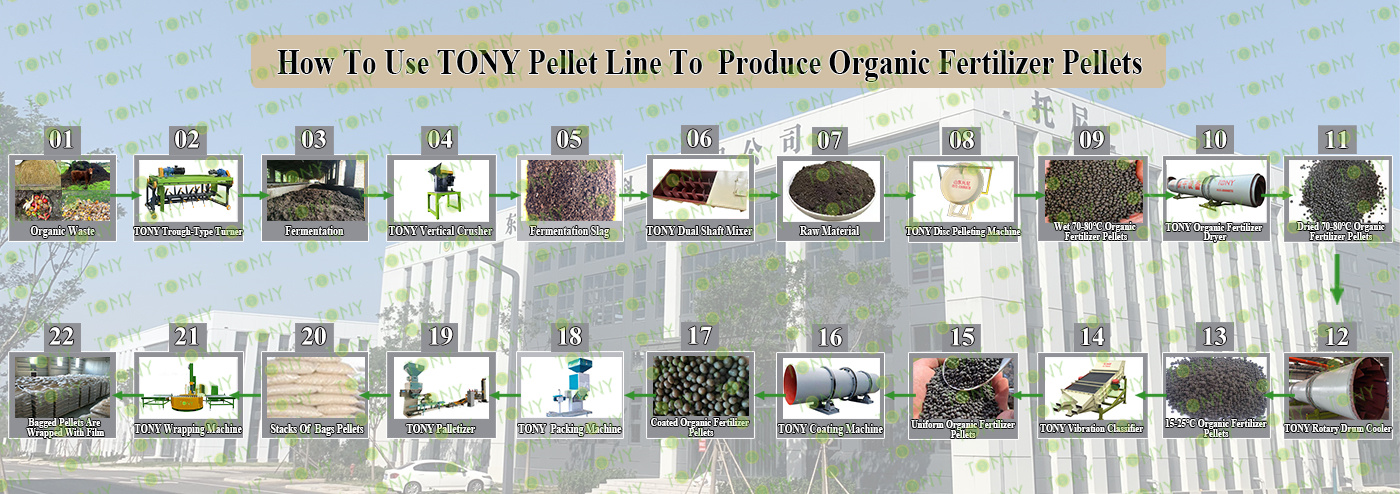

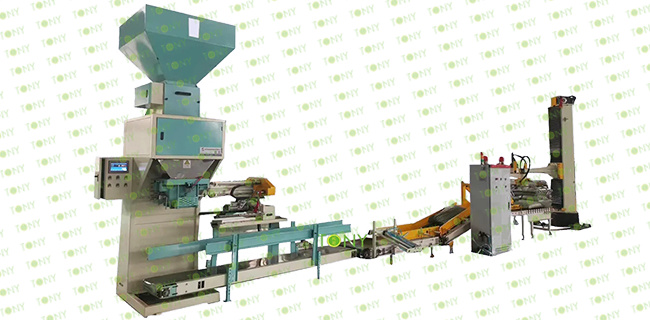

5.Proecss: Raw material fermenting process→ Grinding process→ Mixing and dosing process→ Granulation process→ Drying process→ Cooling process→ Screening process→Coating process→Packaging process→Palletizing process→Wrapping process

6.Main Machine: Trough Type Turner, Vertical Disintegrator, Dual Shaft Mixer, Disc Pelleting Machine, Organic fertilizer ,Dryer Drum cooler, Vibration Classifier, Coating machine, Semi-automatic Packing Machine And Belt Conveyors

7.Total Power: Based on all selected equipment models, according to all the equipment models selected, different models have different power

8.Need Area: Based on all selected equipment models,according to all the selected equipment models, different models of equipment sizes are different

9.Project Country: Can be used in any country

10.Voltage: The voltage standard of the country in which the equipment is used

It mainly contains the following steps and machines as following:

1.To Use TONY Trough-type Turner To Fermentation Of Organic Waste

2.To Use TONY Vertical Crusher To Crush Large Pieces Of Fermentation

3.To Use TONY Dual Shaft Mixer To Mix The Raw Materials After Fermentation With Other Additives

4.To Use TONY Disc Pelleting Machine To Products Pellets

5.To Use TONY Organic Fertilizer Dryer To Dried Pellets ,It Usually Reduces Water Content To Less Than 13%

6.To Use TONY Drum Cooler To Reduce The Temperature Of Organic Fertilizer Pellets To Room Temperature

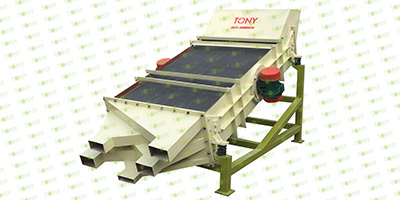

7.To Use TONY Vibration Classifier To Graded Organic Fertilizer Pellets

8.To Use TONY Coating Machine To Coated Organic Fertilizer Pellets

9.To Use TONY Packing Machine To Packing Pellets To 15-50KG/Bags.

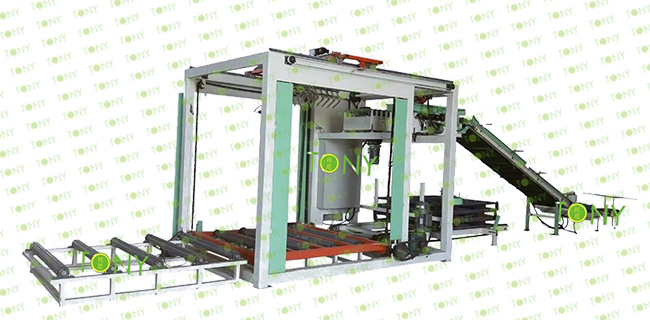

10.To Use TONY Palletizer To Palletizing 15-50Kg/Bags

11.To Use TONY Wrapping Machine ToWrapping Palletized Pellet

You can contact TONY to get for more details information and quoation.

