The production process of pine wood pellet fuel mainly includes raw material crushing, raw material fine crushing, raw material drying,pelleting, cooling screening, packaging and storage. The technical parameters and operating details of each step will affect the quality of the final fuel (such as heat value, density, molding rate, etc.). The following are the specific procedures and key points:

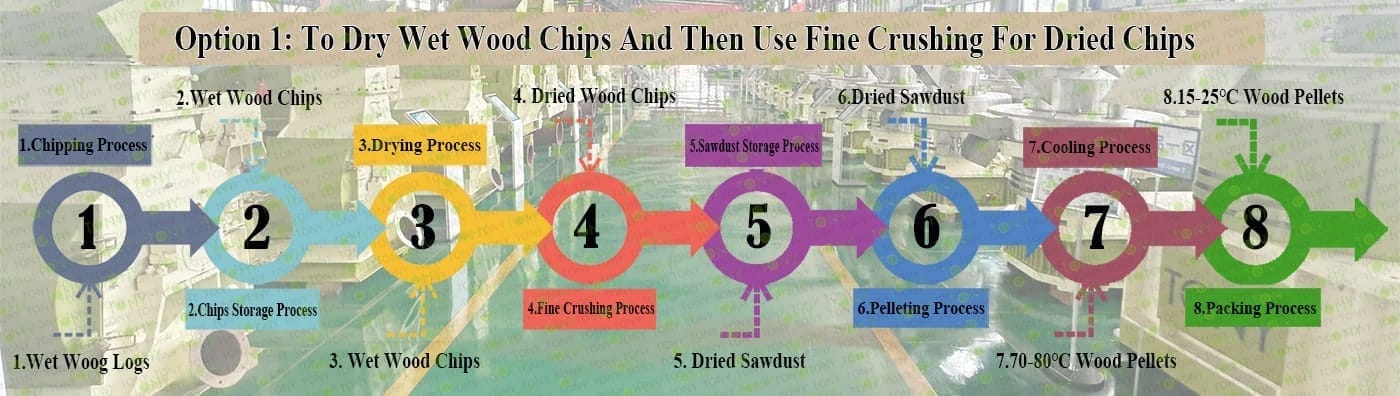

1.To Use TONY Wood Chipper To Grind Wood Logs φ ≤20cm Into 30-40mm Wood Chips.

2.To Use TONY Hammer Mill To Crush 30-40mm Wood Chips Into 8-14mm Sawdust.

3.To Use TONY Single Layer Rotary Drum Dryer To Dry The 45-55% Wood Chips Into 10-15% Wood Chips.

4.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm.

5.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ to 20-30℃.

6.To Use TONY Semi-Auto Packing Machine To Packing Pellets To 15-50KG/Bags.

Storage requirements: Store pellets in dry, ventilated and rain-proof warehouses to avoid direct sunlight.

The stacking height should not be too high (≤3 meters) to prevent the bottom pellets from being crushed and broken.

Storage cycle: It is recommended that no more than 6 months. Long-term storage requires regular checks on humidity and pests.