|

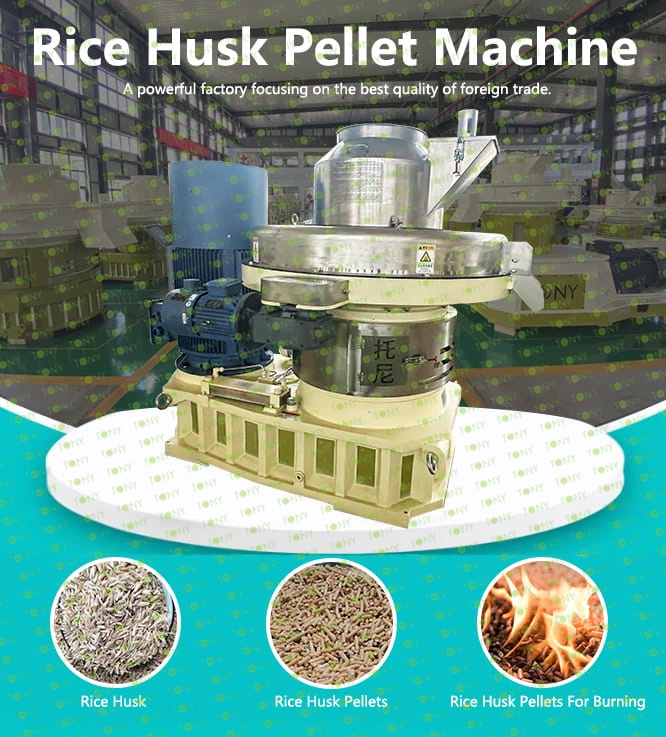

TONY Rice Husk pellets are made by pressing rice husks into high-density particles, which has the advantages of low ignition point, high heating, clean and sanitary combustion process, and is a high-quality fuel to replace coal and other traditional fuels In recent years, coal resources are increasingly lacking, and the development and utilization of biomass is of great significance to global environmental protection and energy conservation. With rice husk as the main raw material, the formed rice husk particles have the characteristics of high combustion efficiency, large heat, less sulfur dioxide, ammonia nitrogen compounds and dust, etc., and the combustion efficiency reaches more than 85% (more than the ordinary coal combustion efficiency of about 60%). Using rice husk to do biomass pellet process is very simple, rice husk does not need pretreatment directly can enter the rice husk pellet machine for granulation, low cost and simple operation, rice husk pellet as a new biomass fuel, with high heat value. In contrast, the heat density of wood chips is only about 1800-2200 kcal/kg. Therefore, the thermal efficiency of rice husk particles is more than 50% higher than that of traditional wood chips, and it is a very excellent biomass fuel. |

The working principle of the TONY brand Rice Husk Pellet Machine is mainly to rely on the pressure and friction between the template and the mold to gradually shape the raw materials and finally cut them into pellet products. The specific process is as follows:

1. Feeding: The biomass raw materials are fed through the feeder, and after pre-treatment such as crushing and mixing, they are sent to the hopper of the 304 Stainless Steel Pellet Machine.

2. Extrusion: The raw materials are subjected to the force between the high-speed rotating template and the stationary mold in the hopper, gradually forming pellet materials.

3. Cutting: After extrusion, the pellet materials are pushed to the inside of the mold to form a ring, and the blade inside the mold cuts the pellets to produce pellet products of the same length.

4. Discharging: The granular products are fed into the discharge port to produce the products of the 304 Stainless Steel Pellet Machine.

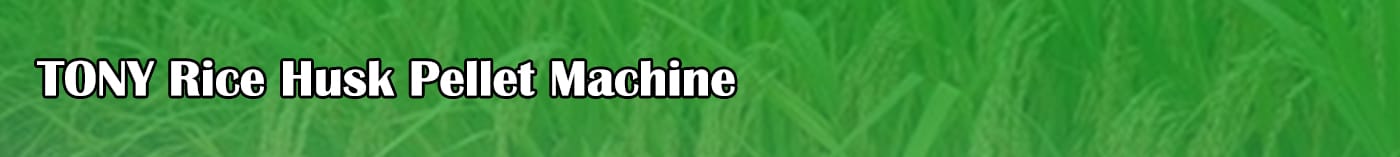

| TONY Rice Husk Machine On Show | TONY Rice Husk Machine On Clinets Site |

|

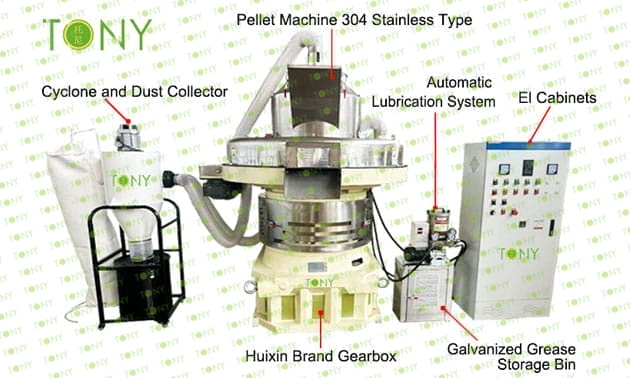

TONY's rice husk pellet machine mainly composed of 4 parts: 1. TONY new rice husk pellet machine. 2. The rollers automatic lubrication system contains galvanized grease storage barrel. 3. New cyclone and dust bag collect system, including fan and pipe and dust collection bucket. 4. Electrical control system for all the above equipment. |