TONY Can Supply You All The Products As Above With Competitive Price And Excellent Quality.

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some machines can be custom made by customer according to different customer's detailed demand.Contact TONY for more details with quotation and layout.

|

|

|

|

| Trough-Type Turner | Vertica Crusher | Dual Shaft Mixer | Disc Pelleting Machine |

|

1. Fermentation Of Organic Fertilizer Raw Materials 2. Models Can Be Selected Or Customized According To Production Needs |

1. The Raw Materials After Fermentation Need To Be Crushed To Reduce The Surface Area 2. Models Can Be Selected Or Customized According To Production Needs |

1. Mix The Fermented Raw Materials With Other Necessary Additives According To a Certain Proportion 2. Models Can Be Selected Or Customized According To Production Needs |

1. Make Raw Materials Into Organic Fertilizer Pellets 2. Models Can Be Selected Or Customized According To Production Needs |

|

|

|

|

| Organic Fertilizer Dryer | Rotary Drum Cooler | Vibration Classifier | Coating Machine |

|

1. Organic Fertilizer Particles With High Water Content Need To Be Dried To Reduce Water Content 2. According To Different Purposes Of Use, The Moisture Content Requirements Of Dried Organic Fertilizer Particles Are Different |

1. After Drying, The Organic Fertilizer Particles Have a High Temperature And Need To Be Cooled To Return To Normal Temperature 2. Models Can Be Selected Or Customized According To Production Needs |

1. Cooled Organic Fertilizer Particles May Contain Fine Powder And Large Particles, Which Need To Be Separated 2. Models Can Be Selected Or Customized According To Production Needs |

1. Wrap The Coating Material On The Surface Of The Organic Fertilizer To Form a Protective Film 2. Models Can Be Selected Or Customized According To Production Needs |

|

|

|

|

| Packing Machine | Palletizer | Wrapping Machine | Belt Conveyor |

|

1. You Can Choose Packaging Machine To Pack Pellets Into 15-50kg/ Bag. 2. According to the degree of machine automation is divided into semi-automatic packing machine and automatic packing machine. |

1. To Palletize bagged pellets. 2. You Can Choose High Level Palletizer Or Column Palletizer According To Your Needs. |

1. To Wrappe film palletized bag pellets. 2. Wrapping Machine Can Be Equipped With Weighing System |

1. Transport Pellets. 2. Design According To The Entire Production Line, Such As Belt Width Or Specific Number Of Uses. |

1.Fermenting Process

A.After fermentation, the raw materials of organic fertilizer can reduce pathogenic bacteria and harmful substances, and improve the decomposition degree and fertilizer efficiency of organic matter. During fermentation, microbial activity generates heat that helps kill pathogens and weed seeds.

B.Main Parts:

(1). TONY's new Trough-type Turner.

(2). Tank body, pile turning mechanism, walking mechanism and ventilation system.

(3). Extraction hydraulic lifting system.

(4). Electronic control system allows the equipment to be used normally.

Different raw materials and production conditions, you can choose different fermentation equipment, the following is a brief introduction to you a few fermentation equipment, specific information can contact TONY.

|

|

|

| Trough-Type Turner | Crawler-Type Turner | Chain Plate Conveyor |

|

Structure: The trapper is usually composed of a walking fermentation tank, a walking track, a power taking device, a turning part and a rotating trough device. Working principle: The track is moved in the fermentation tank, and the fermentation material is flipped by the flip part to promote oxygen into the material and accelerate the fermentation process. Application scenario: It is suitable for the fermentation treatment of organic solid matter such as animal manure, mushroom fungi, domestic waste, sludge and crop straw. |

Structure: Four-wheel walking design, can go forward, backward, turn, driven by one person. Working principle: It is a kind of equipment for the fermentation of organic materials, which realizes the 180 degree turn in place through the auger shaft hydraulic lift and pull rod operation, saving space, labor and diesel. Application scenario: It is widely used in the manure utilization of organic fertilizer production enterprises and large-scale farms, especially suitable for the treatment of sludge, viscous chicken manure and other materials, to create a better aerobic environment for material fermentation. |

Structure: The chain plate tilting machine is usually composed of a chain and a tilting tooth, which is driven by the movement of the chain to flip the material. Working principle: Through the movement of the chain, the flipping teeth turn the fermentation material, promote oxygen into the material and accelerate the fermentation process. Application scenario: Suitable for small and medium-sized farms and farms, processing small and medium-sized organic waste fermentation. |

|

|

|

| Crawler Compost Turner | Horizontal Organic Fertilizer Fermentation Tank | Vertical Fermentation Tank |

|

Structure: Crawler type tilting machine usually adopts crawler type walking mode, equipped with full hydraulic operating system and pull rod type steering wheel operation. Working principle: By walking on the track, the fermentation material is turned by the rollover drum, which promotes the oxygen to enter the material and accelerates the fermentation process. Application scenario: It is suitable for the fermentation treatment of various organic wastes, especially in scenarios that require frequent movement and handling of large quantities of materials. |

Structure: Usually a cylindrical tank placed horizontally with a rotating device. The capacity can be increased without increasing the height. Mixing and stacking: the interior is often equipped with a stirring device, which can evenly mix materials and continuously turn the pile during the fermentation process. Operation: The operation is relatively simple, the material is added from one end and discharged from the other end after fermentation. Repair and maintenance is relatively convenient Application scenario: Suitable for large-scale, continuous production scenarios, such as large-scale farms, agricultural cooperatives, etc. |

