A multifunctional hammer mill is a widely used pulverizing device. Its unique structure and operating principle offer significant advantages in multiple fields, including:

1. Wide range of applicable materials and outstanding multifunctionality

It can process a wide range of materials, including agricultural waste (straw, corn cobs, peanut shells, branches, forage grass, etc.), industrial raw materials (ore, coal, gypsum, glass, etc.), and food ingredients (grains, legumes, Chinese medicinal herbs, etc.).

It efficiently pulverizes dry, brittle materials, as well as some less ductile materials (such as straw), eliminating the need for frequent equipment replacement, meeting diverse needs.

2. High pulverization efficiency and large processing capacity

The core working component is the high-speed rotating hammer (or hammer head). This hammer pulverizes the material through high-speed impact, shearing, and grinding, resulting in strong impact force and high single-pass processing capacity.

Small and medium-sized equipment can produce several tons per hour, while large equipment can even reach tens of tons per hour, making it suitable for large-scale production and significantly improving operational efficiency. 3. Adjustable Particle Size to Meet Diverse Needs

By adjusting the screen aperture (the discharge standard for pulverized material) or the gap between the hammers and the screen, the particle size of the pulverized product can be flexibly controlled (from coarse centimeters to fine millimeters).

For example, feed processing can achieve pulverization down to 2-5 mm, while biomass pellet production can achieve pulverization down to 1-3 mm, meeting the specific particle size requirements of different industries.

4. Simple Structure, Easy Operation and Maintenance

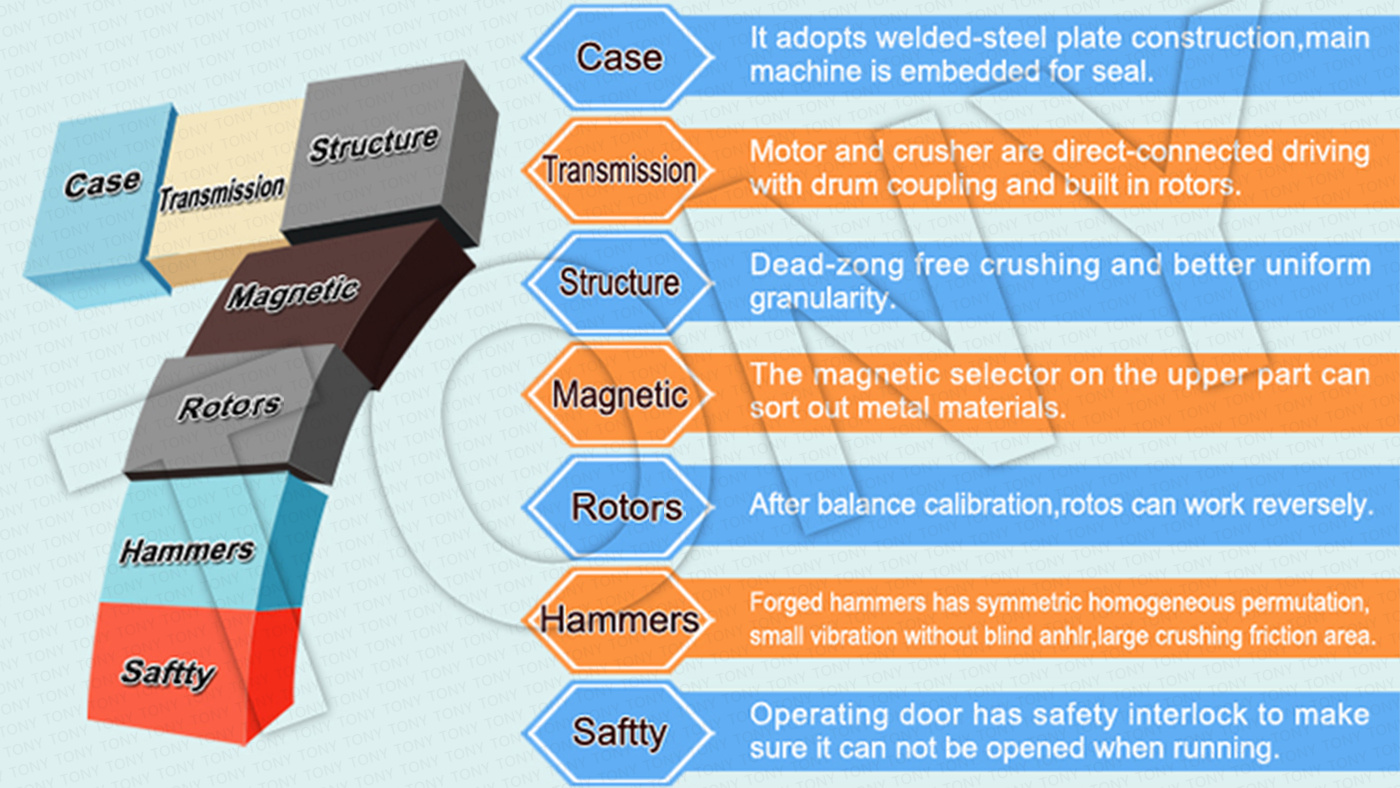

Mainly composed of a frame, rotor (including hammers), screen, feed inlet, and discharge outlet, the compact structure features few parts, making assembly and disassembly easy.

The operator interface is simple: the motor simply drives the rotor, and after feeding, the pulverization process automatically completes, requiring no extensive training.

Low Maintenance Cost: Consumable parts such as the hammers and screen are easily and inexpensively replaced. Routine maintenance primarily involves cleaning residual material, inspecting fasteners, and lubricating bearings, a simple process.

5. Stable Operation and Low Energy Consumption

The dynamically balanced rotor ensures smooth operation with minimal vibration and noise, minimizing impact on the work environment.

Compared to other pulverizing equipment, the hammer mill's motor power is optimally matched, resulting in lower energy consumption per unit of material, saving energy costs over the long term.

6. Wide Application Areas and High Cost-Effectiveness

In agriculture, it is used for feed processing and straw return to fields (composting after pulverization); in the energy industry, it is used for biomass pellet fuel production.

One unit can replace multiple dedicated pulverizers, reducing equipment purchase and maintenance costs. This outstanding cost-effectiveness makes it particularly suitable for small and medium-sized enterprises or individual users.

Summary

With its wide range of applications, high efficiency, adjustable particle size, and easy operation and maintenance, the multifunctional hammer mill is an ideal choice for material pulverization in agriculture, industry, energy, and other fields. Its comprehensive performance is particularly significant in applications requiring the processing of multiple materials or large-scale production.