|

TONY Rice Husk Pellet Machine Type Model |

|||||||||

|

Main Parts: 1.TONY new 304 stainless steel rice husk pellet machine. 2. The rollers automatic lubrication system with galvanized grease storage barrel. 3. New cyclone and dust bag collect system, including fan and pipe. 4. Electrical control system for all the above equipment. |

|||||||||

|

NO |

Model |

Main Power |

Lubrication Power |

Dust Power |

Capacity |

Weight |

Ring Die Inner Size |

Machine Size |

Remarks |

|

1 |

TYJ551-III-90 |

90KW+3KW |

0.25KW |

0.95KW |

1-1.5TPH |

5.2T |

560MM |

2364*1550*1705MM |

Same Model For Huixin Brand Gearbox Everthing the same,just motor differentGearbox Center Distance:1048mm |

|

2 |

TYJ551-III-110 |

110KW+3KW |

0.25KW |

0.95KW |

1.5-2TPH |

5.3T |

560MM |

2364*1550*1705MM |

|

|

3 |

TYJ551-III-132 |

132KW+3KW |

0.25KW |

0.95KW |

2-2.5TPH |

5.5T |

560MM |

2364*1550*1705MM |

|

|

4 |

TYJ760-III-160 |

160KW+4KW |

0.25KW |

0.95KW |

2.5-3TPH |

9T |

760MM |

2464*1750*2150MM |

Huixin Brand Gearbox Gearbox Center Distance:1098mm |

|

5 |

TYJ760-III-185 |

185KW+4KW |

0.25KW |

0.95KW |

2.8-3.3TPH |

9.2T |

760MM |

2564*1850*2150MM |

Bigger Model Huixin Brand Gearbox |

|

6 |

TYJ760-III-200 |

200KW+4KW |

0.25KW |

0.95KW |

3-3.5TPH |

9.3T |

760MM |

2564*1850*2150MM |

Bigger Model Huixin Brand Gearbox |

|

7 |

TYJ850-III-220 |

220KW+4KW |

0.25KW |

0.95KW |

3-4TPH |

11T |

860MM |

2664*1950*2150MM |

Huixin Brand Gearbox Gearbox Center Distance:1238mm |

|

8 |

TYJ860-III-250 |

250KW+4KW |

0.25KW |

0.95KW |

3.5-4.5TPH |

12T |

860MM |

2864*2150*2150MM |

Bigger Model for Huixin Brand Gearbox |

|

9 |

TYJ860-III-280 |

280KW+4KW |

0.25KW |

0.95KW |

4-5TPH |

13T |

860MM |

2864*2150*2150MM |

Bigger Model for Huixin Brand Gearbox |

1. TONY Rice Husk pellet machine motor shaft is directly connected to the gear shaft, which provides stronger power transmission, greater torque resistance, greater stability and lower maintenance rate.

2. TONY Rice Husk pellet machine bearing chamber has been modified, the sealing method has been changed, and the forged and tempered wear-resistant materials have been used to prevent dust from falling into the bearing chamber.

3. TONY gearbox body is larger, the gears are larger, the output is higher, and the power consumption is lower.

4. TONY Rice Husk pellet machine bearings are made of genuine heavy-duty Ha shafts, which have a longer bearing life and a lower maintenance rate for the entire machine.

5. TONY Rice Husk pellet machine rhe ring die is vertical and double layered, with dual use of upper and lower layers, improving utilization, reducing costs, and increasing efficiency.

6. The pressure wheel rotates, the material is centrifuged, and the surrounding material is evenly distributed.

7. Efficient and energy-saving, automatic timed oil lubrication, ensuring sufficient lubrication of bearings and safer and more reliable operation.

8. High pressure filtration, clean and smooth independent frequency conversion device, ensuring the yield of pellets.

|

TONY Rice Husk Pellet Machine has a variety of models, according to the customer production of different models, pellet machine factory price from USD20000-USD70000. You get what you pay for. The price always depends on the value. Because the pellet machine market is currently more chaotic, customers must be careful to buy! To make a purchase decision after a comprehensive inspection of a number of comprehensive indicators such as product quality, manufacturer scale strength, pre-sales and after-sales service ability, research and development design ability, rather than just looking at the price! Please note: If your purchase cost is very low, the later use cost will be very high! Because the purchase of very low cost equipment is likely to cause you to face endless maintenance later, continuous downtime and maintenance will delay your production and make you pay more money. |

