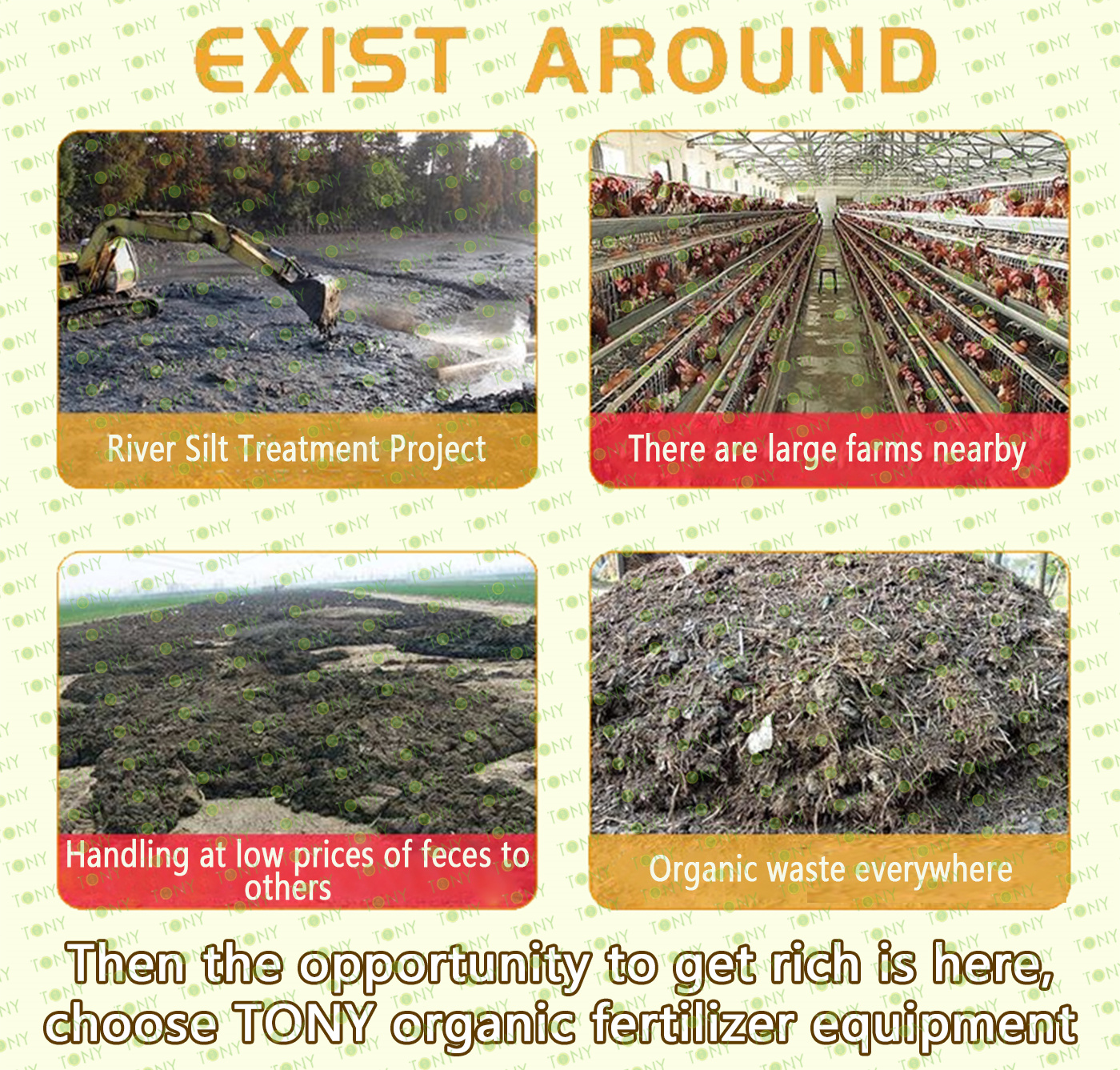

1. The Definition And Type Of Organic Fertilizer

Organic fertilizers are mainly derived from plants and (or) animals, and fertilizers made of fermentation, including various animal feces, plant residues or metabolites. In a broad sense, organic fertilizer also includes compost, fertilizer, fertilizer, biogas fertilizer, green fertilizer, crop straw, pure natural mineral fertilizer, mud fertilizer and cake fertilizer, etc.

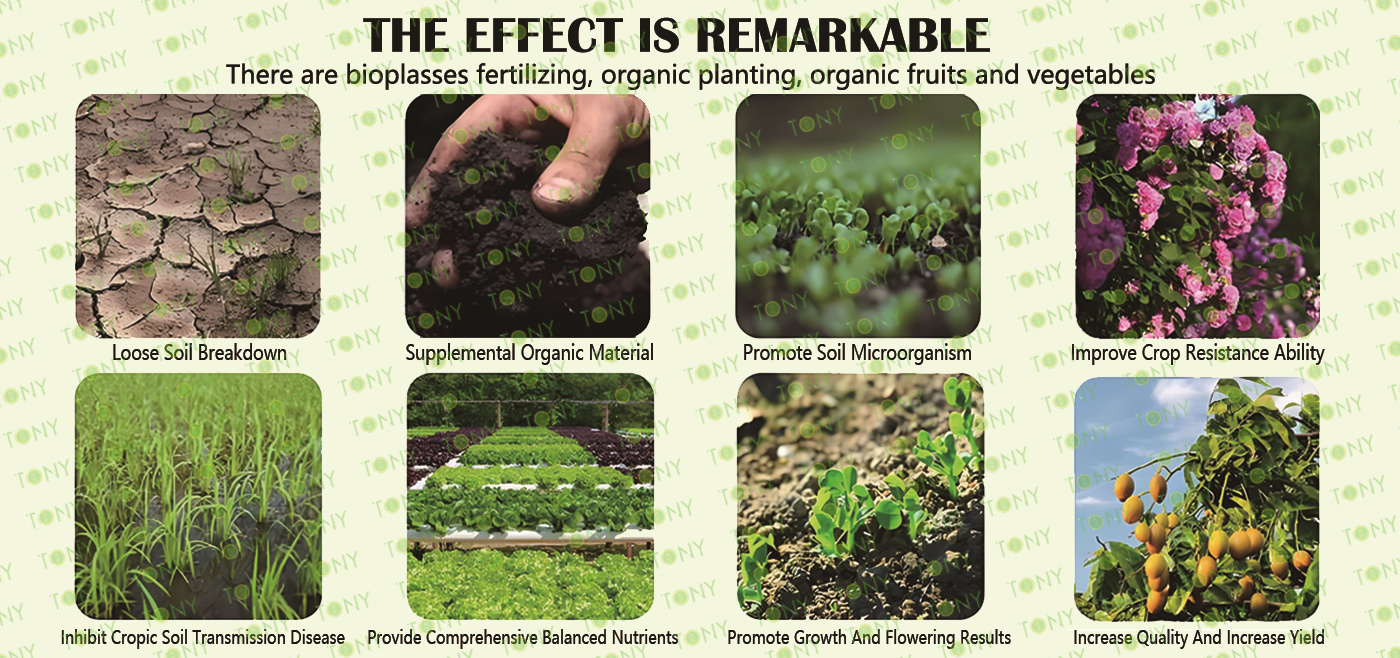

2. The Contribution Of Organic Fertilizer To Soil Health

Improve the soil structure: Increase the organic matter content of the soil, improve the level of soil fertility, and increase the ability to keep the soil water and fertilizer.

