|

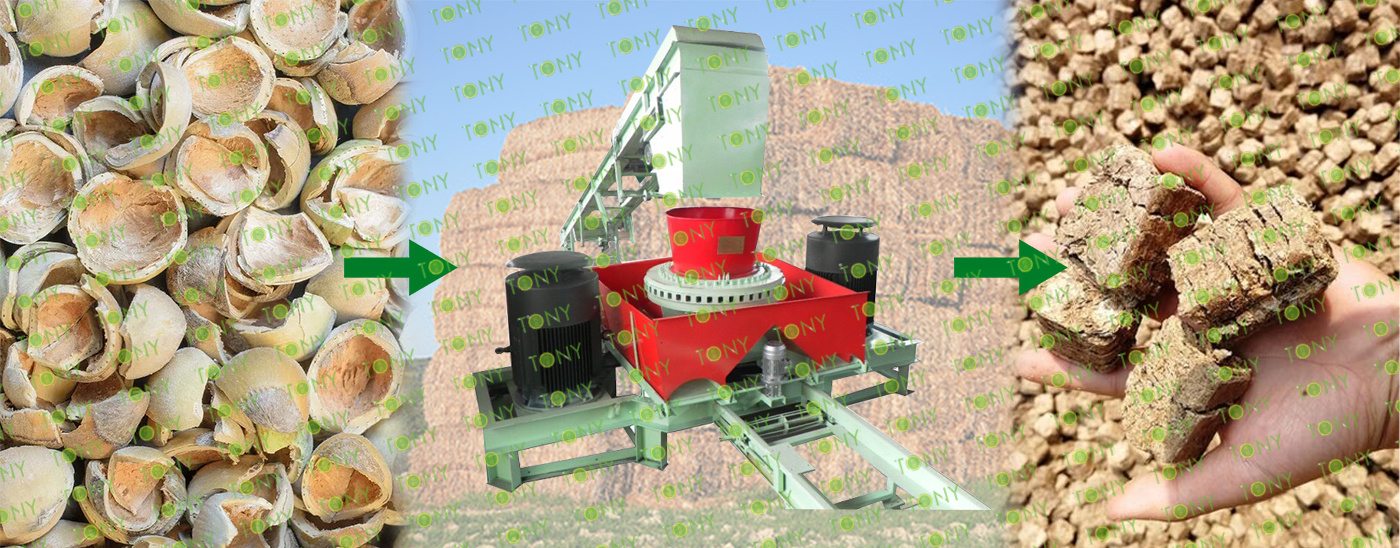

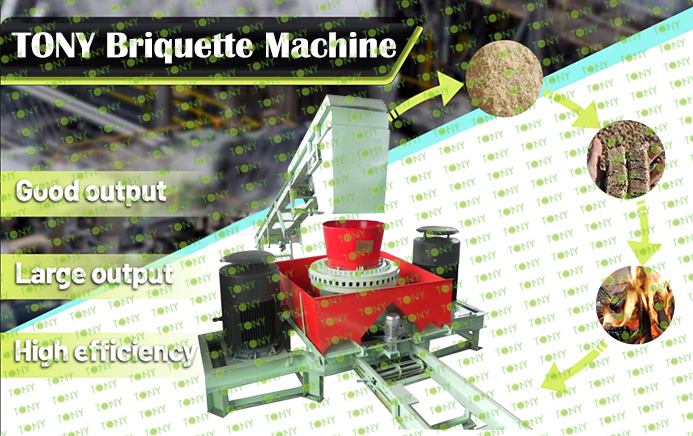

TONY Briquette Machine is a special equipment to extrude crop stalks into blocks, mainly corn stalks, branches, grass, wood chips, shavings and other stalk biomass raw materials. First use the crusher and other equipment to crush the raw materials with a growth degree of 20~50 mm and moderate water content, through the feeding conveyor, and then enter the pressing machine processing, extrusion into the block, the block density is 0.6~1.0 g/cubic centimeter, convenient transportation and preservation. The production of the pressing block overcomes the weaknesses of the straw itself, such as light weight, large volume, easy to use the external conditions such as wind, rain, snow and fire, and meets the requirements of commercialization. Corn straw, bean straw is generally used to press feed, known as the ruminant "compression biscuits", can also be used as fuel straw pressing, so that the pressing raw materials more extensive. In the pressing of feed, it is necessary to pay attention to the raw materials can not be mildew, and pay attention to dust removal in areas with large sand, and pay attention to air drying after pressing the block to reduce the humidity to below 15%. Pressing the fuel can be relatively simple, without considering the problems of mildew and dust removal. |