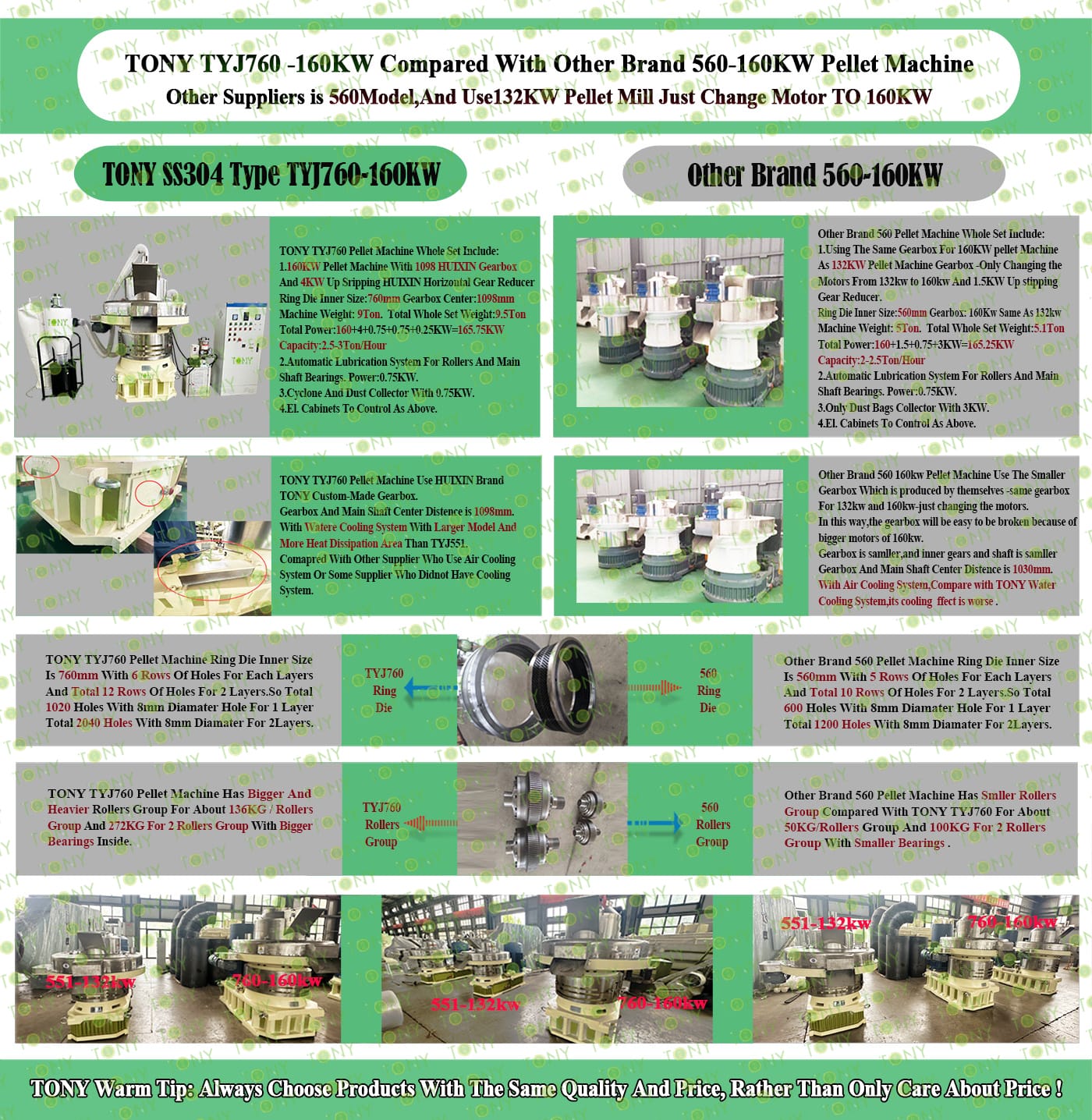

TONY TYJ760-160KW Pellet Machine Compared With TONY TYJ551-132KW Pellet Machine

TONY TYJ760-160KW Pellet Machine Compared With Other Brand 560-160KW Pellet Machine

