|

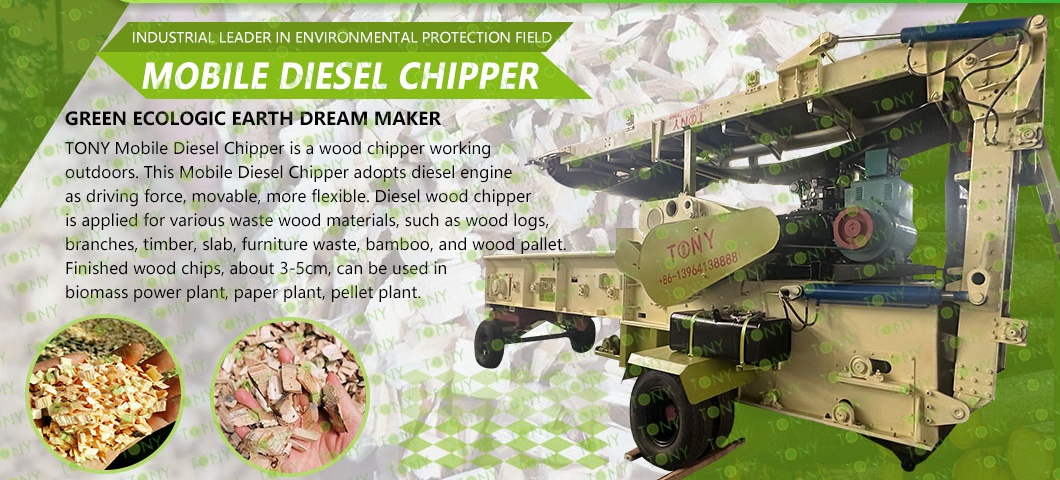

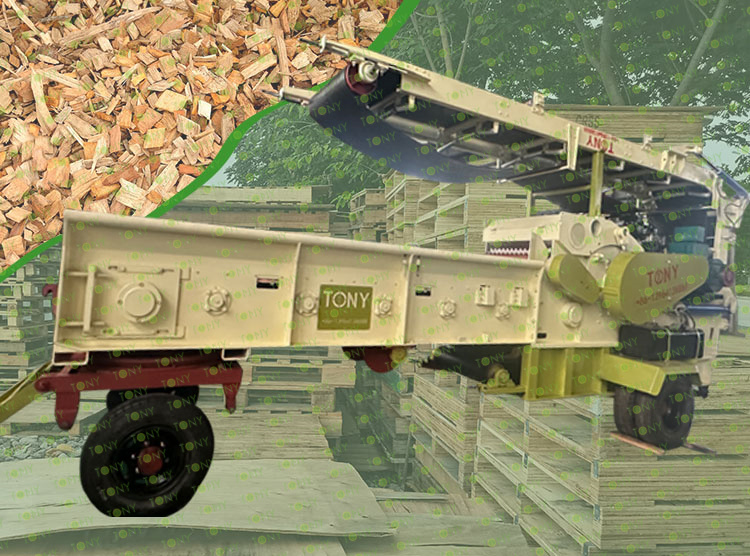

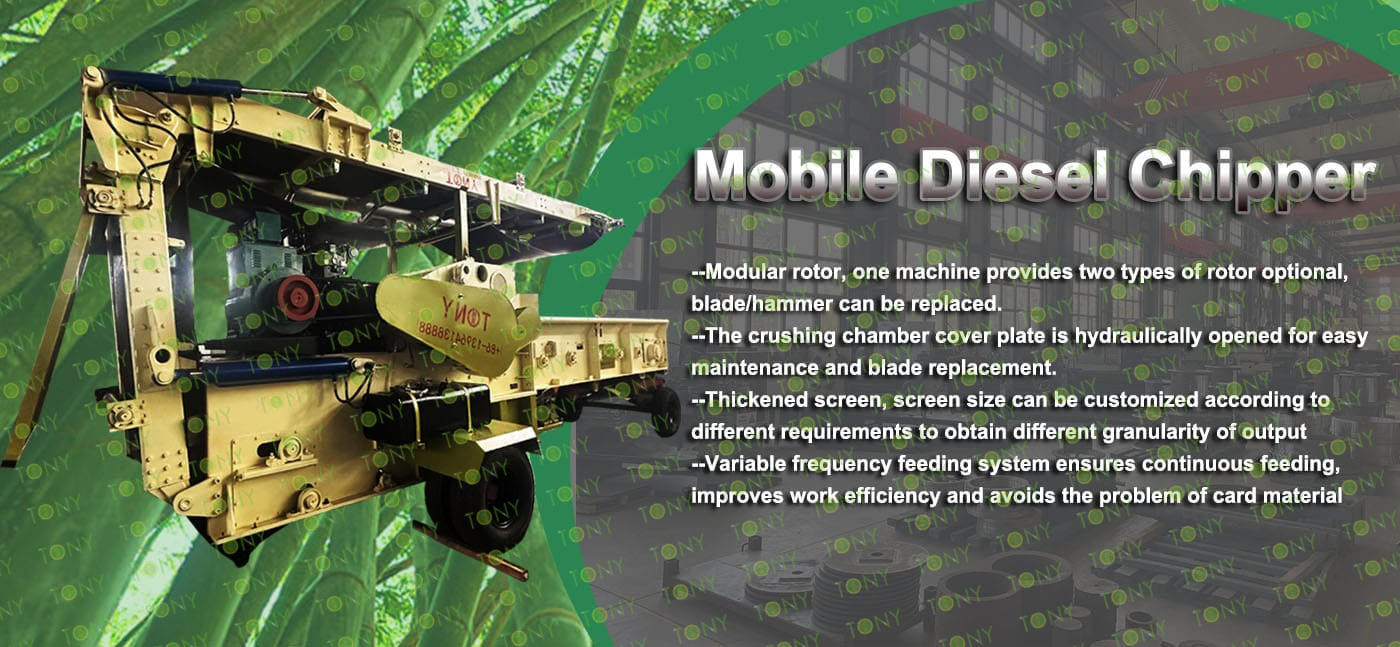

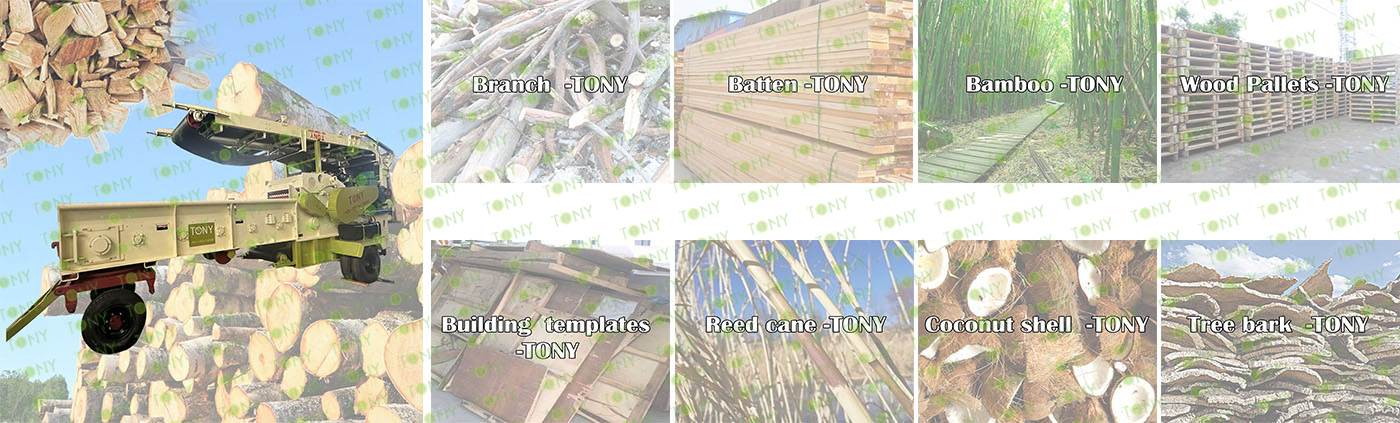

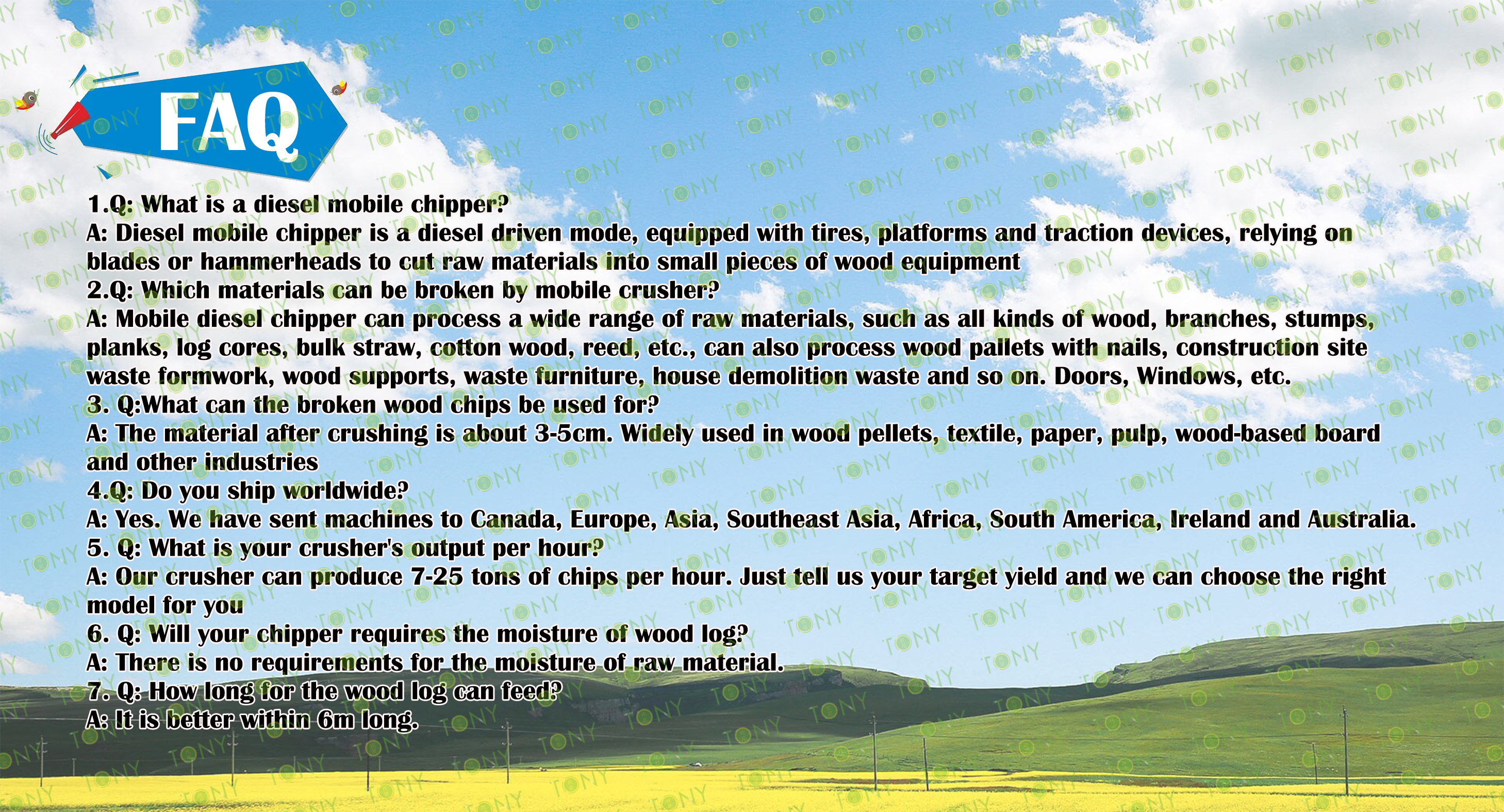

TONY Mobile Diesel Chipper is a wood chipper working outdoors. This Mobile Diesel Chipper adopts diesel engine as driving force, movable, more flexible. TONY Mobile Diesel Chipper is mainly used for processing pine, weed trees, cedar wood, bamboo and so on. More suitable for processing mushroom substrates. It is convenient to cut bamboo, thatch, corn straw, sorghum straw and other fiber stem materials. The wood crusher can also be used to produce particle board, fiberboard, wood. Advantages of wood crusher: When the crusher is working, the wood material can be effectively broken in the chamber. This kind of wood crusher has the advantages of large processing capacity, low energy consumption, high efficiency, average output size, low noise, no pollution to the environment, easy handling, easy maintenance. Raw materials can be plywood, scrap wood and residues from agriculture, landscaping, logging and sawmills.It can also be produced from leftover forestry material, including canopies, branches, unsalable material, or dwarf trees. The finished product is usually a small piece of wood, 3-5 cm in size can be used in biomass power plant, pape If you want to process waste pallets, waste plywood, building formwork, waste furniture boards and other board-like wood into small wood chips. Especially raw materials with nails Mobile Diesel Chipper will be more suitable for you. Highly trusted in Australia,Fiji,Italy,Malaysia,Mauritius,Russia,South Africa,Thailand,UK,USA,Vietnam |

