There are several reasons for using wood and biomass waste to make pellets:

1. Energy Utilization Perspective

Renewable Energy Sources

Wood and biomass waste are renewable resources. Unlike fossil fuels (such as coal, oil and natural gas), wood can be continuously regenerated through the growth of trees. As long as forest resources are properly managed and planted, they can continue to provide raw materials for pellet production.

Biomass waste such as crop straw and forestry residues are also produced continuously. my country is a large agricultural country, and a large amount of crop straw is produced every year. If these wastes are not utilized, most of them will be burned in the open air, which not only wastes resources, but also causes serious air pollution. Making them into pellet fuel can turn waste into treasure and realize the recycling of resources.

2. Good Combustion Performance

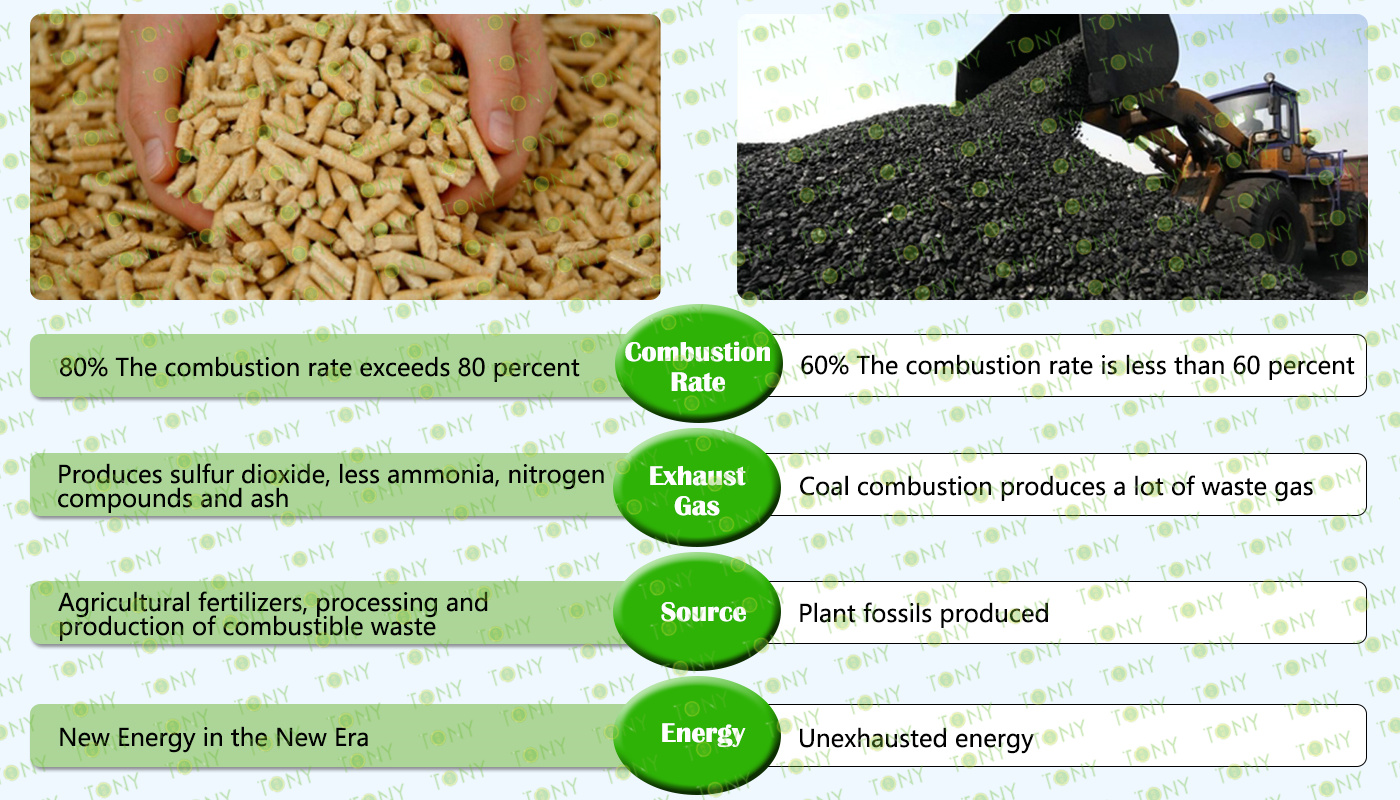

Pellets have regular shapes and uniform sizes, which are conducive to the automatic feeding and stable combustion of combustion equipment. Compared with raw wood, pellet fuel can burn more fully during the combustion process, reducing the production of incomplete combustion products (such as harmful gases such as carbon monoxide). Its combustion efficiency can reach about 80% - 90%, which is significantly improved compared with direct combustion of wood and biomass waste.

