Crop straw mainly includes the following types:

Corn Straw: The stems and leaves remaining after corn is harvested.

Sorghum Straw: The stems and leaves remaining after sorghum is harvested.

Wheat Straw: The stems and leaves remaining after wheat is harvested.

Rice Straw: The stems and leaves remaining after rice is harvested.

Sugarcane Bagasse: The stems and leaves remaining after sugarcane is harvested.

Flax Straw: The stems and leaves remaining after flax is harvested.

The main reasons for using crop straw to make pellets include the following aspects:

1.Economic Benefits: Making pellet fuel from crop straw can replace non-renewable energy sources such as coal and oil, and has significant economic benefits. Biomass pellet fuel made through processes such as crushing, steam mixing, extrusion, and drying has a low cost and can save a lot of energy consumption during the production process.

2.Environmental Benefits: The ash produced by burning biomass pellet fuel is a good natural fertilizer, helping to reduce the use of chemical fertilizers and protect the soil. In addition, the sulfur content of biomass pellet fuel is much lower than that of coal, and it emits less sulfur dioxide when burned, helping to reduce air pollution.

3.Social Benefits: The promotion and use of biomass pellet fuel can reduce dependence on fossil fuels, promote the diversification of the energy structure, and help achieve sustainable development of energy. At the same time, the use of straw pellet fuel machines can also solve the problem of returning straw to the field and reduce the pressure of agricultural waste disposal.

4.Wide Range Of Uses: Straw pellets can not only be used as biomass fuel, but also as livestock feed. High-density straw pellets are easy to store and transport, and are easy to digest and absorb by livestock. In addition, straw pellets can also be used to burn to generate electricity, and the gases emitted during combustion will not cause pollution to the environment.

The application fields of crop straw pellets are very wide, mainly including the following aspects:

1.Biomass Energy: Straw pellets can be used as fuel for biomass boilers, with high combustion efficiency and low pollution emissions, and are an ideal choice to replace traditional fossil energy such as coal and oil. Globally, more and more countries and regions have begun to promote the use of straw pellets as clean energy to reduce greenhouse gas emissions and achieve carbon neutrality goals.

2.Agriculture: Straw pellets can be used as soil conditioners, rich in organic matter and trace elements, which can improve soil structure, increase soil fertility, and promote crop growth. This utilization method not only realizes the resource utilization of agricultural waste, but also helps to improve the quality and yield of agricultural products.

3.Industrial Raw Materials: Straw pellets can be used as raw materials for the production of paper, furniture, building materials, etc. Due to its high fiber content and high strength, it can produce various environmentally friendly and durable industrial products after deep processing by scientific and technological means, which meets market demand while promoting the development of the circular economy.

4.Environmentally Friendly Materials: Straw pellets can be made into degradable tableware, packaging materials, etc., replacing traditional plastic products, reducing plastic pollution, reducing dependence on oil resources, and contributing to the sustainable development of the earth.

5.Livestock Feed: High-density straw pellets are easy to store and transport, and are also easier for livestock to digest and absorb. Using it as a biomass fuel can replace some fossil fuels and reduce pollution to the environment.

6.Biomass Power Generation: Straw pellets can be used as raw materials for biomass power generation, providing a sustainable energy supply for the power industry. In addition, straw pellets can also be used to produce building materials such as cement and lime, as well as as fuel for ships.

In summary, crop straw pellets are widely used in many fields such as energy, agriculture, industry, environmental protection, feed and building materials, with significant economic and environmental benefits.

