1. Before starting the biomass pellet machine and pellet machine, thoroughly clean and inspect the entire machine to confirm that the belt is properly tight and the drive bearings are securely tightened. Then, connect a phone and observe whether the motor is rotating in the direction indicated by the markings.

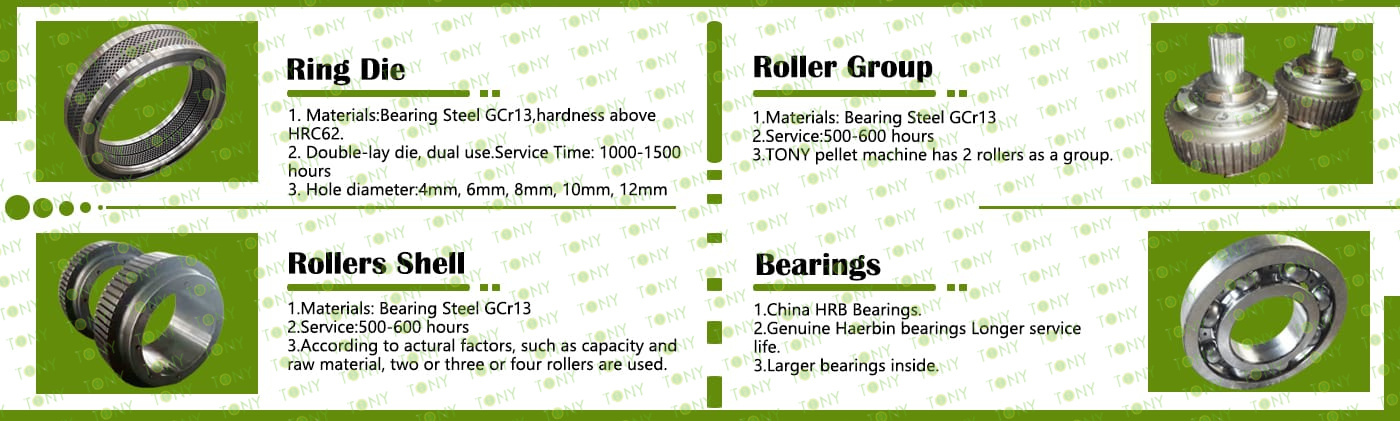

2. Check the distance between the press wheel and the die plate of the biomass pellet machine. It is generally between 0.1-0.3mm and can be adjusted using the "clamp screw" on the press wheel.

3. When testing the biomass pellet machine, take 15 kg of powder. It is best to use bran. If bran is unavailable, 5 catties of peanuts and 15 kg of wheat bran can be used instead. After the powder is prepared, perform a test press. Repeat the press for about 15 minutes. If the feed does not come out, clamp the feed in the die hole with a steel nail in a vise (note that pointed nails should not be used; it is best to grind the nail heads flat). After the feed is pushed through, press again until pellets are produced normally. If the user is having trouble pressing pellets with their own feed formula, clear the holes in the mold, apply some cooking oil to the mold surface, and repeat the above process. After the bran is pressed out, add fine construction sand and continue pressing for about 10 minutes until the pellets are discharged normally.

4. The length of the pellets produced by the biomass pellet machine can be adjusted by adjusting the upper and lower positions of the biomass pellet machine's cutter.

5. To replace the biomass pellet machine's mold plate, remove the hopper and barrel, remove the press wheel and cutter, unscrew the gong cap from the main shaft, and use the "puller" accessory to lift out the flat mold. (The mold plate is reversible and is generally flipped over after more than 1,000 hours of processing.)

When the biomass pellet machine has produced 20,000 kilograms of pellets, the press wheel needs to be removed for cleaning and maintenance, and lubricated with copper. The biomass pellet machine should also undergo comprehensive maintenance and oiling every six months. 6. For safe production, after removing the lower cover of the biomass pellet machine, you must first disconnect the power supply and turn off the machine's power switch. Only then can you touch the press rollers and die with your hands or other tools.

7. When the biomass pellet machine has produced 20,000 jin of pellets, the press rollers must be removed and the machine must be cleaned and lubricated with copper. The biomass pellet machine should also be fully maintained and lubricated every six months.

8. Motors must be grounded to prevent leakage and short circuits.

When using a motor, select the appropriate model for the biomass pellet machine. The motor's power supply circuit must be equipped with an overload protection device.