|

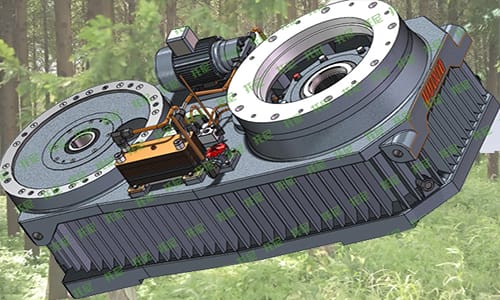

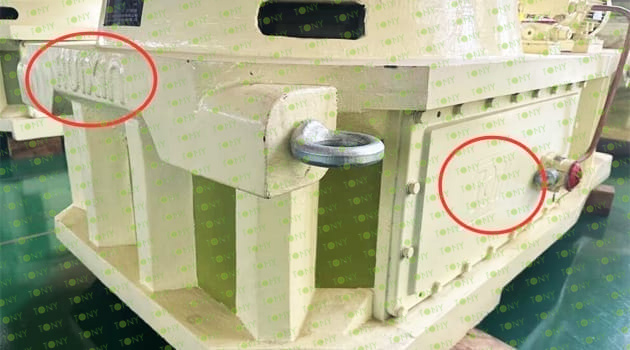

Shandong TONY Environmental Protection SCI-TECH CO., LTD adopts a gearbox customized with HUIXIN specifically for Tony particle machines. The advantages are as following: 1.Compared to ordinary counterparts, the gearbox is one size larger in both the box and internal gears to ensure sufficient stable transmission power for the operation of the particle machine. 2.The integrated power base is made of high-strength gray cast iron-HT250; All are high-precision hard tooth surface gear transmissions - the carburized tooth surface hardness of low-carbon alloy steel reaches HRC59-64, with an accuracy level of 5-6. 3.The high-speed bearings of the gearbox are imported from NSK brand in Japan. |

|

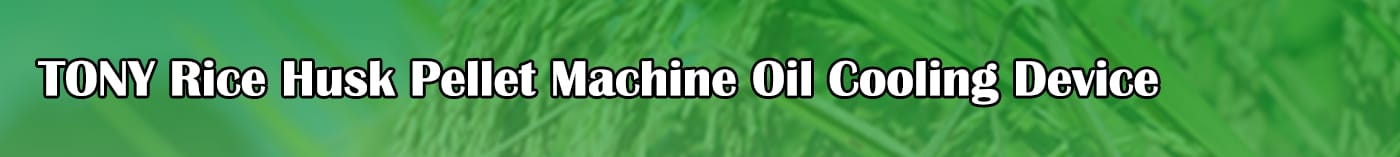

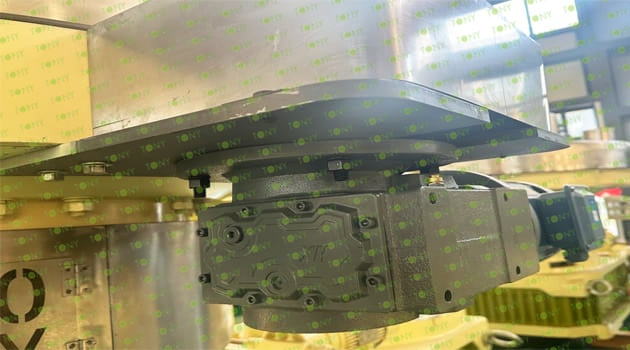

1.TONY use HUIXIN brand custom-made TONY special gearbox with bigger and heavier gears inside. 2.TONY 90KW HUIXIN brand gearbox center distance is 1048mm which is bigger than competitors 3.The sealing elements adopt the high-temperature resistant fluororubber oil seals of NAK from Taiwan, China. 4.The integrated reducer has a forced lubrication pump to provide thin oil lubrication for the rolling shaft system above the bearing chamber, reducing the impact of impurities and high temperature on its service life. 5.The gearbox of Shandong TONY Environmental Protection SCI-TECH CO., LTD only uses plate heat exchangers (oil cooling devices). Compared to traditional tube heat exchangers (oil cooling devices) only used by some manufacturers, they have more advantages. |

|

The advantages of plate heat exchangers (oil cooled devices) over tube heat exchangers (oil cooled devices) are as following: (1) Higher Heat Transfer Coefficient Due to the fact that different corrugated plates are in the opposite direction, forming complex channels, the fluid between the corrugated plates flows in a three-dimensional rotating flow. Turbulence can occur at lower Reynolds numbers (generally Re=50-200), resulting in a higher heat transfer coefficient. Generally, it is considered that the red color is 3-5 times that of the shell and tube type. (2) Large Logarithmic Mean Temperature Difference, Small End Temperature Difference The hot surface and no bypass of the plate heat exchanger (oil cooling device) result in a small temperature difference at the end of the plate heat exchanger, and the heat transfer to water can be less than 1 ℃, while the shell and tube heat exchanger can only reach 5 ℃, which is not conducive to low-temperature heat dissipation and oil cooling. (3) Larger Heat Exchange Area The plate heat exchanger has a compact structure, and the heat transfer area per unit volume is 2-5 times that of a tube heat exchanger. Unlike shell and tube heat exchangers, it does not require a reserved maintenance position for the extraction of tube bundles. Therefore, in order to achieve the same heat transfer capacity, the plate heat exchanger occupies an area of approximately 1/5 to 1/8 of the shell and tube heat exchanger. (4) Easy To Change Heat Exchange Area Or Process Combination Plate heat exchangers (oil cooled devices) can achieve the required process combination by changing the layout of plate types or replacing multiple plate types, making the heat exchange area of shell and tube heat exchangers adapt to new heat exchange conditions, resulting in more obvious heat dissipation and more prominent oil cooling. The heat exchange area of a tubular heat exchanger is fixed and cannot be increased. |