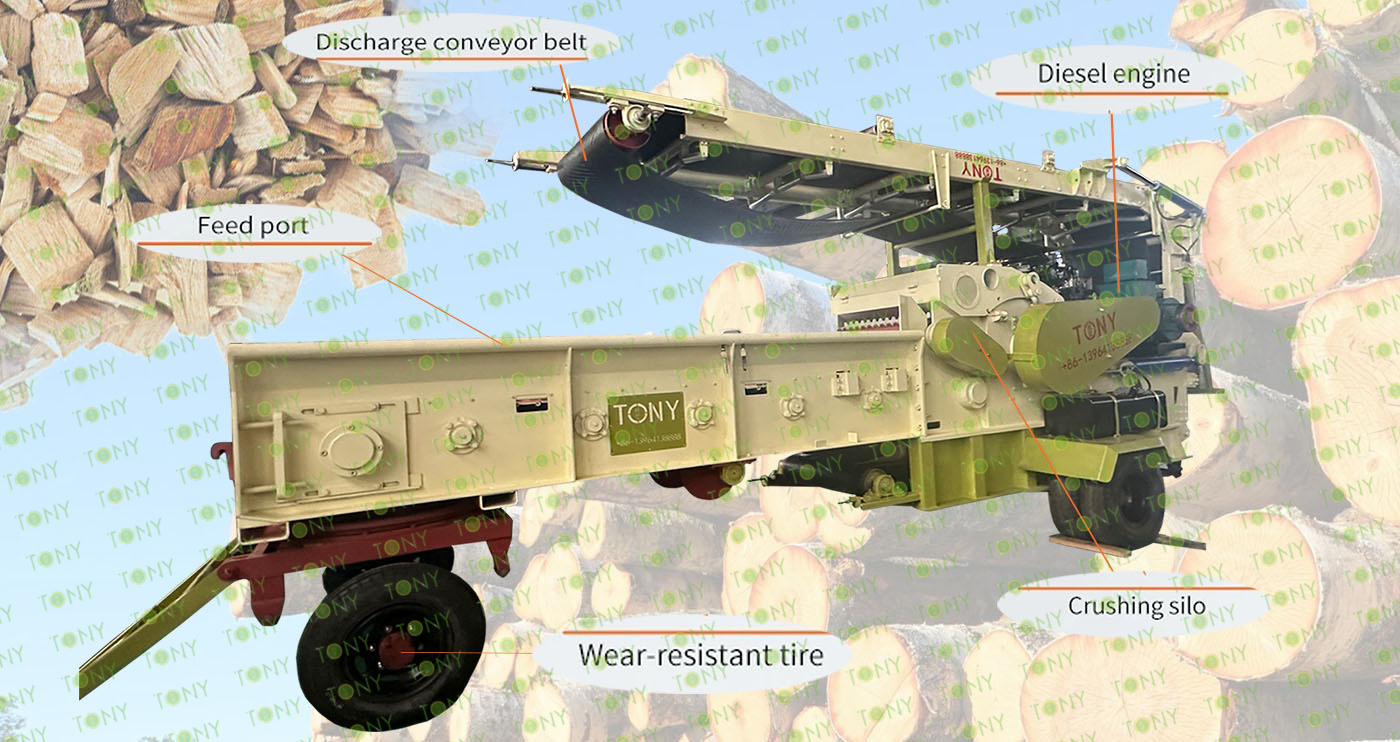

Structural composition

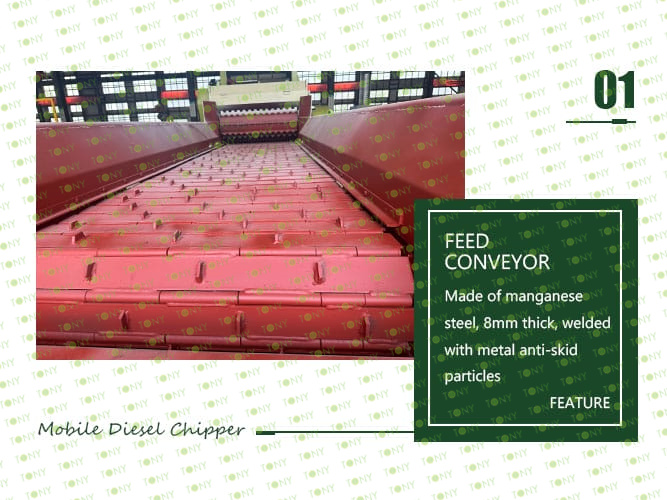

Feed mechanism:

Usually adopts vibrating feeders or chain plate conveyors, etc. Its function is to uniformly send wood into the crushing chamber, ensuring the continuity and stability of the crushing process, and also controlling the speed and quantity of the feed.

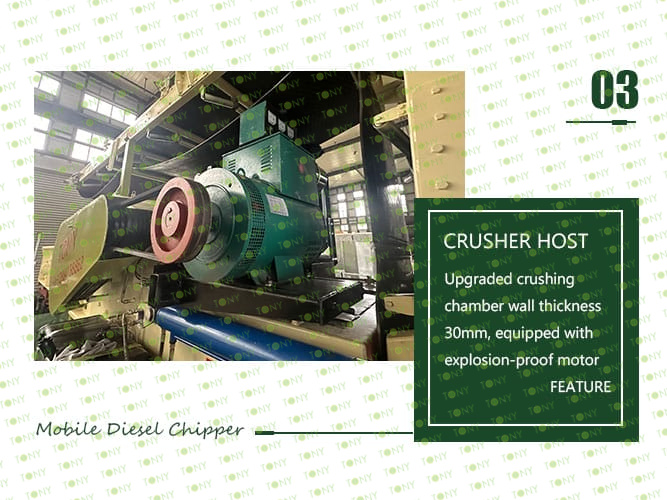

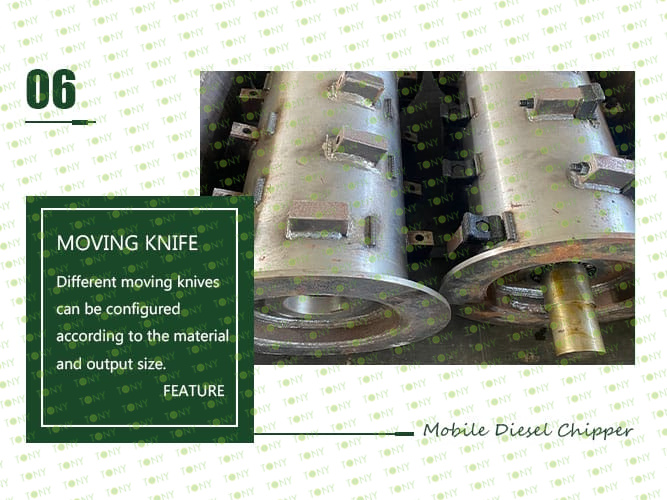

Crushing system:

Mainly consists of rotors, blades, hammer plates, screens, etc., and is the core component for achieving wood crushing. The rotor rotates at high speed under the drive of the diesel engine, driving the blades or hammer plates to cut and impact-crush the wood, and the screen is used to control the particle size of the discharged material.

Discharge system:

Generally adopts wind separation or conveyor belt transportation methods, discharging the crushed wood particles from the crushing chamber and conducting classification and collection. Wind separation can utilize the air flow to separate wood powder from impurities, and conveyor belt transportation can directly transport the crushed wood to the designated location.

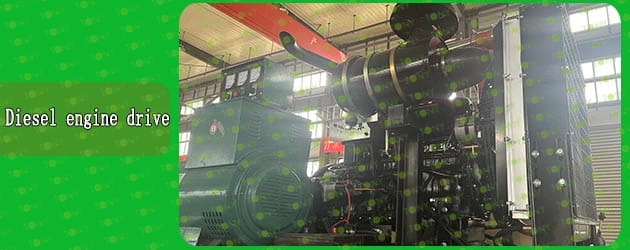

Power system:

Uses an efficient diesel engine as the power source, with advantages such as strong power and convenient mobility. It can operate in an electricity-free environment and provide sufficient power support for the operation of the equipment.

