|

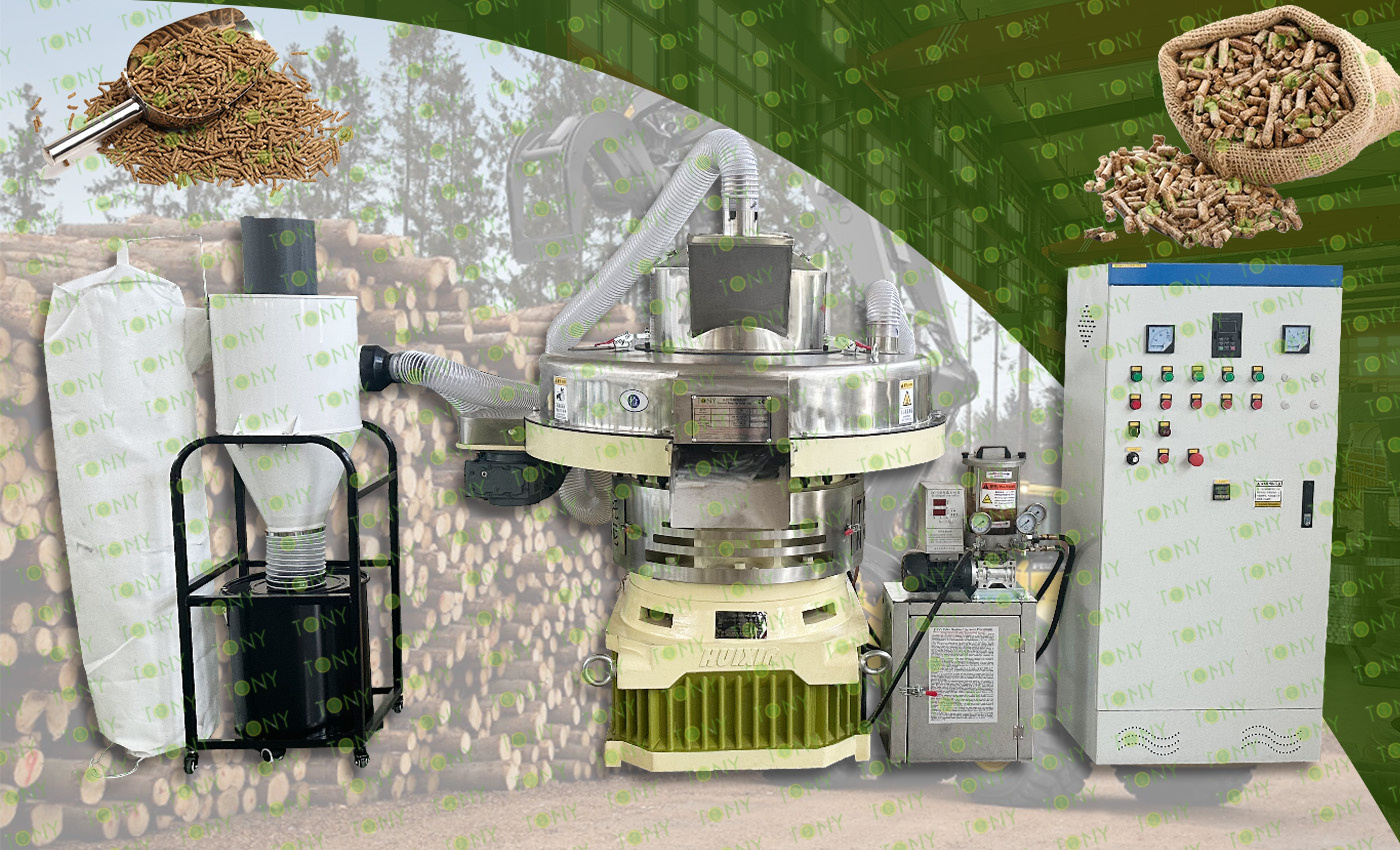

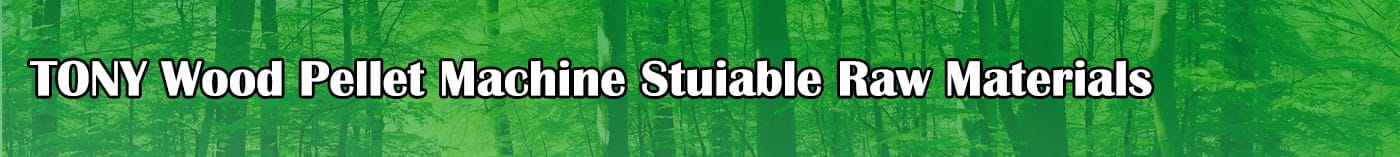

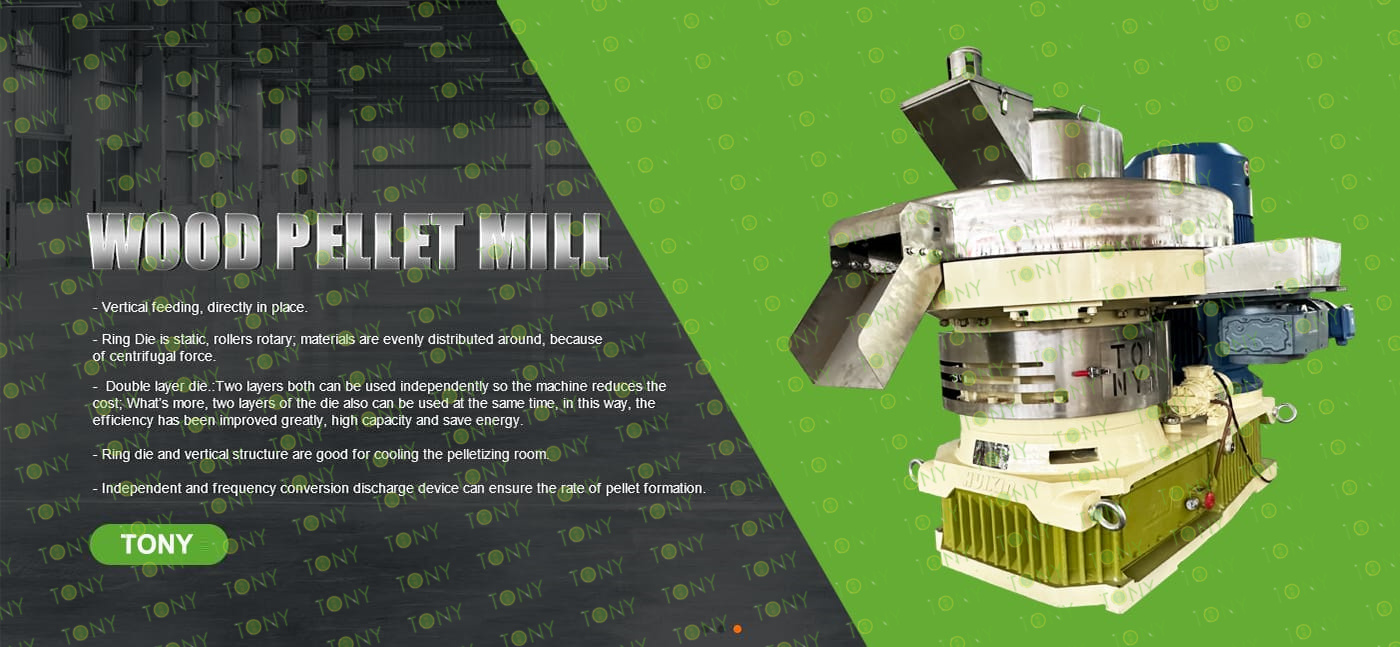

TONY specializes in selling wood pellet machines online. TONY Wood Pellet Machines have all the advantages of vertical ring die pellet machines. It can process all kinds of wood raw materials, such as Various wood scraps, branches, bark, wood strips and other logs and wood chips. TONY brand pellet machines are widely used in various industries and recommended by experts. Wood pellet machines can be used in fertilizers, wood processing, electricity, biomass energy fuel and chemical plants. For low investment and high profits, TONY brand pellet machines will be your best choice for biomass pellet processing. TONY brand pellet machines are sturdy and durable. Their unique design, after research for a long trouble-free service life, is constantly developing to become more and more versatile and tailor-made: different models, versions and options can meet the needs of different customers, the needs of all production areas and the requirements of process automation. |

