The treatment of abandoned clothing has always been a problem. Traditionally, people tend to donate, sell or discard scrap cloth. However, these practices will affect the environment.

For example, when donating abandoned clothing to charity, if the clothing does not meet the requirements, it may be discarded and causes waste.

If the waste clothing is sold to second -hand merchants, these merchants may treat the clothes into chemical fibers, and these fibers will have adverse effects on the environment, which will exacerbate pollution

If the scrap cloth are directly incinerated, there will be some residues that cannot be eliminated by flames, and many such things will be thrown into the land by people. However, the land does not have the ability to degrade these substances. In the long run, it will have inferior effects on the soil. In addition, when burning old clothes, a large amount of toxic gases will be generated.If you are inhaled into the body, you can imagine how harmful it will be to human health.

To mitigate these impacts, we need to adopt more environmentally friendly ways to dispose of discarded clothes, such as processing old clothes and household garbage into environmentally friendly pellet fuel, thereby reducing the burden on the environment

The impact of scrap clothe and household garbage on the environment is mainly reflected in the following aspects:

1. Soil Pollution

The widespread use of synthetic fibers in clothing has also brought the problem of soil pollution. Because synthetic fibers are relatively large molecular weight and do not contain biodegradable active matrix, most synthetic fibers are difficult to degrade and can pollute the soil for up to one hundred years

2. Air Pollution

Burning waste clothing can produce toxic and harmful gases, the most serious of which is dioxins. Dioxin is a colorless, odorless persistent pollutant with toxicity, which is not easy to degrade. It can lead to skin diseases, immune function impairment, endocrine and metabolic disorders, teratogenic and carcinogenic damage to the human body. Due to its serious harm, the World Health Organization listed it as a first-class carcinogen in 1997.

3. Waste Of Resources

Disposing of discarded clothes also involves a waste of resources. The textile and garment industry consumes a lot of resources in the production process, including water, energy and raw materials. When these garments are discarded and incinerated or landfilled, resources that could otherwise be reused in the production of new garments are wasted.

4. Increased Carbon Emissions

The process of disposing of discarded clothes also contributes to carbon emissions. Compared with the processing and production of raw materials, the recycling and use of waste textiles can significantly reduce carbon dioxide emissions. Therefore, the improper disposal of discarded clothes not only wastes resources, but also contributes to global climate change

1. Project Overview

Scrap cloth and household garbage processing biomass pellets fuel is an emerging environmental protection project that aims to achieve recycling of resources by converting scrap cloth and household garbage into biomass pellets fuel. This project not only helps reduce environmental pollution, but also creates economic value.

2. Technical Method

(1) Raw Material Selection

The project mainly uses waste resources such as household garbage, scrap cloth, waste cloth strips, fragmented cloths, and sports upper as raw materials. After these raw materials can be treated by crushing, crushing, etc., they will be squeezed into the granular machine to squeeze and mold, and finally make biomass granules fuel

(2) Production Process

The production process of biomass pellets fuel includes the following steps:

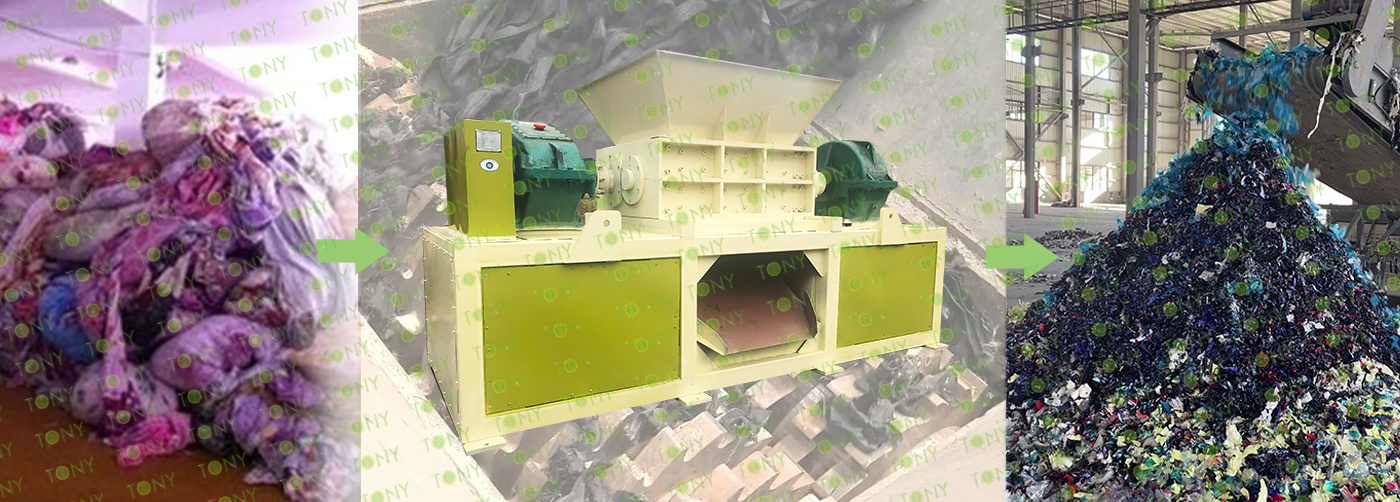

Shredding: Broken scrap cloth into small pieces.

Fine Crushing: Further crushed the broken materials into powder.