|

|

Main Pellet Machine 1.SS304type 2.Capacity:1-5T/hour (It depends on clients raw materials) 3.Power:90kw-280kw(Stripping Material Motors) 4.Motors can be changed to frequency motors according to clinets' demand. 5.Use HUIXIN Brand TONY Custom-made bigger and heavier gearbox. |

|

|

Automatic Lubrication System For Rollers Bearing 1.The pellet machine is equipped with an advanced Automatic Grease lubrication system, specifically designed for the roller bearings. This system ensures that each roller bearing receives precise and consistent lubrication, reducing friction and wear, and ultimately prolonging the service life of these crucial components. 2.In addition to the rollers, there is also an Automatic Grease lubrication system dedicated to the main shaft bearings. Given the high rotational speed and heavy load that the main shaft endures during operation, this lubrication system plays a vital role in maintaining smooth operation, minimizing heat generation, and safeguarding the integrity of the main shaft and its associated bearings. 3.One of the remarkable features of this lubrication setup is its ability to keep the pellet machine in optimal maintenance condition for an extended period of up to 20 hours. This means fewer interruptions in the production process, allowing for greater productivity and efficiency. 4.Automatic fixed time lubrication.Customer can set time by himself. 5.Increase the oil circuit failure alarm device, once blocked, alarm immediately. |

|

Cyclone And Dust Collecter 1.This equipment is primarily designed to gather the dust generated during the pellet production process by the pellet machine. As the pellets are being manufactured, a significant amount of dust is emitted, and this device plays a crucial role in maintaining a clean working environment by effectively capturing that dust. 2.It features three dust removal interfaces, each serving a specific purpose. One interface is connected to the steam outlet of the pellet machine, where steam and accompanying dust are released. Another is linked to the dust discharge hole in the pellet machine's bearing room, preventing the accumulation of dust that could potentially affect the machine's performance. These connections ensure comprehensive dust removal. 3.The system incorporates a newly developed cyclone and dust bag collection setup. It comprises a powerful fan that generates the necessary suction force, a network of pipes to transport the dust-laden air, and a dust collection bucket where the captured dust is finally deposited, providing an efficient and reliable solution for dust management. |

|

|

Motors 1.TONY Motors employs the Qingao SHUOBO brand. This brand is known for its quality and reliability, ensuring smooth and efficient operation of the equipment. 2. The motors are pure copper national standard motors. Pure copper windings offer superior conductivity and durability, reducing energy loss and increasing the lifespan of the motor. 3. Additionally, the motors can be transformed into a variable frequency motor as per customer requirements. For inquiries regarding the price difference of the variable frequency motor, please consult TONY. This option provides greater flexibility in controlling the motor's speed and performance, allowing for optimized operation in different applications. 4. Customers also have the option to choose their preferred motor brand. To determine the price difference for alternative brands, please consult TONY. This allows customers to select a motor that best suits their specific needs and budget, while still ensuring high-quality performance. |

|

Galvanized Belt Conveyor 1. This component is specifically designed to transport sawdust to the pellet machine. It is an optional accessory, which can be customized based on the specific requirements and preferences of our customers. 2. In cases where the customer opts to dig a pit, a belt conveyor with a width of 50cm and a length of 10 meters will be necessary. This particular specification ensures efficient material transfer in such setups. Conversely, if the customer decides not to dig a pit, a belt conveyor with a width of 50cm and a length of 8 meters will suffice to meet the operational demands. 3. The belt conveyor ought to be fitted with a frequency converter. This addition enables one-button simultaneous operation in tandem with the pellet machine. Moreover, it can control the conveying speed of the belt conveyor by sensing the current of the pellet machine. This intelligent control mechanism optimizes the overall production process, ensuring seamless coordination between the two pieces of equipment and enhancing operational efficiency. |

|

|

Screw Conveyor 1.This equipment is primarily utilized for transporting sawdust to the pellet machine. It is an optional component, and its inclusion can be determined based on the specific requirements and preferences of our customers. 2.In cases where the customer has dug a pit on-site, a screw conveyor with a diameter of φ219 and a length of 6 meters will be necessary to facilitate the smooth transfer of materials. Similarly, if the customer has not dug a pit, the same specification of screw conveyor, namely φ219 in diameter and 6 meters in length, will still be required to ensure the proper conveyance of the sawdust. 3.The screw conveyor ought to be fitted with a frequency converter. This addition enables it to achieve one-button simultaneous operation in tandem with the pellet machine. By sensing the current of the pellet machine, the conveying speed of the screw conveyor can be precisely controlled, thus optimizing the overall production process and ensuring seamless coordination between the two pieces of equipment. |