The working principle of the TONY brand 304 Stainless Steel Wood Pellet Machine is mainly to rely on the pressure and friction between the template and the mold to gradually shape the raw materials and finally cut them into pellet products. The specific process is as follows:

1. Feeding: The biomass raw materials are fed through the feeder, and after pre-treatment such as crushing and mixing, they are sent to the hopper of the 304 Stainless Steel Pellet Machine.

2. Extrusion: The raw materials are subjected to the force between the high-speed rotating template and the stationary mold in the hopper, gradually forming pellet materials.

3. Cutting: After extrusion, the pellet materials are pushed to the inside of the mold to form a ring, and the blade inside the mold cuts the pellets to produce pellet products of the same length.

4. Discharging: The granular products are fed into the discharge port to produce the products of the 304 Stainless Steel Pellet Machine.

| TONY Pellet Machine On Show | TONY Pellet Machine On Clients' Site |

|

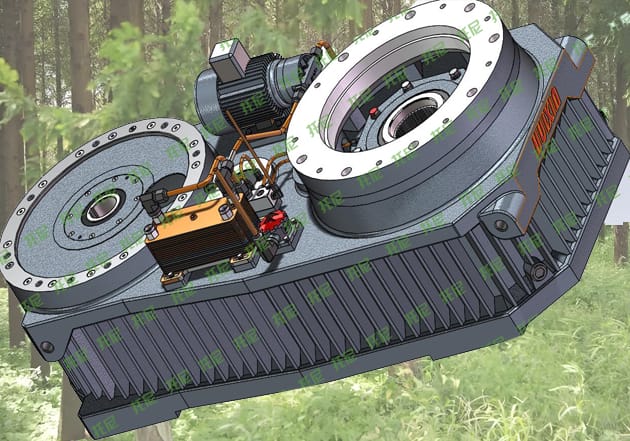

TONY's new 304 stainless steel wood pellet machine mainly composed of 4 parts: 1. TONY new 304 stainless steel vertical ring die pellet machine 2. The rollers automatic lubrication system contains galvanized grease storage barrel. 3. New cyclone and dust bag collect system, including fan and pipe and dust collection bucket. 4. Electrical control system for all the above equipment. |