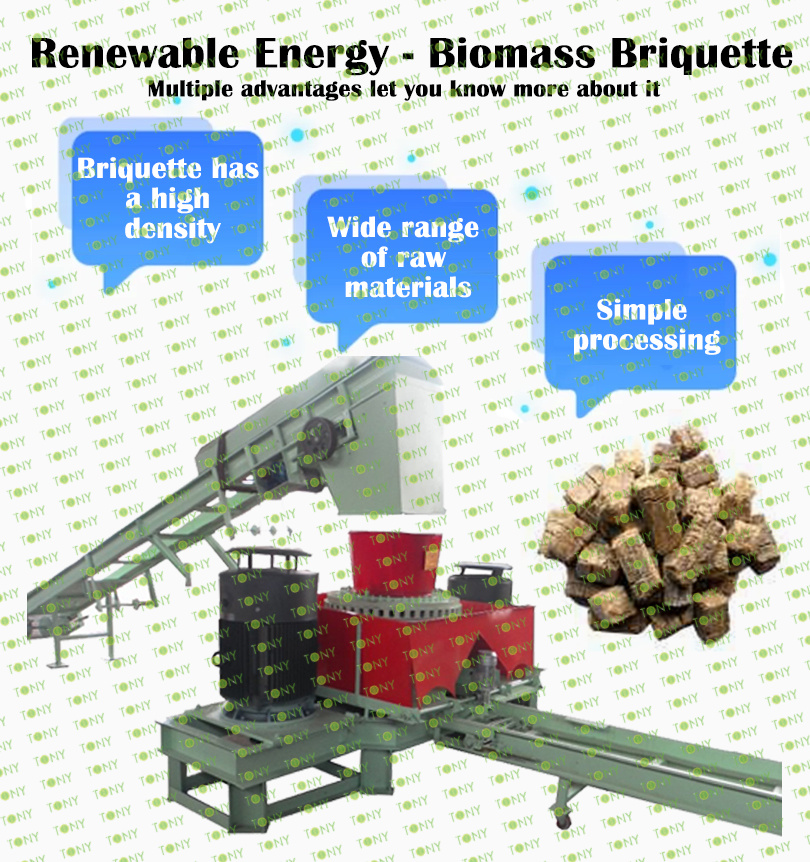

1. The Briquette after TONY processing has a small volume and a large ratio, and is resistant to combustion. The dry storage and transportation volume is only 1/30 of the dry original release, which is 10-15 times that of the same weight stover, the base density is 09-1.40/m3, and the caloric value can reach 3500-55(0 kcal), which is a high volatile solid fuel. Briquette can replace wood, raw coal, liquefied gas and other heat sources and is widely used in domestic stoves, heating furnaces, hot water boilers, industrial boilers, biomass electricity, plant biological gasification boilers, etc.

2. Straw coal is a new type of biomass renewable energy, environmental protection and clean, far lower than the cost and market price of raw coal, Briquette application is extremely wide, urban heating and heating and hotels, restaurants, bathing and other industries to solve the use of coal-fired boilers do not meet the environmental requirements of the problem. The cost of fuel oil is more than ten times higher than that of straw coal.

3. TONY Briquette Machine is a complete set of mechanized production equipment through crushing, pressurizing and densification molding. Practical raw materials such as corn stalk, wheat stalk, straw, edible fungus residue, Chinese medicine residue, cotton wood, bark and so on. The equipment has good performance, high production capacity, convenient operation and convenient use. It is an environmental protection and energy-saving product production equipment relying on rural areas and taking biomass resources as the advantage. It is a way for the majority of farmers to become rich in the field, using crop straw waste to become waste and increase income.

First of all, raw materials should be selected according to the use of the product. It can choose wheat, corn, sorghum, peanut, grain grass, grass, leaves, potato vine and other edible straw for livestock. And to choose no rot, no mildew, no soil, end contaminated straw. All kinds of straw can be used, as long as it is non-rotting herbs and woody plant raw materials with a diameter of less than 2cm. Production of straw blocks, to have a large enough site to store the required raw materials, at the same time, to develop strict fire prevention measures, and ready enough fire prevention materials. The water content of the raw material should be kept between 15%-30%. The moisture content is high to dry or dry, and the moisture content is less than 14% to add water. The straw should be crushed and rubbed before pressing the block, and then dried.

