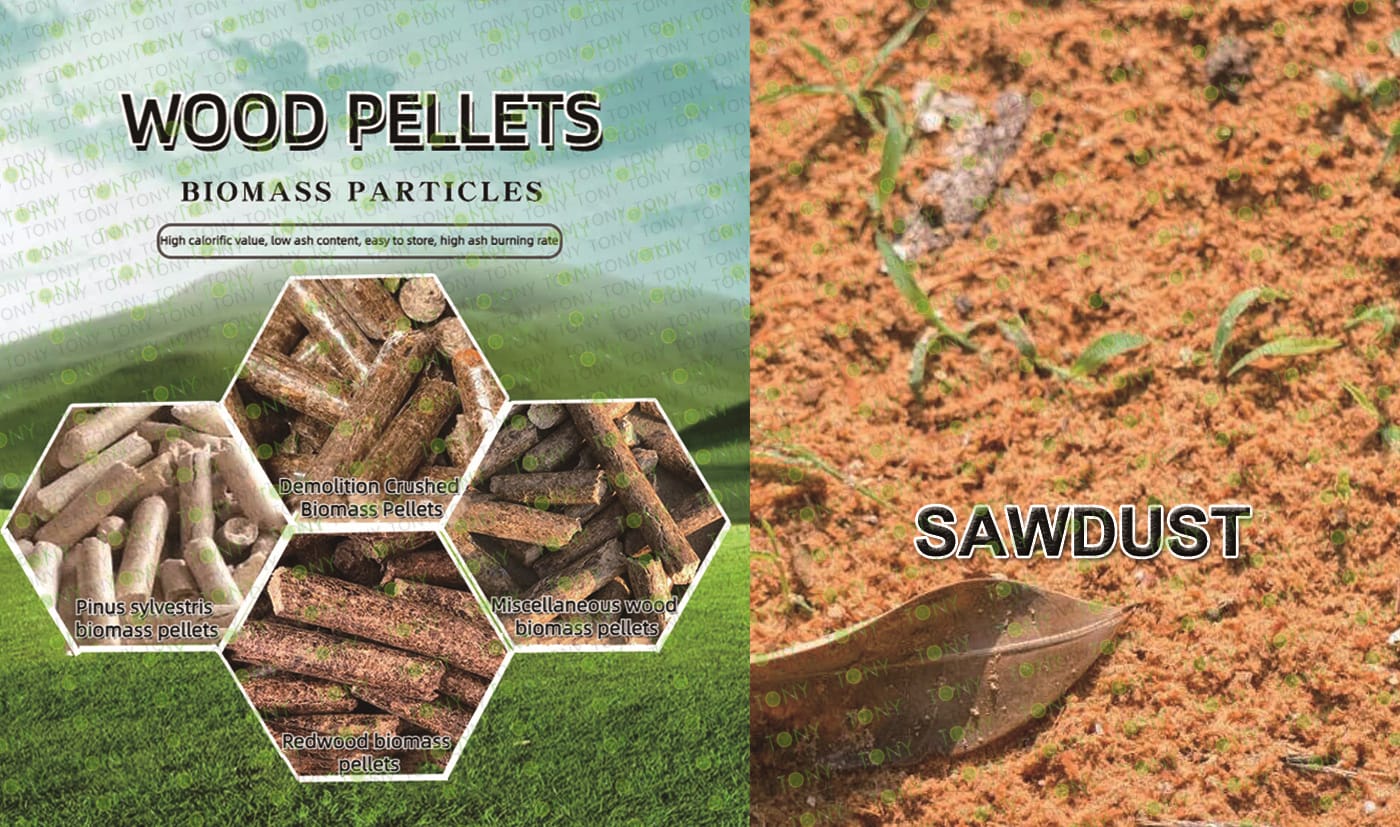

The sawdust pellet machine utilizes biomass energy such as waste boards, sawdust and straw to produce fuel pellets that can replace coal, making significant contributions to environmental protection and energy industries. In rural areas, there are numerous reusable resources. For instance, "scraps from furniture factories and crop straws" are common raw materials. The emergence of sawdust pellet machines has effectively facilitated the reuse of discarded straws and agricultural and forestry waste.

When sawdust pellet machine produce fuel, the following three issues need to be noted:

1.Storage of raw materials

Attention should be paid to the storage of raw materials. Generally, they should be piled up upright with a certain distance in the middle to facilitate the evaporation of moisture inside the raw materials. They need to be exposed to the sun frequently to prevent mold.

2. The quality of raw materials

Freshly harvested straw has a relatively high moisture content and is prone to mold when piled up. Therefore, it should be dried separately to ensure good ventilation and dryness before being stored. Sawdust pellet machines also have requirements for the moisture content of raw materials. It is necessary to do a good job in moisture control. The success rate is relatively high when the moisture content is between 10% and 15%.

3. Processing and pressing

Before feeding materials, the machine should be test-run to check if all parts are normal. Any abnormal phenomena should be dealt with in time. Moreover, the feeding should be uniform to ensure the normal operation of the sawdust pellet machine. As the freshly produced granules are relatively hot, if there is no cooling equipment, they need to be sun-dried before being stored, packaged and sent out of the factory.

Biomass fuel can be used in traditional coal-fired steam boilers in large cities and can replace traditional coal. Biomass pellets have a high volatile matter content, are easily dissolved, have good carbon specificity, are flammable, have low ash content, ignite quickly, are more fuel-efficient, and reduce application costs. The formed particles are small in size, have an extremely high specific gravity, are resistant to ignition, and are conducive to storage and transportation. The ash content and sulfur and nitrogen components of biomass pellets are slightly lower. They are renewable fuels with the characteristics of energy conservation and environmental protection, and can indirectly cover power energy sources such as coal, oil, electricity and gas.

So, sawdust pellet machines are very important for environmental protection. If customers want to process pellets. You can consider purchasing the TONY wood pellet machine.