|

TONY Wood Pellet Machine Model |

||||||

|

Main Parts: |

||||||

|

NO |

Model |

Power |

Capacity |

Weight |

Machine Size |

Remarks |

|

1 |

TYJ450-II |

55KW |

0.8-1.2TPH |

4T |

1900*900*1600MM |

Big gearbox produced by TONY |

|

2 |

TYJ551-II |

90KW |

1-1.5TPH |

5.2T |

2364*1550*1705MM |

Same Model ForHuixin Brand Gearbox Everthing the same,just motor different |

|

3 |

TYJ551-II |

110KW |

1.5-2TPH |

5.3T |

2364*1550*1705MM |

|

|

4 |

TYJ551-III |

132KW |

2-2.5TPH |

5.5T |

2364*1550*1705MM |

|

|

5 |

TYJ760-I |

160KW |

2.5-3TPH |

9T |

2464*1750*2150MM |

Huixin Brand Gearbox |

|

6 |

TYJ760-II |

185KW |

2.8-3.3TPH |

9.2T |

2564*1850*2150MM |

Bigger Model Huixin Brand Gearbox |

|

7 |

TYJ760-III |

200KW |

3-3.5TPH |

9.3T |

2564*1850*2150MM |

Bigger Model Huixin Brand Gearbox |

|

8 |

TYJ860-I |

220KW |

3-4TPH |

11T |

2664*1950*2150MM |

Huixin Brand Gearbox |

|

9 |

TYJ860-II |

250KW |

3.5-4.5TPH |

12T |

2864*2150*2150MM |

Bigger Model for Huixin Brand Gearbox |

|

10 |

TYJ860-III |

280KW |

4-5TPH |

13T |

2864*2150*2150MM |

Bigger Model for Huixin Brand Gearbox |

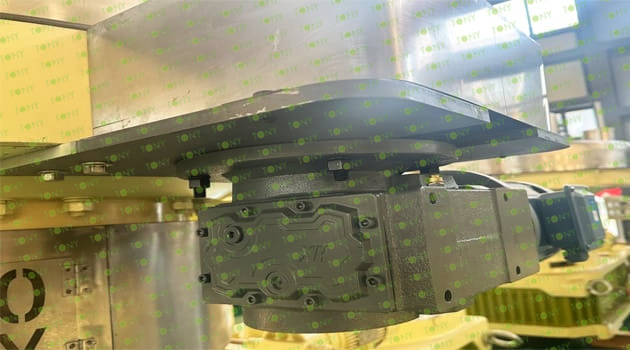

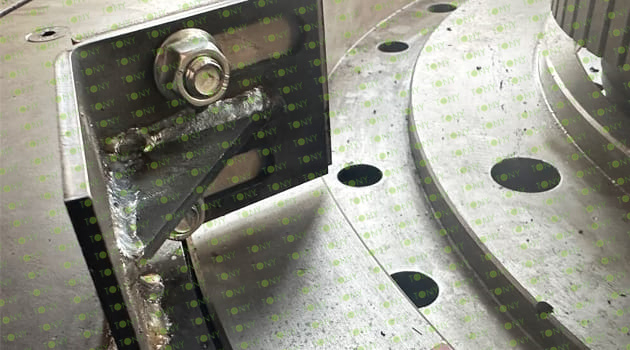

1. TONY Wood Pellet Machine motor shaft is directly connected to the gear shaft, which provides stronger power transmission, greater torque resistance, greater stability and lower maintenance rate.

2. TONY Wood Pellet Machine bearing chamber has been modified, the sealing method has been changed, and the forged and tempered wear-resistant materials have been used to prevent dust from falling into the bearing chamber.

3. TONY gearbox body is larger, the gears are larger, the output is higher, and the power consumption is lower.

4. TONY Wood Pellet Machine bearings are made of genuine heavy-duty Ha shafts, which have a longer bearing life and a lower maintenance rate for the entire machine.

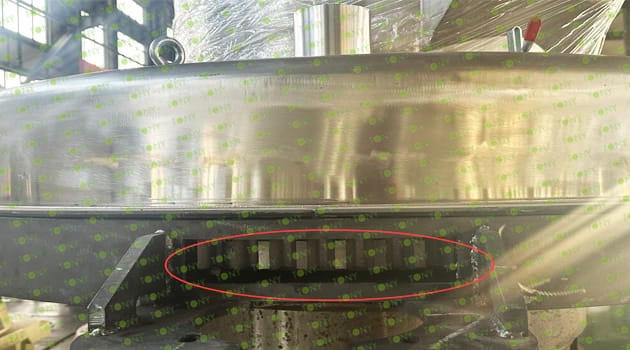

5. TONY Wood Pellet Machine rhe ring die is vertical and double layered, with dual use of upper and lower layers, improving utilization, reducing costs, and increasing efficiency.

6. The pressure wheel rotates, the material is centrifuged, and the surrounding material is evenly distributed.

7. Efficient and energy-saving, automatic timed oil lubrication, ensuring sufficient lubrication of bearings and safer and more reliable operation.