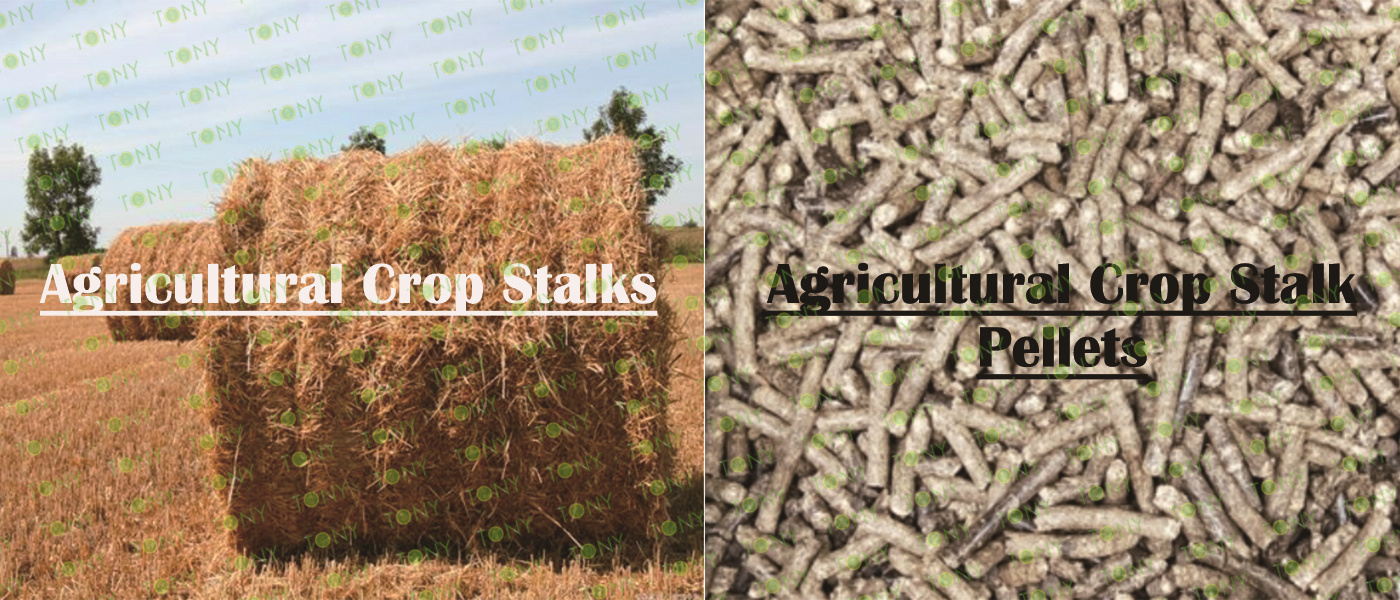

Characteristics of Crop Stalk pellet fuel: The pellets after molding have a high specific gravity, small volume, and are resistant to combustion, making them easy to store and transport. The volume after molding is 1/30~40 of the raw material volume, and the specific gravity is 10~15 times that of the raw material (density: 0.8-1.4). The calorific value can reach 3400~6000 kcal, and it is a solid fuel with high volatile phenol.

