|

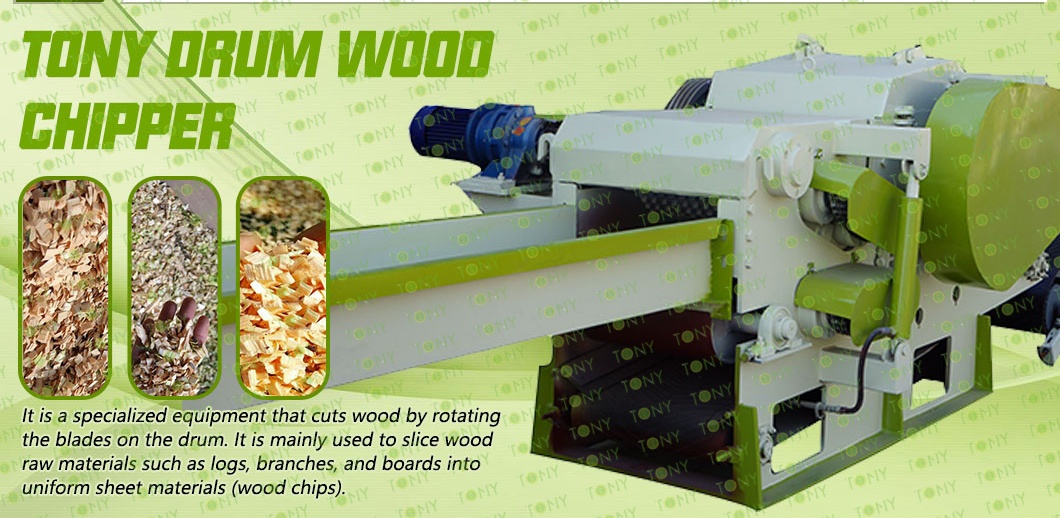

TONY Wood Chipper, also known as drum chipper, With advanced structure and special blades layout, the drum wood chipper is technically suitable for undersized logs processing. In fact, the drum wood chipper can process a variety of materials. The common raw materials for the drum wood chipper are undersized wood logs, wood branches, wood barks, waste board.is mainly used to crush small-diameter logs or, plywood, wood branches, furniture waste into evenly sized wood chips, the size of the wood chips is about 25mm-55mm thickness, and the size of the wood chips can be adjusted by adjusting the knife gap. TONY Wood Chipper has high output, low energy consumption, the size of broken wood chips is uniform, uniform thickness, is a very cost-effective crusherTherefore, the drum chip machine is also widely used, such as in wood chip plants, biomass power plants, pulp plants, wood pellet plants and other places. In addition,TONY Wood Chipper can be fed mechanically or manually, but they have everything you need for a fully automated production operation. Thanks to the most advanced data interface, it is very safe to use and easy to maintain. With reasonable design and has a wide adaption of raw material, wood chipper is the top facility of processing wood log and panel with high efficiency. |

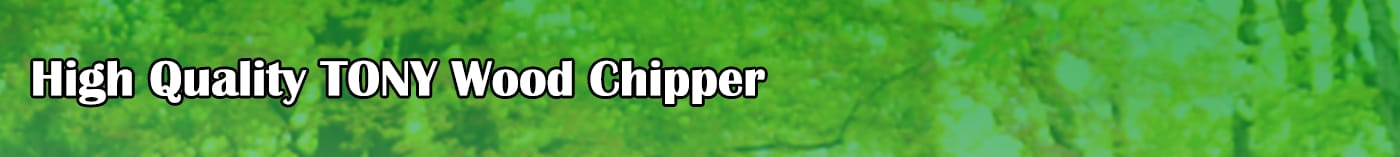

TONY wood chipper is mainly composed of feed belt, discharge belt, machine base, knife roller, feed mechanism, hydraulic buffer system and electrical control system. In addition, there are motor, oil pump, protective cover, blade, screen and other auxiliary parts, wood chip machine design structure is reasonable, some parts if customers have special requirements, we can also customize.