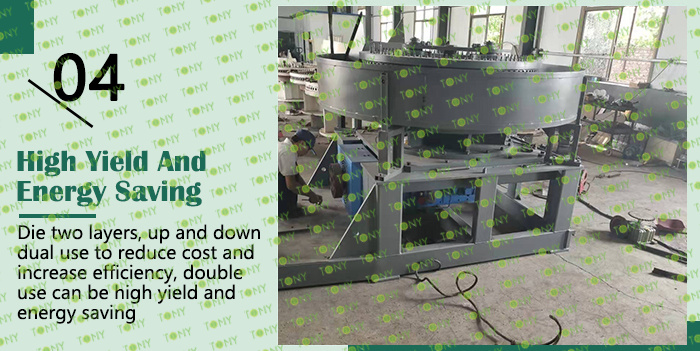

TONY Briquette Machine rotates under the drive of the motor, and the press die and press roll in the machine move relative to each other, producing friction with the fed material during operation and squeezing the material into the ring die hole. With the continuous extrusion and friction of the material, high temperature is generated, the starch in the straw is gelatinized, and the hemicellulose, cellulose and lignin are softened under high temperature and pressure, and the Mosaic structure is partially damaged. The initial deformation of the material pressed into the die is elastic deformation, and it is fixed into plastic deformation under high temperature and high pressure. In the touch process, the shape is fixed and the solid block object is formed with the gradual reduction of the temperature. The press block part is composed of a ring die with a single row of rotating circular die holes and an eccentric press roll with rotation only. Straw cut and kneaded into about 30mm of bulk material, through the feeding mouth into the body cavity with spiral feeding mechanism, with the rotation of the main shaft body to push the material into the ring mold cavity, and covered with ring mold groove, through the relative movement of the ring mold and the press roll into the gap between the ring mold and the press roll, the material is constantly squeezed into the ring mold hole by the rotating press roll. Under the strong extrusion, the material overcomes the friction resistance of the hole wall and continuously extrudes from the ring die hole in a strip shape. When extruded, strips of material are cut into suitable grass blocks by slices on the body shell.

