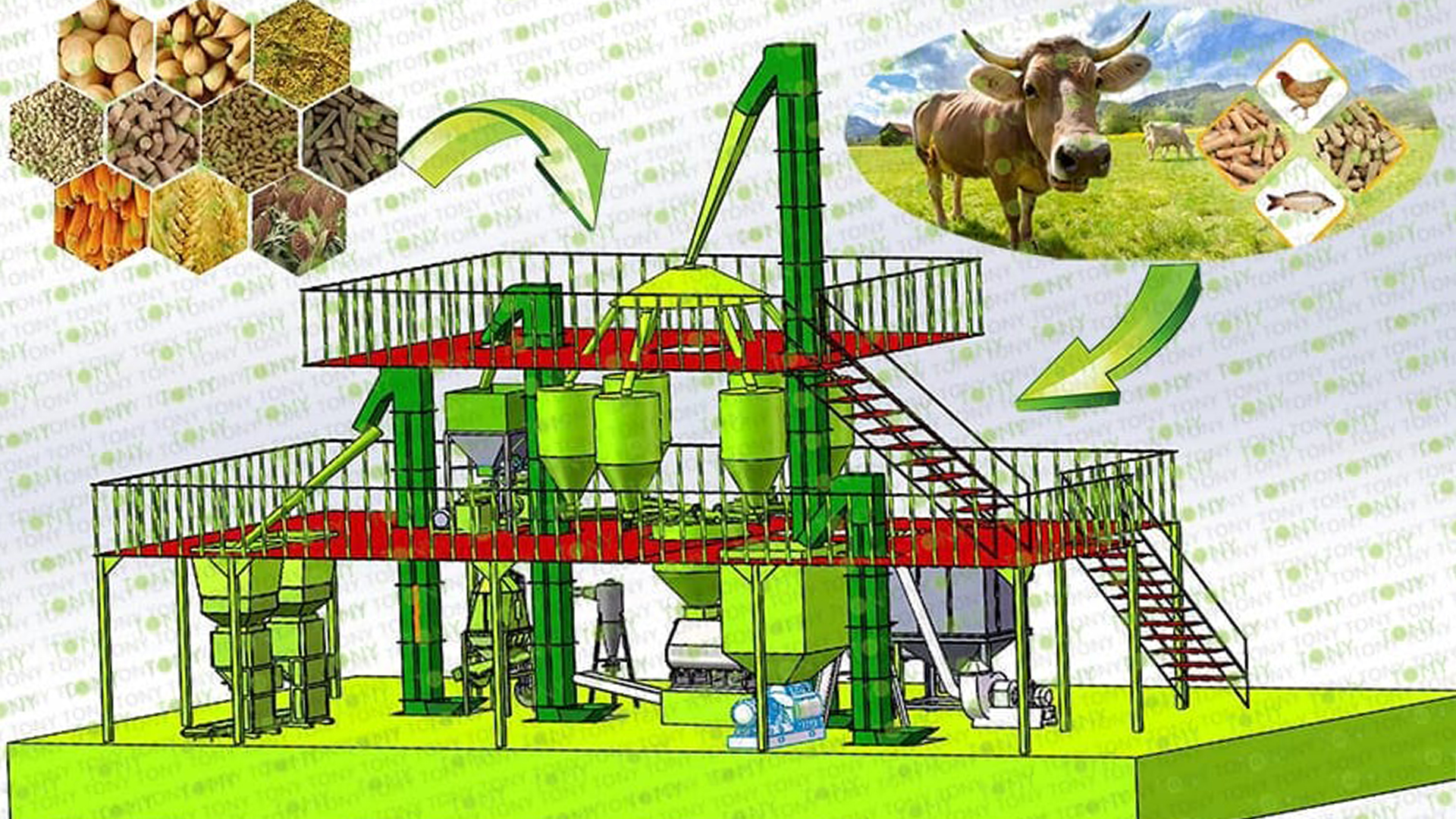

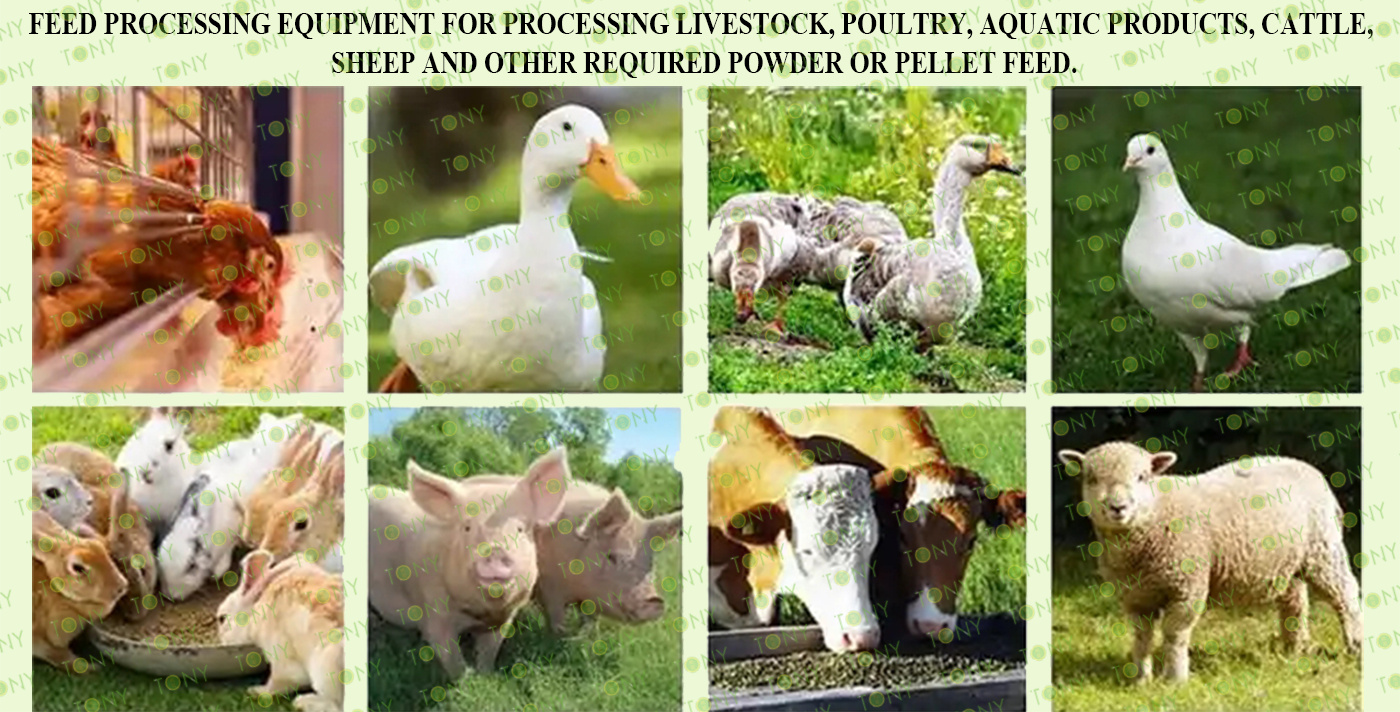

1. Feedpellets are an efficient and convenient animal feed form that plays an important role in modern animal husbandry. Whether it is a large farm or a small farmer, you can choose the appropriate feedpellets and production equipment according to your own needs.