|

|

|

| Rotary Cutter | Hammer Mill | Drying Machine |

|

|

|

| Pelleting Machine | Cooling Machine | Packing Machine |

|

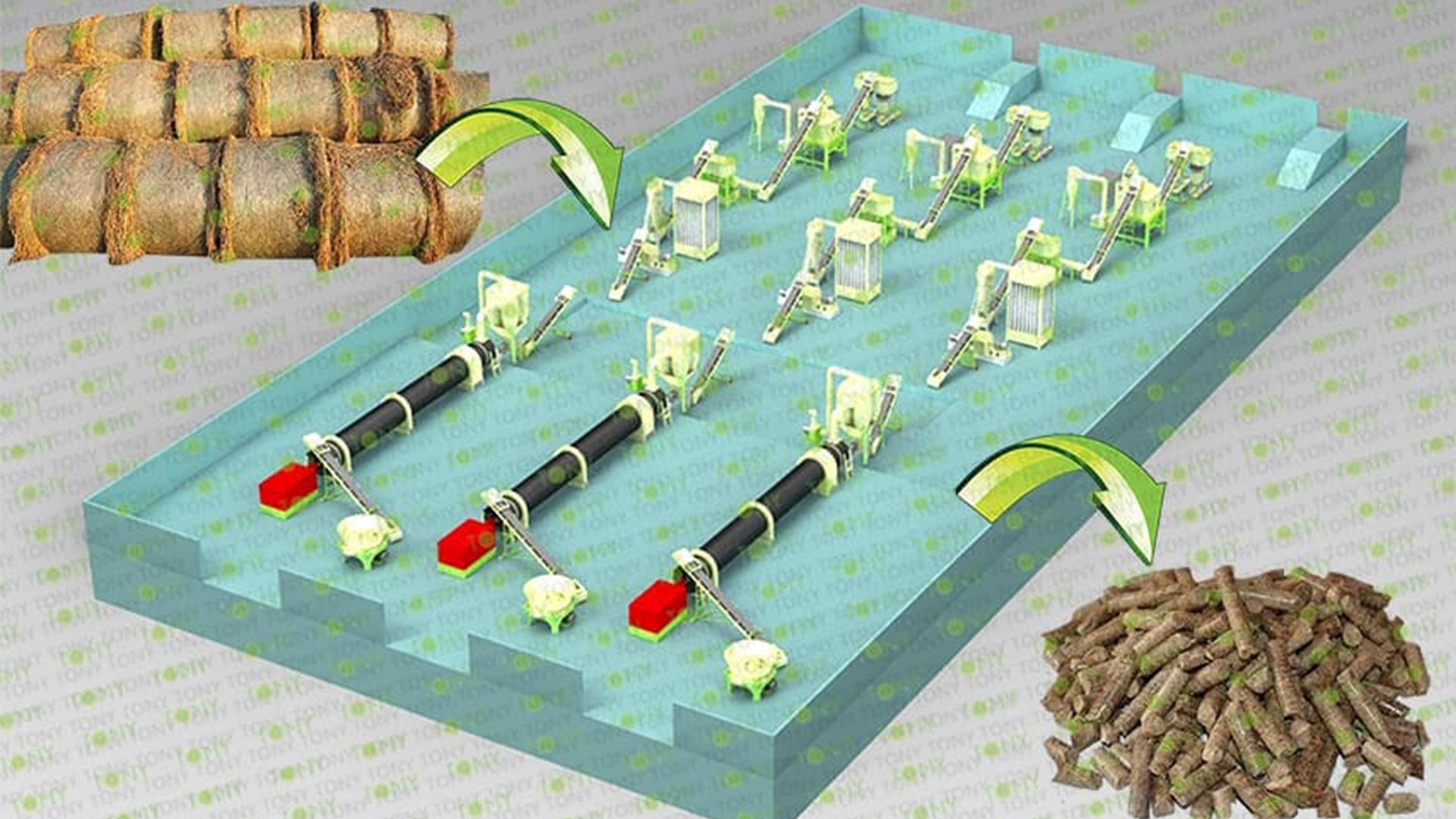

1.Chipping Process: A.This process is mainly used to grind the Agricultural Crop Stalks into Agricultural Crop Stalks Chips with size 25-35mm. The finish Agricultural Crop Stalks Chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the comprehensive chipper. Main Parts: (1) . TONY's new Rotary Cutter. (2) . Feed and unload belt frequency control to prevent card material. (3) . Hydraulic system control for more thickness of raw materials. (4) . Electronic control system allows the equipment to be used normally. (5) . Contact TONY for more details with quotation. |