|

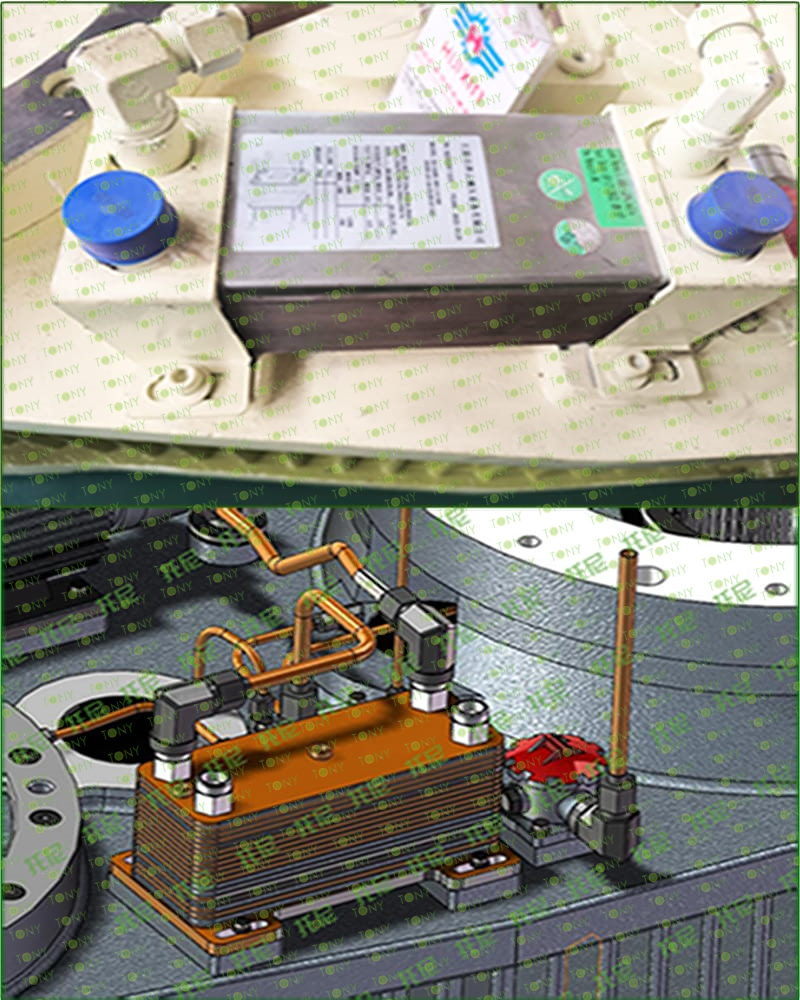

Electrical Cabinets 1.We use well-known Chinese brand electrical components, and we can also choose Schneider and Siemens electrical appliances according to customer requirements. Please consult Tony for the price difference. 2.TONY pellet machine has a one-button start function to prevent the machine from being damaged due to incorrect operation by customers who do not know the start-up sequence. 3.The control panel has 3 sound and light buzzers.One is the lubrication fault alarm indicator. When the automatic lubrication system of the roller and the automatic lubrication pump of the gear box are not started or fail during operation or are overloaded during operation, the alarm indicator will light up.One is when the automatic lubrication system of the roller is overpressured, the alarm indicator will light up.One is when the main machine of the pellet machine is overheated, the alarm indicator will light up. 4.If the customer chooses a variable frequency motor, all components in the electric control cabinet need to adopt variable frequency control. Please contact Tony to obtain the price difference of the variable frequency control cabinet. |

|

|

|

|

|

| The gear box adopts Zhejiang HUIXIN brand TONY custom model to increase the heavy duty. The gear box is engraved with Zhejiang HUIXIN brand and TONY custom LOGO. Compared with the ordinary HUIXIN model, the internal gear is enlarged and thickened, and the gear shaft is strengthened and thickened, which is more durable and stable. | The feed port, discharge shell, discharge port, dust collection cover, lifting knife and internal cutting knife of the pellet machine are made of 304 stainless steel to avoid steam corrosion and rust during the formation of particles and increase the durability of the equipment. | The upper discharge shell is made of 304 stainless steel, which avoids the shortcomings of poor compression resistance and easy cracking caused by welding. Arc profile appearance, to avoid operator injury, and arc profile tensile strength is stronger, not easy to damage | The rotary support is installed under the discharge housing to avoid the traditional return support is easy to be corroded by steam at the top, the internal steel ball is easy to rust corrosion shortcomings. |

|

|

|

|

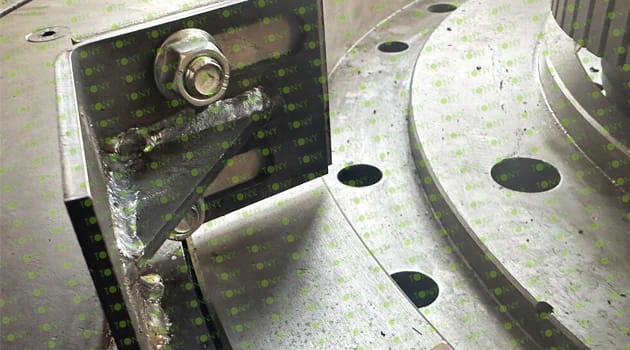

| The gear reducer is installed under the discharge housing, the power is stronger, and the gear reducer is not easy to damage. And adopt the Zhejiang HUIXIN brand hard tooth surface reducer, which is a brand of gear box, the torque resistance is stronger, and the rotation power is more sufficient. | 304 stainless steel dust cover, steam resistance, corrosion resistance is stronger, and in this way ,it is hard to be damaged. | The internal lifting knife is made of thickened stainless steel, which can effectively avoid high temperature and steam corrosion, increase the durability of the lifting knife, and the lifting effect is better, so that the raw materials inside the pellet machine are not easy to cover and pile. | Adjustable internal particle cutter, can be adjusted according to customer needs to adjust the length of the cutter in order to adjust the length of the discharge particle, simple and convenient adjustment. |