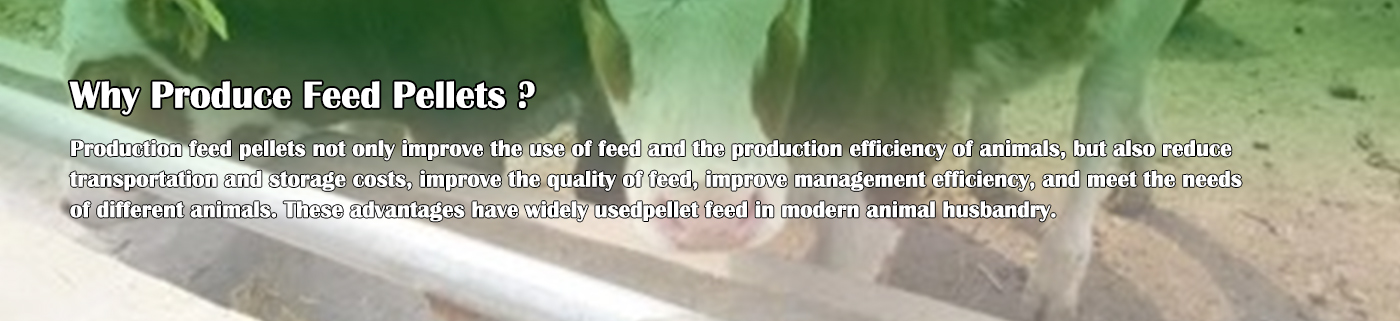

2. The main reasons for production of feedpellets include the following aspects:

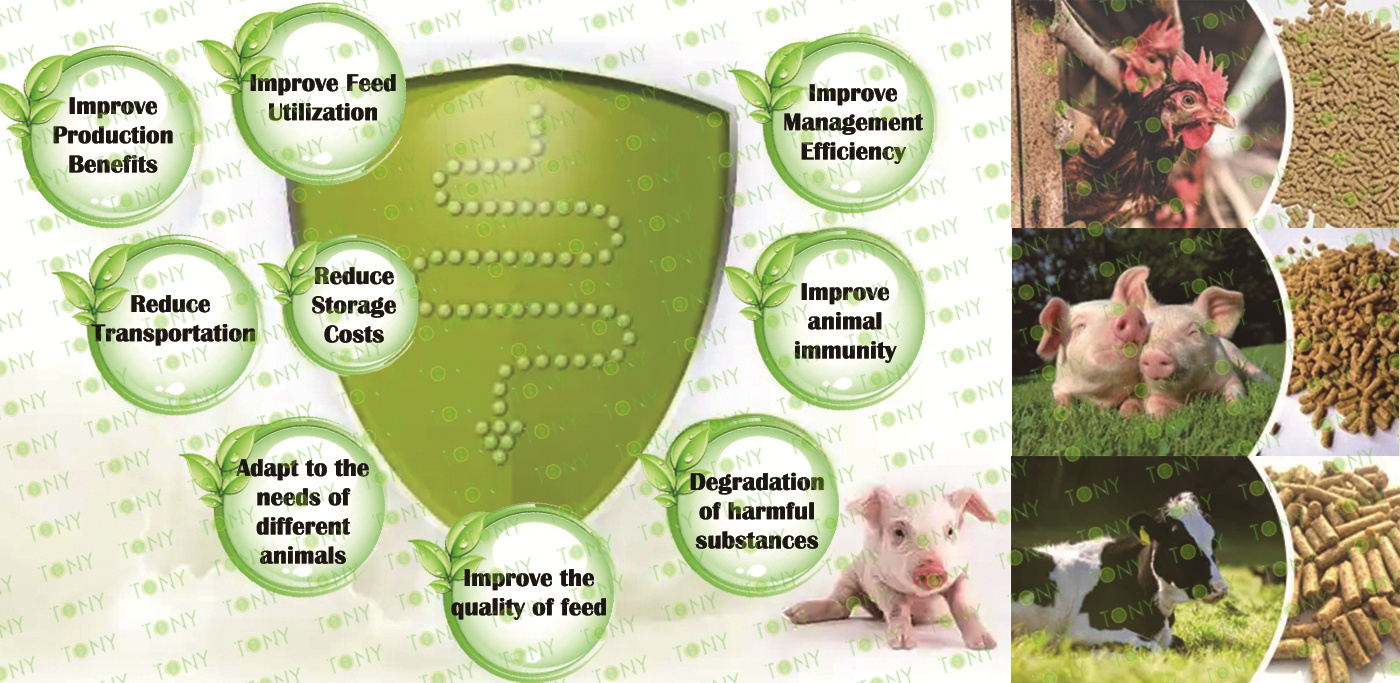

(1) Improve Feed Utilization

Increase the digestion of feed: During the pellet process, due to the comprehensive effect of moisture, temperature and pressure, starch paste and enzyme activity enhance, so that animals digest the feed more effectively, improve the feed conversion rate

Reduce animal picking: Granulet feed can maintain uniformity in the process of storage and transportation and feeding, prevent animals from selecting the ingredients they love to eat from the powder, thereby reducing the feeding loss by 8%~ 10%