Drying: Depending on the humidity of waste clothing, if the raw materials are dry, it does not need to be dried.

Pelleting: squeezing molding through the pellet machine, making biomasspellets fuel

Cooling: The temperature of the processed pellets is high, about 70-80 ° C, and it needs to be dried to normal temperature

Packaging: Biomass pellets are packed or sold after quality inspection

3. Market Demand And Market Application

(1) Market Demand

With the growth of global energy demand and the improvement of environmental awareness, as a renewable energy source, biomasspellets fuels have continued to increase. As one of the sources of raw materials for biomasspellets fuel, Scrap Cloth have a wide range of supply channels. Scrap Cloth can be converted into biomasspellets fuel through professional recycling treatment technology, which not only solves the problem of Scrap Cloth treatment, but also provides stable sources of raw materials for the production of biomasspellets fuel.

(2) Market Application

Many countries and regions have introduced the development of relevant policies to support biomass pellets fuel. For example, relying on advanced technology and policy support, Sweden has promoted the rapid development of the biomasspellets fuel industry. The application of biomasspellets fuel is widely used, and can be used in industrial boilers, civil heating, biomass power generation and other fields. Market demand has continued to increase

In summary, the raw materials for Scrap Cloth as biomass pellets have a broad market prospect, which can not only solve the problem of waste clothing treatment, but also bring significant economic and environmental benefits.

The benefits of scrap cloth and household garbage for biomass pellets are significant, which is mainly reflected in three aspects: environmental protection, economic and social benefits:

1. Environmental Benefits

Scrap cloth and household garbage making biomass pellets fuel help reduce environmental pollution. After processing, the waste fabric can be made into biomass fuelpellets. This particle can be used for coal. The heat value is high and less ashes during burning. It does not smoke or smoke during the combustion process. It is friendly to the environment. In addition, this fuel can also reduce the generation of solid waste and achieve the "threeizations" treatment of solid waste waste (reduced, harmless, resource)

2. Economic Benefits

The cost of making biomass granules in scrap cloth is low and has high economic benefits. The source of old clothes and household garbage is wide and low in price, and the processing technology is relatively mature, which can effectively reduce production costs. For example, there are reports that by processing scrap cloth into particle fuel, a guy earned 2 million yuan within a year. This business model not only creates economic value, but also provides new business opportunities for entrepreneurs.

3. Social Benefits

The social benefits of scrap cloth and household garbage to make biomas spellets have significant social benefits. First of all, this approach helps reduce the waste of resources and convert the abandoned scrap cloth into useful resources. Secondly, by recycling and using waste clothing can reduce the demand for new resources and help sustainable development. In addition, this approach can also improve the public’s awareness of environmental protection, and encourage more people to participate in the recycling and use of waste items.

In summary, scrap cloth and household garbage to make biomasspellets fuel in environmental protection, economy and society have significant benefits, and it is a circular economic model worth promoting.

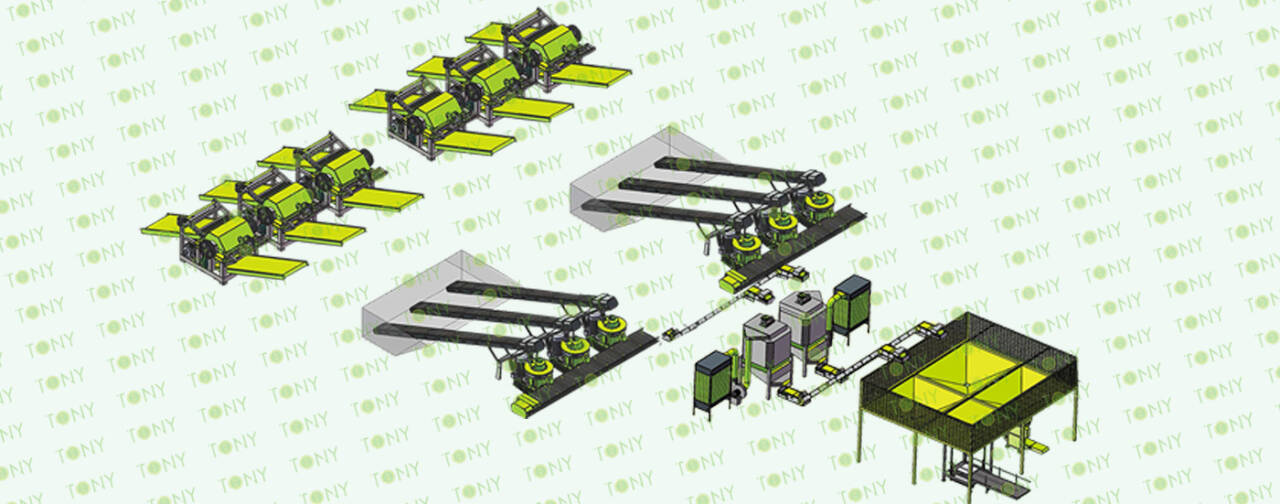

TONY Scrap Cloth Pellet Line Brife lntoruduction

1.Project Name: Scrap Cloth Pellet Line

2.Raw Materisl: Scrap Cloth

3.Moisture Of Raw Material: According to the actual raw material moisture content, 45-55%of the wet materials are taken as an example.