The pressing of wood and biomass waste into pellets has significant economic value .

Aggregate Economic Value

Wood and biomass waste processing into pellets as a new type of energy preparation, because of its rich resources, relatively low price, while burning more clean, harmless and environmentally friendly, gradually favored by the market, showing broad economic prospects.

Concrete Economic Value Analysis

1. Growth In Market Demand

Promote the concept of environmental protection : with the popularization of environmental awareness and the strengthening of the state's environmental protection, wood and biomass waste processing particles as a green renewable energy, the market demand is gradually increasing .

Policy support: The state has issued a series of supporting policies, such as reducing and reducing enterprise income tax, increasing production incentives, etc., to further promote the development of wood and biomass waste processing pellets market .

2. Economic Efficiency Improvement

efficient utilization of resources : wood and biomass waste processing into pellets can make full use of agricultural by-products, forest waste and construction waste and other resources, reduce the pollution of domestic waste and factory waste to the environment, and improve the utilization rate of wood and biomass waste.

cost reduction: compared with traditional fuel, wood and biomass waste pellets have lower cost and higher combustion efficiency, which helps to reduce the production cost and new energy research and development cost .

3. Industrial Chain Development

Promotes rural economic development:

By processing waste straw such as silage into pellets in rural areas and selling them directly in rural areas, it promotes rural economic development and poverty alleviation .

Promotes the development of new energy industry:

The wide application of wood and biomass waste pellets has promoted the development of new energy industry and provided a new impetus for economic transformation and upgrading .

In summary, wood and biomass waste pellets have shown significant economic value in terms of market demand, economic benefits and industrial chain development.

There are many advantages to processing wood and biomass waste into pellets. The main advantages of wood and biomass waste particles include good environmental protection, high strength, good moisture resistance, good wear resistance and easy processing.

Wood and biomass waste pellets are made of natural wood and biomass waste pellets, do not contain any harmful substances, and meet environmental protection requirements. Its strength is higher than that of ordinary wood and biomass waste, and it is not easy to deform, crack or warp. In addition, wood and biomass waste particles have good moisture resistance and are not susceptible to moisture, mold or decay. High surface hardness, good wear resistance, not easy to scratch or wear, easy processing, can be cut, drilling, drilling and other operations .

The surface texture of wood and biomass waste particles is good, with the texture and color of natural wood and biomass waste, beautiful and generous. Its stability is good, not easy to expand or contract under the influence of environmental humidity, and maintain dimensional stability. Due to the special production process, wood and biomass waste particles perform well in moisture-proof and corrosion resistance. In addition, with the progress of technology, modern wood and biomass waste pellet boards use more environmentally friendly ecological glue, reduce formaldehyde release, in line with or even better than the national environmental protection standards .

Wood and biomass waste pellets have a wide range of applications, which can be used in furniture manufacturing, cabinets, wardrobes, office furniture and interior decoration, etc., to meet the needs of different scenarios. Its price is relatively low, the production process is simple, the cost of raw materials is low, and it has a high cost performance. In addition, the nail holding force of wood and biomass waste particles is strong, suitable for the production of various furniture and decorative parts, reducing the difficulty and cost of processing.