Promote crop growth: Organic fertilizers contain a variety of nutrients and organic matter, which can promote the growth of crop root system and absorb nutrients.

Reduce environmental pollution: Compared with chemical fertilizers, organic fertilizer has less pollution to the environment, which is conducive to the sustainable development of agriculture.

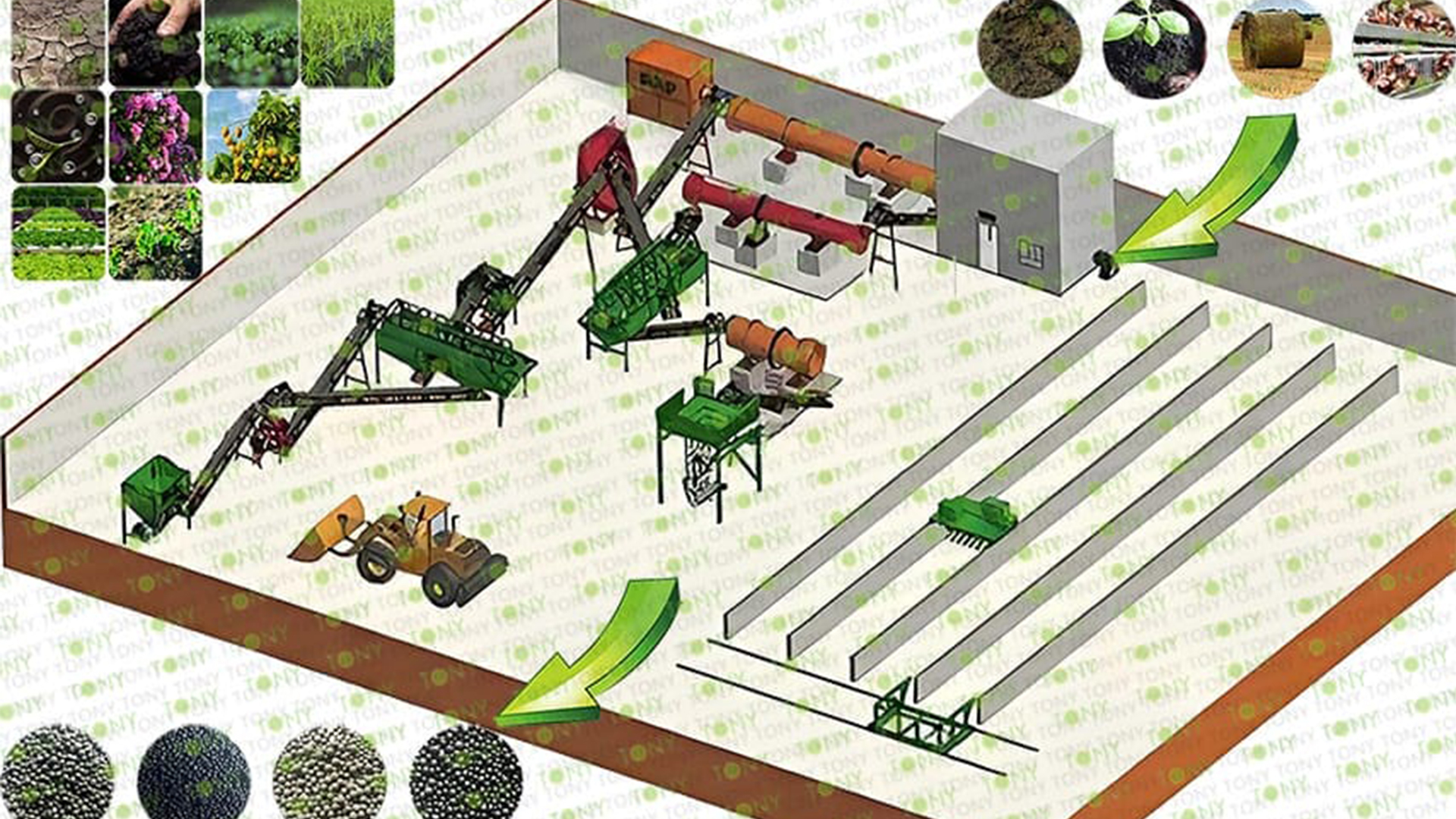

3. The Processing Process Of Organic Fertilizer

The processing raw materials of the product's organic fertilizer are safe. During the production process, high -temperature sterilization and insecticidal killing and weed seed treatment are performed. It is completely fermented by microorganisms to ensure stable nature and safety.

4. Application Of Organic Fertilizer In Agriculture

Organic fertilizer is widely used in agriculture, especially in the cultivation of crops such as fruits and vegetables, which can significantly improve the output and quality of crops. For example, a large amount of biological organic fertilizer is applied each year, which can make the soil organic matter content reaches 5.8%, thereby producing a full red flavor apple

In summary, processing and use of organic fertilizer can not only improve soil health, but also promote the sustainable development of agriculture. It is an environmentally friendly and efficient agricultural production method.