4.Capacity: Our equipment production capacity is 0.8 tons/hour-100 tons/hour, and the biomass pellet line customizes according to the actual production needs of customers.

5.Proecss: Tearing Process→Fine Crushing Process→Drying Process→Pelleting Process→Cooling Process→Packing Process

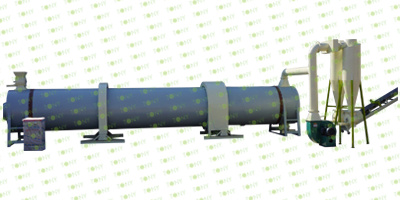

6.Main Machine: Double-axis Tearing Machine, Cloth Special Powder Cutting Machine, Rotary Drum Dryer ,Pellet Machine,Galvanized Pellets Cooler,Ton Packing Machine And Belt Conveyors.

7.Total Power: Based on all selected equipment models,according to all the equipment models selected, different models have different power.

8.Need Area: Based on all selected equipment models,according to all the selected equipment models, different models of equipment sizes are different.

9.Project Country: Can be used in any country.

10.Voltage: The voltage standard of the country in which the equipment is used.

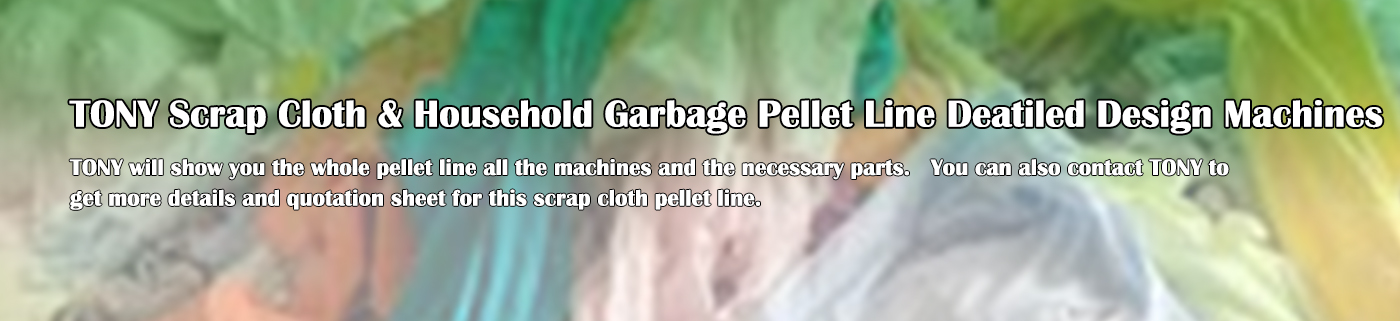

1. Scrap Cloth Tearing Process

|

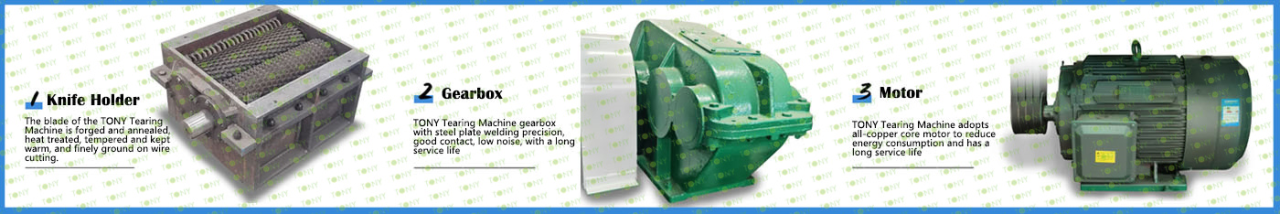

1. This process is mainly to tear the old clothes into small pieces through a double -axis tearinging machine. 2. The working principle of the dual axis tearing machine is as follows: The waste material enters the machine through the conveyor belt, and is crushed by two parallel blades for high -speed rotation. The material is torn into small pieces under the high -speed rotation and interaction of the blade, and is separated and screened through the screen to separate the large pieces of materials and small particles. Finally, collect and transport it through the conveyor belt or other equipment. 3. There are many models for dual-axis tearing machines, please contact TONY to get more products and quotations. |

|

2. Scrap Cloth Fine Crushing Process

1.This process mainly fine crushing of old pieces of scrap cloth into smaller pieces.

Cloth strips special powder cutter is a mechanical equipment specifically used to handle cloth strips.

2.Its main role includes:

Message: The device can crush the cloth strip to make it smaller particles or fragments. This is usually achieved through the internal crushing cylinder and crushing blades. When the cloth strip or straw enters the crushing box, the motor driver chain and linked gear are driven to drive the crushing cylinder to rotate

Size Separation: There are multiple filter plates inside the device, which have different sizes of filtration holes on these filter plates. The crushed materials will stay on different filter plates according to their size, thereby achieving size separation. The larger particles will be left on the upper filter plate, while the smaller particles can fall into the lower layer filter plate or a diversion plate through the filter hole

Vibration Assistance: In order to better help the material slide and collect, the equipment is also equipped with a vibration motor. When the material falls on the filter board and the diversion board, the vibration generated by the vibration motor helps the material decline, making the collection process smoother

Category Collection: Because different sizes of materials are separated in different positions, operators can sort and collect them more conveniently. This is very beneficial for subsequent processing steps (such as reinstation, storage or transportation).

3.Note:

Cloth special powder cutting machine is TONY's patented product, the specific parameters of the product quotation and other details please contact us.