Structure: A tank placed vertically, usually with a cylindrical or conical bottom. Capacity is limited by height Mixing and stacking: Usually by lifting the material from the bottom to the top, and then evenly spread, to achieve stacking. Operation: Operation complexity is high, requiring precise control of lifting and spreading devices, and overhaul and maintenance may require special equipment or platforms. Application scenario: It is suitable for scenes with limited space but need efficient fermentation, such as urban waste treatment centers, small farms, etc Environmental impact: The footprint is small, but due to the vertical arrangement, it may produce a certain odor and dust during the lifting and spreading process. |

1.Grinding Process

A. This process is mainly to crush the raw materials after fermentation

Main parts:

(1). TONY fine crushing equipment

(2). Galvanized dust collector.

(3). Sawdust conveying fan.

(4). Cyclone with airlock.

(5). Electrical cabinet.

According to different raw materials and production conditions, you can choose different grinding equipment, the following is a brief introduction to several grinding equipment, specific information can contact TONY.

|

|

|

| Vertical Disintegrator | Semi-Wet Material Crusher | Cage-Type Crusher |

|

Screen-free design: Screen-free design is usually used to avoid the problem of material clogging. Wide range of applicable materials: Can be used in mixed materials, gypsum, coal gangue, slag and other materials. Application scenario: More suitable for processing a variety of medium hardness below the material, widely used in mineral processing, chemical, building materials and other industries, suitable for a variety of medium hardness below the material. |

High humidity adaptability: Specially designed to handle high humidity, multi-fiber materials, such as pig, sheep, chicken manure and other organic fertilizer raw materials. Application scenario: It is mainly used in the production and processing of organic fertilizers, such as the treatment of animal manure such as chicken manure and cow manure. It is also suitable for the composting of municipal solid waste and the treatment of industrial waste. |

The structure is simple: It is usually composed of one or more high-speed rotating cage rotors. Easy operation: maintenance and operation is relatively simple, suitable for small and medium-sized crushing operations. Limited application materials: Usually suitable for dry and low fiber content materials. Application scenario:It is often used to crush agricultural waste and light industrial waste. Also suitable for some low humidity, low fiber material treatment. |

|

|

|

| Multifunctional Hammer Mill | Effective Hammer Mill | Dual Shaft Hammer Mil |

|

1. Direct motor transmission, one motor, one spindle. 2. The feed port is on the side of the machine, suitable for the raw materials that are difficult to feed. 3. A piece of mesh screen. 4. Spindle single direction rotation, limited output and crushing efficiency. |

1. Direct motor transmission, one motor, one spindle. 2. The feed port is on the upper side of the machine, suitable for raw materials that are easy to feed. 3. Two screens. 4. The spindle can rotate in the opposite direction, and the output and crushing efficiency are higher. |

1. Direct motor transmission, two motors, two spindles. 2. The feed port is on the upper side of the machine, suitable for raw materials that are easy to feed. 3. Two screens 4. The same type of efficient crusher has a higher output than a single shaft. |

2.Dust Removal Of Fine Crushing Process

There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries. 4. High dust removal efficiency, high filtration accuracy, low noise. 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag. |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector. |

3.Storage Of Wet Crushed Fermentation

(1)How to store the crushed fermentation?

Option 1: The user can choose to pile the wet crushed fermentation on the ground.

Option 2: The user can also choose to put the wet crushed fermentation into the stock bin.

(2) What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | The Wet Crushed Fermentation Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required; |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving. Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment. |

(3)There are two types of Silo: Storage Bin and Large Hydraulic Storage Silo.

Please contact TONY for specific parameters and prices.

|

|

| Storage Bin | Large Hydraulic Storage Silo |

|

1. Capacity: 5-30m³,If the capacity is expanded, it is easy to block or stick the material 2. The material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3. Mainly for screw control,the material is pushed to the specified position through the rotation of the spiral blade 4. Advantages: Simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5. Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1. Capacity: 40-300m³,If the capacity is expanded, there will be no clogging 2. The material is galvanized and corrosion-resistant 3. Mainly for hydraulic system control,The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4. Advantages: Good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5. Disadvantages: Complex structure and high maintenance cost. |

1.Wet Crushed Fermentation Mixing And Dosing Process:

A. It is mainly to mix the raw materials after fermentation with other necessary additives in a certain proportion.

B. According to the formula requirements, the proportion of each ingredient is precisely controlled to meet the national standard and market demand. The accuracy of the ingredients directly affects the quality and effect of the final production.

C. According to the actual production process, you can choose to use Dual Shaft Mixer, TMR Mixer, Dual Screw Mixer.

According to different raw materials and production conditions, you can choose different mixinging equipment, the following is a brief introduction to several mixing equipment, specific information can contact TONY.

|

|

|

| Dual Shaft Mixer | TMR Mixer | Dual Screw Mixer |

|

Two-axis design: Having two stirring axes, usually arranged symmetrically. Wide mixing range: Due to the dual-axis design, a wider range of mixing can be achieved, reducing the mixing dead Angle. Complex structure: Compared with the single-axis mixer, the structure of the two-axis mixer is more complex, and the manufacturing and maintenance costs are higher. Application scenario: It is widely used in occasions requiring efficient and uniform mixing, such as mixing large quantities of dry powder materials, manufacturing synthetic resins, carbon materials, refractory materials, ceramic materials, etc. Efficient mixing: The dual-axis design makes the mixing efficiency higher and can achieve the ideal mixing effect in a short time. |