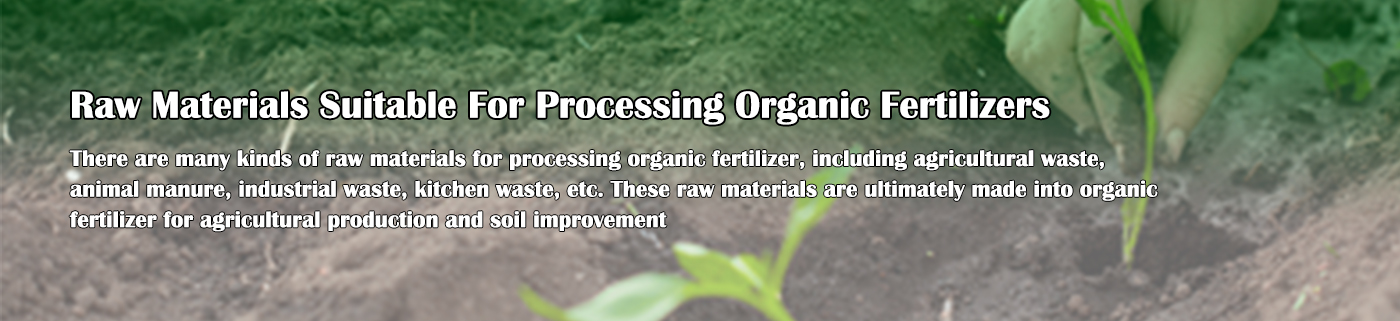

|

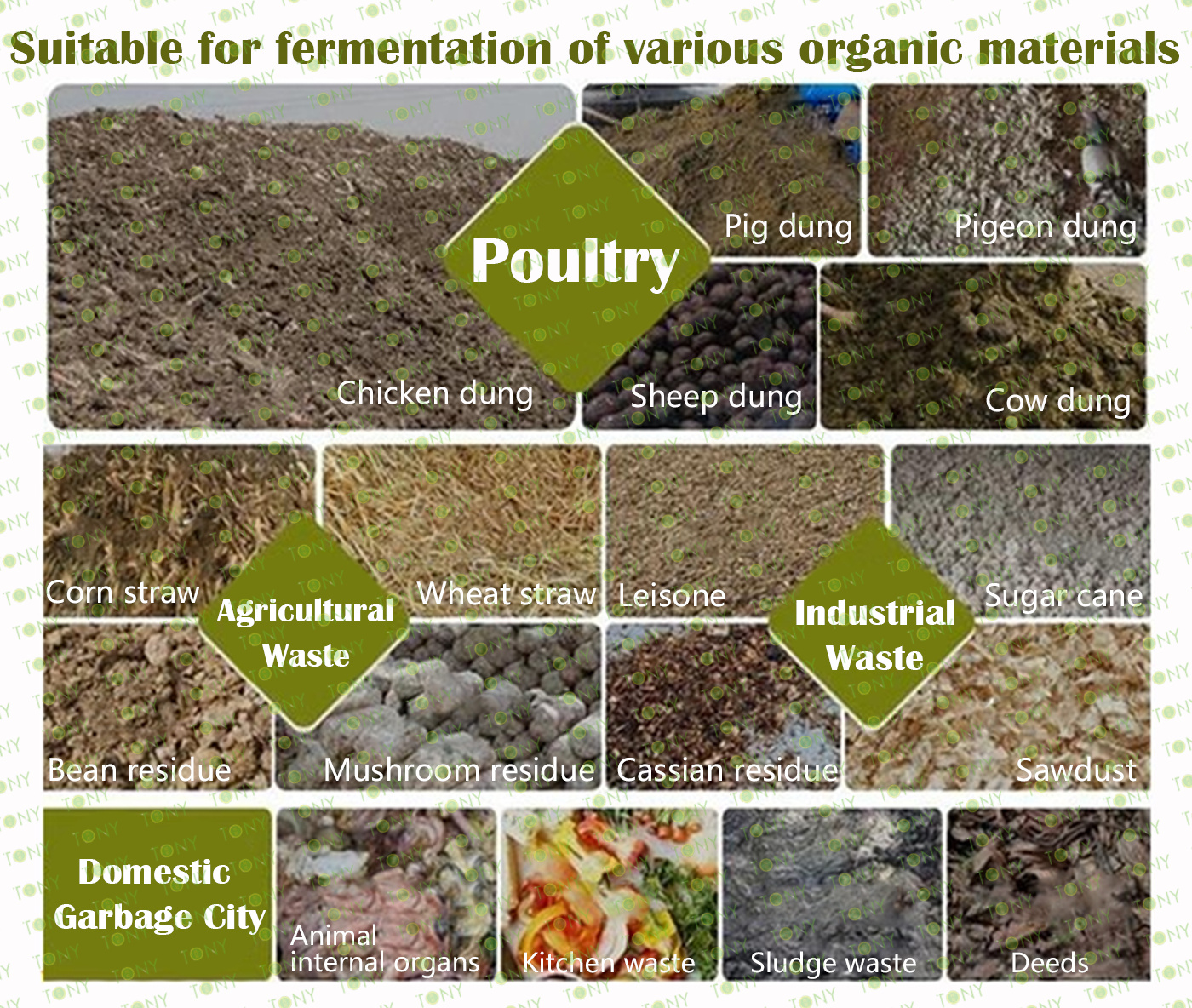

Organic Fertilizer Production Raw Material |

|

|

Livestock manure |

chicken manure, pig manure, cow dung, sheep manure, horse dung, rabbit manure, quail manure, pigeon dung and other animal feces |

|

Stalk |

corn straw, corn core, straw, wheat straw, bean straw, sweet potato straw, valley pole, etc. |

|

Shell bran |

rice shells, rice shell powder, peanut shell powder, peanut seedlings, valley bran, bacteria bran, wood chips |

|

Industrial waste |

grains, soy sauce, vinegar, branfaming residue, wood sugar residue, cedar residue, garlic residue, sugar lucida, waste cotton residue, medicinal residue, etc. |

|

Cake Fertilizer |

bean cake, soybean meal, oil dead, rapeseed cakes, peanut cakes, sesame cakes, etc. |

|

Municipal sludge |

Lives sludge, sugar factory filtering mud, papermaking sludge, etc. |

|

Other categories |

animal corpses, domestic garbage, bone powder, leather, etc. |

|

Add raw materials |

Plant growth regulators, efficient agents, antidents, color agents, optical agents |

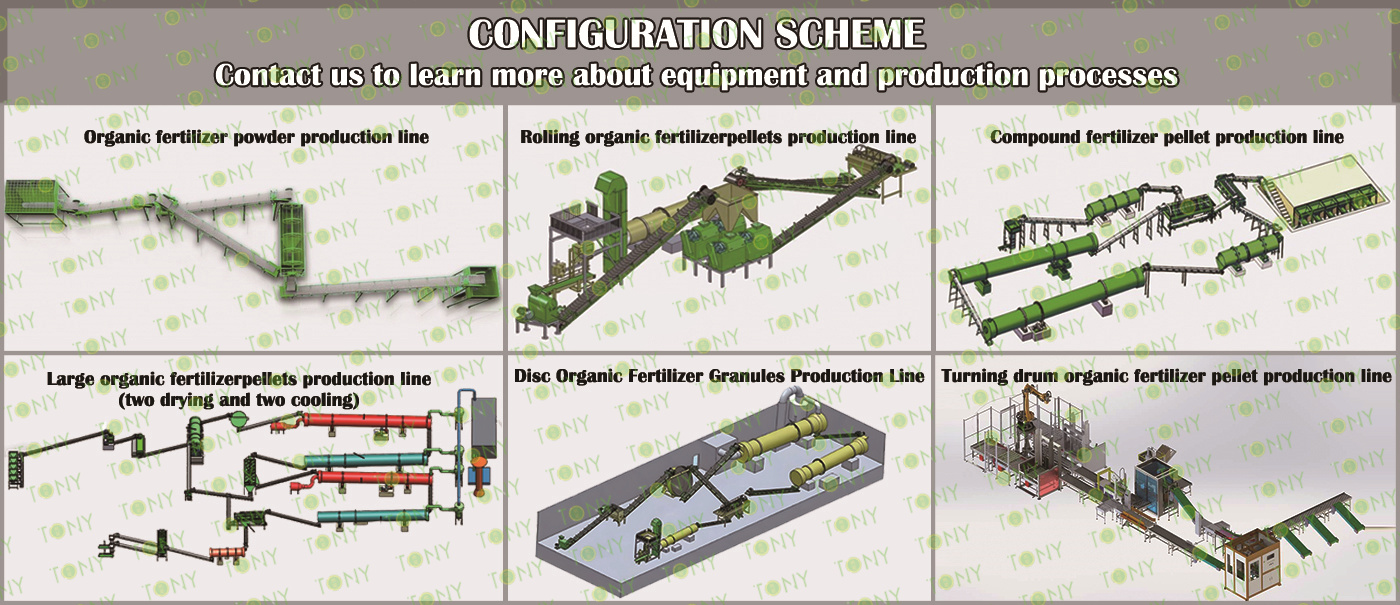

We can provide more reasonable solutions according to customer needs to achieve better configuration, which not only meets the needs, but also saves unnecessary expenses.