|

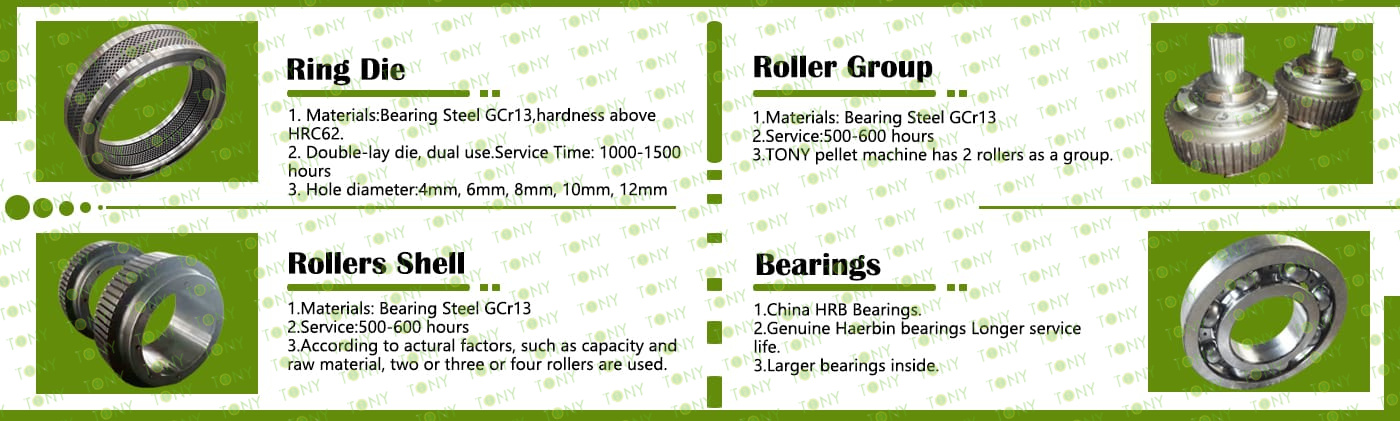

1. TONY Rice Husk pellet machine can press a variety of biomass raw materials, different raw materials only need to replace the ring die. 2. Each raw material corresponds to a ring die with a compression ratio. If you have a variety of raw materials later, it is recommended to buy ring dies with different compression ratios from TONY. 3. The compression ratio of ring die is set by TONY according to his experience for many years. If the customer changes the raw materials, the ring die must be replaced. 4. The ring die of TONY brand is vertical and double-layer ring die. Each time the particles are pressed, only the lower layer of ring die can press the particles. When the life of the lower layer of ring die ends, the mold can be turned to use the other ring die. 5. The life of TONY ring die is generally 1000-1500 hours, and the service life of ring die is different according to the different raw materials of customers. 6. The material of TONY ring die is alloy steel-bearing steel. After quenching heat treatment, the hardness is higher, the wear resistance is greater, and the service life is longer. 7. Contact TONY to obtain the ring die compression ratio of different raw materials. 8.A good ring die can extend the service life of the granulator and reduce the cost of maintenance and replacement. 9.As the core part of the pelletizing machine, the ring die needs to be cleaned and maintained regularly, and needs to be stored in a dry, dust-free and ventilated environment to ensure the service life of the ring mold and the pelletizing effect. |

|

|

|

|

| Rice Husk Pellet Line | Peanut Shell Pellet Line | Sunflower Husk Pellet Line | Coffee Husk Pellet Line |

|

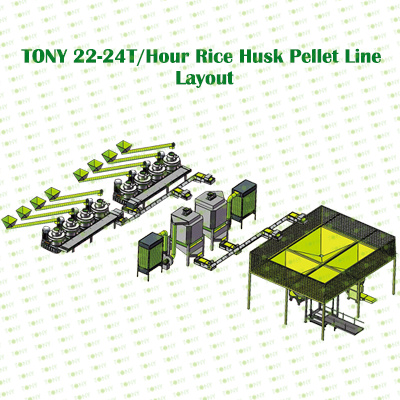

1.Product: Rice Husk Pellet line. 2.Capacity: 22-24T/Hour3.TONY Brand 22-24Ton/Hour Rice Husk Pellet Line Project Process 4.Main Machine: TONY Pellet MachineTYJ760-Ⅲ-185kw,Pellets Coller,Cooling Bin,Packing Machine,Ton Packing MachineAnd Belt Conveyors 5.Total Power: About 180KW 6.Need Area: About 800-900㎡ 7.Country: Myanmar |