The Details Of Rotary Cutter

|

|

|

|

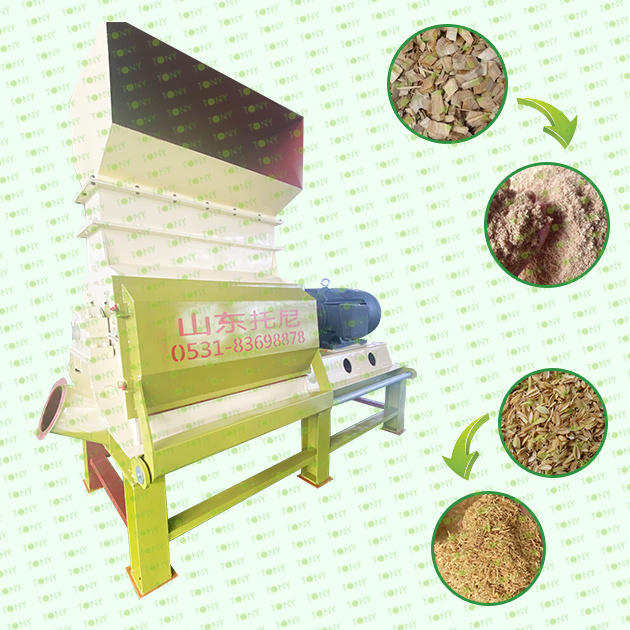

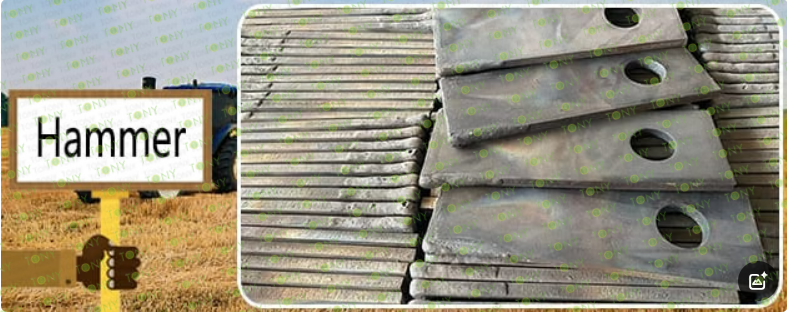

2. Chips Fine Crushing Process: A. This process is mainly used to crush 30-40mm agricultural crop stalks chips into 8-14mm sawdust. B. Capacity: According to the customer's demand. Main Parts: (1) . TONY High Effective Hammer ,Mil. (2) . Galvanized Dust Collector. (3) . Sawdust Transportation Fan Blower. (4) . Cyclone With Airlock. (5) . Electrical Cabinets. |

|

The Details Of Rotary Cutter

|

|

|

|

3. Sawdust Drying Process: A. This process is mainly used to dry the sawdust from moisture 45% To15%. B. Capacity:According to customer's demand. TONY dryer use spiral tube material, which has higher heart rate and is not easy to deform. Unlike other manufacturers with iron plate splicing welding, very easy to deformation. Main Parts: (1). TONY's Rotary Drum Dryer Main Body.(Reducers With Motors and Pips.) (2). TONY's Crop Stalk Hot Stove. (3). Fan Blower+Cyclone With Airlock. |

The Details Of Drum Dryer

|

|

|

|

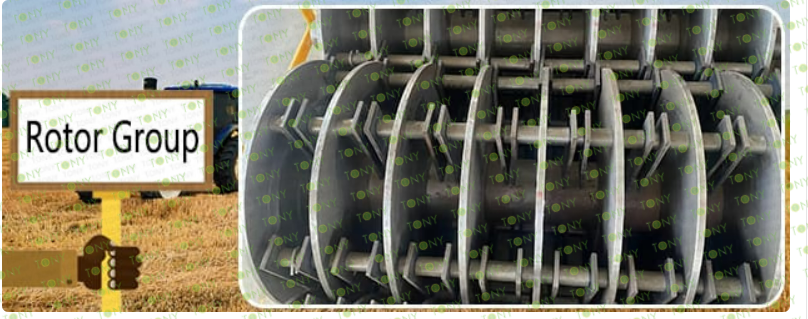

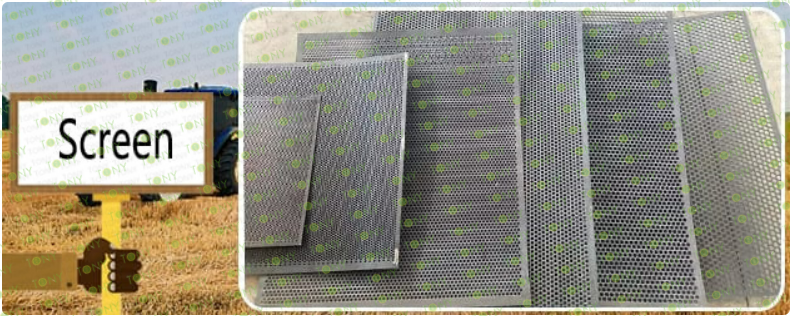

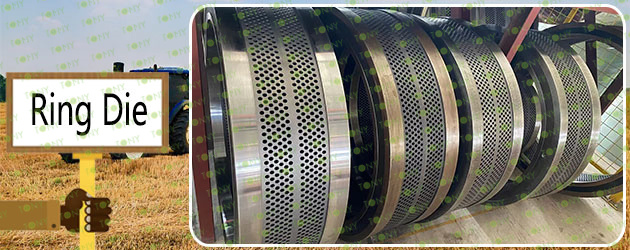

4.Pelleting Process: A. This process is mainly used to product pellets with φ6-8mm. B. Capacity:According to customer's demand. Main Parts: (1). TONY's New Vertical Ring Die Pellet Machine. (2). Cyclone And Bags Dust Collectors. (3). Bearings Automatic Lubrication System. (4). Electrical Cabinets. (5). You can choose TONY new type SS304 pellet machine or old type MS pellet. |

|

The Details Of Pellet Machine

|

|

|

|

|

5.Cooling Process: This process is mainly used to cool pellets from 80-90℃ to 20-30℃ Main Parts: (1). TONY's new Galvanized Cooler Seperator With Vibrating Screen. (2). Cyclone And Bags Dust Collectors. (3). Fan Blower. (4). Connect Pipes. |

|

6.Packing Process: This process is mainly used to pack pellets to 15-50Kg/Bags. Main Parts: (1). TONY's newTONY Semi-Automatic Packing Machine. (2). Sew Machine,Buyer Can Also Chose Hot Seal Machine For Chosen. (3). Bags Transportation Conveyors. (4). Feeding Inlet Silo . (5). Electrical Cabinets. |

|

|

|

|

| Belt Conveyor | Cyclone And Dust Collector | Air Lock |

|

|

|

| Electrical Cabinets | Automatic Lubrication System | Motor |

Price Description

Due to different production line configurations, different outputs require different models of machines. For specific prices, please call us for consultation or visit our factory.

