The TONY biomass pellet machine can turn various types of crop straw, such as corn straw, wheat straw, rice straw, etc., into pellets. When the editor receives inquiries from customers, many of them are still not clear about the process and directly ask if it can be directly processed into granules when placed in a pellet machine. In fact, it's not like that. In this article, the editor will take bundles (round bundles, square bundles) of corn stalks as an example to explain the process of making corn stalks into pellets.

Raw material conditions: Bundles of corn stalks (φ1200mm-φ1500mm), moisture content: 40%-50% after harvest

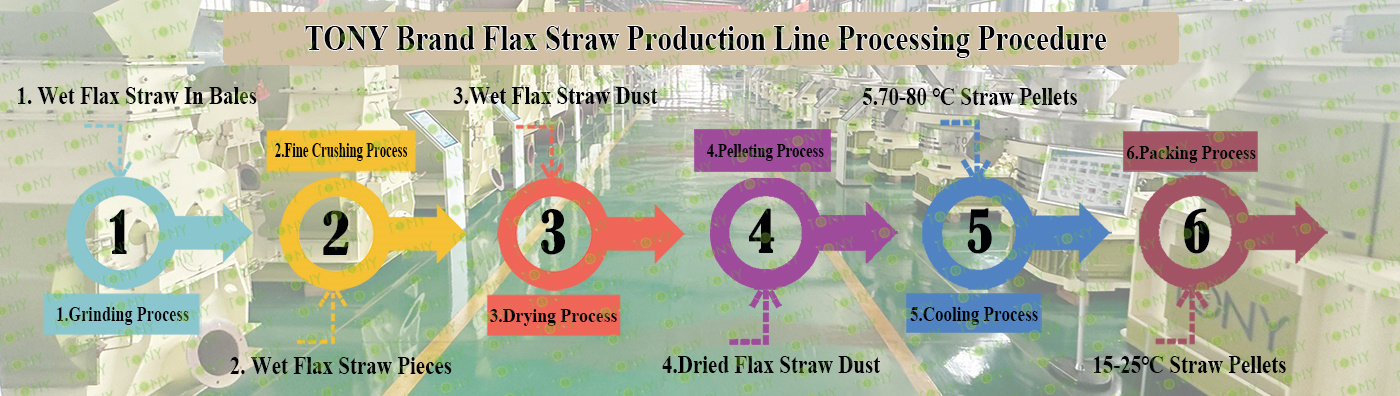

The first step: Grinding

The straw raw materials in bundles are pulled into the production area. The first step is to use a straw rotary cutter for crushing. Here, it is only necessary to put the bundles of straw into the straw rotary cutter through the grabbers. The crushed straw raw materials are in sections, with a length of approximately 4 to 5 centimeters.

Step Two: Fine Crushing

After being crushed, the raw materials are subjected to fine crushing by a crusher. Here, the available models include multifunctional hammer mill and single-shaft and dual-shaft high-efficiency hammer mill, which are determined based on the specific task volume required by the customer. Things like sawdust and wood powder should not be crushed or ground.

Step 3: Drying

The moisture content of the raw materials required for pressing straw pellet fuel should be below 15%. This step also depends on the situation. If the moisture content of the material is too high, a dryer will be needed. The most commonly used type of dryer is the single rotary drum dryer.

Step 4:Pelleting

The raw materials processed by the above-mentioned equipment can be directly fed into the straw pellet machine for pressing and shaping. The diameter and length of the particles can both be adjusted. The commonly used particles in the current market are those with diameters ranging from φ6 to 10mm.

Step 5: Cooling and packaging

During the granulation process, heat is generated and the granules are in a state of high temperature. Particles at high temperatures are not suitable for direct packaging. They need to be cooled down by a cooler first, and then packaged in kilogram bags or ton bags.

At this point, the entire granulation process is completed. This can be said to be a standardized granulation production line process. If your raw materials are simple and the hourly output is low, then only one pellet machine is needed. TONY offers production line solution matching, price consultation for straw and wood pellet machines, as well as solutions to common malfunction problems during equipment operation.