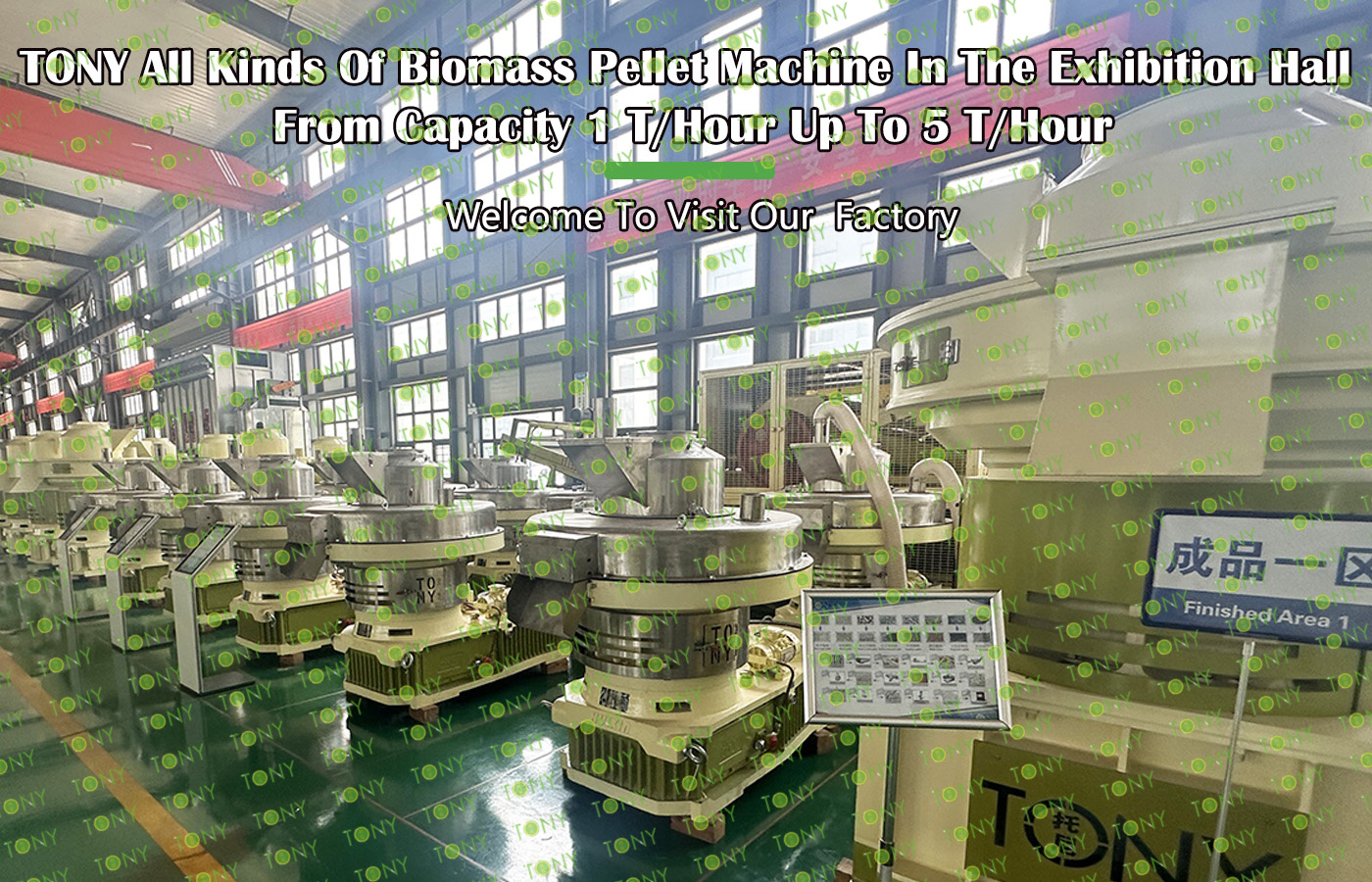

| TONY Briquette Machine On Show | TONY Briquette Machine On Clinets Site |

|

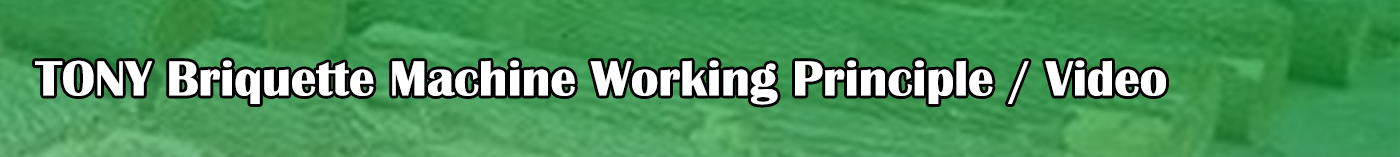

TONY Briquette Machine is mainly composed of Feeding Belt Conveyor, Discharge Belt Conveyor, Motor. Inlet, Motor, etc,TONY's Briquette Machine mainly used for corn /cotton /wheat straw, alfalfa, haulm, peanut seed.ing (shell), etc. lt can produce both feed and biomass fuel. In the process of pressing the block almost all other equipment is the most critical part of its auxiliary equipment. There are three pressure points: 1.The roll acting on the material squeezes the material into the die. 2.The die itself has a resistance, which can prevent material flow over the hole on the die. The pressure applied by the roller is combined with the friction pressure generated by the formula itself. This pressure squeezes the material against and prevents it from ejecting along the surface of the die in front of the roller. Before we improve change 3.When the adjustment value of the speed drive or control is increased and the feed amount of the straw press is increased, the material amount is routinely thickened in front of the roller. |

|

TONY Briquetting Machine Type Models |

||||||

|

NO |

Model |

Power |

Capacity |

Size:L*W*H |

Die Hole Size |

Die Hole QTY |

|

1 |

9YHP-2200 |

22*2 |

1.0-1.5 |

3050*6000*2200 |

32*32 |

38 |

|

2 |

9YHP-3200Ⅰ |

37*2 |

1.5-2.0 |

3300*8000*2400 |

45*33 |

45 |

|

3 |

9YHP-3200Ⅱ |

37*2 |

2.0-2.5 |

3800*8000*2400 |

32*30 |

48 |

|

4 |

9YHP-3600 |

45*2 |

2.5-3.5 |

3300*6000*2300 |

32*36 |

50 |

|

5 |

9YHP-4200 |

110/55*2 |

3.5-4.2 |

3800*6000*2400 |

32*30 |

60 |

|

Depending on the raw material, the density is different, the yield is different |