Walking mechanism: Usually consists of tires or tracks, enabling the equipment to have good mobility, facilitating movement between different sites, such as construction sites, forests, urban roads, etc., and being convenient for use in different operation sites.

|

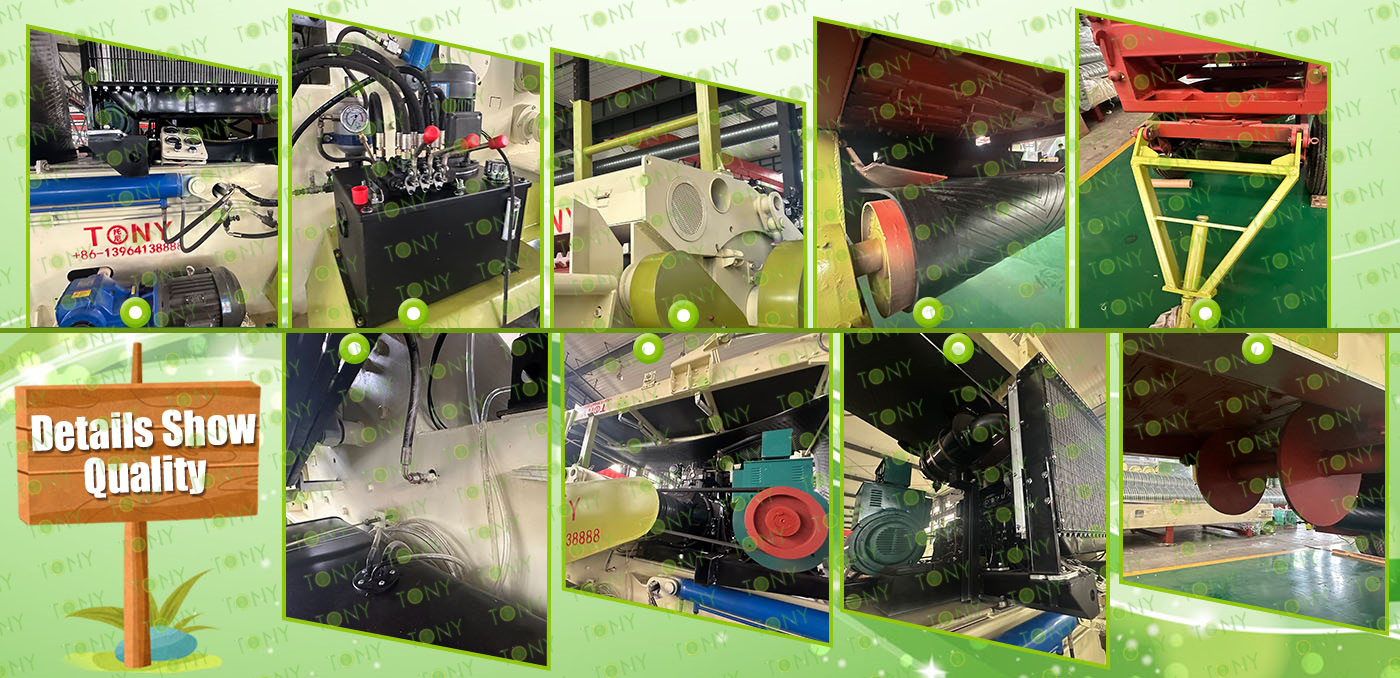

TONY Mobile Diesel Chipper On Show |

TONY Mobile Diesel Chipper On Clinets Site |

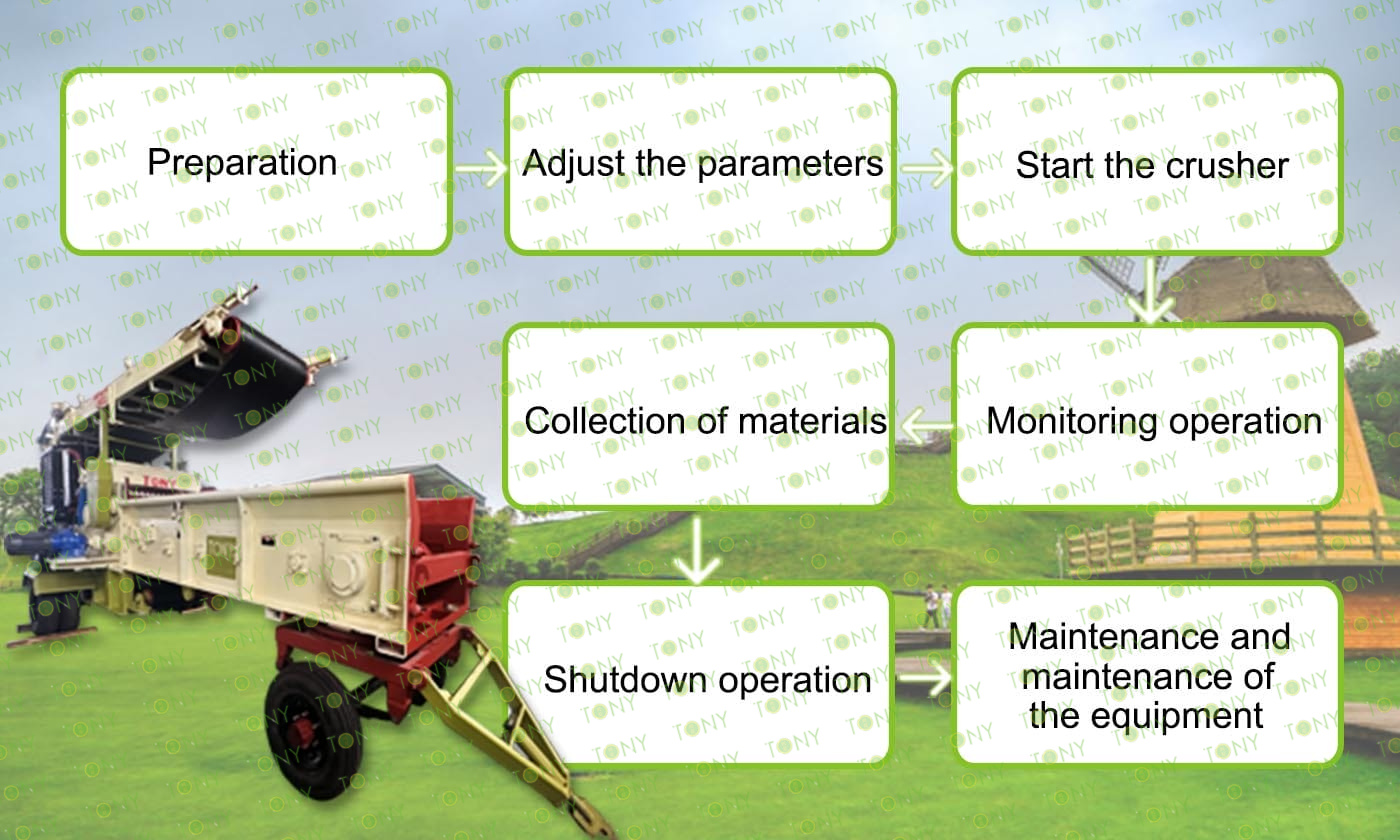

1. Preparation: Check whether the various parts of the crusher are in good condition, clean up the remaining materials and debris, and prepare the materials that need to be broken.