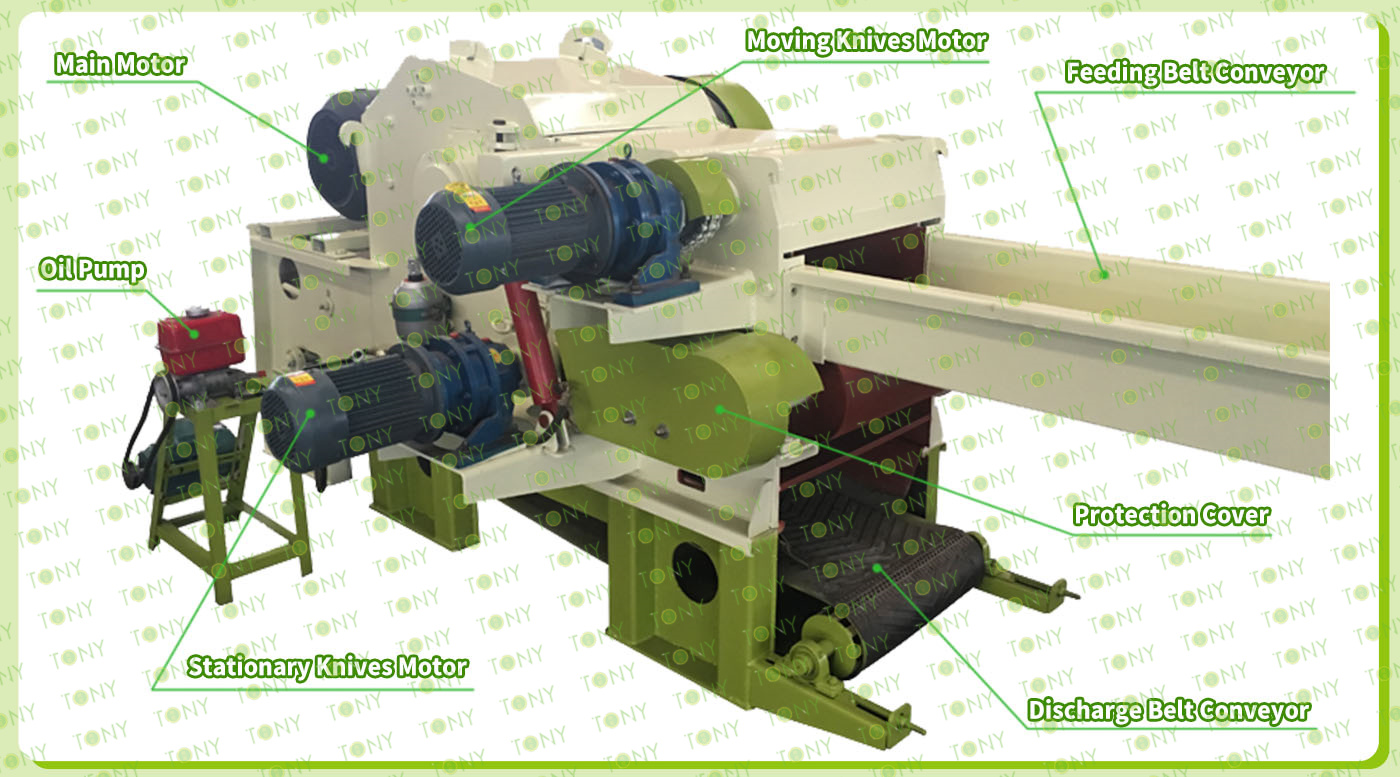

The raw materials are fed in through the feeding port and pushed towards the knife drum by the conveying device. The high-speed rotating flying knife works in coordination with the bottom knife to cut the raw materials into wood chips. The cut wood chips are screened through a screen. Those that meet the particle size requirements are discharged from the discharge port, while those that are too large will continue to be cut inside the machine

Structural composition and core components

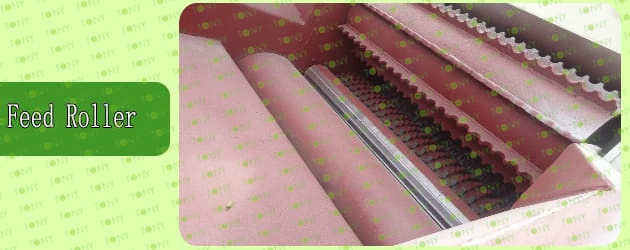

Feed Roller:

Multiple flying knives (blades) are fixed on a cylindrical spindle, generating cutting force through high-speed rotation.

Feeding device:

It includes the feeding port, conveyor chain plate or feeding roller to ensure that the raw materials are evenly sent into the cutting area.