||||||

|

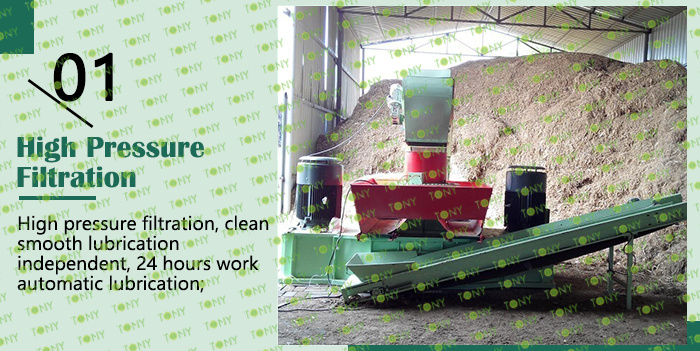

1. TONY Briquette Machine Saves Energy High output, low price, less power consumption, simple operation. If there is no electric equipment can be replaced by diesel engine. 2. TONY Briquette Machine Material Adaptability Suitable for the molding of various biomass raw materials, straw from powder to 50mm length between, straw pressing machine can be processed. 3. TONY Briquette Machine Roller Automatic Adjustment Function By using the principle of bidirectional rotation of thrust bearing, the pressure Angle is automatically adjusted, so that the material is not squeezed and not bored, and the stability of discharge molding is ensured. 4. TONY Briquette Machine Is Simple To Operate And Easy To Use High degree of automation, less labor, the use of manual feeding or conveyor automatic feeding can be. |

|

Biomass press applicable materials:

1. Solid waste generated from agriculture and forestry (such as: corn stalk, wheatgrass, straw, peanut husk, corn cob, cotton stalk, soybean stalk, rice husk, weeds, branches, leaves, sawdust, tree bark, bagasse, furfural residue, etc.).

2. Scraps, scraps, strips of leather, waste cloth, old clothes, old curtains, old tablecloths, car cushions, and other waste cloth from garment factories.

3. Solid waste such as waste, household waste and kitchen waste after household decoration.

|

【 Main Technical Indicators Of Solidified Fuel 】 Density: 0.8-1.3g/c m3 Overall dimensions: 32mm×32mm×20mm - 80mm Calorific Value: 15500-20930KJ/kg; 3700-5000Kcal/kg Ash content: 1-20% Moisture: ≤ 14% 1. Large Capacity And Small Volume The bulk weight of general heat dissipation capacity biomass fuel is 30-50kg/m3, while the bulk weight of this product is 800-1300kg/m3, which is about 20 times the bulk volume. 2. High Thermal Efficiency And Good Combustion The heat utilization rate of biomass heat dissipation is only 10 to 20 percent, and the combustion utilization rate after curing can reach more than 40 percent, and the combustion heat of biomass solidification. 3. Clean And Hygienic, No Pollution The biomass solidified fuel can achieve "zero emission" in the combustion process, that is, no slag discharge, smokeless, no sulfur dioxide and other harmful gases, and does not pollute the environment. 4. Biomass Resources Are Huge, Generally Easy To Obtain Recyclable curing fuel processing is simple, practical and convenient, and can be commercialized production and sales of energy. 5. The Product Is Widely Used Biomass solidified fuel can be widely used in biological stoves, heating furnaces, hot water boilers, steam boilers, drying furnaces and biomass gasifiers. |