|

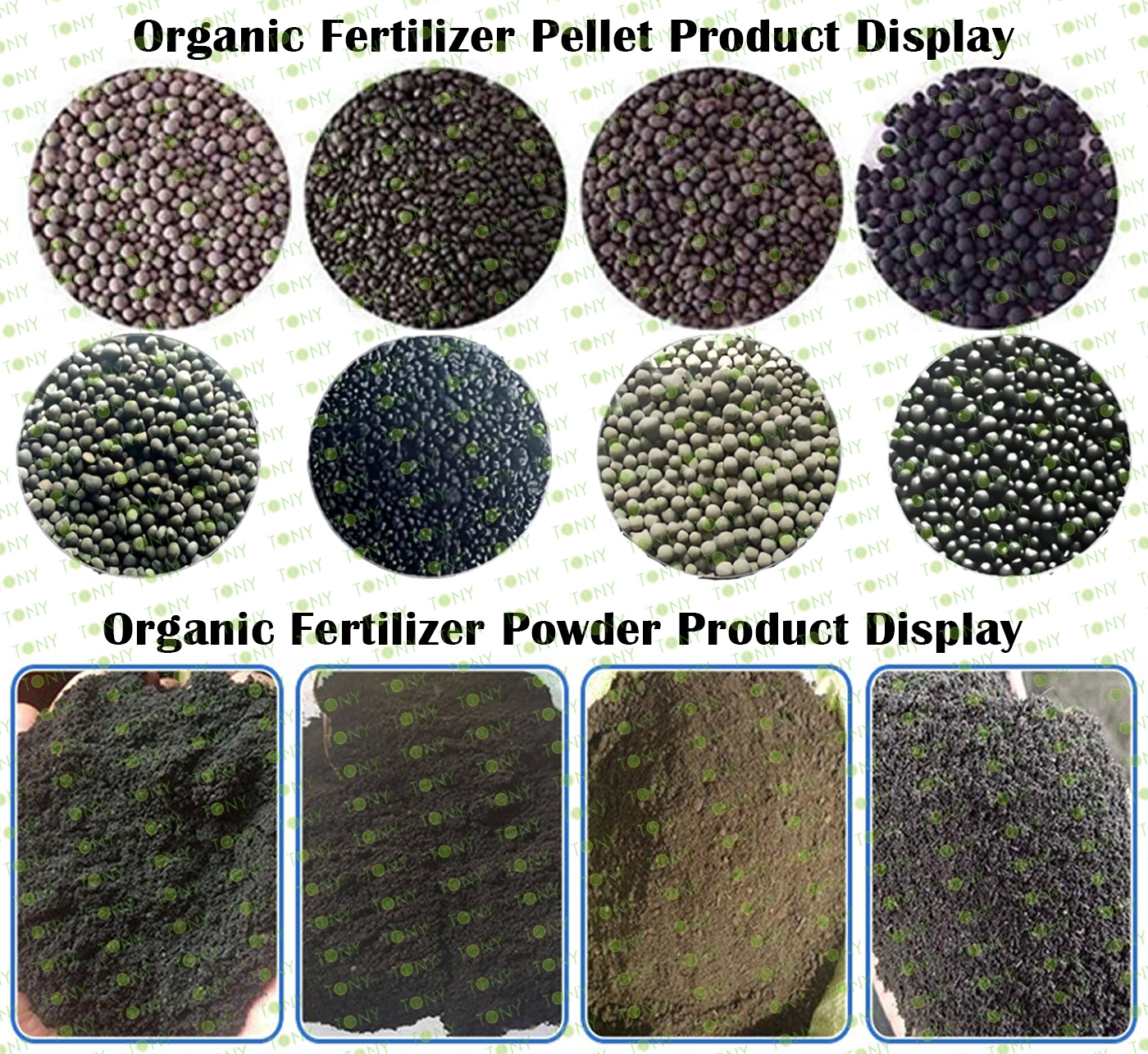

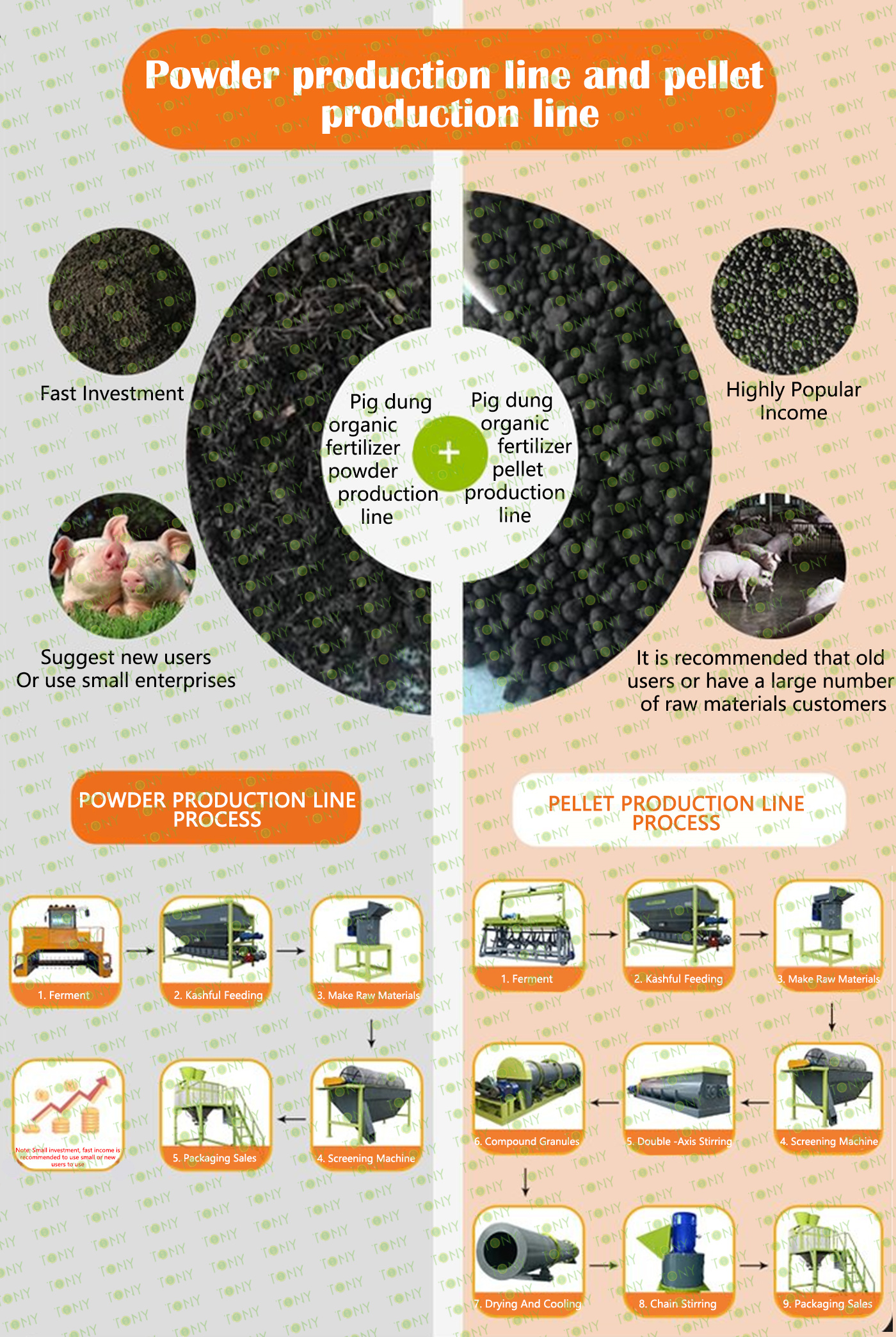

Characteristic |

Organic Fertilizer Powder |

Organic Fertilizer Pellet |

|

Particle size |

The particles are small, usually powder -shaped |

The granularity is relatively large and the shape is regular |

|

Method of applying |

Suitable for evenly sprinkle or spray application, usually use manual application |