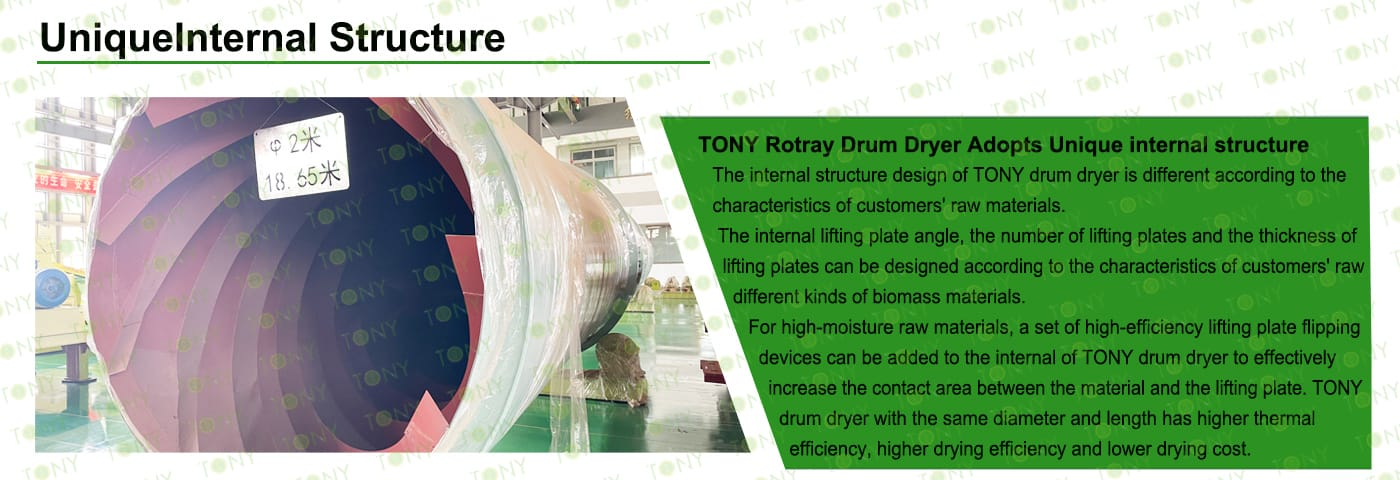

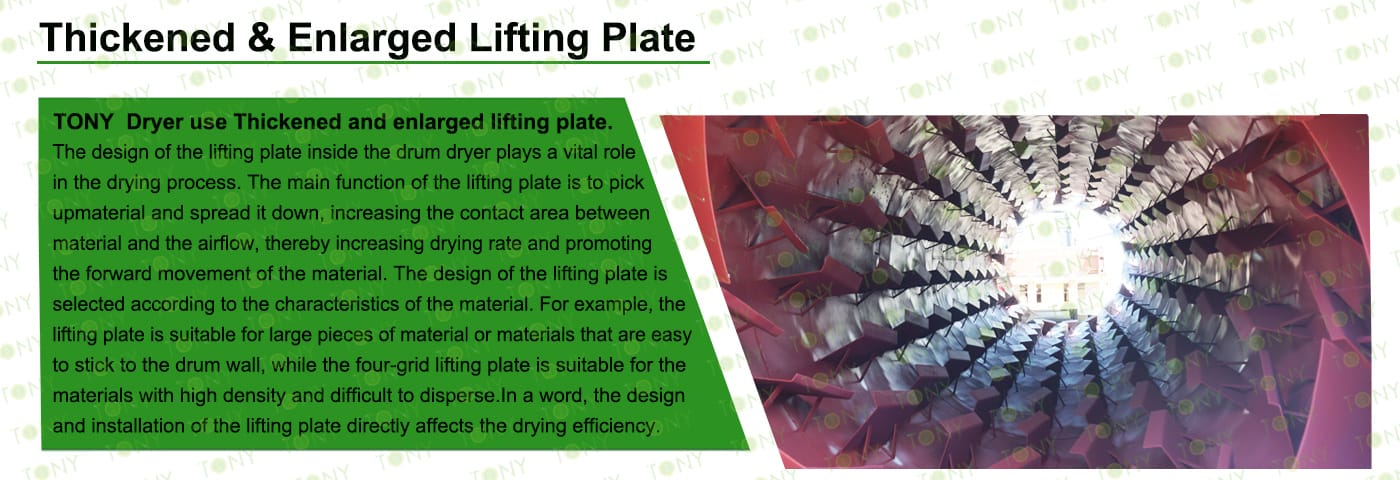

3. Scrap Cloth Smaller Pieces Drying Process

|

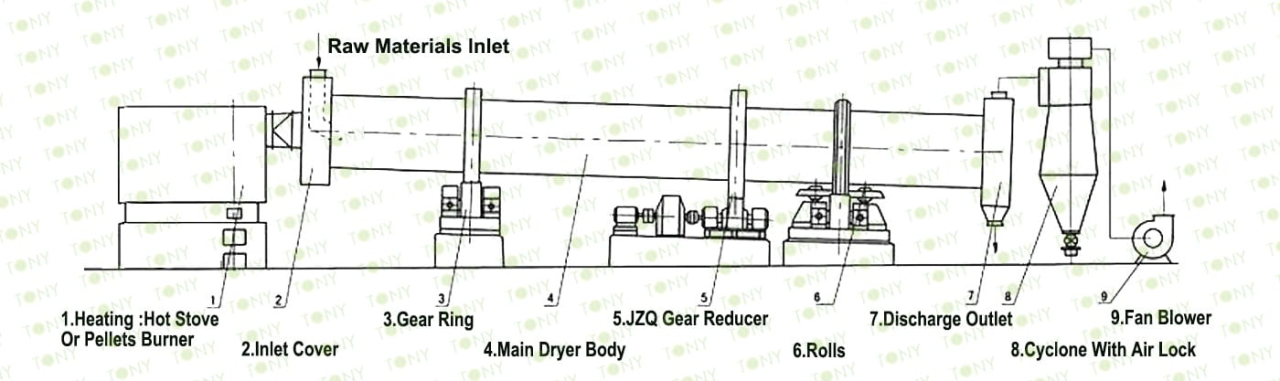

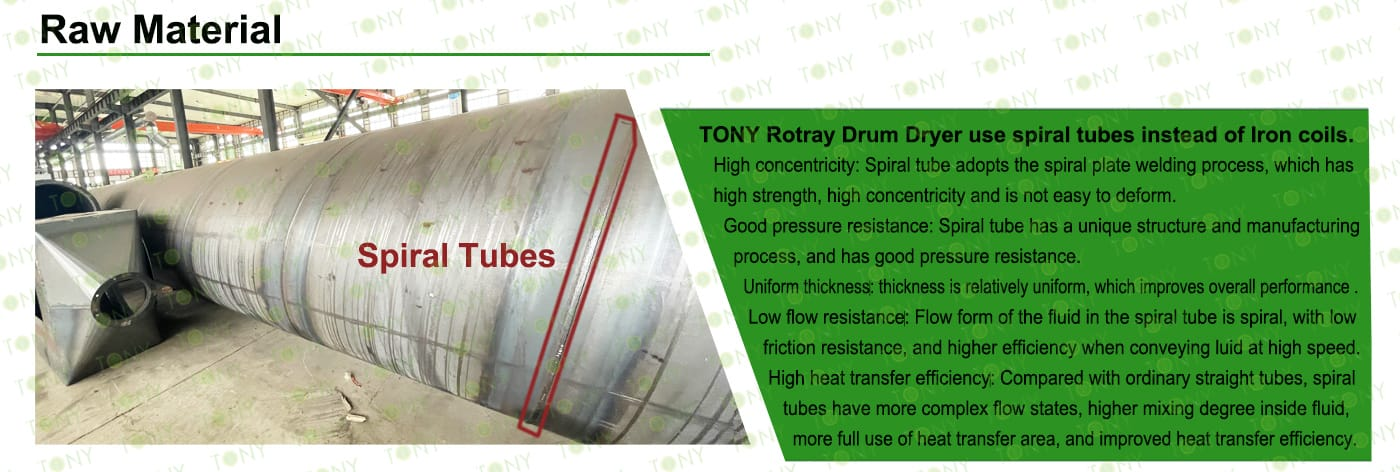

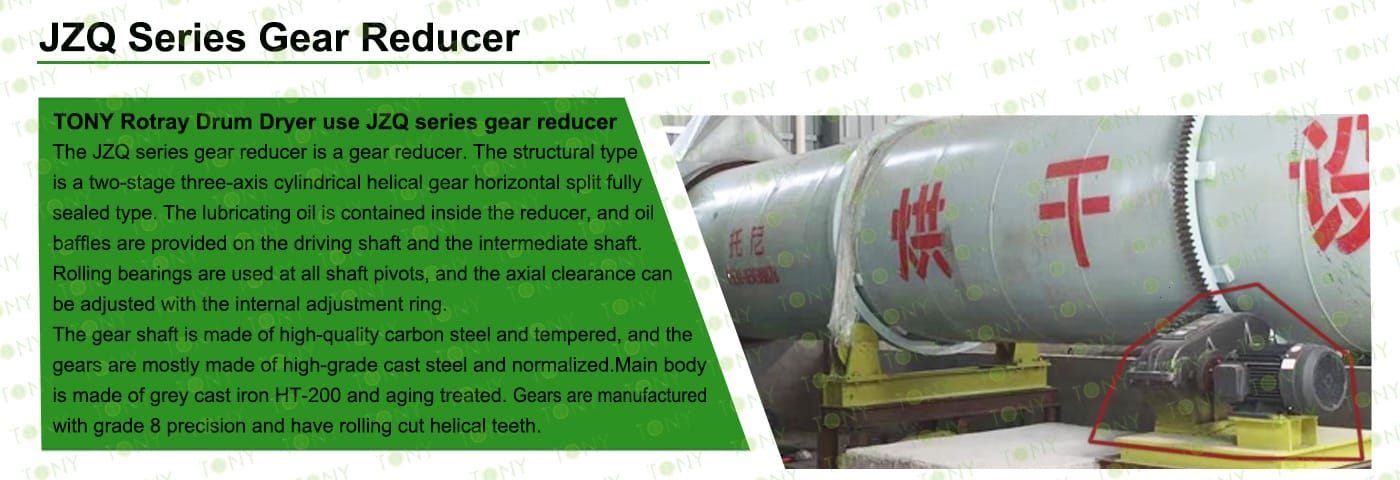

1.This process is mainly to dry the wet waste clothes fragments. 2. Whether the drying process is to be carried out depends on the humidity of the customer's raw materials. Because to suppress the biomass particles, the moisture requirements of the raw material are below 15%. If the humidity of the customer's raw material is large, it needs to be dried. If the humidity of the raw material itself is suitable, it can be dried without saving costs, which can save costs more costly. 3. The drying process requires a hot air furnace to provide a heat source for the dryer. TONY hot blast stove is made of firebrick pan, shell with h steel plal posted as the frame. There are 3 layers of fire blocking device inside, whit can effectively present fire from entering the tumble dryer. TONY Dryer uses spiral tube material, which has a higher heat transfer rate and is not easy to deform. |