|

|

|

| Comprehensive Chipper | Hammer Mill | Drying Machine |

|

|

|

| Pelleting Machine | Cooling Machine | Packing Machine |

|

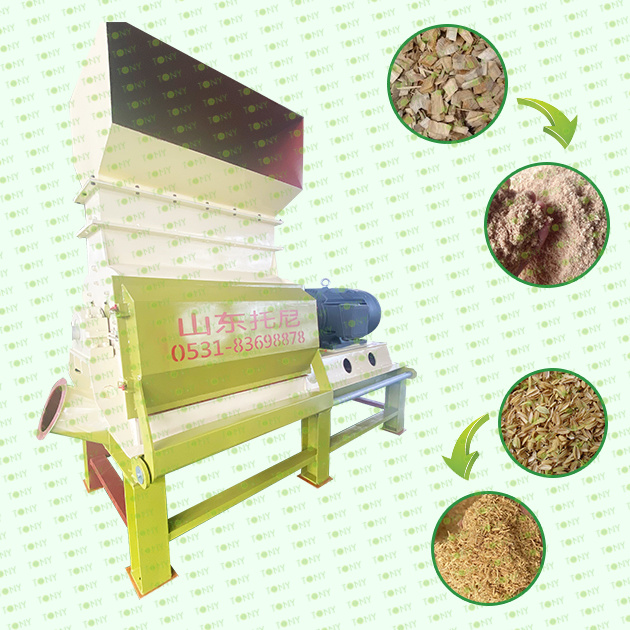

1.Chipping Process: A.This process is mainly used to grind the wood and biomass waste into wood and biomass waste chips with size 25-35mm. The finish wood and biomass waste chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the comprehensive chipper. Main Parts: 1). TONY's new comprehensive chipper. 2). Feed and unload belt frequency control to prevent card material 3). Hydraulic system control for more thickness of raw materials 4). Electronic control system allows the equipment to be used normally 5). Contact TONY for more details with quotation. |

| The Details Of Comprehensive Chipper | ||

|

|

|

|

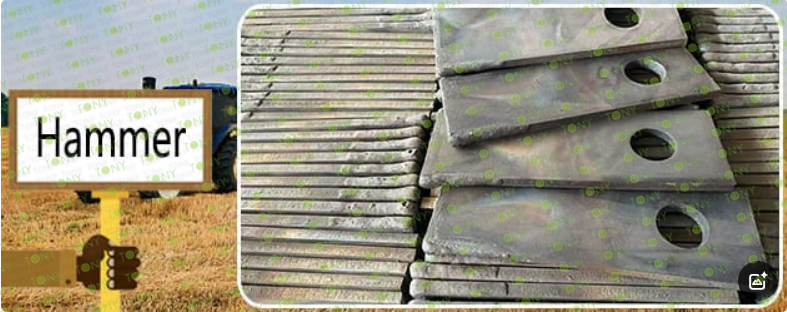

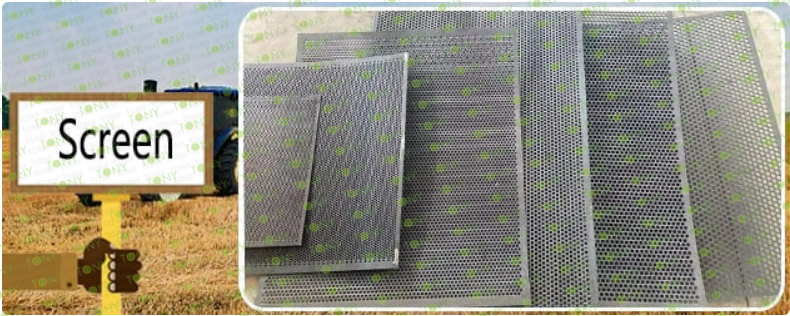

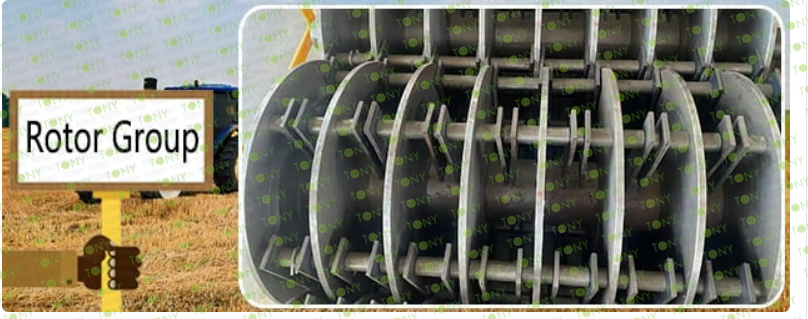

2. Chips Fine Crushing Process: A.This process is mainly used to crush 30-40mm wood and biomass waste chips Into 8-14mm sawdust. B.Capacity: According to the customer's demand. Main Parts: 1).TONY High effective hammer mil. 2).Galvanized Dust Collector 3).Sawdust Transportation Fan Blower. 4).Cyclone With Airlock. 5).Electrical Cabinets. |