2. Adjust The Parameters: according to the need to break the material and crushing requirements, set the crusher speed, the number of hammer heads and the size of the discharge port and other parameters.

3. Start The Crusher: press the start button to start the crusher. In the crushing process, it is necessary to pay attention to monitoring the crushing effect and discharge of the material, and adjust the parameters in time to ensure the crushing effect.

4. Monitoring Operation: In the crushing process, closely observe the operation of the equipment, including the motor temperature, crushing effect, discharge situation, etc., if you find anomalies, such as abnormal noise, overheating, stalling, etc., you should immediately stop for inspection.

5. Collection Of Materials: When the crusher work is completed, the crushed materials are collected to the required position to avoid accumulation affecting work efficiency and safety.

6. Shutdown Operation: After the work is completed, stop feeding and let the equipment idling for a period of time to remove the remaining wood inside. Power off the devices in the order specified in the operation manual.

7. Maintenance And Maintenance Of The Equipment: check the wear of the tool, timely replacement of severely worn parts, regular cleaning, lubrication, tightening and other maintenance work on the wood crusher, extend the service life of the equipment, if the equipment is not used temporarily, it should be stored in a dry, ventilated and safe place to prevent moisture, damage or theft.

|

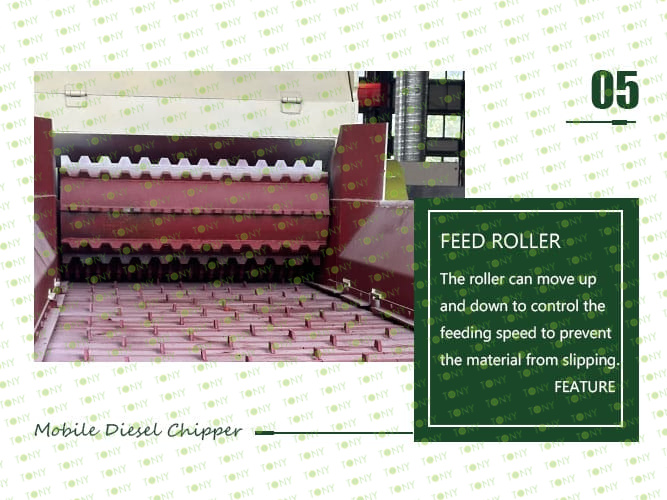

Mobile diesel crusher is a mechanical equipment that breaks waste wood into pieces, mainly by impact to complete the crushing of wood operations 1.TONY Mobile Diesel Chipper uses a diesel engine as the crushing power. Start the diesel engine and the machine starts working. The wood is put into the chain plate intelligent conveying feeding table through the claw machine, which is convenient for conveying wood and can automatically adjust the feeding speed according to the load of the main motor.. 2.After being transported, the wood reaches the hydraulic feed roller. The main function of the hydraulic feed roller is to forcibly crush and squeeze the wood. It has the characteristics of self-priming feeding and labor saving. When the wood is squeezed and crushed by the hydraulic roller, it naturally enters the crushing chamber. 3.TONY Mobile Diesel Chipper has blades installed in the crushing chamber. The blades are mainly used to cut wood. After being transported, crushed and cut, the wood flows out from the bottom discharge conveyor. The discharge conveyor can also be installed in the discharge part to facilitate the direct loading and transportation of the crushed wood |

|

TONY Mobile Diesel Chipper Model-Blades Type |

|||||||||

|

No. |

Model |

Main Power |

Capacity |

Fly Knives QTY |

Max Processing Diamater |

Out Chips Size |

Weight |

Inlet Size Width*Length*Height |

Machine Size |

|

1 |

TPQ216 |

200HP |

3-6TPH |

2Pieces |

20CM |

25-55mm-Adjustable |

4.8T |

50cm*4.5m*24cn |

5800*1900*1200MM |

|

2 |

TPC1000 |

350HP |

7-10TPH |

6Pieces |

20CM |

25-55mm-Adjustable |

9.8T |

1m*4.5m*45cm |

8100*1400*2125MM |

|

3 |

TPC1300-600 |

420HP |

10-15TPH |

6Pieces |

30CM |

25-55mm-Adjustable |

13.8T |

1.3m*4.5m*60cmChain Inlet |

9100*1900*2220MM |

|

4 |

TPC1400-700 |

480HP |

15-25TPH |

6Pieces |

35CM |

25-55mm-Adjustable |

17.8T |

1.4m*4.5m*70cm Chain Inlet |

11100*2400*2525MM |

|

TONY Mobile Diesel Chipper-Hammer Head Type |

|||||||||

|

NO. |

Model |

Power |

Capacity |

Hammer Head QTY |

Max Processing Diamater |

Out Chips Size |

Weight |

Inlet Size Width*Length*Height |

Main Machine Machine Size |

|

1 |

TPQ216 |

200HP |

3-6TPH |

12Pieces |

20CM |

25-55mm-Adjustable |

4.8T |

50cm*4.5m*24cm |

5800*1900*1200MM |

|

2 |

TPC1000 |

350HP |

7-10TPH |

16Pieces |

20CM |

25-55mm-Adjustable |

9.8T |

1m*4.5m*45cm |

8100*1400*2125MM |

|

3 |

TPC1300-600 |

420HP |

10-15TPH |

24Pieces |

30CM |

25-55mm-Adjustable |

13.8T |

1.3m*4.5m*60cmChain Inlet |

9100*1900*2220MM |

|

4 |

TPC1400-700 |

480HP |

15-25TPH |

24Pieces |

35CM |

25-55mm-Adjustable |

17.8T |

1.4m*4.5m*70cm Chain Inlet |

11100*2400*2525MM |

|

Chain Plate Conveyor Belt 1.Tony usually adopts two transportation methods: belt conveyor belt and metal chain conveyor belt (according to different materials) 2. Generally, the chain plate conveyor belt is used instead of the belt conveyor belt, because the chain plate conveyor belt has a larger throughput, is not afraid of nails, and has a longer service life 3.Feed frequency conversion, card automatically stop |

|

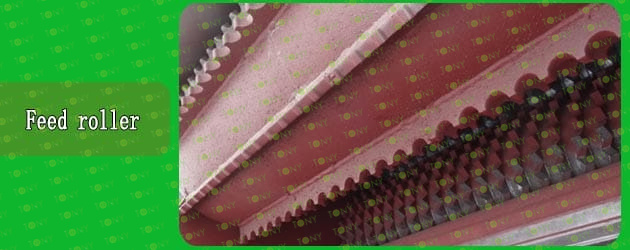

Feed Roller 1.Welding parts with high strength and performance have strong wear resistance and accurate bite force. 2.Feeding Roller Positive and Negative Adjustable to Prevent Material Clogging. 3.Tony manufacture it by factory to guarantee the quality. 4.You can confirm with TONY for spare parts price. |

|

|

Blade And Hammer Head 1. According to the different raw materials, you can choose a blade or hammer head for broken 2. High -speed hammers make the material as small -sized raw materials with high hardness and high hardness, and the hammer head is more abrasion. 3.Tony manufacture it by factory to guarantee the quality and longer sercve time. 4.The blades raw material can be chosen by cutomers. |