Design: TMR mixers may be single-axis or multi-axis designs, depending on the manufacturer and usage requirements. Other functions: Usually also have cutting, kneading and electronic weighing functions to improve feeding efficiency. Emphasize the nutritional balance of feed and consistency of dry matter ratio. When using a TMR mixer, the operator needs to pay attention to the water content and dry matter ratio of the feed to ensure the quality of the feed. The blades of the TMR mixer rotate at high speed, which can effectively spray water mist evenly into the material. Main Use: Specially designed for animal husbandry, for the preparation of total mixed diets. It can mix all kinds of forage, crop straw, silage and concentrate together to ensure the nutritional balance of the feed. |

Double helix shaft design: usually refers to the double helix shaft mixer, the design of the helix shaft helps to transport and mix materials. Efficient conveying: Especially suitable for simultaneous conveying and mixing. Specific application scenario: It is often used for the humidification and mixing of powdered materials such as fly ash and mineral powder. Humidification stirring: Especially suitable for the humidification stirring of powdered materials, which can uniformly humidify materials and avoid dry ash flying and water dripping. Application scenario: Widely used in thermal power plants, mining and other industries such as fly ash or similar materials humidification mixing. Unique design: The design of the spiral shaft facilitates the conveying and mixing of materials, especially for occasions where conveying and mixing are required at the same time. |

2.Storage Of Organic Fertilizer Raw Material

(1)How to store the Organic Fertilizer Raw Material?

Option 1: The user can choose to pile the Organic Fertilizer Raw Material on the ground.

Option 2:The user can also choose to put the Organic Fertilizer Raw Material into the stock bin.

(2)What's the difference between stacking on the ground and storing in a stock bin?

| Pile On The Ground | Raw Material Are Stored In The Stock Bin |

|

Advantages: No need for customers to buy silo equipment, saving investment and reducing costs; Disadvantage: Occupy workshop area; Obstructing the traffic of the workshop, affecting people and vehicles to move around; Dust flying affects the environment of production workshop; More manual handling of materials is required |

Advantages: Large storage capacity, save workshop area. Closed storage, reduce dust, improve the cleanliness of the workshop environment Better automation and labor saving Closed storage to avoid the impact of the external environment on the material Disadvantage: Customers need to buy silos and increase investment |

3. There are two types of Silo: Auger Silo and Large Hydraulic Storage Silo. Please contact TONY for specific parameters and prices.

|

|

| Raw Material Storage Bin | Large Hydraulic Storage Silo |

|

1.Capacity: 5-30m³,If the capacity is expanded, it is easy to block or stick the material 2.The material is ordinary iron plate,compared with galvanized materials, corrosion resistance is lower 3.Mainly for screw control, the material is pushed to the specified position through the rotation of the spiral blade 4.Advantages: Simple structure, easy to maintain, suitable for conveying powder, granular and small block materials. 5.Disadvantages: The conveying distance is limited, and the conveying effect is poor for the material with large viscosity. |

1.Capacity: 40-300m³,If the capacity is expanded, there will be no clogging 2.The material is galvanized and corrosion-resistant 3.Mainly for hydraulic system control,The hydraulic system can precisely control the conveying amount and conveying speed of the material. 4.Advantages: Good sealing, can effectively prevent dust and pollution of materials; The bottom adopts the power to push the material, which can effectively prevent the phenomenon of material bridging; Suitable for conveying a variety of powder, granular and small block materials, especially stickier materials. 5.Disadvantages: Complex structure and high maintenance cost. |

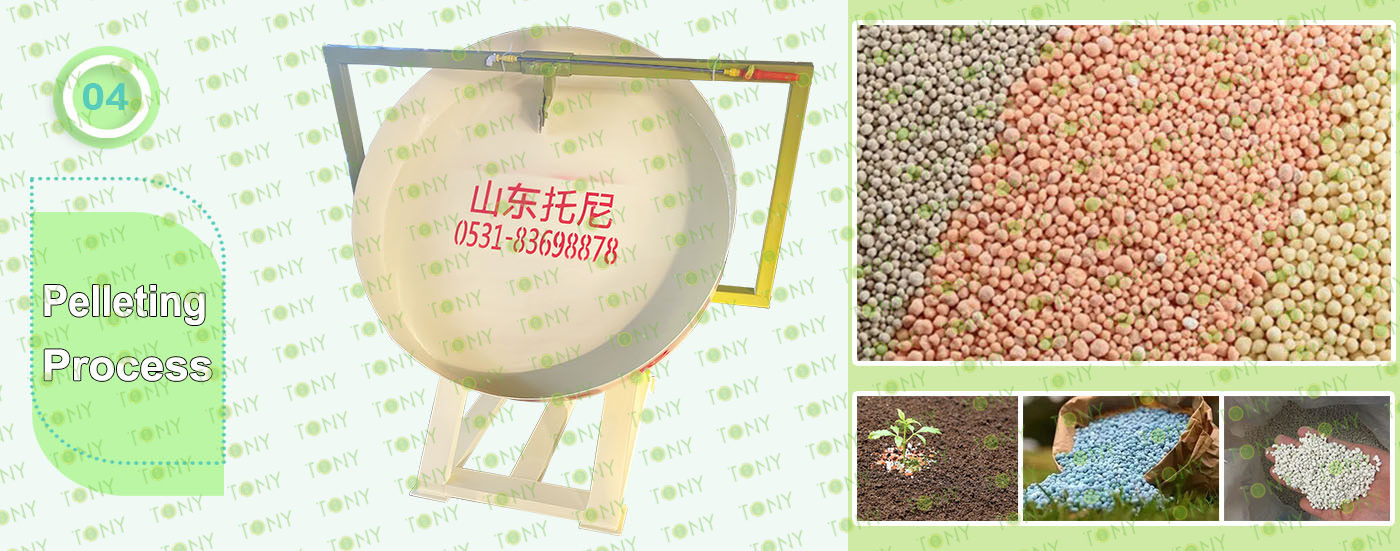

1.Pelleting Process:

A.It forms spherical particles by mixing powdery materials with water, which is suitable for granulation treatment of various materials.