8. High pressure filtration, clean and smooth independent frequency conversion device, ensuring the yield of pellets.

|

TONY Wood Pellet Machine has a variety of models, according to the customer production of different models, pellet machine factory price from USD30000-USD80000. You get what you pay for. The price always depends on the value. Because the pellet machine market is currently more chaotic, customers must be careful to buy! To make a purchase decision after a comprehensive inspection of a number of comprehensive indicators such as product quality, manufacturer scale strength, pre-sales and after-sales service ability, research and development design ability, rather than just looking at the price! Please note: If your purchase cost is very low, the later use cost will be very high! Because the purchase of very low cost equipment is likely to cause you to face endless maintenance later, continuous downtime and maintenance will delay your production and make you pay more money. |

|

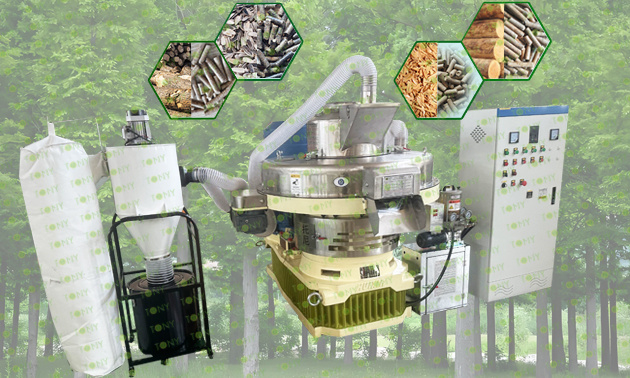

Shandong TONY Environmental Protection Technology Co., Ltd. adopts a gearbox customized with HUIXIN specifically for TONY particle machines. The advantages are as following: 1. The gearbox is larger in size compared to ordinary ones to guarantee sufficient and stable transmission power for the particle machine's operation. 2. The integrated power base is made of high-strength gray cast iron-HT250; All are high-precision hard tooth surface gear transmissions - the carburized tooth surface hardness of low-carbon alloy steel reaches HRC59-64. 3. The high-speed bearings of the gearbox are imported from NSK brand in Japan. |

|

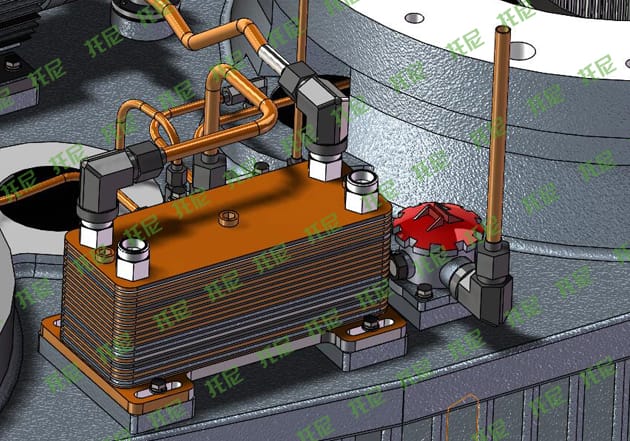

1. The sealing element adopts Taiwan NAK high-temperature resistant fluororubber oil seal. 2. Equipped with a forced lubrication pump on the integrated reducer, it provides a thin oil lubrication system for the rolling shaft system above the bearing chamber to improve the impact of impurities and high temperature on the service life of the rolling shaft system. 3. The gearbox of Shandong TONY Environmental Protection Technology Co., Ltd. only uses plate heat exchangers (oil cooling devices). Compared to traditional tube heat exchangers (oil cooling devices) only used by some manufacturers, they have more advantages. |

|

Plate heat exchanger (oil cooling device) is composed of many stamped corrugated thin plates at certain intervals, sealed with gaskets around them, and overlapped with a frame and compression screws. The four corner holes of the plate and gasket form the fluid distributor and collection pipe. At the same time, the cold and hot fluids are separated reasonably so that they are separated on both sides of each plate. Flow in the channel and conduct heat exchange through the plate. The Advantages Are As Following: (1) Higher Heat Transfer Coefficient. (2) Large Logarithmic Mean Temperature Difference, Small End Temperature Difference. (3) Larger Heat Exchange Area. (4) Easy To Change Heat Exchange Area Or Process Combination. (5) Easy To Clean. |