|

| The Details Of Hammer Mill | ||

|

|

|

|

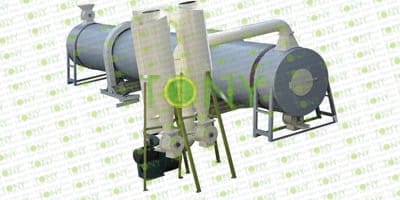

3. Sawdust Drying Process: A.This process is mainly used to dry the sawdust from moisture 45% to15%. B.Capacity: According to customer's demand. TONY dryer use spiral tube material, which has higher heart rate and is not easy to deform. Unlike other manufacturers with iron plate splicing welding, very easy to deformation. Main Parts: 1). TONY's Rotary Drum Dryer Main Body.(Reducers With Motors and Pips.) 2). TONY's Wood Waste Hot Stove. 3). Fan Blower+Cyclone With Airlock. |

| The Details Of Drum Dryer | ||

|

|

|

|

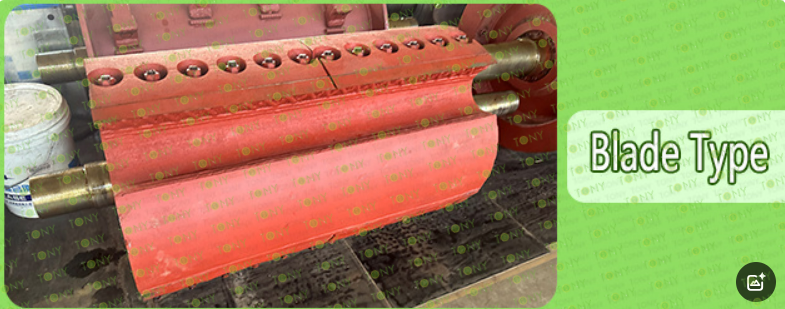

4.Pelleting Process: A.This process is mainly used to to product pellets with φ6-8mm. B.Capacity: According to customer's demand. Main Parts: 1). TONY's new vertical ring die pellet machine. 2). Cyclone and bags dust collectors. 3). Bearings automatic lubrication system. 4). Electrical cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

|

| The Details Of Pellet Machine | ||

|

|

|

|

5.Cooling Process: This process is mainly used to to cool pellets from 80-90℃ to 20-30℃. Main Parts: 1) TONY's new Galvanized Cooler Seperator With Vibrating Screen. 2) Cyclone And Bags Dust Collectors. 3) Fan Blower. 4) Connect Pipes. |

|

6.Packing Process: This process is mainly used to pack pellets To 15-50Kg/Bags. Main Parts: 1) TONY's newTONY Semi-Automatic Packing Machine. 2) Sew Machine, Buyer Can Also Chose Hot Seal Machine For Chosen. 3) Bags Transportation Conveyors. 4) Feeding Inlet Silo . 5) Electrical Cabinets. |

|

|

|

|

| Belt Conveyor | Cyclone And Dust Collector | Air Lock |

|

|

|

| Electrical Cabinets | Automatic Lubrication System | Motor |

Price Description

Due to different production line configurations, different outputs require different models of machines. For specific prices, please call us for consultation or visit our factory.

+86-13964138888(Tel or WhatsApp)

The development prospects of waste wood and biomass pellets are very broad, with significant market demand and policy support.

Market Demand And Policy Support

With the transformation of the global energy structure and the improvement of environmental awareness, the market demand for biomass pellets, as a clean and efficient form of energy, continues to grow. Biomass pellets are mainly processed from biomass materials such as wood and straw. They have the advantages of clean and environmental protection, high combustion thermal efficiency, and safe use. With the government's strong support for renewable energy, the biomass pellet market is expected to continue to grow at a rapid pace.

Advantages Of Biomass Pellets

Environmental Protection Advantages: The ash remaining after the complete combustion of biomass pellet fuel basically contains no carbon and produces less pollution. It is a new type of clean energy. It can digest biomass waste generated in rural areas and avoid environmental pollution caused by incineration.

Economy: The caloric value of biomass pellet fuel is relatively high, with the heat value per kilogram reaching more than 5,000 kilocalories. It is not much different from coal, but the price is lower, which can effectively reduce costs.

Wide Application: Biomass pellet fuel can replace electricity, gas, coal and other energy sources, and is widely used in hotels, bathing centers, factories and other places.

Entrepreneurship Opportunities And Challenges

The biomass pellet processing industry has broad market prospects and huge development potential. Entrepreneurs can produce biomass pellet fuel by processing biomass materials such as waste wood and straw. This industry not only conforms to the strategic direction of national energy structure adjustment, but can also drive the development of related industrial chains and inject new vitality into the local economy. However, entrepreneurs need to fully understand market demand, technical characteristics, policies and regulations, etc., and formulate reasonable business plans and risk control strategies.