(2) Improve Production Benefits

Increase the feed conversion rate: feed poultry and pigs withpellet feed. Compared with powder, the feed conversion rate (that is, the return rate) is 10%-12%. For example, feeding feed feed feed feed pigs, an average daily weight increase of 4%, and the ingredient meat ratio decreases by 6%; feeding chicken, the meat ratio can be reduced by 3%-10%

Increase the amount of animal feed: the pellet feed is good, and the animals are easier to accept, thereby increasing the amount of feeding

(3) Reduce Transportation And Storage Costs

Increasingpellet density: After the metering, it will generally increase the bulk density of the feed by 40%-100%, which can reduce the capacity and save the transportation cost of 3.

Easy to transport large transportation: Gravals have high density and large capacity, which is conducive to long -distance transportation and realizes the digestion and utilization of crop straws in different places

(4) Improve The Quality Of Feed

Bybidal effect: During the pellet process, high temperature can kill bacteria, insect eggs, bacteria, etc. in feed to ensure animal health

Avoid automatic grading of feed ingredients: Powder is prone to classification during the storage and transportation process, while pellet feed avoids this problem, reducing environmental pollution

(5) Improve Management Efficiency

Good liquidity: Granua feed is good, and it is not easy to adhere to the library, which is convenient for management and automated materials

Reduce waste: Penal feed has less pollution to air and water during the feeding process, and reduces waste

(6) Adapt To The Needs Of Different Animals

Diversity recipes: Granu feed can adjust the formula according to the needs of different animals to provide more comprehensive nutritional nutrition

Easy to accept: The pellet feed of the new formula is more likely to be accepted by animals, reducing the stress caused by changes in the formula

Summarize

Production feedpellets not only improve the use of feed and the production efficiency of animals, but also reduce transportation and storage costs, improve the quality of feed, improve management efficiency, and meet the needs of different animals. These advantages have widely usedpellet feed in modern animal husbandry.