|

|

|

|

| Gear box adopts HUIXIN brand TONY custom made to increase the heavy duty. Gear box is engraved with HUIXIN brand and TONY custom LOGO. Compared with the ordinary HUIXIN model, the internal gear is enlarged and thickened, and the gear shaft is strengthened and thickened, which is more durable and stable. | The feed port, discharge shell, discharge port, dust collection cover, lifting knife and internal cutting knife of the pellet machine are made of 304 stainless steel to avoid steam corrosion and rust during the formation of particles and increase the durability of the equipment. | The upper discharge shell is made of 304 stainless steel, which avoids the shortcomings of poor compression resistance and easy cracking caused by welding. Arc profile appearance, to avoid operator injury, and arc profile tensile strength is stronger, not easy to damage. | The rotary support is installed under the discharge housing to avoid the traditional return support is easy to be corroded by steam at the top of the pellet machine, the internal steel ball is easy to rust corrosion shortcomings. |

|

|

|

|

| Gear reducer is installed under the discharge housing, the power is stronger, and the gear reducer is not easy to damage. And adopt HUIXIN brand hard tooth surface reducer, torque resistance is stronger. | TONY new pellet machine uses the 304 stainless steel dust cover, steam resistance, corrosion resistance is stronger, and in this way ,it is hard to be damaged. | Internal lifting knife is made of thickened stainless steel, which can effectively avoid high temperature and steam corrosion, increase the durability of the lifting knife, and the lifting effect is better. | Adjustable internal particle cutter, can be adjusted according to customer needs to adjust length of cutter in order to adjust the length of the discharge particle, simple and convenient adjustment. |

|

1. TONY Wood Pellet Machine can press a variety of biomass raw materials, different raw materials only need to replace the ring die. 2. Compression ratio of ring die is set by TONY according to his experience for many years. If the customer changes the raw materials, the ring die must be replaced. 3. Ring die is vertical and double-layer ring die. When pellet machine is working only the lower layer of ring die can press the particles. When reach the lifetime,you can use the other layer. 4. The life of TONY ring die is generally 1000-1500 hours, and service life of ring die is different according to the different raw materials of customers. 5. TONY ring die use alloy steel-bearing steel. After quenching heat treatment, the hardness is higher, the wear resistance is greater, and the service life is longer. |

|

Main Pellet Machine 1.SS304 type 2.Capacity:1-5T/hour(It depends on clients raw materials) 3.Power:90kw-280kw(Stripping Material Motors) 4.Motors can be changed to frequency motors according to Customer demand 5.Use HUIXIN Brand TONY Custom-made bigger and heavier gearbox. |

|

|

Automatic Lubrication System For Rollers Bearings 1.Automatic Grease lubrication system for rollers bearings. 2.Automatic Grease lubrication system for main shaft bearings. 3.It can keep the pellet machine in maintenance for 20 hours. 4.Automatic fixed time lubrication.Customer can set time by himself. 5.Increase the oil circuit failure alarm device, once blocked, alarm immediately. |

|

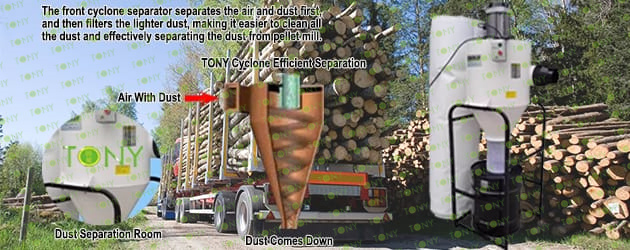

Cyclone And Dust Collecter 1.It is mainly used to collect dust that come out of pellet machine during producing the pellets. 2. There are 3 dust removal interfaces, respectively connected to the pellet machine 2 steam outlet, pellet machine bearing room dust discharge hole to remove the dust. 3.New cyclone and dust bag collect system, including fan and pipe and dust collection bucket. |