B.Pelleting principle: In the pelleting process, raw materials are compressed into particles under the action of mechanical forces. At the same time, the appropriate amount of water and the addition of the adhesive help to form a stable particle structure. The granulated particles have a certain strength and shape, which is easy to transport and apply.

Main Parts:

(1)TONY's Disc Pelleting Machine.

(2)Water Jet

(3)Feed And Feed Belt Machine

(4)Electric Control

The price varies according to the model, specifications and other factors. The specific price needs to be determined according to the fluctuation of raw material price and user demand. Please contact TONY for a quotation.

According to different raw materials and production conditions, you can choose different pelleting equipment, the following is a brief introduction to several pelleting equipment, specific information can contact TONY.

|

|

|

|

| Disc Pelleting Machine | Rotary Drum Granulator | Extrusion Pelletizer | Flat Die Pellet Machine |

|

Principle: Using the centrifugal force of the material in the disc and its own cohesiveness, the material is rolled into granules on the disc. Advantages: The product is round grain type, uniform particles, good miscibility, has good automatic classification ability, can control the solution to spray on the fine particles, so the granulation efficiency is high. Disadvantages: The collection of dust and smoke produced by granulation is difficult, and can not be effectively ammoniated; The one-time investment is large, the material requirements are high, the grain texture is loose, which is not conducive to storage and transportation and mechanized application. |

Principle: Through a certain amount of water or steam, the basic fertilizer is fully chemical reaction after humidification in the cylinder body, under certain liquid phase conditions, with the help of the rotating movement of the cylinder, the extrusion pressure between the material particles is aggregated into particles. Advantages: high particle strength, good appearance, low moisture, improve subsequent drying efficiency, can handle a wide range of materials, large output, low maintenance costs. Disadvantages: High requirements for process conditions, if the control is not good may produce a small amount of return material, the equipment is large and occupies a large area. |

Principle: The material is extruded through a mold of a specific shape by an external force, and then cut into particles. Advantages: The product is a long column shape, the particle section is regular, uniform, the production capacity is large, but the production process is simple, the material requirements are not high, the particle hardness is large, suitable for storage and mechanization operations. Disadvantages: the grain shape of the product is not good-looking, the particle length and end shape can not be accurately controlled, the proportion of high, product quality is difficult to guarantee, the production capacity is low, the mold wear is large, the cost is high. |

Principle: The material is formed into particles by the extrusion action of the roll on the flat die. Advantages: can be directly processed into spherical particles, saving energy, save power consumption; Equipped with rolling sheet forming hydraulic automatic compensation pressure device, mirror window, etc. After the powder material is passed through the bucket elevator, the whole process can be completed at one time from feeding, spiral degassing, rolling, shredding, screening to granular products. Disadvantages: The equipment is complex, the initial investment is high, and the operation requires certain technology. |

2.Dust Removal Of Pelletizing Process

There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices.

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise. 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag. |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple,only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector. |

|

1.Wet Organic Fertilizer Pellets Drying Process: A. This process is mainly used to dry the organic fertilizer pellets. B. Capacity:According to raw material humidity and production requirements. C. Drying equipment is usually a rotary dryer, through the interior is covered with lift sheet design, so that the particles fully contact with the hot air, improve the drying efficiency. D. Drying requirements: According to different purposes of use, the moisture content requirements of dried organic fertilizer particles are different. The moisture content of products for short-term sales should be ≤30%, and the moisture content of products for long-term storage or further processing should be ≤13%. E. It is necessary to provide heat source for Rotary Drum Dryer with Biomass Hot Stove. Waste wood, waste straw and Biomass particles can be used as fuel for Hot blast Stove. The models of Biomass Hot Stove are different and can also be customized. Main Parts: (1). TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.) (2). TONY's Hot Stove. (3). Fan Blower and Cyclone With Airlock. |

According to different raw materials and production conditions, you can choose different drying equipment, the following is a brief introduction to several drying equipment, specific information can contact TONY.

|

|

|

| Single-Layer Rotary Drum Dryer | Double-Layer Rotary Drum Dryer | Three-Layer Rotary Drum Dryer |

|

1. Structure: Only one drying layer. 2. Applicable materials: Usually used for drying light materials, such as sawdust, wood chipping, bean residue, cow dung, coal slime, etc. 3. Advantages: Simple structure, low cost, easy operation and maintenance. 4. Disadvantages: The drying efficiency is relatively low, which is suitable for scenes with small scale or low drying efficiency requirements. |

1. Structure: There are two drying layers, usually two concentric cylinders of different diameters. 2. Applicable materials: Suitable for drying granular materials with a certain humidity and pellets size range, such as river sand, wood chips, sawdust, etc. 3. Advantages: Compared with single-layer dryer, it has higher thermal efficiency, faster drying speed and smaller footprint. 4. Disadvantages: The structure is complex, the cost is high, and the operation and maintenance are relatively complex. |