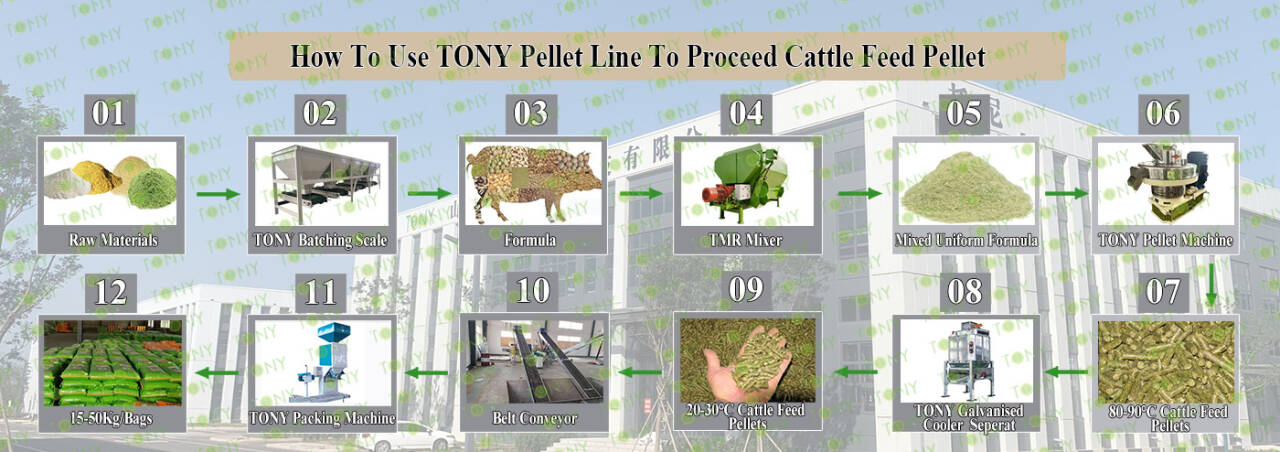

1. Mixing Equipment

2. Pelleting Equipment

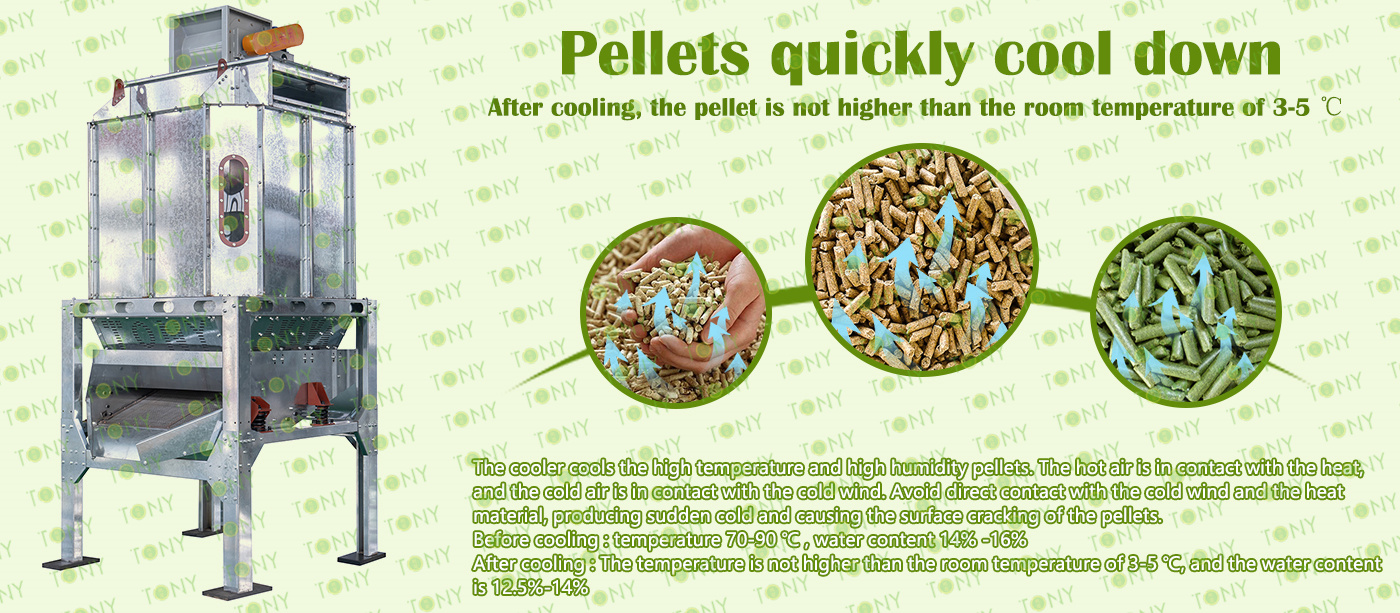

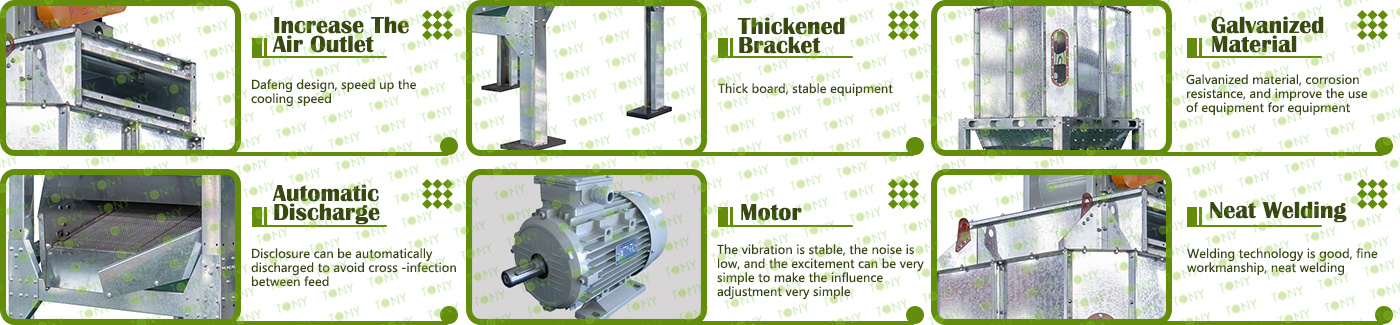

3. Cooling Equipment

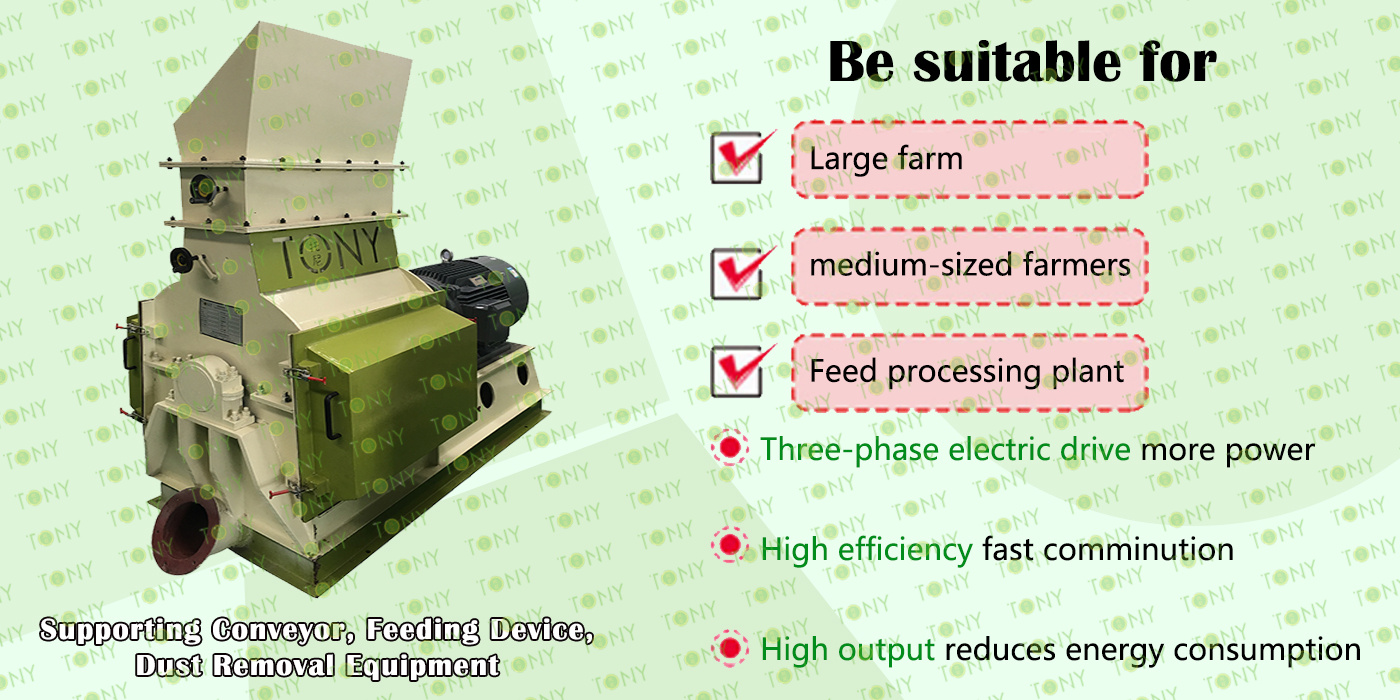

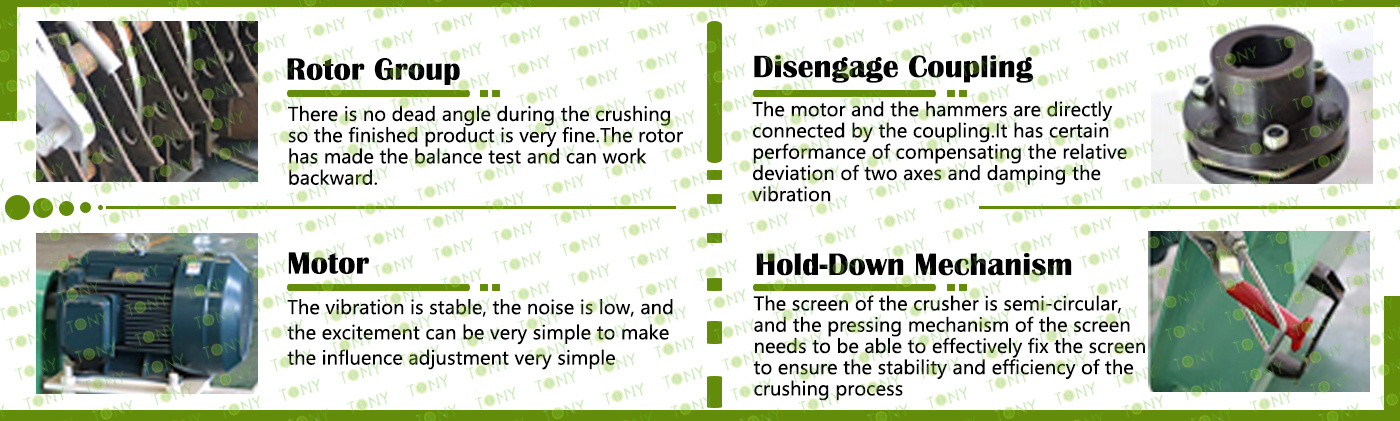

4. Fine Crushing Equipment

5. Other Auxiliary Equipment

|  |  |  |

| TMR Mixer | Feed Expander | Flat Die Pellet Machine | Grinding And Mixing Machine |

|  |  |  |

| Belt Conveyors | Dum Screener | Vibration Classifier | Packing Machine |

Feed Pellet Concrete Advantages:

1. Avoid Picky Eating:

The compound feed formula has a variety of raw materials and comprehensive nutrition, which can prevent animals from choosing their favorite food from the powder and refusing to ingest other ingredients. Because pellet feed can maintain uniformity during storage and feeding, feeding loss can be reduced by 8%~10%.