It is more suitable for mechanical application, such as fertilizers, sowing machines, etc. |

|

Application |

Suitable for small -scale application, mixing with soil before sowing, or used as base fertilizer |

Suitable for large -scale application, mechanical fertilization, and long -term fertilization, etc. |

|

Nutrition release speed |

Nutrition of nutrient release is fast and can quickly provide nutrients required for plants |

The speed of nutrient release is relatively slow. It needs to be gradually decomposed and transformed in the soil to provide plants |

|

Storage and transportation |

It is relatively sensitive in the storage and transportation process, and it is easy to spread, humid or lump |

It has good liquidity and packaging stability, and it is easier to store and transport |

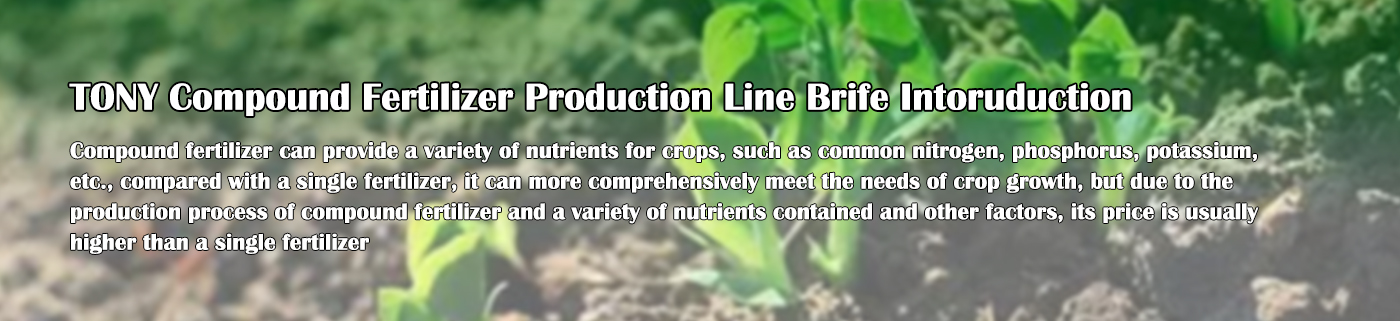

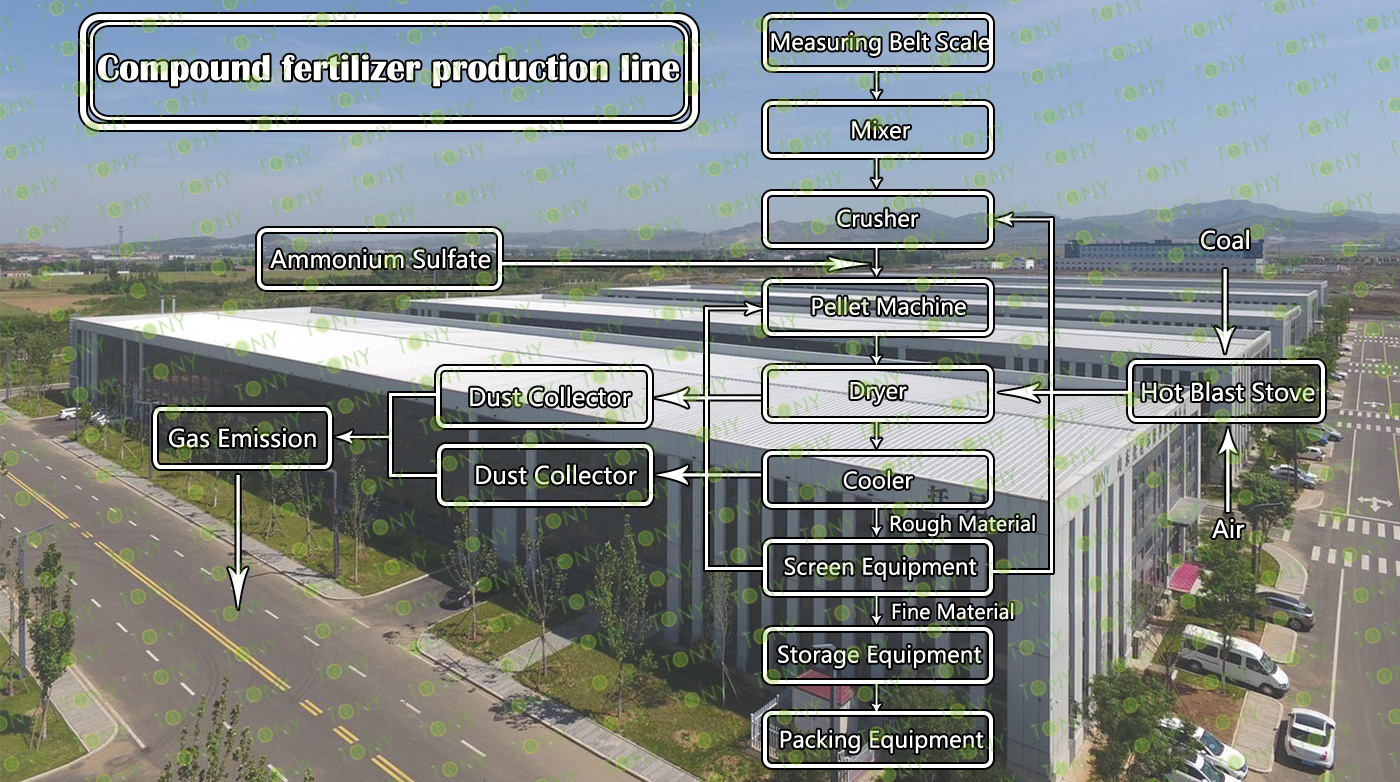

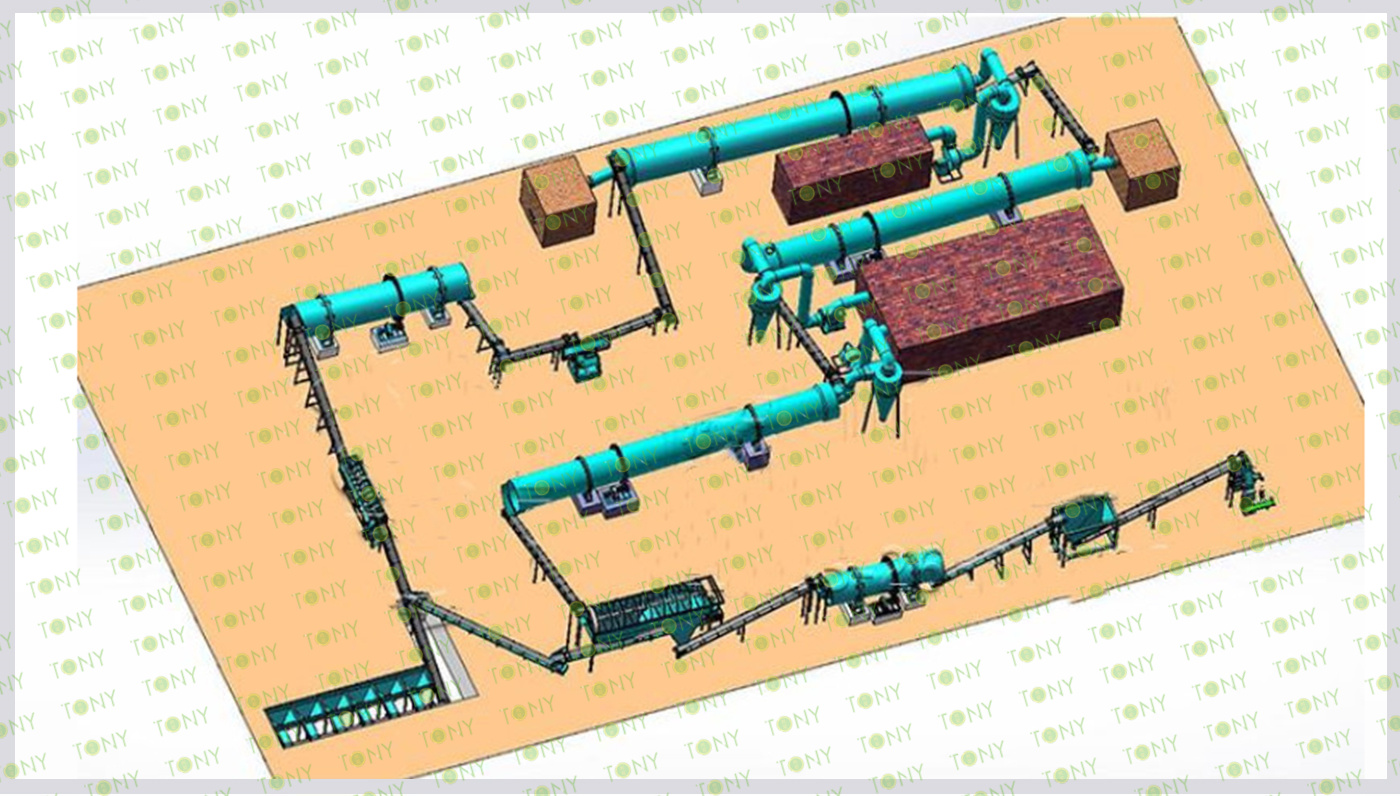

1. Compound Fertilizer Production Process

2. How To Produce Compound Fertilizer?

The compound fertilizer production process mainly includes the following 8 processes:

Ingredients → mixing → crushing blocks → pelleting → pellet drying → pellet cooling → pellet grading → finished quantitative packaging

(1) Ingredients Of Raw Materials: One can choose urea, beryllium nitrate, cymbals, cymbals of sulfur, beryllium phosphate (beryllium phosphate, beryllium phosphate, heavy calcium, calcium), potassium gasification (potassium sulfate) and other raw materials technical ratio equipment (mainly according to the local market demand and local soil test results to decide)