+86-13964138888(Tel or WhatsApp)

The development prospects of crop straw pellets are very broad, mainly reflected in the following aspects:

First, the demand for crop straw pellets is increasing in the fields of feed, biomass energy and biomass chemicals. With the rapid development of animal husbandry, the demand for corn straw feed is also increasing. At the same time, corn straw pellets, as a renewable energy source, have broad market prospects.

Secondly, the comprehensive utilization technology of crop straw particles continues to innovate, and the market demand shows a growing trend. The Agricultural and Forestry Waste Branch of the China Renewable Resources Recycling Association is promoting the resource utilization of agricultural and forestry waste such as straw, livestock and poultry manure, integrating the primary, secondary and tertiary agricultural industries and the EOD model to promote dual carbon agriculture, green agriculture, modern agricultural industrial parks, etc. develop. This kind of policy support and technological innovation provide a good external environment for the development of crop straw pellets.

Finally, the production and application of crop straw pellets has significant environmental benefits. Crop straw is rich in nitrogen, phosphorus, potassium, calcium, magnesium and organic matter, and is a valuable biomass energy resource. Through comprehensive utilization, the agricultural production environment can be improved and the green and organic development of agriculture can be achieved. For example, returning straw to fields as fertilizer can increase soil organic matter, improve soil structure, and promote crop growth.

In summary, the development prospects of crop straw pellets are very broad, with increasing market demand, continuous innovation in comprehensive utilization technology, and significant environmental benefits, which will make new and greater contributions to the green development of agriculture and rural revitalization.

Main disadvantages of burning agricultural crop stalks include the following aspects:

Air Pollution: Burning agricultural crop stalks will produce a large amount of harmful gases such as smoke, nitrogen oxides, and carbon dioxide. These gases will not only pollute the air, but also reduce air quality and aggravate global climate change.

Harm To Human Health: The harmful gases and dust produced by burning will affect human health, especially the respiratory system, and may induce or aggravate respiratory diseases such as asthma and pneumonia. Long-term inhalation of these harmful gases may cause symptoms such as coughing, chest tightness, and tears, and may cause bronchitis in severe cases.

Affect Traffic Safety: The smoke formed by burning straw will reduce visibility, affect the normal operation of civil aviation, railways, and highways, and easily cause traffic accidents, affecting personal safety.

Cause Fire: Burning straw can easily ignite surrounding flammable materials, especially in dry seasons. Once out of control, it may cause serious damage to surrounding forests, houses, and farmland.

Destroy Soil Structure: Straw burning will cause the beneficial microorganisms in the soil to be burned to death, humus and organic matter to be mineralized, destroy the balance of the soil's biological system, change the physical properties of the soil, and affect the growth and yield of crops. Destroy the ecological environment: Straw burning will destroy the ecological balance, affect the habitat of wild animals, and reduce biodiversity. In order to reduce the harm of agricultural crop stalks burning, the following measures can be taken: Return straw to the field: Return straw directly to the field to increase soil organic matter and improve soil structure. Biomass energy utilization: Use straw for biomass power generation or production of biofuels. Feed utilization: Use straw as feed for animal husbandry. Base material utilization: Use straw as a base material for edible fungus cultivation. Compost utilization: Compost straw for agricultural production. Through these measures, the harm of agricultural crop stalks burning can be effectively reduced, and resource recycling and environmental protection can be achieved.

TONY can provide different kinds of complete pellet production line. The whole pellet production line suitable for press the different kind of Crop Stalk log,Crop Stalkchips,Crop Stalk , Crop Stalk scrap, Crop Stalk shaving and other biomass materials suchas rice husk, corn cob, straw, palm fiber and other agriculture into goodquality biomass fuel pellets.

2025 Tony Machinery - All Rights Reserved. Map