2. High Rate Of Return:

In the granulation process, due to the combined effect of water, temperature and pressure, some physical and chemical reactions occur in the feed, starch gelatinization, enzyme activity is enhanced, which can make the fed animals digest the feed more effectively and convert to weight gain. Feeding poultry and pigs pellets can increase feed conversion (i.e. return) by 10%-12% compared to meal.

3. Transportation Economy:

After granulation, the bulk density of feed is generally increased by 40%-100%, which can reduce storage capacity and save transportation cost.

4. Good Mobility:

Easy to manage. Many powders, especially those with small specific gravity and fluffy feeds, and those with molasses or high fat and urea are often adhered to the feed bank. Because pellet feed has good fluidity and rarely produces adhesion, pellet feed is most popular for large-scale dairy cattle or poultry farms with automatic feeders.

5. Reduce Pollution:

Avoid automatic grading of feed ingredients. In the process of powder storage and transportation, it is easy to produce classification because of the different volume and quality of various powders. There is no classification of feed components after the pellet is made, and the pellet is not easy to dust, and the pellet is much less polluted to air and water than the powder during the feeding process.

6. Sterilization:

Salmonella in animal feed. Salmonella remains in the tissues of animals after ingestion, and people who eat animals infected with the bacteria can get Salmonella enteropathy.