|

Diesel Engine Drive 1. High -power diesel engine drive operation, strong power, high work efficiency, larger output 2. Suitable for areas with difficulty moving and inconvenient power consumption, such as mountains, forests, large forest farms, pastures, etc. 3.The energy drive brand can be chosen by cutomers. 4.Please confirm with TONY for price difference. |

|

|

Screen 1.A range of screens are available to process chips of various sizes and thicknesses for different requirements 2.The qualified sheet material cut down is discharged from the bottom through the screen hole, and the large sheet material will be cut again in the machine. 3.The screeener inner size can be chosen by the customer. 4.Please confirm with TONY for price difference. |

|

|

|

|

|

|

|

|

|

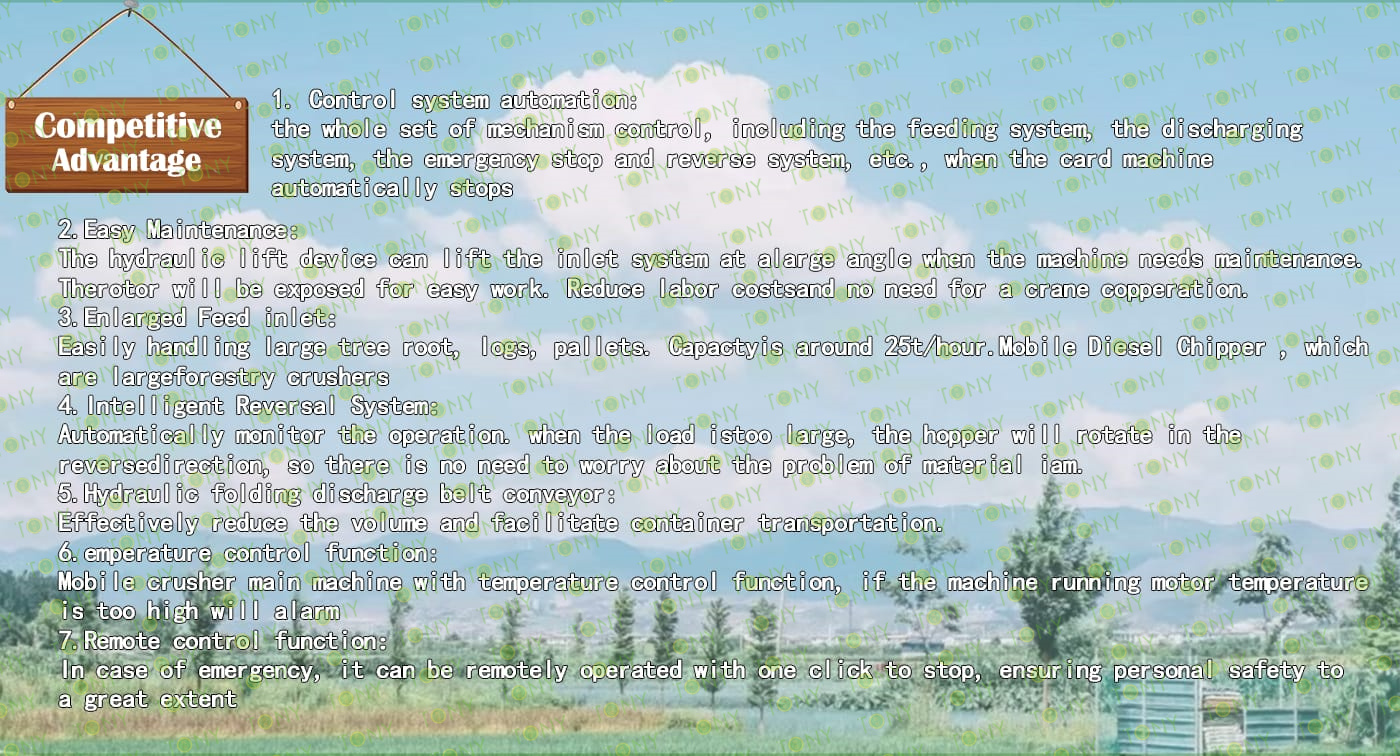

1. High mobility and flexible transfer capability Free mobile operation: Adopting a chassis design with either tracks or tires, it does not require fixed installation and can be directly dispatched to the operation site. The track-type model can adapt to complex terrains such as mountains, wetlands, and steep slopes, while the tire-type model is suitable for road transportation and has a fast transfer speed, significantly reducing equipment transportation and site construction costs. Advantage of rapid production: After arriving at the site, no complex installation and debugging are required. Power supply or starting the diesel generator set can be connected to start operation. This is particularly suitable for scenarios where the operation site needs to be frequently changed, shortening the project preparation period. 2. Independent power supply and dual fuel compatibility Free from power grid restrictions: Equipped with a diesel generator set, in areas without power grid coverage, such as in the wild, remote mines, or temporary construction sites, it can operate entirely relying on diesel power, avoiding production interruptions caused by power outages. Flexible power supply switching: Supports external power grid connection and diesel power supply switching. When there is stable mains electricity, use grid power supply to reduce fuel costs; when power is insufficient, switch to diesel mode to ensure continuous production. Especially suitable for areas with unstable power supply. |

|

|

3. Full-process integration and efficient crushing capability Integrated production line: Integrates functions such as feeding, crushing, screening, and conveying. No additional configuration of multiple equipment is required, reducing equipment connection losses. The production efficiency is over 30% higher than that of traditional fixed crushers. Multi-material adaptability: Can be equipped with different main machines, suitable for wood, construction demolition materials, used furniture, wooden pallets, and other materials. 4. Environmental protection design and low pollution emissions Dust and noise control: The equipment adopts a sealed crushing chamber and dust removal system, with dust emissions meeting environmental protection standards; combined with shock-absorbing bases and other designs, it reduces the impact on the surrounding environment. Energy-efficient utilization: The diesel generator set adopts turbocharging and electronic fuel injection technology, with fuel efficiency 15%-20% higher than traditional models, reducing carbon emissions and meeting green production requirements. 5. Material resource utilization and flexible configuration High utilization rate of recycled materials: For waste wood crushing, achieve waste resource utilization, reducing raw material procurement costs. Modular customization capability: Can flexibly select modules such as the number of screening layers (2-4 layers) and conveyor belt length (6-15 meters) according to production capacity and material characteristics. |

|

6. Cost optimization and low maintenance requirements Initial investment savings: Integrated design reduces site construction costs, and a single unit can replace multiple fixed machines, reducing investment costs by 40%-60%. Low operation and maintenance costs: Key components (such as crusher hammers, liners) use wear-resistant materials (high manganese steel, alloy cast iron), with a lifespan of 2-3 times longer; the intelligent lubrication system automatically adds grease, reducing manual maintenance, and reducing downtime and maintenance time by over 50%. 7. Intelligent operation and safety guarantee Automated control system: Equipped with a PLC intelligent control system, which can monitor equipment operation parameters (such as crushing chamber pressure, motor current, oil temperature) in real time, automatically adjust feeding speed and crushing force to avoid overload damage; the touch screen interface supports one-click start/stop, fault warning, with low operation threshold. Multiple safety protections: Set up iron protection, hydraulic overload protection devices. When foreign objects enter the crushing chamber, it automatically stops to prevent equipment damage; equipped with anti-skid stability devices to ensure safety during slope operations. |

|

Forestry Management:

Used for clearing trees and handling waste, it quickly crushes the large amounts of wood residues generated after forest management and logging operations into small pieces or particles, reducing ground debris and maintaining the ecological environment of the forest. The crushed wood can also be used as biomass fuel.