1. Structure: There are three drying layers, usually three concentric cylinders of different diameters. 2. Suitable materials: Suitable for drying materials that require higher thermal efficiency and faster drying speed, such as slag, clay, pulverized coal, etc. 4. Advantages: The highest thermal efficiency, the fastest drying speed, can handle larger scale material drying. 5. Disadvantages: The most complex structure, the highest cost, the most complex operation and maintenance. |

2.Dust Removal Of Drying Process

Dust removal of Drying Process There are four kinds of dust removal equipment available

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Option 3: Water Spray Dust Removal

Option 4: Wet Electrostatic Precipitator

Please contact TONY for specific parameters and prices.

|

|

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector | Water Spray Dust Removal | Wet Electrostatic Precipitator |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector |

1. The water film caused by a certain method on the inner wall of the dust collector or other special components is used to impact the dust, so that the dust is captured by the water film and the gas is purified. 2. Often used to deal with gas containing high humidity and sticky dust, suitable for boiler, chemical, spray paint, spray glaze, pigment and other industries. 3. Simple structure, small metal consumption, small water consumption. 4. It has higher dust removal efficiency for dust pellets with larger pellets size. 5. It is high and difficult to arrange. There may be water phenomenon in actual operation. |

1. The dust and liquid droplets in the flue gas are adsorbed to the surface of the anode and cathode using electric field load, and cleaned with water spray. 2. It usually used to deal with gas containing fine pellets, which is suitable for boiler, chemical industry, waste incineration and other industries. 3. The dust removal efficiency of fine pellets is high, up to 98%~99%. 4. It can remove some gaseous pollutants at the same time. 5. The structure is more complex, and the investment and operation cost are higher. Regular cleaning and maintenance is required. |

1.Cooling Process:

A. This process is mainly used to To Cool Pellets From 80-90℃ to 15-25℃

B. The rotary cooler is often used, and the design of the lifting sheet is covered with the inside, so that the particles are fully in contact with the cold air to achieve the cooling effect

Main Parts:

(1). TONY's new Drum Cooler.

(2). Cyclone and bags dust collectors.

(3). Fan Blower.

(4). Connect Pipes.

2.Dust Removal Of Cooling Process

There are two kinds of dust removal equipment available:

Option 1: Bag Dust Collector

Option 2: Galvanized Pulsed Dust Collector

Please contact TONY for specific parameters and prices.

|

|

| Bag Dust Collector | Galvanized Pulsed Dust Collector |

|

1. Filter bags are used to filter and capture dust in the gas. 2. The structure is relatively complex, mainly composed of filter bag, ash cleaning system, intake pipe, outlet pipe, etc. 3. It is suitable for occasions with low dust concentration, such as chemical, food, medicine and other industries 4. High dust removal efficiency, high filtration accuracy, low noise. 5. Maintenance is relatively complex, and it is necessary to regularly clean the dust on the surface of the filter bag and clean the dust of the filter bag. |

1. Dust removal equipment for cleaning filter bags with pulse injection. 2. The structure is relatively simple, mainly composed of filter bag, pulse injection system, ash hopper, etc. 3. It is suitable for occasions with high dust concentration, such as cement, mining, metallurgy and other industries. 4. High dust removal efficiency, good cleaning effect, easy maintenance and so on. 5. Maintenance is relatively simple, only need to clean the dust in the ash hopper regularly. If the filter bag is damaged, it can be replaced separately, without the need to replace the entire dust collector. |

A. Vibration Classifier is the use of vibration motor as the vibration source, through a reasonable screen surface inclination and screen aperture, to achieve the classification of materials according to particle size

B. Technical specifications

Amplitude: 3.5~5mm

Vibration frequency: 15.8Hz

Vibration direction Angle: 0~45°

C.The component structure has no dead Angle, fully closed structure, and the material can be automatically discharged in 360 degree direction

A. Organic fertilizer coating machine is mainly composed of screw conveyor, stirring tank, oil pump, host machine, etc., using powder powder or liquid coating process, can effectively prevent the agglomeration of organic fertilizer

B. Precautions

(1)Choose the appropriate coating material, different organic fertilizers need to use different coating materials

(2)Control the thickness of the envelope, generally between 0.02-0.05mm

(3)Pay attention to the storage and transportation after the envelope, to avoid moisture, heat, direct sunlight and other effects

(4)Safe operation, avoid contact with hot parts, avoid coating material clogging the machine, etc.

1.Packing Process:

A.This process is mainly used to pack pellets.

B.The main equipment: Semi-automatic Packing, Machine Automatic Packing Machine

|

|

| Semi-Automatic Packing Machine | Automatic Packing Machine |

|

1. Packing Pellets To 15-50kg/bags 2. Manual assistance is required to complete some operations, such as bagging. 3. Production Efficiency: Compared with the automatic packaging machine, the production efficiency of the semi-automatic packaging machine is lower, but it is still higher than the complete manual operation. 4. Cost: Usually the price is relatively close to the people, suitable for small enterprises with limited budgets. 5. Flexibility: Due to the need for manual intervention, semi-automatic packaging machines have a certain degree of flexibility when dealing with products of different specifications and shapes. 6. Sew Machine, Buyer Can Also Chose Hot Seal Machine For Chosen. |

1. Packing Pellets To 15-50kg/bags 2. All steps from feeding, metering, bagging to sealing are automatically completed by the machine. 3. Production Efficiency: The production efficiency is significantly higher than the semi-automatic packaging machine, which can greatly reduce labor costs. 4. Cost: The price is higher, but the investment can be recovered in the long run by improving efficiency and reducing labor costs. 5. Accuracy And Consistency: It can provide high-precision packaging to ensure that the weight of each bag of products is consistent. 6. Sew Machine,Buyer Can Also Chose Hot Seal Machine For Chosen. |

