The comprehensive chipper plays a vital role in the production of biomass pellets. The following is a detailed introduction:

The working principle and structure of the comprehensive chipper

Working principle: The comprehensive chipper mainly drives the internal core rotor to rotate at high speed through the motor, which generates high-intensity impact force, compression force, cutting force and friction force on the crushed material, thereby crushing the biomass raw materials entering the crushing chamber. For example, when the wood enters the crushing chamber evenly, it will be impacted by the high-speed rotating hammer, causing the wood to be crushed. At the same time, the dead weight of the wood causes it to be pushed to the inner baffle and screen bar by the high-speed rotating hammer. The wood smaller than the screen hole size will pass through the screen plate, while the wood larger than the screen hole size will continue to be hit and ground by the hammer.

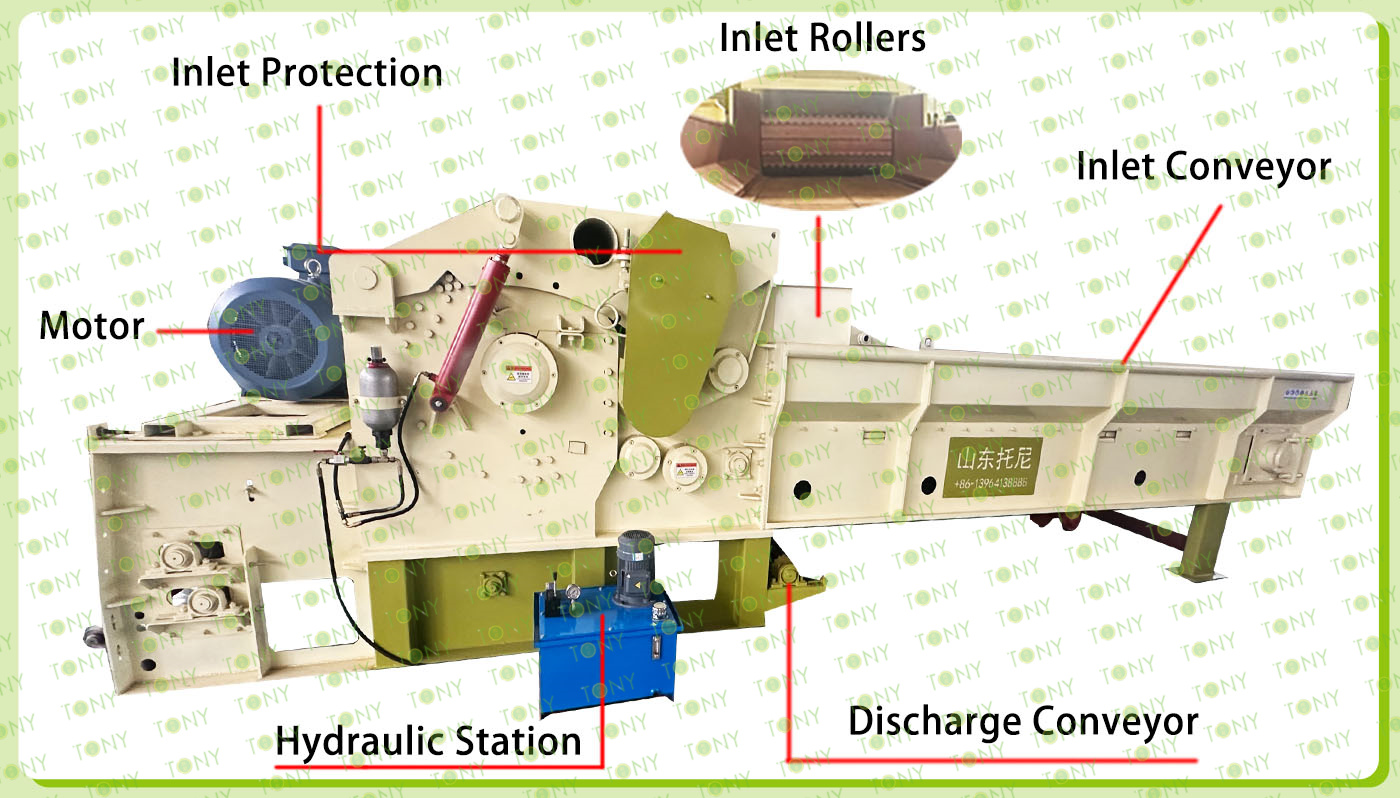

Structural composition: It is usually composed of a feeding device, a crushing chamber, a discharging device, a transmission device, a motor, etc. Some comprehensive chippers also use fully automatic hydraulic systems and liquid buffer systems, and are equipped with racks, knife rollers, upper and lower feeding devices, automatic screen tensioning mechanisms, liquid backstop systems, etc., to improve equipment performance and convenience.

The role of comprehensive chippers in biomass pellet production

Raw material pretreatment: It can effectively break large biomass raw materials such as stumps, branches, trunks, and various crop straws into small particles or powdery materials, which is convenient for subsequent drying, granulation and other processing steps. Mixing and crushing different types of biomass raw materials can improve production flexibility and meet various production needs.

Improve production efficiency: The chain plate intelligent feeding system can automatically adjust the feeding speed according to the load of the main motor, so that the machine can run at full load, avoid idling, and feed more smoothly, greatly improving production capacity, and providing guarantee for the large-scale production of biomass pellets.