Horticulture And Landscape Beautification:

When gardeners prune trees and shrubs, the branches, leaves, and trunks can be processed by a crusher. The crushed wood can be used as an ornamental covering, helping to maintain soil moisture and inhibit weed growth.

Construction And Demolition:

During demolition processes, waste wood can be efficiently crushed to facilitate transportation and recycling, providing convenience for the reuse of construction materials. The crushed wood can be sent to a recycling center for further processing and utilization.

Agricultural Waste Treatment:

Can be used to handle agricultural waste such as dead branches and leaves, and crop residues in farmland. After crushing, it can be used as organic fertilizer or feed, reducing the accumulation of agricultural waste and promoting soil improvement.

Waste Disposal:

Can effectively handle wood waste in cities, such as discarded furniture and wooden packaging materials. After crushing, this wood waste can reduce the pressure on landfill sites, increase the recycling rate of garbage, and at the same time, the treated wood waste can be transformed into recycled materials and enter the circular economy.

|

|

Here are many models of TONY crusher, and the ex-factory price ranges from USD25000-USD70000.

We have our own factory, specializing in production, complete equipment, and delivery as soon as possible. We have our own technical team. According to your production capacity and raw materials, the appropriate model is quickly recommended. We have a special quality control team to strictly test the products to ensure quality. We always believe in the power of quality and integrity. The price is just one of the factor when you buy your equipment. Looking forward to your comprehensive consideration! |

|

1. Wide applicability: TONY diesel crusher can process a variety of raw materials, such as wood, small diameter wood, board, strip, round wood core, building template, furniture waste, wood tray, etc. 2. High -power diesel engine drive operations: strong power, saving time and effort, and work efficiency significantly improved 3. Automatic feeding: Use a conveyor belt -type intelligent feed, which can automatically adjust the feeding speed according to the main motor load. Make the machine full load and avoid air load, make the feed more smooth, greatly improve the production capacity 4. Easy operation: You can use the wheel traction type according to different user needs. The equipment does not require complex installation work. After manufacturing, place it directly on the ground to produce. The performance is stable and the quality of the crushing material is good |

|

|

|

|

|

|

|

1.The core function of the hydraulic folding system

The hydraulic folding system is the key mechanism for the mobile diesel crusher to achieve "compact transportation - expanded operation". It completes the folding and unfolding of equipment components through hydraulic drive, mainly addressing two major issues:

Reducing volume during transportation: Folding and storing external components such as the screening device, conveyor belt, and feeder, reducing the equipment's transportation height (typically from 4-6 meters in the operating state to 3-4 meters), meeting height restrictions.

Quickly unfolding during operation: Precisely controlling the unfolding angle of components through hydraulic cylinders, completing the transition from the transportation state to the operating state within 10-15 minutes, improving production efficiency.

2.Technical advantages of the hydraulic folding system

Efficient transfer capability:

Folding / unfolding time ≤ 15 minutes, which is 3 times more efficient than traditional mechanical folding methods.

Transportation state width ≤ 3 meters, allowing for direct transportation through standard containers or road trailers, reducing the cost of obtaining approval for oversized transportation.

Stability guarantee:

After the folding components are unfolded, they are fixed by hydraulic locking valves to prevent displacement during operation due to vibration, for example, after the screening frame is unfolded, the hydraulic lock can withstand a vertical load of 20 tons.

Equipped with a balance valve group to ensure synchronized operation of multiple cylinders and avoid component tilting (synchronization error ≤ ±5mm).

Intelligent control upgrade:

Some high-end models support remote control of folding (such as through a wireless remote control), allowing operators to complete equipment status switching from a safe distance.

Integrated fault diagnosis system, when the hydraulic system pressure is abnormal or the folding exceeds the time limit, it will automatically alarm and stop (response time ≤ 0.5 seconds)