Bottom knife and screen:

The bottom knife is fixed to the machine base and forms a shearing effect with the flying knife. The screen is located at the discharge port and controls the thickness and particle size of the wood chips.

Transmission system:

The motor drives the knife drum to rotate through a belt or gear. Some equipment is equipped with a hydraulic system to regulate the feeding speed.

|

1. Transmission: At the front end of the wood chipper, there is a hydraulic system to help feed, which is composed of the motor and its coupling and gear. 2. Chipping: When the wood comes into contact with the cutting blade, it is cut through the high-speed rotation of the cutting disc. The cutting mechanism is a rotating drum on which several flying knives are mounted. The knife spins the wood into sawdust 3. Adjustment: It is composed of the centrifugal device at the bottom and outside of the spindle adjustment device. 4. Screening And Sorting: This part consists of coarse sieve and fine sieve. 5. Coarse Grain Recovery And Crushing: the outer edge of the drum has a number of square through holes. The cut wood chips fall through the mesh and are discharged from the bottom. Large pieces of wood will be cut again in the machine. Influence of key parameters The blade Angle (usually 30°-45°) and the rotational speed of the drum determine the cutting force. The gap between the baffle plate and the blade controls the thickness of the wood chip (adjustable range: 1-5mm). |

|

1. Quality advantages of wood chips: Uniform specifications, suitable for high-end applications High cutting accuracy: The precise fit between the blade and the baffle plate can control the thickness of the wood chip within the range of 1-5mm, with a length error of ≤2mm, and the cutting surface is smooth without burrs Excellent shape regularity: The wood chips are in the shape of regular rectangles or squares, with a low fiber damage rate (only 5%-8%), retaining the original physical strength of the wood 2. Production efficiency advantage: Industrialized characteristics of high output and low consumption Strong processing capacity: Taking the processing of 200mm diameter pine wood as an example, the drum chipper can cut about 20 tons of raw materials per hour, which is equivalent to the efficiency of 10 workers splitting firewood by hand. Energy consumption ratio optimization: Achieving remarkable energy-saving effects. |

|

3. Raw material adaptability: Full-scene coverage from logs to branches and twigs Wide diameter range: It can handle raw materials with diameters ranging from 5 to 300mm, including logs, board veneers, branches and twigs, and waste wood, etc. Wood type compatibility: It has good adaptability to both soft and hard woods 4. Maintenance and operation advantages: Low failure rate and long service life design Long service life of vulnerable parts: The blades are made of hard alloy or high-speed steel, with a hardness of HRC55-62. Under normal working conditions, they can cut 500-1000 tons of wood. Maintenance convenience: The hydraulic tensioning device enables rapid blade replacement (the replacement time for a single set of blades is ≤15 minutes), reducing downtime costs. 5. Process adaptation advantage: Core equipment for pretreatment in multiple industries Papermaking and pulping,Biomass pellet fuel,Production of artificial boards,Garden waste treatment |

|

|

|

6. Safety and environmental protection design: In line with modern industrial standards Multiple safety protections: The feeding port is equipped with an anti-reverse rotation device and an overload protection sensor, which automatically stops the machine when the wood gets stuck. The drum wheel protective cover is made of soundproof steel plates, which complies with occupational health standards. Outstanding environmental performance: No waste liquid is produced during the cutting process. Only regular cleaning of wood chips is required, resulting in low maintenance and environmental protection costs. 7. Technological upgrade advantages: Trends of intelligence and energy conservation Automation control: Integrated with a PLC intelligent system, it can monitor the blade temperature, feeding speed and motor current in real time, and automatically adjust production parameters , reducing the error of manual intervention. Energy-saving technology application: Variable frequency drive is adopted, reducing energy consumption by 40% when no-load. |