|

|

|

|

|

|

According To Different Output And Needs, We Have Three Drum Dryers To Provide Choices

|

|

|

|

|

Single-Layer Rotary Drum Dryer |

Double-Layer Rotary Drum Dryer |

Three-Layer Rotary Drum Dryer |

|

1. Structure: Only one drying layer. 2. Applicable materials: Usually used for drying light materials, such as sawdust, wood chipping, bean residue, cow dung, coal slime, etc. 3. Advantages: Simple structure, low cost, easy operation and maintenance. 4. Disadvantages: The drying efficiency is relatively low, which is suitable for scenes with small scale or low drying efficiency requirements. |

1. Structure: There are two drying layers, usually two concentric cylinders of different diameters. 2. Applicable materials: Suitable for drying granular materials with a certain humidity and particle size range, such as river sand, wood chips, sawdust, etc. 3. Advantages: Compared with single-layer dryer, it has higher thermal efficiency, faster drying speed and smaller footprint. 4. Disadvantages: The structure is complex, the cost is high, and the operation and maintenance are relatively complex. |

1. Structure: There are three drying layers, usually three concentric cylinders of different diameters. 2. Suitable materials: Suitable for drying materials that require higher thermal efficiency and faster drying speed, such as slag, clay, pulverized coal, etc. 3. Advantages: The highest thermal efficiency, the fastest drying speed, can handle larger scale material drying. 4. Disadvantages: The most complex structure, the highest cost, the most complex operation and maintenance. |