(2)Mixing: Stir the prepared raw materials evenly to improve the uniform fertilizer efficiency content of the fertilizer pellets as a whole, and use a horizontal mixer or a tray mixer to mix and stir:

(3)Caking And Crushing: The mixed and mixed raw materials such as bulk caking are crushed, which is convenient for subsequent granulation processing, mainly using shredders:

(4) Material Granulation: The material after mixing and crushing is sent to the granulation machine through the belt conveyor for granulation (the drum granulation machine can be used, and the roll extrusion granulation machine A, disk granulation machine, etc.), this step is essential and the most important link in the production process of compound fertilizer;

(5) Pellet Drying: Send the pellets made by the granulator into the dryer to dry the moisture in the pellets, increase the strength of the pellets, and facilitate preservation 1.

(6)Pellet Cooling: The temperature of the dried pellets is too high, easy to caking, and easy to bag and store and transport after cooling.

(7) Pellet Grading: The cooled pellets are graded, the unqualified pellets are crushed and re-granulated, and the qualified products are screened out.

(8)Quantitative Packaging Of Finished Pellets: The finished pellets are sent to the silo through the belt conveyor for temporary storage, and then connected to the electronic quantitative packaging scale, sewing machine and other automatic quantitative packaging bags.

Store in a ventilated place to achieve full automation.