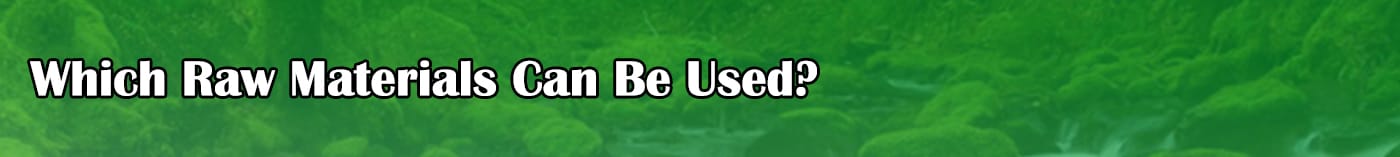

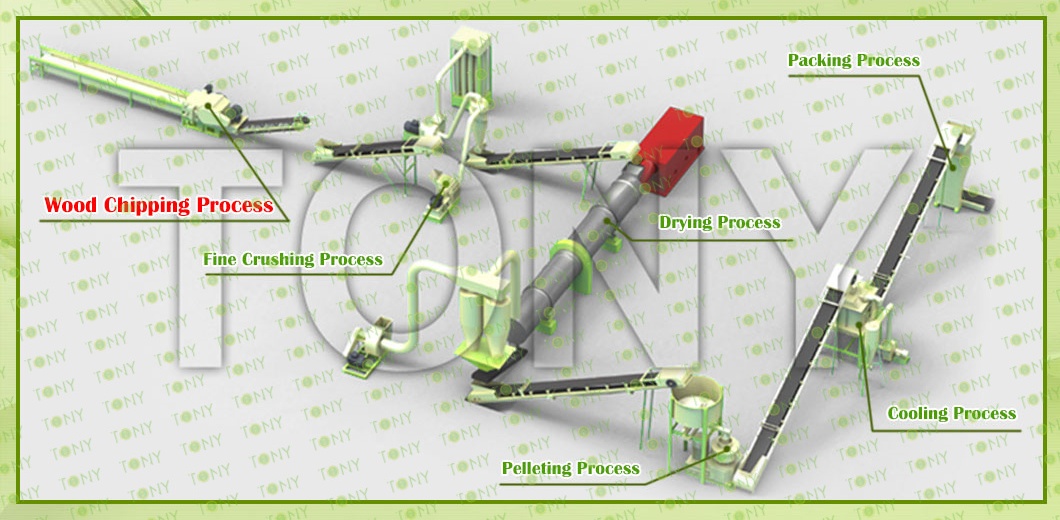

TONY Wood Chipper can process small diameter wood, corncob,wood, waste furniture, branches, straw, grass, bamboo and so on for crushing.

The materials after the wood chip machine crushing can also be widely used to do biomass particles, wood-based panels, wood furniture factories, organic fertilizer and other primary raw materials, can also be used in paper mills, power plants, textile mills, etc., in addition, it is necessary for the mechanical equipment in landscaping work, ground-free operation,The equipment can be operated on the ground, powerful function and high efficiency.