In summary, the development prospects of waste wood and biomass pellets are very optimistic, with large market demand, strong policy support, and significant environmental and economic advantages. Entrepreneurs should seize current market opportunities, actively respond to challenges, and achieve sustainable development.

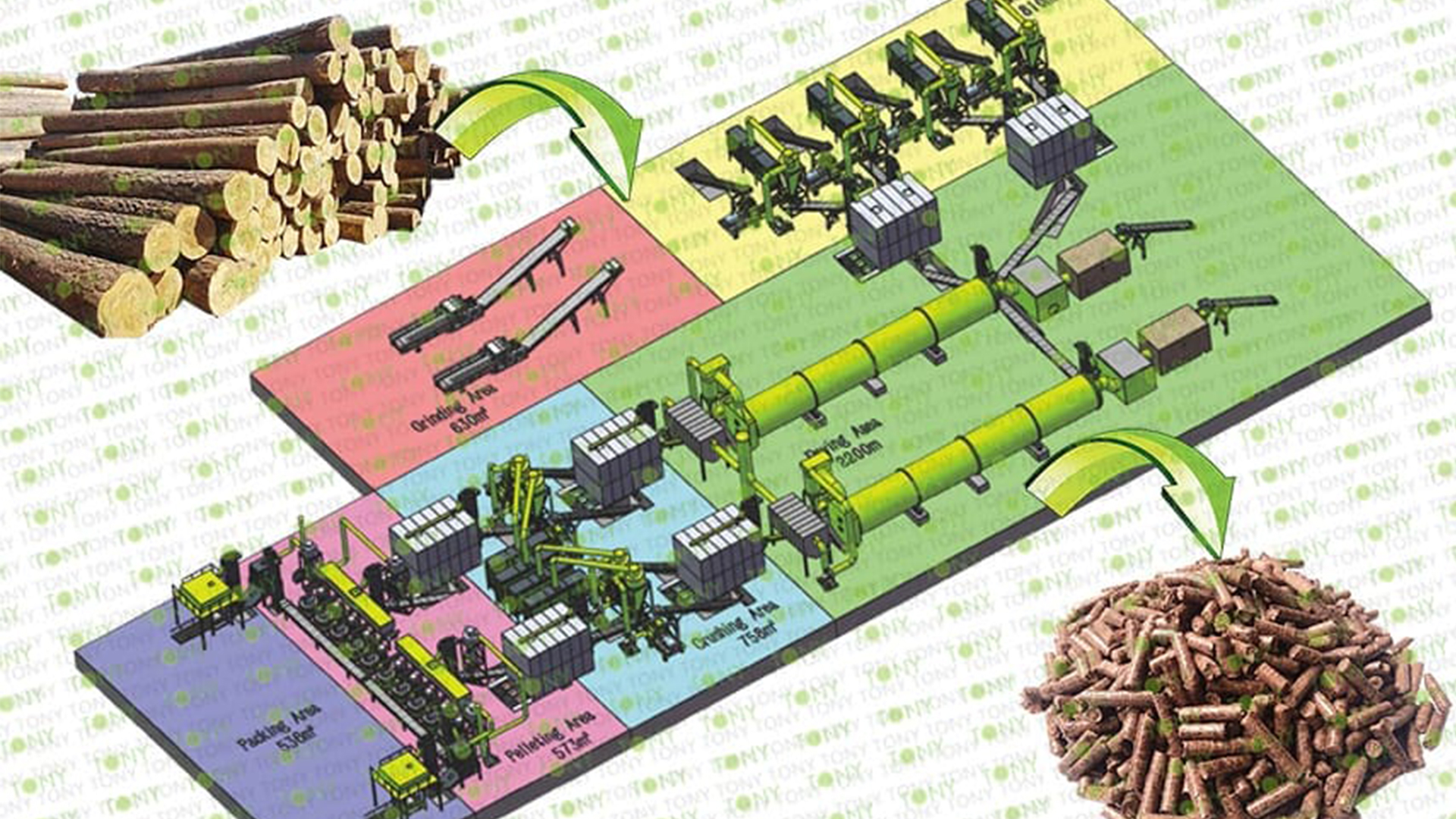

TONY can provide different kinds of complete pellet production line. The whole pellet production line suitable for press the different kind of wood log,woodchips,wood waste, wood scrap, wood shaving and other biomass materials suchas rice husk, corn cob, straw, palm fiber and other agriculture waste into goodquality biomass fuel pellets.

2025 Tony Machinery - All Rights Reserved. Map