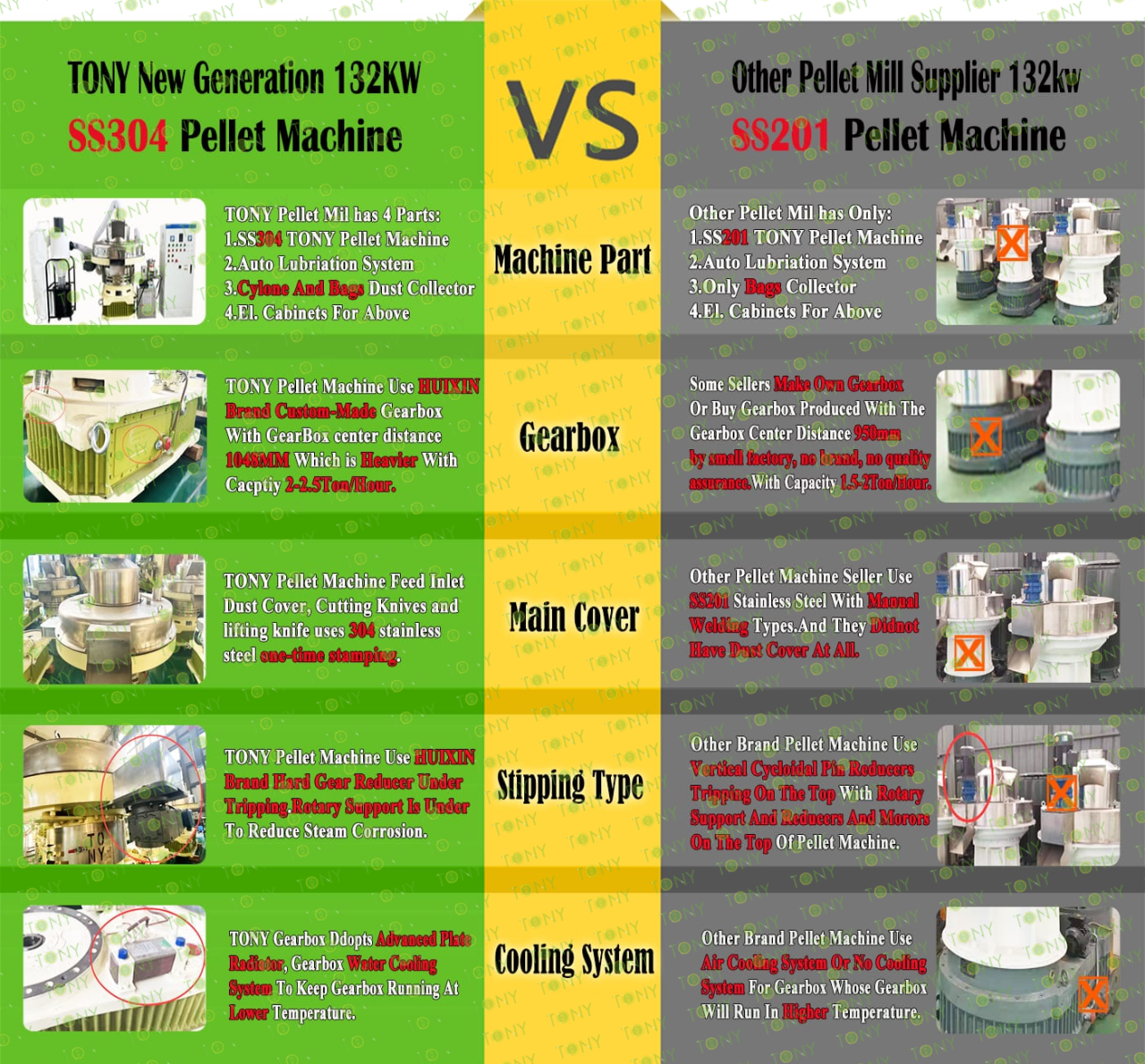

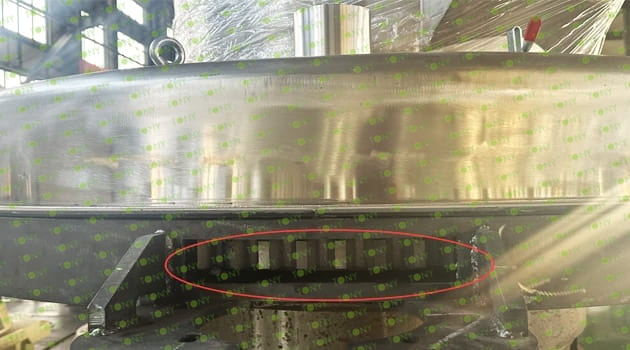

4. Scrap Cloth Pelleting Process

|

1. This process is mainly used to product pellets .It is the core process of the entire production line. 2. Biggest Capacity: The model of biomass pellet machine is different, the production capacity is different, the production capacity of a single pellet machine ranges from 0.8 tons/hour to 5 tons/hour, multiple pellet machines work together, the production capacity can reach up to 100 tons/hour. 3. Main Parts: (1) TONY's new Vertical Ring Die Pellet Machine. (2) Cyclone And Bags Dust Collectors. (3) Bearings Automatic Lubrication System. (4) Electrical Cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. 4. There are many models for TONY pellet machines, please contact TONY to get more products and quotations. |

|

|

|

|

|

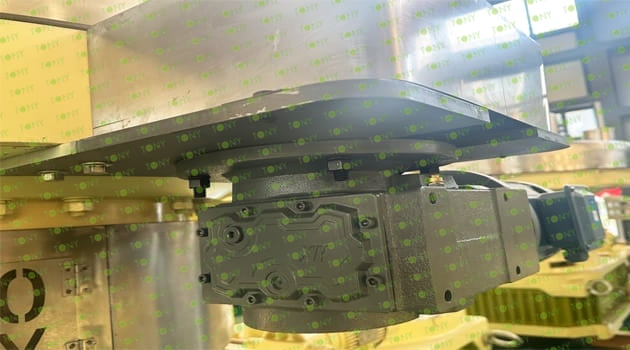

The gear box adopts Zhejiang HUIXIN brand TONY custom model to increase the heavy duty. The gear box is engraved with Zhejiang HUIXIN brand and TONY custom LOGO. Compared with the ordinary HUIXIN model, the internal gear is enlarged and thickened, and the gear shaft is strengthened and thickened, which is more durable and stable. |

The feed port, discharge shell, discharge port, dust collection cover, lifting knife and internal cutting knife of the pellet machine are made of 304 stainless steel to avoid steam corrosion and rust during the formation of particles and increase the durability of the equipment. |

The upper discharge shell is made of 304 stainless steel, which avoids the shortcomings of poor compression resistance and easy cracking caused by welding. Arc profile appearance, to avoid operator injury, and arc profile tensile strength is stronger, not easy to damage. |

The rotary support is installed under the discharge housing to avoid the traditional return support is easy to be corroded by steam at the top, the internal steel ball is easy to rust corrosion shor |

|

|

|

|

|

The gear reducer is installed under the discharge housing, the power is stronger, and the gear reducer is not easy to damage. And adopt the Zhejiang HUIXIN brand hard tooth surface reducer, which is a brand of gear box, the torque resistance is stronger, and the rotation power is more sufficient. |

304 stainless steel dust cover, steam resistance, corrosion resistance is stronger, and in this way ,it is hard to be damaged. |

The internal lifting knife is made of thickened stainless steel, which can effectively avoid high temperature and steam corrosion, increase the durability of the lifting knife, and the lifting effect is better, so that the raw materials inside the pellet machine are not easy to cover and pile. |

Adjustable internal particle cutter, can be adjusted according to customer needs to adjust the length of the cutter in order to adjust the length of the discharge particle, simple and convenient a |