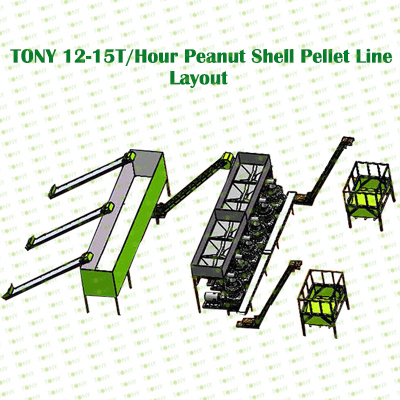

1.Product: Peanut Shell Pellet Line. 2.Capacity:12-15T/Hour 3.TONY Brand 12-15Ton/Hour Peanut Shell Pellet Line Project Process 4:Main Machine: TONY Storage Silo,TONY Pellet MachineTYJ551-Ⅲ-132kw,Pellets Cooler And Belt Conveyors 5.Total Power: About 880KW 6.Need Area:About 600-700㎡ 7.Country: China |

1.Product:Sunflower Husk Pellets Line 2.Capacity:8-10T/Hour 3.TONY Brand 8-10Ton/Hour Sunflower Husk Pellet Line Project Process 4.Main Machine: Mixing Chamber,Hammer Mill, TONY Pellet Machine TYJ551-III-132KW,Pellets Coller,And Belt Conveyors. 5.Total Power: About 790KW 6.Need Area:About 800-900m㎡ 7.Country: Kazakhstan |

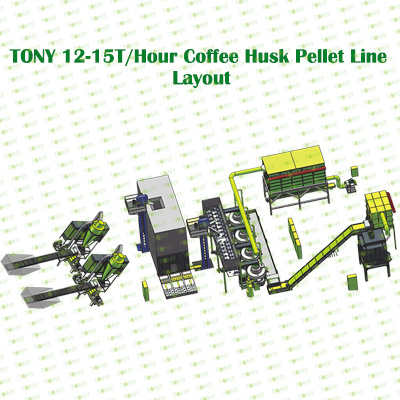

1.Product: Coffee Husk Pellets Line 2.Capacity: 12-15T/Hour 3.TONY Brand 12-15Ton/Hour Coffee Husk Pellet Line Project Process 4.Main Machine:Hammer Mill, Storage Bin,TONY Pellet MachineTYJ760-III-200KW,Pellets Coller,And Belt Conveyors. 5.Total Power: About 2000KW 6.Need Area: About 800-900m㎡ 7.Country: Vietnam |

|

|

|

|

| Hazelnut Husk Pellet Line | Walnut Shell Pellet Line | Coconut Shell Pellet Line | Palm Nut Shell Pellet Line |

|

1.Product: Hazelnut Husk Pellet Line. 2.Capacity: 5-6T/Hour 3.TONY Brand 5-6Ton/Hour Hazelnut Husk Pellet Line Project Process 4.Main Machine: Hammer Mill,Rotary Drum Dryer,TONY Pellet MachineTYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors Packing Machine And Belt Conveyors. 5.Total Power: About 695KW 6.Need Area: About 700-900㎡ 7.Country: Turkey |

1.Product: Walnut Shell Pellet line. 2.Capacity: 17-18T/Hour 3.TONY Brand 17-18Ton/Hour Walnut Shell Pellet Line Project Process 4.Main Machine: Hammer Mill,Rotary Drum Dryer,TONY Pellet MachineTYJ760-Ⅲ-185KW,Pellets Cooler,Packing Machine And Belt ConveyorsPacking Machine And Belt Conveyors 5.Total Power: About 1950KW 6.Need Area: About 1600-1800㎡ 7.Country: Mexico |

1.Product: Coconut Shell Pellets Line 2.Capacity: 24-27T/Hour 3.TONY Brand 24-27Ton/Hour Coconut Shell Pellet Line Project Process 4:Main Machine: Comprehensive chipper, Hammer Mill,Rotary Drum Dryer,.Sawdust Storage ,TONY Pellet MachineTYJ860-III-250KW,Pellets Coller,Packing Machine ,Palletizer And Belt Conveyors. 5.Total Power: About 2234KW 6.Need Area: About 2400-3000m㎡ 7.Country: Indonesia |

1.Product:Palm Nut Shell Pellets Line 2.Capacity:14-16Ton/Hour 3.TONY Brand 14-16Ton/Hour Palm Nut Shell Pellet Line Project Process 4.Main Machine:Comprehensive Chipper, Hammer Mill,Rotary Drum Dryer,TONY Pellet MachineTYJ860-III-250KW,Pellets Coller,Packing MachineAnd Belt Conveyors. 5.Total Power:About 2260KW 6.Need Area:About 1800-2000m㎡ 7.Country:Malaysia |

|

|

|

|

|

|

2025 Tony Machinery - All Rights Reserved. Map