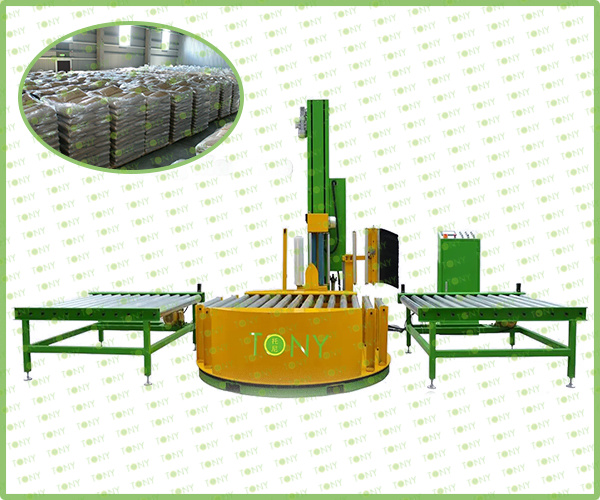

2.Palletizing Machine

It is a kind of high-efficiency palletizing equipment with high degree of automation and good integration. The palletizer groups the bags according to the predetermined way, and then puts the whole layer of bags on the tray layer by layer. Usually used as a follow-up equipment to the packaging line to improve production capacity and transfer capacity, TONY has two types of column palletizer and high palletizer to choose from, you can contact TONY for more product details and price differences.

|

|

| High Level Palletizer | Column Palletizer |

|

1. Gantry type structure, the entire mechanical system is located above the production line, through horizontal and vertical movement to move items from the production line to the pallet. The structure of the high palletizer makes it suitable for efficient palletizing at the end of the production line. 2. Mainly used in packaging bag palletizing production line, such as feed, fertilizer, flour, cement and other industries. The high palletizer can realize efficient packaging bag palletizing, and the palletizing shape is neat and beautiful. 3. High degree of automation, can achieve automatic flattening, automatic bag, automatic stratification and other functions. 4. Installation requires large space and is usually fixed at the end of the production line. The operation of the high palletizer requires professional technical personnel to maintain and operate. 5. The cost of use is low and maintenance is relatively simple, but in some cases a higher initial investment may be required. |

1. With a vertical column, the robot arm moves up and down the column, and can rotate or move on the horizontal plane at the same time. This design allows the post palletizer to have high stability and accuracy when handling heavy and large items. 2. It is suitable for high-speed and stable palletizing of large and heavy goods, which is commonly used in chemical industry, building materials and other industries. Due to its stable structure, it can ensure the accuracy and quality of palletizing when handling heavy items. 3. It has high flexibility and adaptability, and can adapt to items of different sizes and shapes by adjusting parameters. Its intelligent design makes it possible to handle many types of items. 4. The installation is relatively flexible and can adapt to different production line layouts. Due to its compact structure and relatively small occupation space, it is suitable for the use of small production workshops. 5. The initial investment is high, but in the long run, due to its stability and efficiency, the overall operating cost can be reduced. |

3. Wrapping Machine

Wrapping Machine the use of stretch film (also called winding film) as consumables, and pallet baler, pallet wrapping machine and other titles. People's requirements for logistics efficiency continue to improve, in order to reduce labor, save packaging costs, to achieve economical handling and the emergence of a packaging machine. It has gradually become a necessary packaging machine for large enterprises, especially export-oriented enterprises.

|

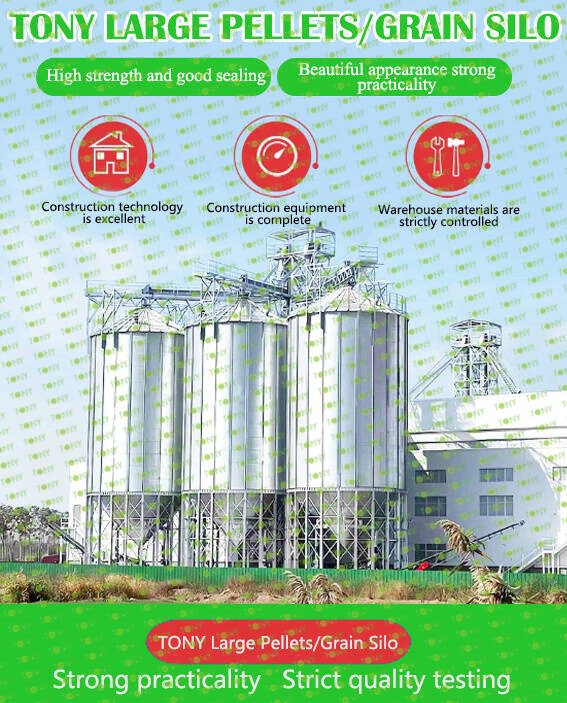

The characteristics of the wrapping machine 1. Various Operation Modes: Including manual operation and automatic operation of two modes, can be changed at any time. 2. Automatic Sensing Function: Automatic sensing cargo height, equipped with top pressing device. 3. Versatility: Suitable for single or multiple cylindrical combination packaging requirements and general packaging. 4. Control Panel Is Convenient: Touch control panel, fool type and intelligent control design, easy operation. 5. Parameters Can Be Adjusted: Winding specifications, winding film lifting speed, tightness can be adjusted at any time, convenient and rapid. 6. Smooth Operation: Slow start, slow stop, fixed stop. 7. Automatic Film Breaking: When the packaging is completed, the film will be automatically pulled and broken without cutting knife. 8.Easy Maintenance: Easy parts replacement, low failure. 9.Safety Guarantee: With self-protection switch device and emergency safety shutdown device, electromagnetic pre-drawing device, different from the general mechanical, safer for operators. |