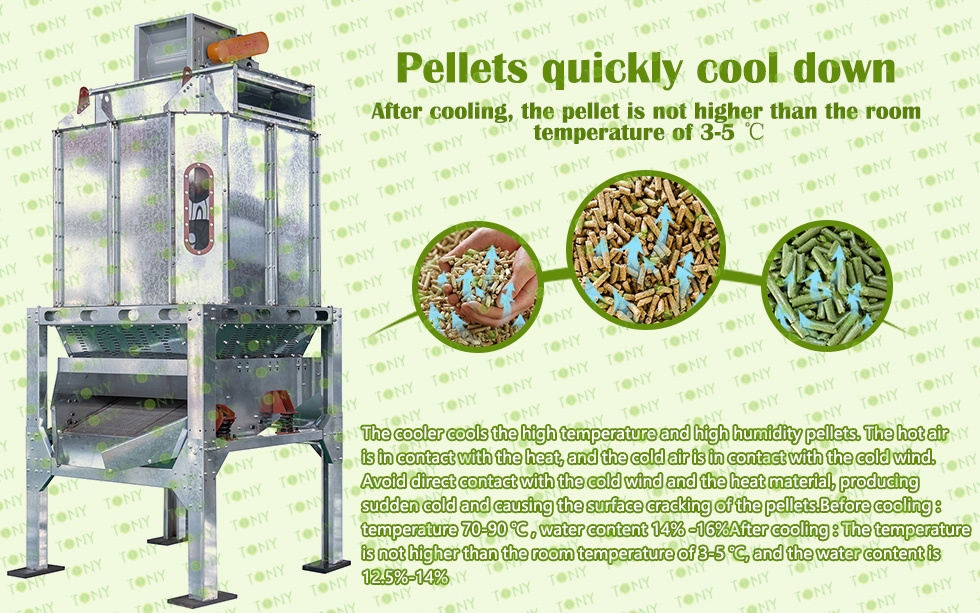

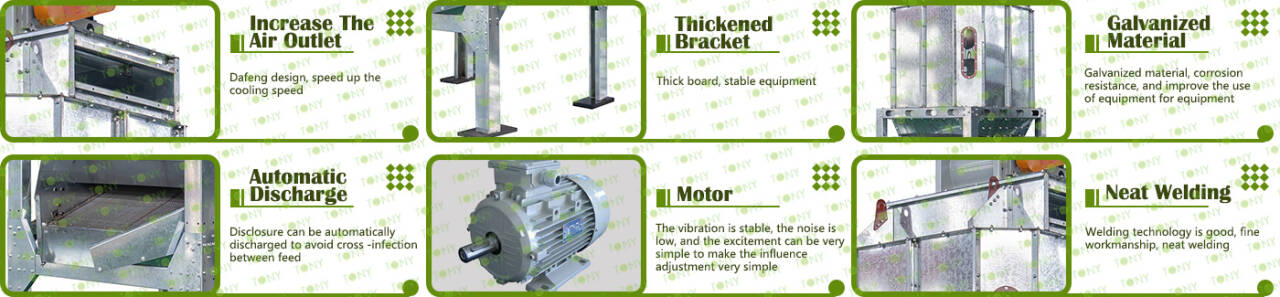

5. Scrap Cloth Pellet Cooling Process

|

1.This process is mainly used to cool pellets from 80-90℃ to 15-25℃ 2.Main Parts: (1) TONY's new Galvanized Cooler Seperator With Vibrating Screen. (2) Cyclone And Bags Dust Collectors. (3) Fan Blower. (4) Connect Pipes. TONY brand galvanised cooler seperator to cool the pellets from 80-90℃ to the normal temperature to 15-25℃, in this way,the pellets will have beautiful shape which will not easy to be broken during transporation. |

|

6. Scrap Cloth pellet Packing Process

|

1. This process is mainly to pocket the processed biomass pellets. Generally, the fuel fuel of the clothes is tons, which is the specification of one ton/package. 2. If you choose not packing, you can also load the car directly and transport. 3. Main Parts: (1) TONY's new Ton Packing Machine. (2) Bags Transportation Conveyors. (3) Feeding Inlet Silo. (4) Electrical Cabinets. |

|

7. Scrap Cloth Pellet Other Equipment

|

|

|

|

|

Angle Belt Conveyor |

Belt Conveyor |

Galvanized Hydraulic Silo |

Auger Silo |

|

|

|

|

| Bag Dust Collector |

Galvanized Pulsed Dust Collector |

Water Spray Dust Removal |

Wet Wlectrostatic Precipitator |

1.Physical Characteristics

Shape: Scrap cloth pellet Fuel is usually suppressed into a stick-shaped solid granules with a section size of 33-40mm and a length greater than 150mm

Density: The granular proportion of the particles after molding is large and the volume is small, which is convenient for storage and transportation

2. Burning Performance

Heat Value: Its heat value can reach 3200-4000 kcal, which has high combustion efficiency

Flammable: Scrap cloth pellet fuel is easy to ignite, suitable for fast starting heating process

Gray Score: less gray scores produced by combustion, reducing the complexity and cost of subsequent processing

3. Environmental Protection Benefits

Replacement Of Traditional Fuel: can replace traditional fuels such as wood, raw coal, gas, etc., and help reduce dependence on natural resources and environmental pressure

Reduce Waste: By converting waste clothes into fuel, environmental pollution caused by garbage landfill and incineration

4. Economic Benefits

Low Cost: Compared to traditional fuels, the cost of Scrap cloth pellet fuel is relatively low, and it has a certain economic advantage

Source Stable: waste textiles, waste clothing, waste leather corners and other raw materials such as stable sources, and low pre -processing difficulty, which is conducive to large -scale production and application

In summary, Scrap cloth pellet fuel not only has good physical characteristics and combustion performance, but also has significant environmental protection and economic benefits. It is a new type of renewable energy worthy of promoting.

2025 Tony Machinery - All Rights Reserved. Map