Many customers ask the most frequently when inspecting pellet machine: "How much does one pellet machine cost?" In fact, this is not correct. There are many factors that affect the price of biomass pellet machine. First of all, it depends on the customer's raw materials, the purpose of the pellet machine, and the output required. Because of these, the equipment selected for the pellet machine production line is different, and of course the prices are different.The price of biomass pellet machine is affected by a variety of factors, mainly including the following aspects:

1. Equipment output:

Yield is an important factor affecting price. Generally speaking, biomass pellet machine with high hourly output have relatively high prices. For example, small household biomass pellet machine may produce around dozens of kilograms per hour, and the price is relatively cheap, usually ranging from a few thousand yuan to one or two thousand yuan. Large industrial biomass pellet machine can produce several tons per hour, and the price may reach hundreds of thousands of yuan.

2. Model and configuration:

The prices of different models of biomass pellet machine will also vary greatly due to different design principles, structural characteristics and scope of application. For example, the ring mold granulator has an annular mold, and the pressed particles have a high density and good quality. They are often used in large biomass pellet manufacturers and have relatively high prices. The flat mold pellet machine has a simple structure and convenient operation. It is suitable for small processing plants or breeders, and the price is relatively low.

The price of biomass pellet machine with high configuration will also increase accordingly. For example, equipment that uses key components such as high-quality motors and reducers have more stable performance and prices are much higher than those of ordinary equipment.

3. Brand and quality:

Biomass pellet machine of well-known brands are usually more expensive. This is because these brands have a high reputation and reputation in the market, reliable product quality and perfect after-sales service. For example, although the domestic first-tier brand biomass pellet machine is relatively expensive, it is still favored by many users because of its stable performance and strong durability.

Product quality is also a key factor in determining price. A good quality wood pellet machine uses high-quality materials and advanced production processes. The equipment has a long service life and low failure rate, which can bring higher economic benefits to users, so the price will be relatively high.

4. After-sales service:

Perfect after-sales service will increase the added value of the product, thereby affecting the price. Some manufacturers provide timely technical support, door-to-door installation and debugging, regular follow-up visits and other after-sales services, and these service costs will be reflected in product prices. When purchasing, users cannot only look at the price, but also consider the manufacturer's after-sales service capabilities to ensure that problems encountered during use of the equipment can be solved in a timely manner.

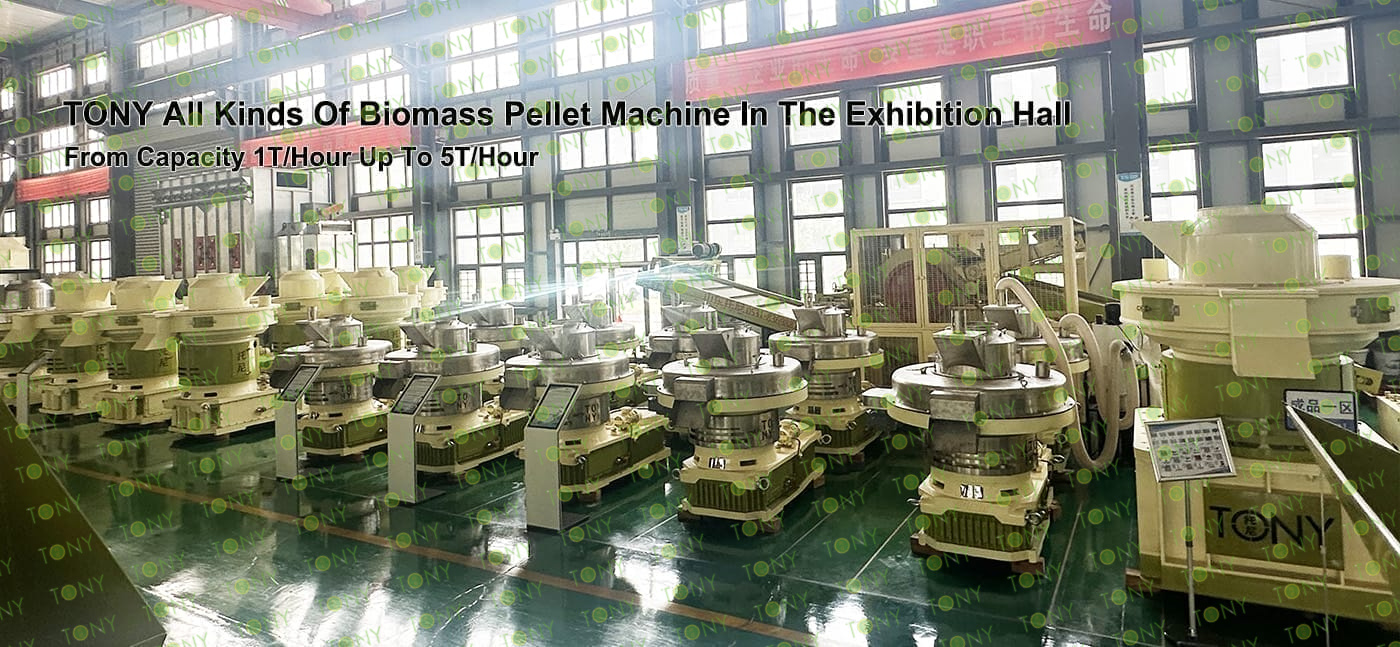

TONY has more than 20 years of production experience in the biomass energy industry. The pellet machine equipment produced is of quality assurance and has a high cost-effectiveness. You are welcome to visit the factory.