|

TONY Wood Chipper Type Models |

|||||||||

|

Name |

Model |

Power |

Capacity |

Fly Knives QTY |

Inlet Size Width*Length*Height |

Max Processing Diamater |

Out Chips Size |

Weight |

Main Machine Machine Size |

|

1 |

TPQ216 |

55KW |

4-7TPH |

2Pieces |

50cm*4.5m*50cm |

20CM |

25-55mm-Adjustable |

4.8T |

5800*1900*1200MM |

|

2 |

TPC1000 |

90KW |

7-10TPH |

6Pieces |

1m*4.5m*50cm |

25CM |

25-55mm-Adjustable |

9.8T |

8100*1400*2125MM |

|

3 |

TPC1000 |

110KW |

8-10TPH |

6Pieces |

1m*4.5m*50cmChain Inlet |

25CM |

25-55mm-Adjustable |

9.8T |

8100*1400*2125MM |

|

4 |

TPC1300-600 |

132KW |

10-15TPH |

6Pieces |

1.3m*4.5m*60cm Chain Inlet |

30CM |

25-55mm-Adjustable |

13.8T |

9100*1900*2220MM |

|

5 |

TPC1300-600 |

160KW |

12-15TPH |

6Pieces |

1.3m*4.5m*60cm Chain Inlet |

30CM |

25-55mm-Adjustable |

13.8T |

9100*1900*2220MM |

|

6 |

TPC1400-600 |

200KW |

14-20TPH |

6Pieces |

1.4m*4.5m*60cm Chain Inlet |

35CM |

25-55mm-Adjustable |

17.8T |

10100*2400*2525MM |

|

7 |

TPC1400-600 |

220KW |

15-20TPH |

6Pieces |

1.4m*4.5m*70cm Chain Inlet |

35CM |

25-55mm-Adjustable |

17.8T |

10100*2400*2525MM |

|

8 |

TPC1400-700 |

250KW |

20-30TPH |

6Pieces |

1.6m*4.5m*1mChain Inlet |

35CM |

25-55mm-Adjustable |

17.8T |

11100*2400*2525MM |

|

9 |

TPC1600-1000 |

315KW |

25-35TPH |

6Pieces |

1.8m*4.5m*1mChain Inlet |

40CM |

25-55mm-Adjustable |

25.8T |

12100*2400*2825MM |

|

10 |

TPC1850-1000 |

355KW |

30-40TPH |

6Pieces |

1.8m*4.5m*1.2m Chain Inlet |

40CM |

25-55mm-Adjustable |

35.8T |

13100*2500*2925MM |

|

11 |

TONY8000 |

400KW |

35-80TPH |

6Pieces |

1.8m*4.5m*1.5m Chain Inlet |

55CM |

25-55mm-Adjustable |

55.8T |

14100*2800*3125MM |

|

12 |

TPQ81138 |

560KW |

40-50TPH |

6Pieces |

1.3m*4.5m- Belt Inlet |

40CM |

25-45mm-Adjustable |

32.8T |

15100*2570*1933MM |

|

13 |

TONY10000 |

630KW |

50-100TPH |

6Pieces |

1.8m*4.5m- Chain Inlet |

60CM |

25-55mm-Adjustable |

65.8T |

15100*3000*3225MM |

|

TONY Wood Chipper On Customer Site |

TONY Wood Chipper Working |

|

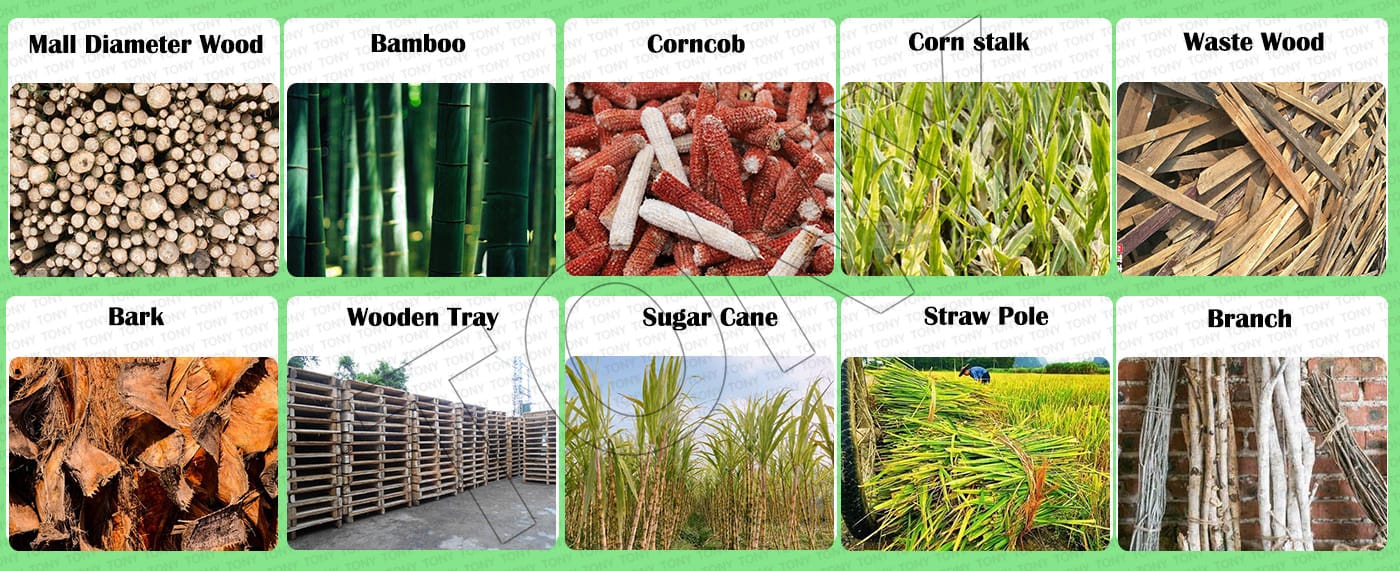

Feeding Belt 1.Transport raw materials, intelligent forward and backward, The higher the gear, the faster the speed and the higher the output 2.As needed,you can choose between belt transport or chain plate transport, chain plate is stronger than belt 3.You can contact TONY to get the price for chain inlet belt conveyors. |