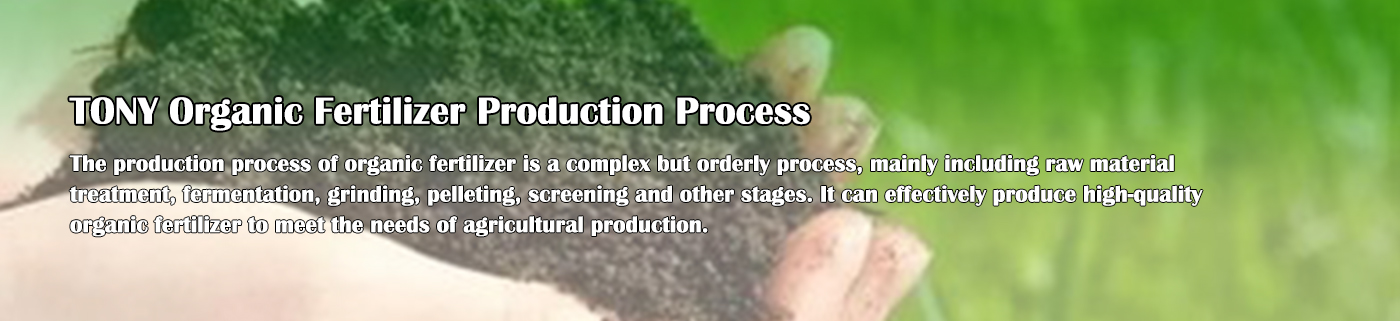

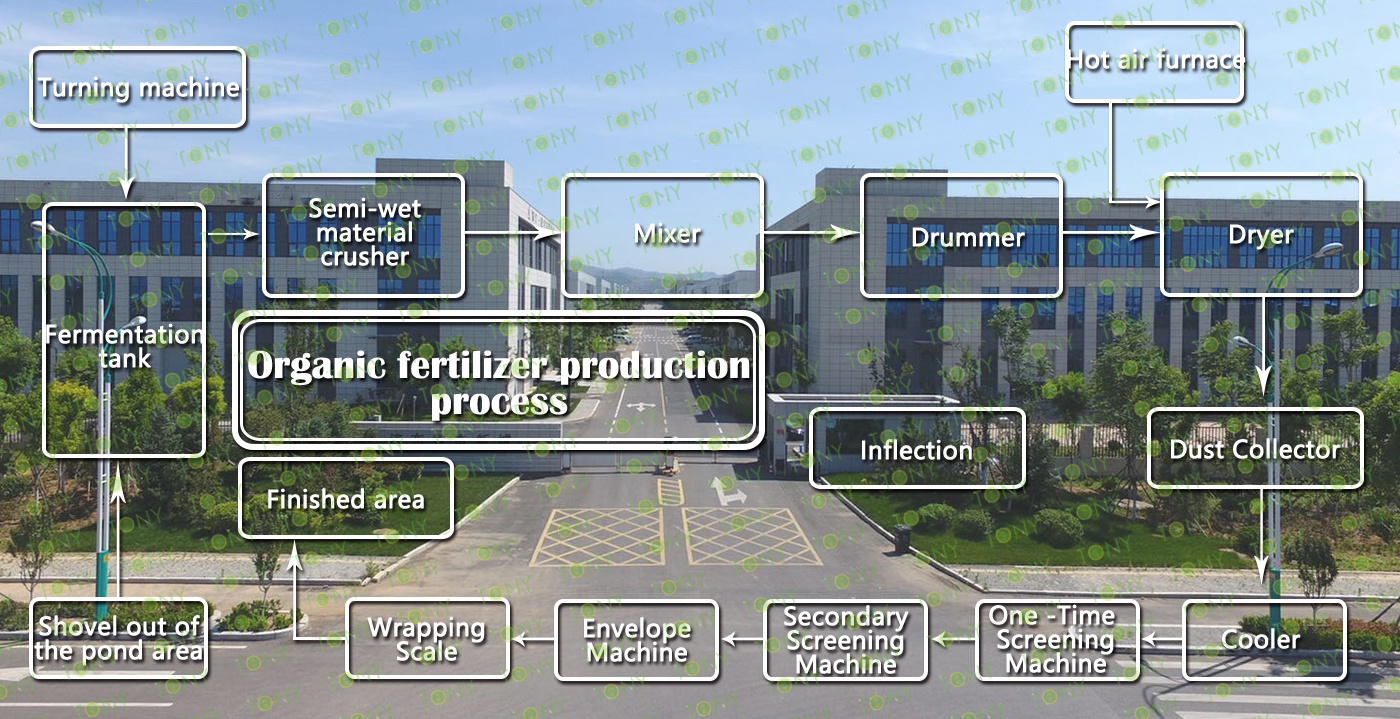

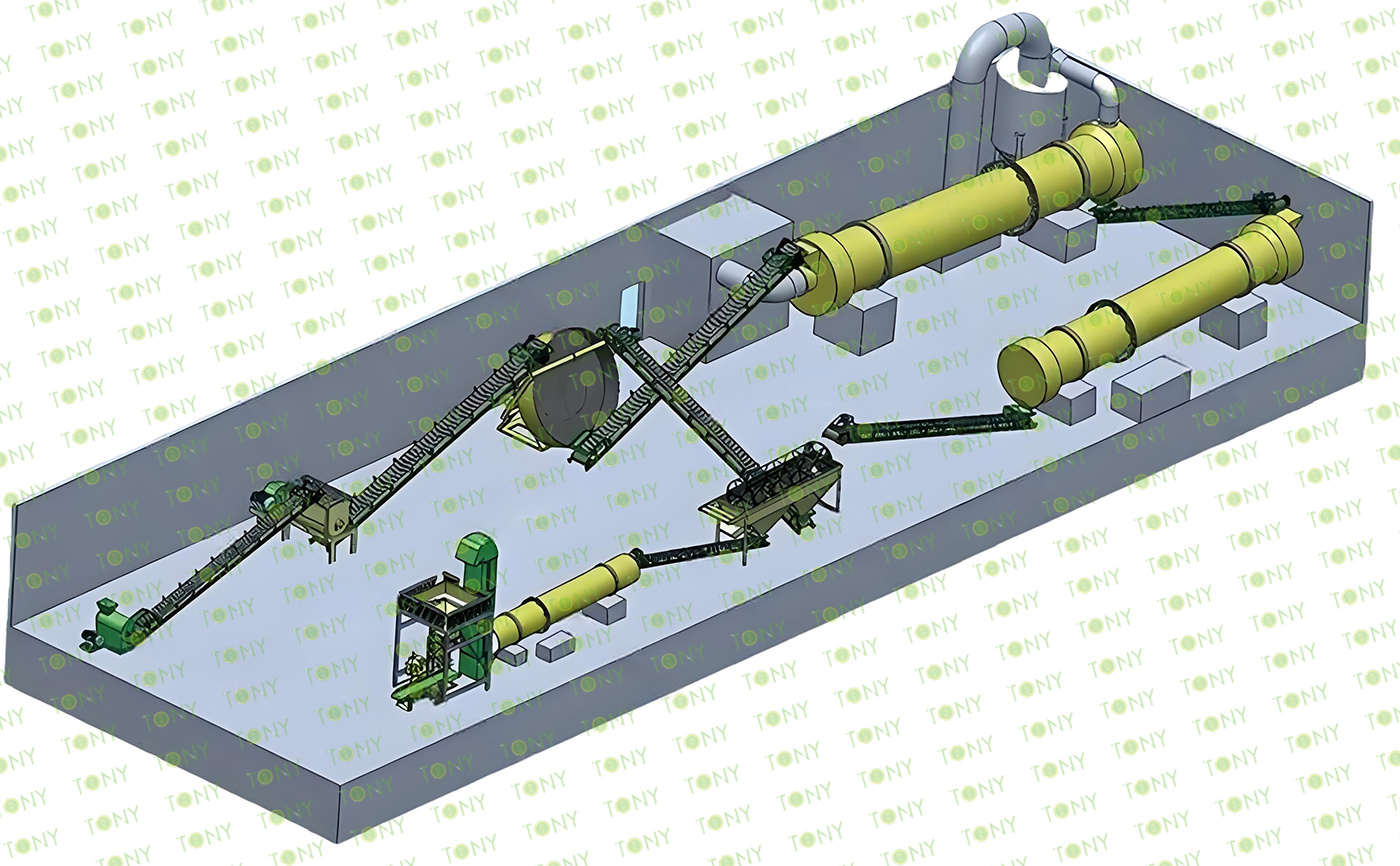

3. Organic Fertilizer Pellet Production Process

4. How To Produce Organic Fertilizer Pellet?

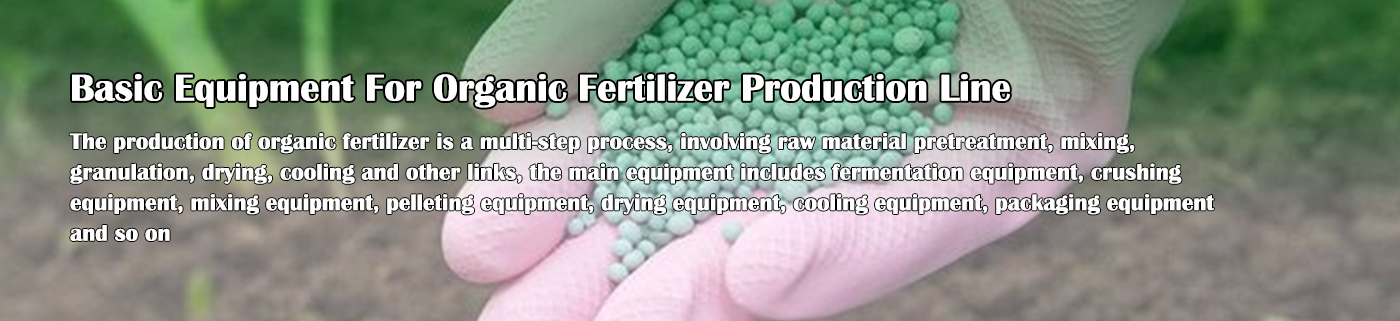

The production process of organic fertilizer pellets involves several steps:

1. Raw material preparation → 2. Fermentation → 3. Material grinding → 4. Mixing → 5. Molding granulation → 6. Drying and cooling → 7. Screening and material return → 8. Coating treatment → 9. Packaging storage, from the collection of raw materials to the packaging of the final product, every link is crucial. The following is the detailed production process:

(1)Raw Material Preparation

Raw material collection: collect animal dung such as cow dung, chicken dung, pig dung, and other organic waste, such as crop straw, industrial waste, etc.

