In the industrial chain of biomass resource utilization, wood processing, etc., wood chipper does play the key role of connecting "raw material recycling" and "efficient granulation". Its core value is reflected in the "standardized pretreatment" of raw materials, which can be specifically developed from the following aspects:

1. Acceptance and transformation of "raw material recycling"

In the process of wood processing, forestry production, building demolition, etc., a large amount of wood waste of various shapes will be generated, such as:

Branches, branches, trunk cuts (coarse blocks)

Bark, wood chips, scraps (fine or irregular shapes)

Old furniture, waste boards (blocks mixed with metal or other impurities)

The common characteristics of these recycled raw materials are different specifications, large size differences, and uneven density. Direct use for granulation will face many problems (such as feed blockage, large load fluctuations of granulator, etc.).

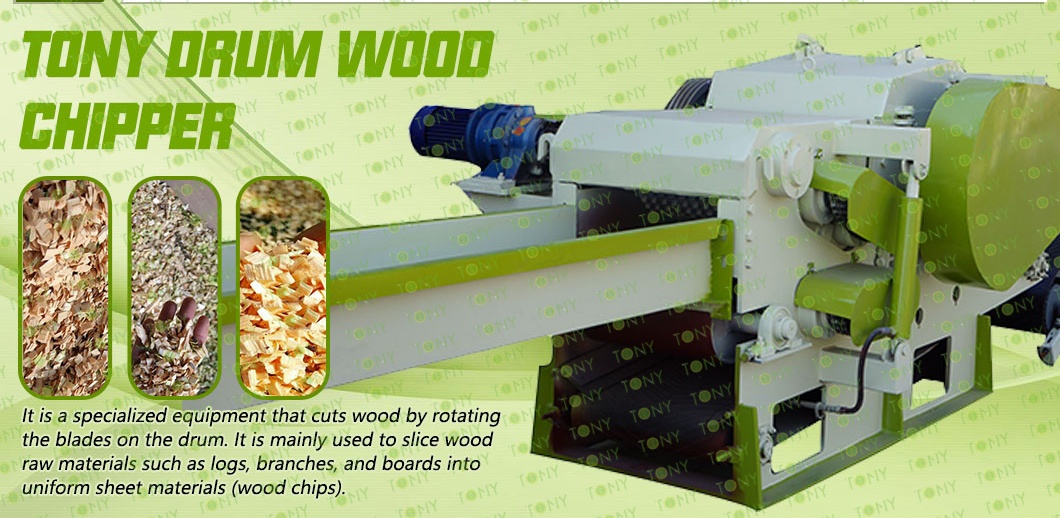

The role of the wood chipper is to convert these "disorderly" recycled raw materials into wood chips with uniform specifications and uniform particle size (usually 3-5mm thick and 20-50mm long) through cutting and crushing processes, realizing the transformation of raw materials from "recycled state" to "processable intermediate state", laying the foundation for subsequent pelletizing.

2. Provide core guarantee for "efficient pelletizing"

Pelletizing (such as biomass pellet fuel pelletizing, wood-based board pelletizing, etc.) has strict requirements on the physical properties of raw materials, and wood chips processed by chippers can directly solve the key pain points of pelletizing:

Improve pelletizing efficiency

Wood chips of uniform specifications have good fluidity and can stably enter the tempering and compression links of the pelletizer, avoiding machine jams and shutdowns caused by excessive raw materials, reducing equipment idling time, and increasing the pellet output per unit time.

Ensure pellet quality

The wood chips have uniform particle size, and are more evenly heated and pressed during the pelletizing process. The pellets made have consistent density, high strength, and are not easy to break, which can meet the requirements of subsequent combustion, processing or transportation.

Reduce overall costs

Reduce the wear of pelletizers: Direct pelletizing of large pieces of raw materials will increase the wear of equipment tools and molds, while wood chips can reduce mechanical impact and extend the life of equipment.

Optimize energy consumption: Uniform wood chips require more stable compression force during pelletizing, which can reduce motor power consumption and reduce energy waste.

3. The industrial value of the "link" role

In industries that rely on wood raw materials such as biomass energy, wood-based panels, and pulp, "raw material recovery - chipping - pelletizing" is a core industrial chain:

Therefore, the wood chipper is not only a pretreatment equipment, but also a technical node that connects the "raw material recovery" and "efficient pelletizing" links. Its performance (such as chip size adjustment ability, processing capacity, and energy consumption) directly affects the economy and sustainability of the entire industrial chain.