|

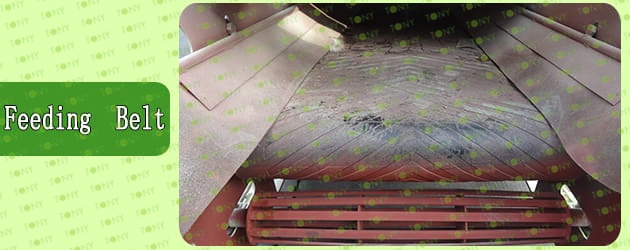

Engine Bed The main structure of the machine is the basis of the whole machine, the use of high-strength thick carbon steel manufacturing, strong structure, which can ensure that the wood chip machine even without foundation can be stable operation. TONY can supply you with the wood chipper machine with competitive price and excellent quality. |

|

|

Feed Roller 1. The feed roller is made of 45# Mn steel, which has strong wear resistance and higher strength and performance than the welding parts. 2. Zigzag cross distribution structure, more accurate bite force. 3.TONY rollers are produced and procced by TONY factoty to ensure processing accuracy and ensure the durability of the equipment. |

|

Hydraulic Control 1. According to the different thickness of the raw material to be cut, with the help of the hydraulic system, the upper feed roller assembly can be lifted and lowered within a certain range. 2. Hydraulic forced feeding, feeding speed can be adjusted at will, to a large extent to avoid the card material. 3.TONY use excellent brand hydraulic system to to ensure processing accuracy and ensure the durability of the equipment. |

|

|

Motor 1. Adopt well-known brand motor, higher quality 2. Pure copper core motor has the advantages of energy saving, quiet, high mechanical strength and durability 3. If you have special requirements, we can customize it for you. 4.TONY use famous motor brand QINGDAO SHUOBO Brand. 5.You can also chose the motor brand that you like to add price. |

|

Electric Control 1. The basic function controls the opening, running and stopping of the chipper. 2. With flash back alarm protection (when foreign matter enters the chip machine) 3. Motor temperature protection function, to achieve over-heat protection of the motor, while eliminating the heat relay protection easy adhesion 4.With frequency inlet and we will use famous brand electric parts. |

|

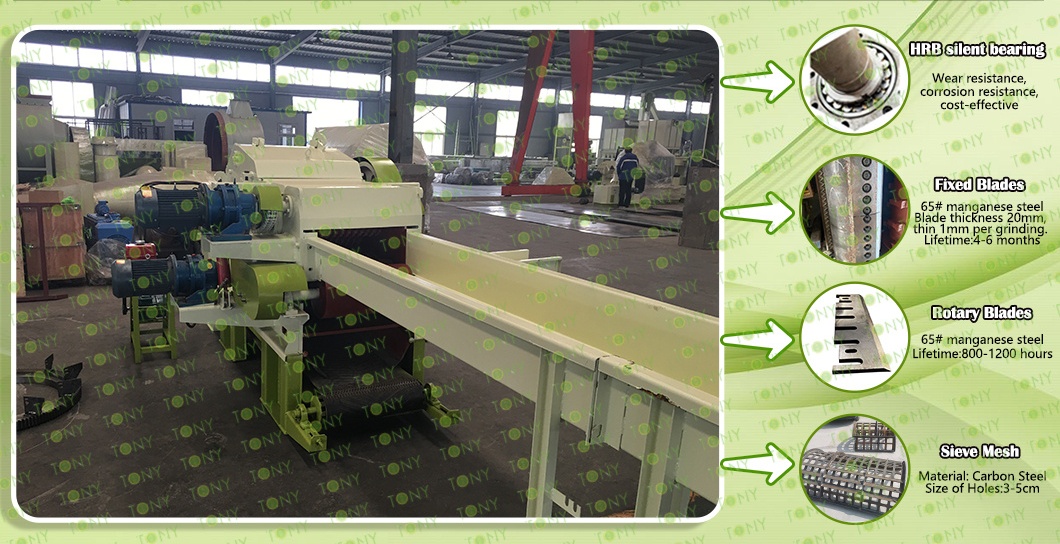

We provide some free spare parts, such as blades, belts, washers and other small parts, because blades, hammer, bearings and other important wear parts, we recommend customers to buy some appropriate to save freight, we have enough spare parts, now in stock.