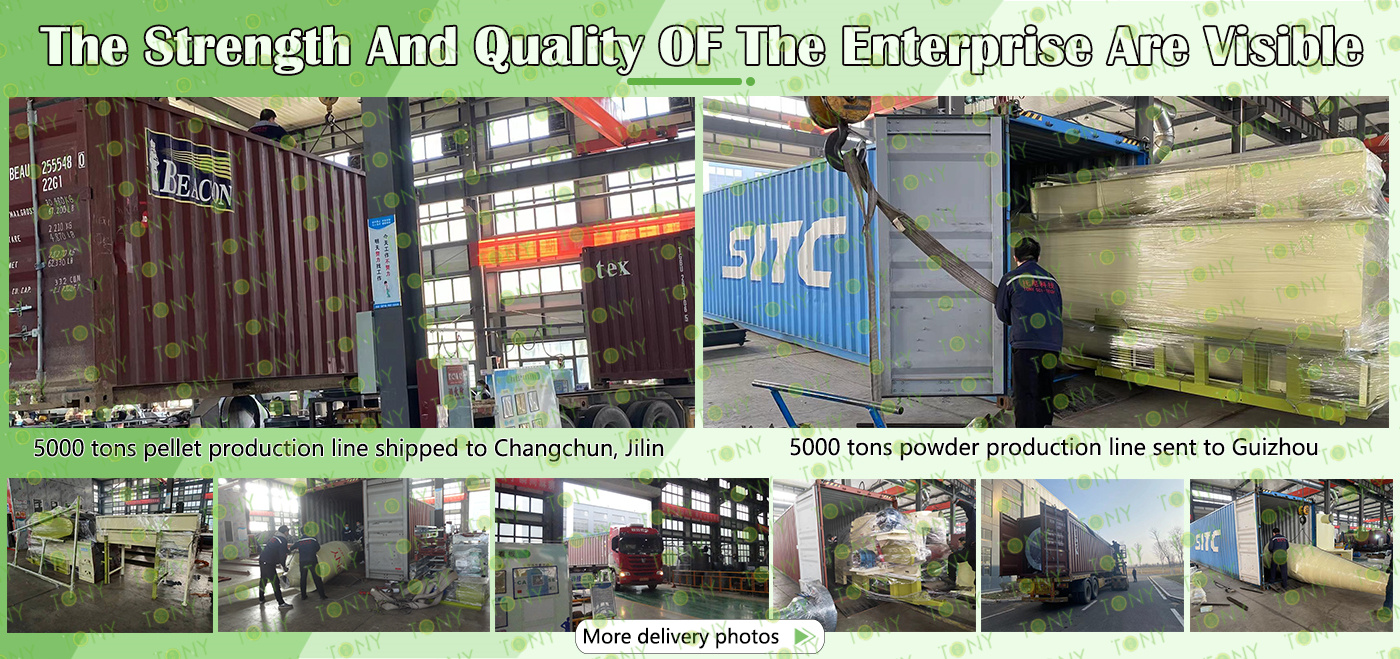

Customer-Centric

Ensuring the safety and reliability of the production line of feed pellets is an important issue. On the one hand, it can ensure the safety and health of employees, on the other hand, it can also ensure the continuity of production and the quality stability of the product. Here are some methods and measures to ensure the safety and reliability of the production line of feed pellets.

1. Reasonable Production Planning And Process Design

Production planning and process design is an important factor in ensuring the safety and reliability of the production line of feed pellets. Production planning should take into account factors such as the cycle of production, production, equipment configuration, process process to ensure the balance and stability of various parameters in the production process. At the same time, the process design should be as simple as possible, reducing human operation and interference, thereby ensuring the continuity and stability of the feed pellets production line.

2. The Maintenance And Maintenance Of Equipment

Regular maintenance and maintenance equipment is the key to ensuring the safety and reliability of the feed pellets production line. Equipment maintenance and maintenance should be carried out in accordance with the instructions of the equipment, including the cleaning, lubrication, maintenance, and fastener inspection of the equipment to ensure the normal operation and safety of the feed pellets production line.

3. Improved Employee Training And Safety Awareness

Employees' safety awareness and skill level also play a vital role in the safety and reliability of the feed pellets production line. Therefore, employees 'safety education and training should be strengthened, employees' understanding and understanding of production equipment and operations should be improved, and the safety and correctness of employees operate equipment.

4. Automated Control System

The automation control system can greatly improve the safety and reliability of the feed pellets production line. The automated control system can realize the automation control and monitoring of the device, ensure the accuracy and stability of various parameters in the production process, thereby reducing accidents and failures in the production process, and improving the reliability of production efficiency and feed pellets production line.

5. Safety Inspection And Emergency Plan

Regular safety inspections and formulation emergency plans are also an important means to ensure the safety and reliability of the feed pellets production line. Emergency plans should be formulated for various possible situations, including equipment failure, personnel damage, and so on. During the production process, measures should be taken quickly according to the emergency plan to avoid unnecessary losses.

In summary, the safety and reliability of the feed pellets production line can be ensured through the above measures and methods. Only on the premise of ensuring safety, the safety and reliability of the feed pellets production line also needs to be continuously monitored and improved. During the production process, the safety and reliability of the equipment can be ensured by regular inspection of the safety status of the equipment, the operating parameters of the equipment, and strengthening the safety training of employees. At the same time, it can also strengthen the detection and management of raw materials to prevent the use of unqualified raw materials and cause damage to the equipment.

2025 Tony Machinery - All Rights Reserved. Map