|

|

|

|

|

|

|

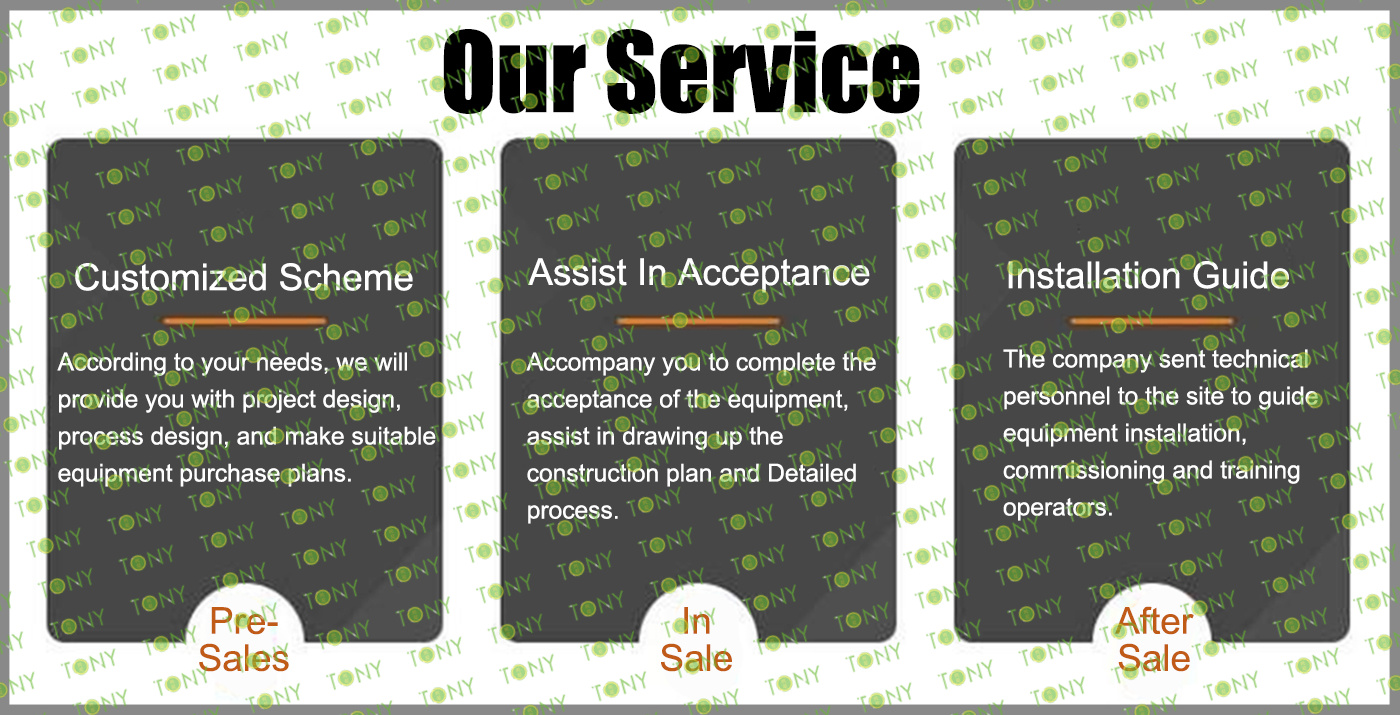

TONY Briquette Machine has a variety of models, according to the customer production of different models, Briquetting Machine factory price is not the same. You get what you pay for. The price always depends on the value. Because the pellet machine market is currently more chaotic, customers must be careful to buy! To make a purchase decision after a comprehensive inspection of a number of comprehensive indicators such as product quality, manufacturer scale strength, pre-sales and after-sales service ability, research and development design ability, rather than just looking at the price! Please note: If the purchase cost is very low, the later use cost will be very high! Because the low-cost equipment causes you to face endless maintenance later, which will delay your production and make you pay more money. |

|

|

|

|

1. Please inject the gear oil before starting, and tighten the plug head of the oil injection hole after refueling. 2. Carefully check the power line, prevent the affected point, leakage, to ensure the safety of electricity. 3. Carefully check whether the bolts and screws of the connecting parts of the machine motor and transmission components are firm and loose in order to tighten them in time. 4. Set the preheating temperature according to the type of material. Corn and wheat straw are between 80 degrees Celsius and 90 degrees Celsius, and peanut shell rice husks are between 80 degrees Celsius and 100 degrees Celsius. 5. Idle for 1 minute after starting the machine, check whether the machine is running normally, and then feed a small amount when normal, until the remaining material in the machine is net, it can be evenly fed. 6. Before loading, please be sure to pay attention to the hard debris in the raw materials, prevent stone, iron, etc. from entering the silo to avoid damage to the machine. 7. Fill the oil filling air on the universal joint once every 8 hours of operation, and fill 2-3 drops of oil at a time. 8. Please put on a little wet material before stopping, so as to smooth discharge after starting the next day. |

2025 Tony Machinery - All Rights Reserved. Map