Raw material pretreatment: Initial treatment of the collected raw materials, such as dehydration, crushing, etc., to ensure the uniformity of raw materials and appropriate moisture content.

(2)Fermentation And Rot

Mixing: Mix the raw material with the fermentation inoculant to ensure that the inoculant is evenly distributed in the raw material.

Compost fermentation: The mixed raw materials are piled into fermentation piles for aerobic fermentation. The fermentation process needs to be turned over regularly to ensure uniform fermentation and temperature control. The fermentation temperature should be controlled at 50-65°C, and the fermentation cycle is usually about 8 days

Moisture control: The moisture content of raw materials should be kept between 60% and 65% during the fermentation process, and water should be added if necessary.

(3)Pulverize Materials

Initial crushing: The organic raw materials after fermentation are initially crushed to reduce particle size and improve the efficiency of subsequent processing.

Secondary crushing: If necessary, secondary crushing is performed to ensure that the material reaches the required fineness.

(4)Mix And Stir

Add trace elements: According to the formula, add an appropriate amount of trace elements such as N, P, K and other excipients, such as humic acid, clay, etc.

Mix well: Use a stand mixer or other mixing equipment to ensure all ingredients are evenly mixed.

(5)Molding And Pelletizing

Pelletizing: The use of disk pelletizing machine, organic fertilizer gear granulator or a new type of gear rotating strand three combination granulator, the mixed material into particles.

Particle size control: To ensure that the size of the particles is uniform and meets the standard requirements.

(6)Dry And Cool

Drying: The granulated particles are sent to the dryer to remove excess water, so that the moisture content of organic fertilizer meets the standard requirements.

Cooling: The dried particles are sent to the cooling machine to reduce the temperature and facilitate storage and transportation.

(7)Screening And Refeeding

Screening: The particles after drying and cooling are screened to separate the particles that meet the standard and the unqualified particles.

Return treatment: The unqualified particles are re-crushed and returned to the granulation system for re-granulation.

(8)Coating Treatment

Coating: The coating machine is used to wrap the qualified particles to increase the stability and shelf life of the particles

Coating material: You can choose powder or liquid coating process.

(9)Packing And Warehousing

Packaging: The coated particles are sent to the packaging equipment for quantitative weighing and packaging.

Warehousing: The packaged organic fertilizer particles are stored in the warehouse, waiting for sale.

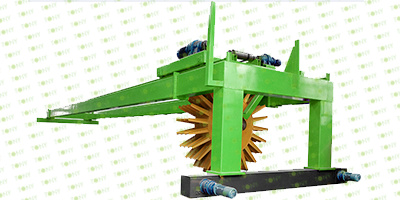

| Fermentation Turning Equipment | |||

|

|

|

|

| Trough Turner | Circle Fermentation Tank | Polish Turninger | Impeller Pile Machine |

|

|

|

|

| Walking Rolller | Vertical Fermentation Tank | Chain Board Turning Machine | Crawler Rollover |

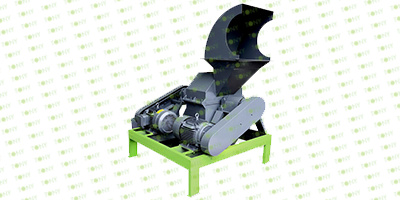

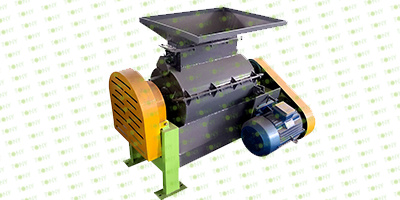

| Fine Crushing Equipment | ||

|

|

|

| Vertical Crusher | Cage Crusher | Urea Crusher |

|

|

|

| Semitrigoral Material Pieces | Chain Crusher | Straw Crusher |

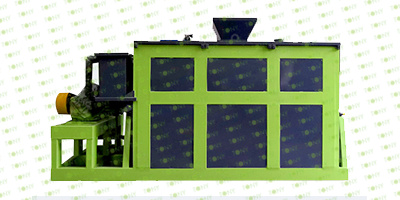

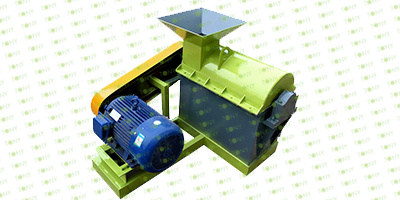

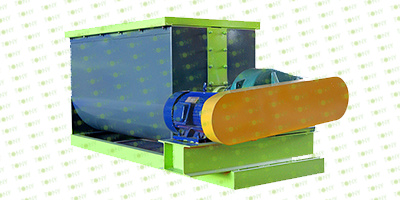

| Mixing Equipment | ||

|

|

|

| BB Fertilizer Mixer | Double Shaft Mixer | Horizontal Mixer |

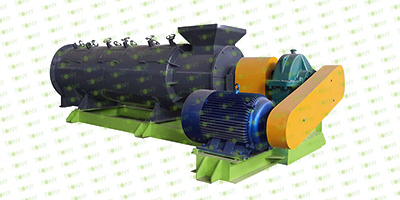

| Pelleting Equipment | |||

|

|

|

|

| Extrusion granulator | Agitated Tooth Granulator | Disc Pelleting Machine | Rotary Drum Granulator |

| Other Supporting Equipment | |||

|

|

|

|

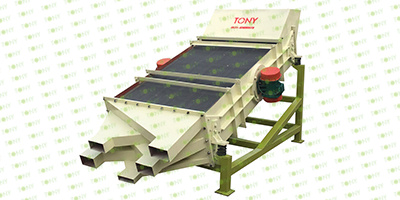

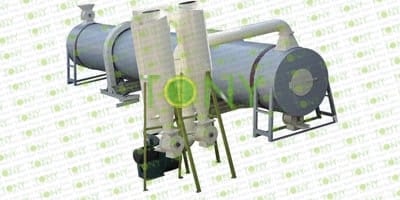

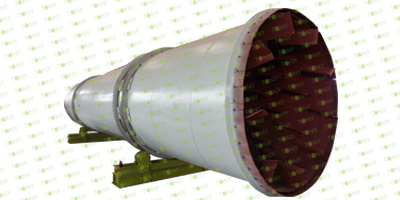

| Screen Equipment | Rotary Drum Dryer | Rotary Drum Cooler | Conveyor Electronic Belt Scale |

|

|

|

|

| Klitter Feeder | Packing Machine | Ton Packing Machine | Palletizer |

2025 Tony Machinery - All Rights Reserved. Map