In fact, corn stalk pellet fuel is not as complicated as everyone imagines. Because there is straw pellet production line equipment, it is relatively simple to make. The raw material for corn stalk pellet fuel is corn stalks. No chemical substances are added during the processing process. It is pressed into a granular cylinder through a straw pellet machine. Generally, it is normal to have a length of 3 to 5 cm. In fact, in addition to corn straw raw materials, such as wheat straw, rice straw, and flax straw, these raw materials can also be made into fuel through a biomass pelletizer.

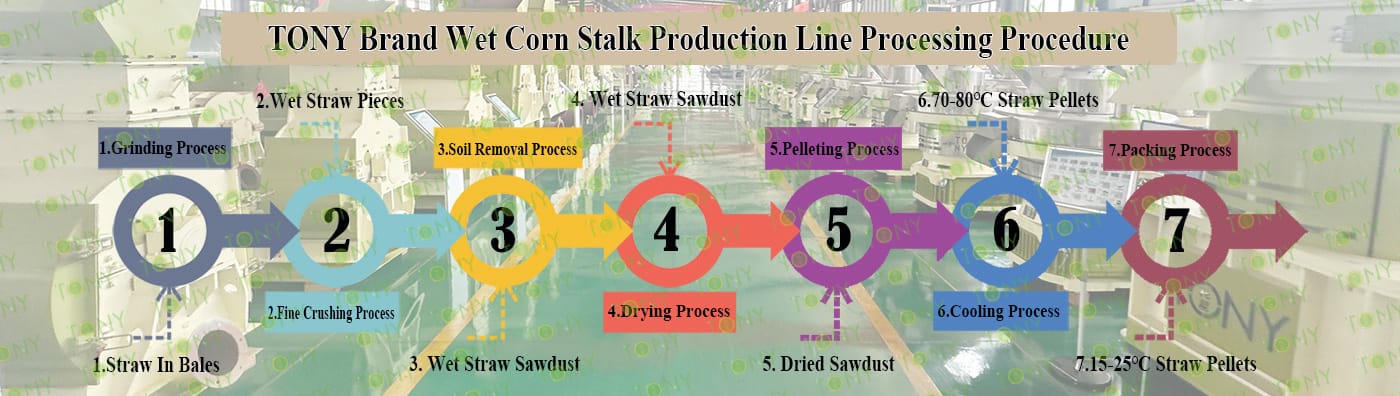

The production process steps of general corn stalk pellet fuel are as follows:

1. Raw material pretreatment

Corn stalks often appear in a round bale, which requires the use of a straw cutter to unpack the bale raw materials and crush them coarsely. If it occurs in bulk, you can go directly to the crusher for fine crushing.

2. Moisture treatment

The dryer equipment is considered based on the moisture content of the raw material and the yield. If the output is low at the time, you can dry it yourself; if the output is high at the time and the moisture content of the raw materials is large, dryer must be used.

3. Mechanical forming of pellet machine

The treated straw raw materials are shoveled to the feeding port of the granulator through the forklift, and the straw raw materials are fed into the straw pellet machine through the feeder. After mechanical high temperature and high pressure processing, the diameter of the corn pellet fuel can be adjusted, with a length of 30 to 50mm. The finished straw particles are granular and can be adjusted in length.

4. Cooling

The fuel temperature of the newly processed straw pellets is high, about 80-90℃. After cooling by galvanized pellet cooler, the temperature drops to 20-30℃.

5. Packaging

According to different customer requirements, straw pellet fuel is generally available in bulk, bagged, ton bags, etc.

The above is an answer to how straw pellet fuel is processed. The seemingly inconspicuous production and processing actually requires a summary of actual production experience, raw material control, machine maintenance and other aspects to ensure the stable production of straw pellet fuel. If you have ever wanted to process straw pellets, you can consult TONY.