|

|

Motors 1.TONY Motors uses Qingao SHUOBO Brand. 2.Pure copper national standard motor. 3.The motors can also be changed into a variable frequency motor according to customer needs. Please consult TONY for the price difference of variable frequency motor. 4.You can also chose your motor brand by consulting TONY price difference. |

|

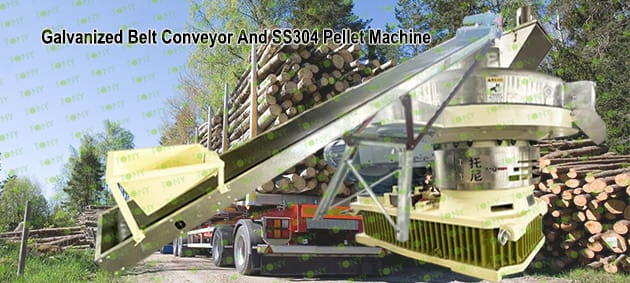

Galvanized Belt Conveyor 1. It is used to transport the sawdust to the pellet machine, optional according to customer needs. 2. If customer digs a pit, you will need belt conveyor with 50cm width and 10 meters length . If customer does not dig a pit, you will need belt conveyor with 50cm width and 8 meters length . 3. The belt conveyor needs to be equipped with a frequency converter to achieve one-button simultaneous operation with the pellet machine, and control the conveying speed of the belt conveyor by sensing the current of the pellet machine. |

|

|

Screw Conveyor 1. It is used to transport the sawdust to the pellet machine, optional according to customer needs. 2. If customer digs a pit, you will need screw conveyor with φ219 and 6m length. If customer does not dig a pit, you will need screw conveyor with φ219 and 6m length. 3. The screw conveyor needs to be equipped with a frequency converter to achieve one-button simultaneous operation with the pellet machine, and the conveying speed of the screw conveyor is controlled by sensing the current of the pellet machine. |

|

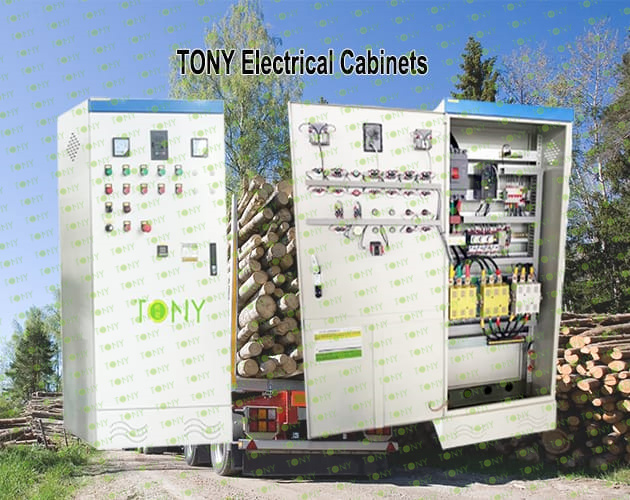

Electrical Cabinets 1.We use well-known Chinese brand electrical components, and we can also choose Schneider and Siemens electrical appliances according to customer requirements. Please consult TONY for the price difference. 2.TONY pellet machine has a one-button start function to prevent the machine from being damaged due to incorrect operation by customers who do not know the start-up sequence. 3.The control panel has 3 sound and light buzzers. One is the lubrication fault alarm indicator. When the automatic lubrication system of the roller and the automatic lubrication pump of the gear box are not started or fail during operation or are overloaded during operation, the alarm indicator will light up. One is when the automatic lubrication system of the roller is overpressured, the alarm indicator will light up. One is when the main machine of the pellet machine is overheated, the alarm indicator will light up. 4.If the customer chooses a variable frequency motor, all components in the electric control cabinet need to adopt variable frequency control. Please contact TONY to obtain the price difference of the variable frequency control cabinet. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2025 Tony Machinery - All Rights Reserved. Map