1. The core of the circular economy is "efficient recycling of resources", and energyization is the most large-scale utilization method of agricultural and forestry waste. However, this transformation does not occur naturally and must rely on standardized processing of the pellet machine:

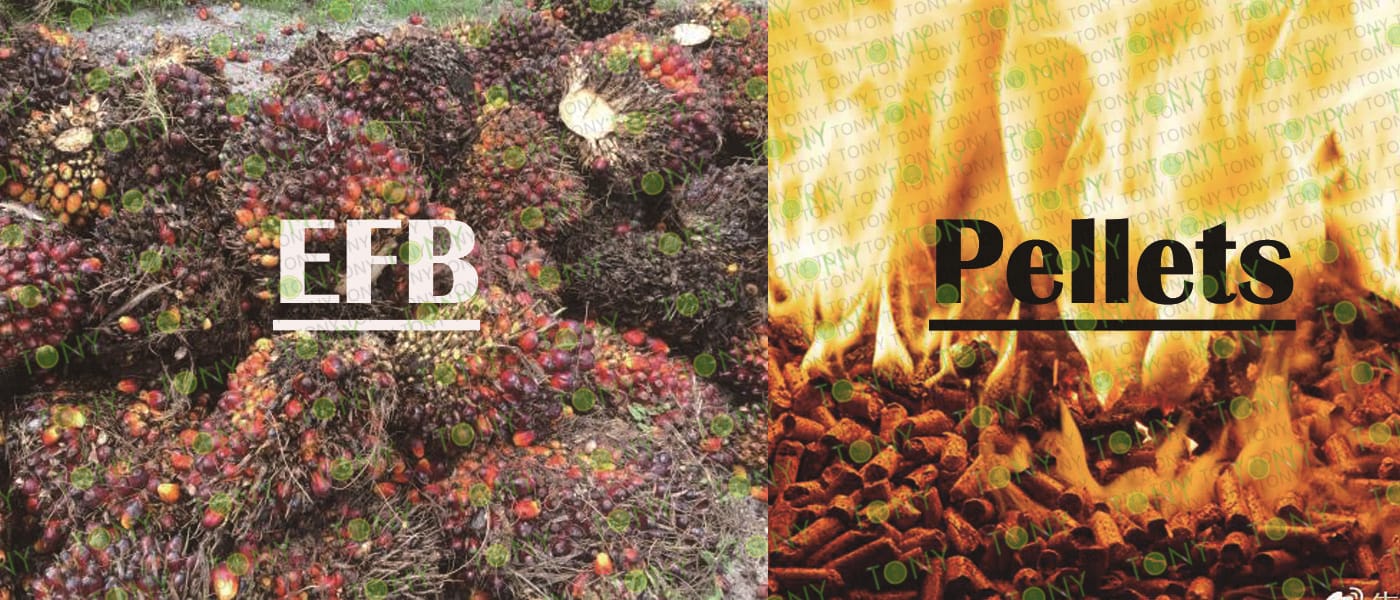

Solve the "non-standardization" problem: the physical characteristics of different wastes vary greatly (straw contains high cellulose, wood chips contain high lignin, and fruit shell hardness). By adjusting the mold hole diameter, forming pressure, and temperature parameters, the biomass pellet machine can uniformly process the mixed raw materials into standardized particles with a diameter of 6-12mm and a calorific value of 15-18MJ/kg to meet the "stable combustion" needs in downstream scenarios such as industrial boilers and biomass power plants;

Improve "full-chain efficiency": the transportation cost of unprocessed waste is extremely high (the freight per kilometer is 5-8 times that of pellet fuel), and the volume of the pellet machine is reduced by 70%-80% after compression, making long-distance transportation economical, and promoting efficient flow of waste from dispersed production sites to centralized processing points and to the consumer market.

2. The ultimate goal of circular economy is "environmentally friendly development". The role of the pellet machine is ultimately reflected in the downstream ecological and economic synergy benefits:

(1) Closed loop of carbon emission reduction for energy substitution

The CO₂ released by the combustion of biomass particles comes from carbon absorbed during plant growth, which theoretically achieves "carbon neutrality" (compared to coal burning, CO₂ 1.8 tons and SO₂ 0.02 tons per ton of particle). This characteristic makes it the core clean energy to replace coal and natural gas, and the standardized particles produced by pellet machines are the "material basis" that supports this replacement - Europe has reduced carbon emissions by replacing coal with pellet fuels.

(2) Agricultural cycle of waste return to the field

The ash after the pellet burns (containing potassium, calcium and other elements) can be used as organic fertilizer to return to the field, forming an agricultural cycle of "straw → granular fuel → ashes → farmland". The starting point of this chain is still the resource processing of straw by the pellet machine.

(3) Economic cycle of employment in the industrial chain

The popularity of pellet machines has driven upstream and downstream employment: upstream waste collection, midstream pellet production, downstream fuel distribution and application maintenance, forming an economic cycle of "rural - enterprise - market".

Summary: The pellet machine is a "gear hub" of circular economy

Without a pellet machine, upstream waste cannot be converted into available resources, and the cycle "release cuts" is circulated;

Without a pellet machine, standardized processing and efficient transportation in the midstream cannot be achieved, and the cycle is "inefficient";

Without a pellet machine, downstream energy substitution and ecological benefits cannot be implemented, and the cycle is "idling".

From "garbage treatment" to "energy production", from "farmers' income increase" to "global emission reduction", the pellet machine connects every link of the industrial chain to make the cycle of "agricultural and forestry waste → clean energy → ecological protection → economic benefits" a reality. Therefore, it is not only a kind of equipment, but also an irreplaceable core gear in the circular economy industrial chain.