|

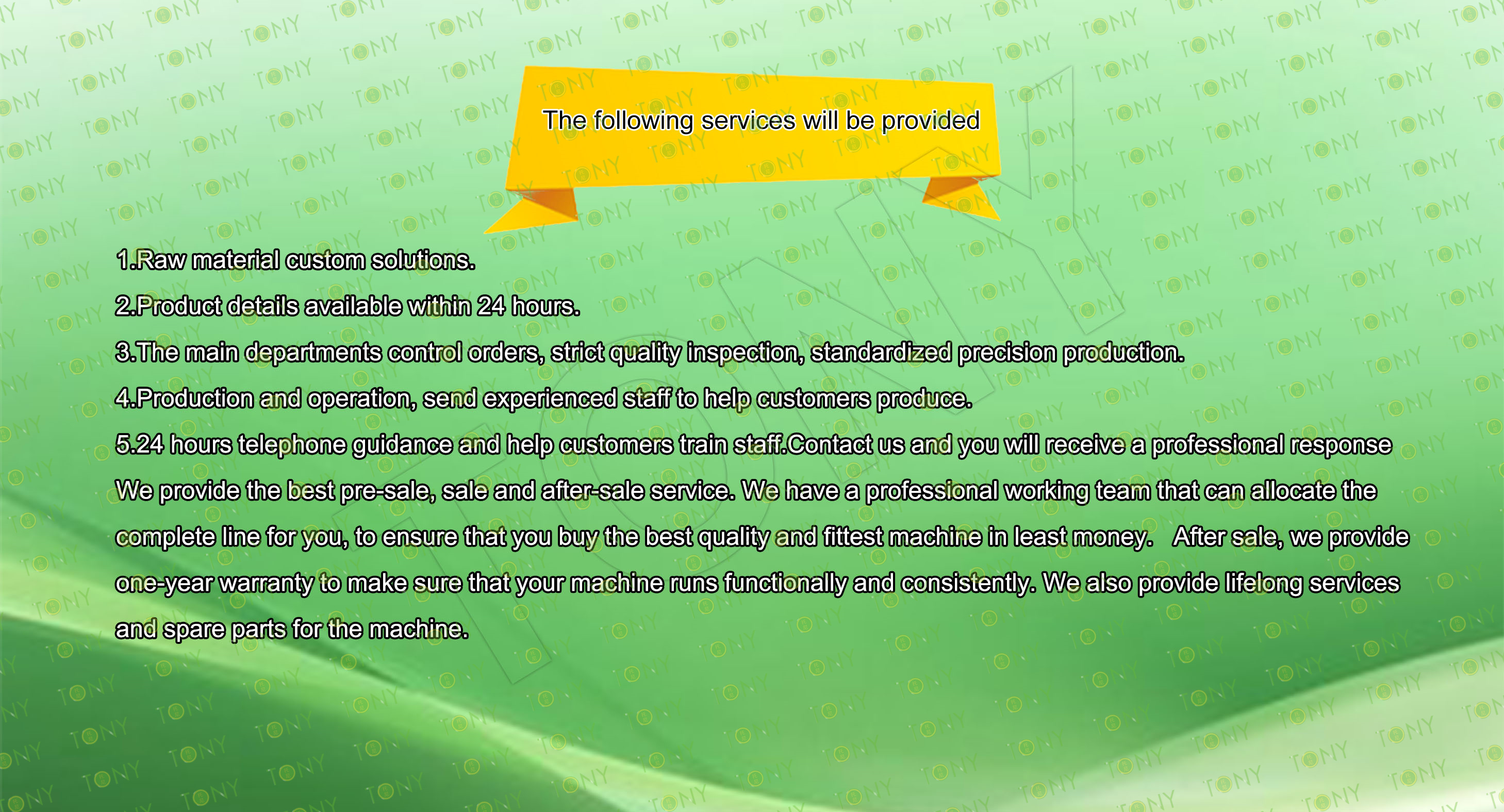

1. A full range of design, construction, equipment supply, construction, installation supervision and commissioning, staff training; 2. License for the design, construction, installation, wiring, and other works; 3. Full certification of equipment; 4. officially registered trade mark; 5. Full warranty, post warranty and service; 6. Warranty on all equipment - 13 months; 7. We have a dedicated quality control personnel, strict inspection of products to ensure quality. 8. Vast project experience. we have established and put into operation so many productivity on the finished product from 0.5 to 20 t / h in Malaysia, Thailand, Vietnam, Germany, France, Bulgaria, Serbia, Romania, Korea,Australia etc; 9. Large stock of finished equipment and spare parts; 10. For over ten years, our products and services have been enjoying a good reputation in this market. |

|

|

|

|

|

|

|

|

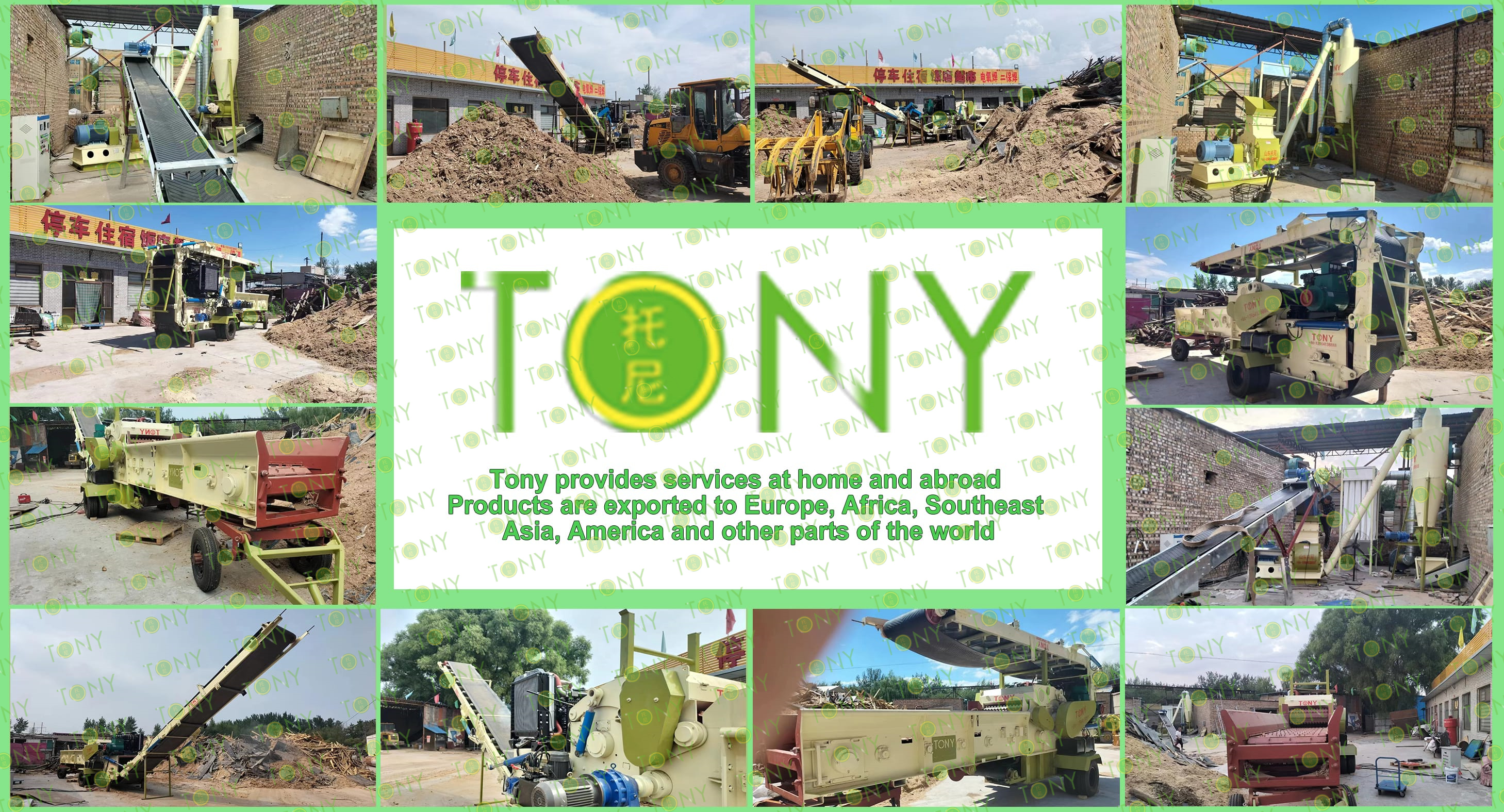

| History :TONY has more than ten years of professional experience in crusher development, design, export and installation. | R&D: TONY has a design team of 30 engineers, which can customize crushing equipment according to customers' specific requirements. | Hardware :TONY has the world's leading machining and numerical control center, to ensure the quality and quantity of the machine. | Inspection :TONY has a professional quality inspection team responsible for pre-delivery inspection to ensure product quality. |

|

|

|

|

|

Standard: All TONY machines are in line with national standards, German standards, American standards, and CE certification.TONY your best choice> |

Quality of spare parts: All spare parts of TONY are made of heavy machinery anti-fatigue and wear-resistant materials to extend the service life. | Installation :TONY has more than 30 professional installers and engineers, with more than 15 years of installation and commissioning experience,can provide overseas mechanical services. |

After-sales service :TONY has 24 hours online service, contact us, you will get a professional reply. |

|

|

|

Shandong TONY Environmental Protection SCI-TECH CO., LTD. (formerly Zhangqiu TONY Machinery Co., LTD.) is located in the east of Jinan, the capital of Shandong Province, the west of Zibo, there are 309 National Road and Jiqing high-speed east-west through, west of Jinan International Airport, the traffic environment is very convenient, is an important production base of biomass new energy equipment. TONY company has brought together a group of outstanding scientific research, production and management talents, creating a united, efficient and strict team. At present, the company's product sales have covered nearly the world, including: Russia, Japan, South Korea, France, Germany, Italy, Romania, Bulgaria, Malaysia, Vietnam, Thailand, Singapore, Cambodia, Indonesia, Iceland and many other countries and regions, well received by domestic and foreign users. TONY promise to let customers get the maximum benefit with the lowest investment! |

2025 Tony Machinery - All Rights Reserved. Map