4.Large Pellets Silo:

Organic fertilizer pellets can indeed be stored in large silos, which is a very common practice in practical applications. The following are a few key points to ensure the storage effect of organic fertilizer particles in the large pellets silo.

|

A. TONY Large Pellets Silo selection and design: 1.Material Selection: TONY selects galvanized material, which is resistant to corrosion and moisture to prevent organic fertilizer particles from being spoilt by moisture. Ventilation Design: with a good ventilation system to avoid high internal humidity, resulting in organic fertilizer particles caking. Capacity Design: TONY selects the appropriate bin capacity according to the actual needs to ensure that the production or storage needs can be met. 2. Storage Conditions: Dry Environment: Organic fertilizer particles should be stored in a dry, ventilated environment to avoid moisture. Temperature Control: Avoid high temperature environment, so as not to affect the microbial activity in organic fertilizer. Tightness: TONY silo has good tightness to prevent foreign impurities from entering and affecting the quality of fertilizer. |

|

1. Market Prospects

With the increasing awareness of healthy food and environmental protection, the demand for organic fertilizer market continues to grow. Compared with traditional fertilizer, organic fertilizer has the advantages of improving soil structure and reducing environmental pollution, so it is more and more widely used in agricultural production. In addition, the state has also given policy support to the production and use of organic fertilizers, which has further promoted the development of the industry.

2. Raw Material Supply

The main raw materials of organic fertilizer particles include animal manure (such as chicken manure, cow manure, etc.), biogas and kitchen waste. These raw materials are not only cheap, but also easy to obtain, which can effectively reduce the raw material cost of production enterprises. At the same time, the rational use of these waste resources can also reduce environmental pollution and realize the recycling of resources.

3. Production Process

The production process of organic fertilizer particles mainly includes raw material pretreatment, fermentation, granulation and drying steps. Through high temperature fermentation treatment, harmful bacteria and eggs in raw materials can be killed to ensure the safety of fertilizer. The granulation process forms a granular form of fertilizer that is easy to store and transport. The entire production process can be automated and intelligent to improve production efficiency and product quality.

4. Investment Estimation And Financing

The investment estimate includes equipment purchase, raw material purchase, labor wages, utilities and other expenses. The specific amount needs to be calculated in detail according to the actual situation. Financing can be solved through various ways such as own funds, bank loans, and government subsidies.

Characteristics of organic fertilizer particles

1. Nutrition

(1) Many Types Of Nutrients: Compared with chemical fertilizers, organic fertilizer particles contain rich types of nutrients, including nitrogen, phosphorus, potassium, calcium, magnesium, sulfur and trace elements, etc., can provide a variety of nutrients required for crop growth, and chemical fertilizers are relatively simple, such as nitrogen fertilizer only contains nitrogen 1.

(2) Low Concentration: Although there are many types of nutrients, the concentration is relatively low. Taking chicken manure as an example, the nitrogen content is about 1.6%, the phosphorus content is about 1.5%, and the potassium content is about 0.9%, while the nutrient concentration of fertilizers is much higher than that of organic fertilizers, such as urea nitrogen 46%

2. Effect On Soil

(1) Improve Soil Structure: Organic fertilizer particles can increase the soil's aggregate structure, make the soil more porous and breathable, and facilitate the growth and development of crop roots.

(2) Increase Soil Microbial Activity: provide a food source for soil microorganisms, promote the reproduction and activity of microorganisms, and these microorganisms participate in the process of material circulation and energy conversion in the soil, which contributes to soil health.

3. Product Advantages

(1) Easy Storage And Transportation: Granular organic fertilizer is relative to other forms such as powder, and occupies relatively regular space during storage, which is easy to stack; It is not easy to scatter and fly during transportation.

(2) Customizability: According to the needs of different crops, soil conditions, etc., the formula can be adjusted during the production process, and specific nutritional elements or microbial inoculants can be added to produce targeted organic fertilizer pellet products.

The organic fertilizer pellets market has broad prospects and is expected to continue to grow in the next few years with the increase in environmental awareness and consumer demand for organic food.

1. Market Growth Trend

According to the latest market analysis report, the global bio-organic fertilizer market is experiencing significant growth. The global bio-organic fertilizer market capacity is $114.071 billion in 2023 and is expected to reach $227.06 billion by 2028, with a high compound annual growth rate (CAGR) 1. This growth trend reflects the continued increase in demand for bio-organic fertilizers worldwide, mainly due to the increased sustainability and environmental requirements of agricultural production.

2. Market Drivers

(1) Environmental Protection Policy

Many countries and regions around the world are strengthening the implementation of environmental protection policies, such as regulating the treatment and resource utilization of organic waste such as livestock and poultry manure, which will help promote the development of organic fertilizer market.

(2) Consumer Demand

Increasing consumer demand for food safety and environmentally friendly products has made organic fertilizer pellets favored for their natural, environmentally friendly properties. This trend is particularly evident in developed countries, where the proportion of organic fertilizers used is increasing.

3. Market Challenges

Despite the positive market outlook, the organic fertilizer pellets market still faces some challenges, including higher production costs and the need for technological innovation. In addition, the market competition is fierce, and small and medium-sized enterprises need to enhance their competitiveness through product innovation and differentiated competition to reach one million US dollars by 2030 (specific value is not clear), showing a growth trend.

2025 Tony Machinery - All Rights Reserved. Map