|

|

|

|

|

|

|

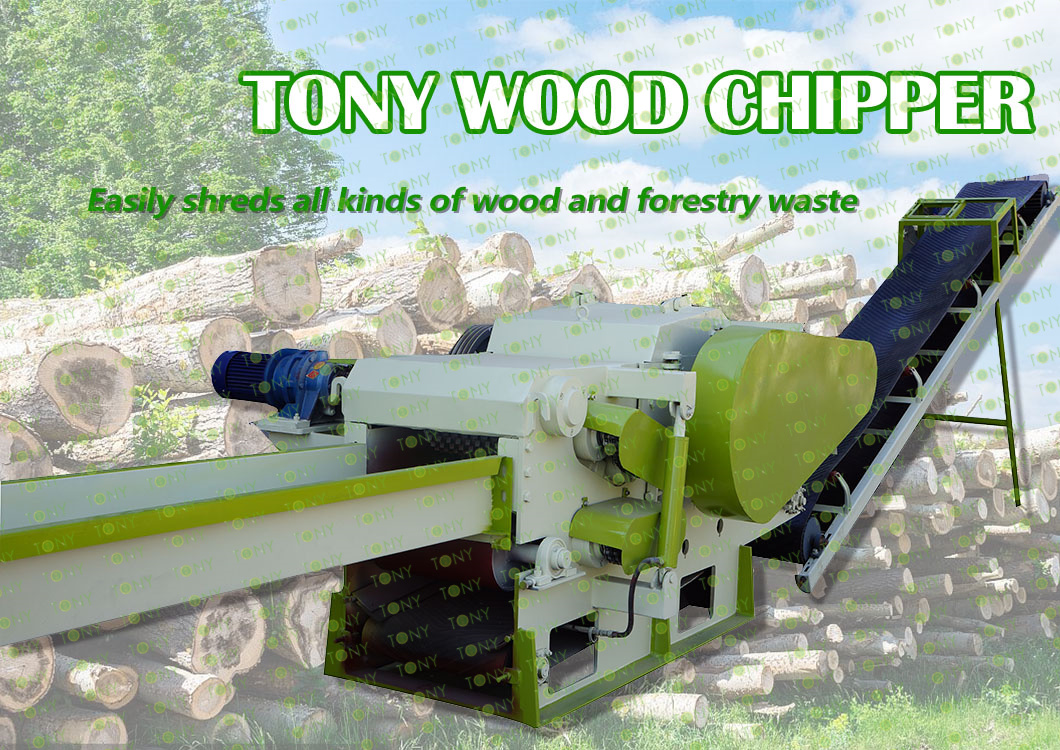

TONY Wood chipper can turn diameter under 50cm logs,trail wood,etc into excellentindustrial wood chip which is uniform in length, flat in cut,uniform in thicknessRaw material can be small diameter wood, wood harvesting residues (branchesbranches, etc.) and wood processing surplus (plate, slats, logs, etc.). Can also beused to cut non-wood raw materials (Such as linen, reed, bamboo, etc.) Wood chipper is mainly composed of inlet belt conveyor, discharge beltconveyor,machine base, rollers ,feeding device and pressure buffer system andelectrical control system. Wood material can be effectively crushed in the chamber,when crusher is working.This wood crusher has advantage of high capacity,low energy cost, high efficiency,average output size, low noise, no pollution to environment,easy handling,and easy maintenance. |

|

|

There are many models of TONY chip machine, the factory price is between USD25,000 - USD70,000. Before quotation, we first need to know what your raw materials are, what is the capacity you want, and choose the right model for you according to your situation We always believe in the power of quality and integrity. Price is only one of the factors you should consider when buying equipment. I look forward to your full consideration. TONY wood chipper wil be your best choice for processing wood logs into wood chips. We can supply capacity 4-100Ton/Hour. Quality first. We always attach great importance to quality It's under control from start to finish. Our factory has obtained CE certification We recommend that you come to our factory to see the goods, verify the real situation of the products, and learn more about our factory. Our factory is located in Zhangqiu City, Shandong Province, China. We warmly welcome you to visit our factory at any time |

2025 Tony Machinery - All Rights Reserved. Map