Fuel pellets processed by biomass pellet machines have a very promising market prospect. The raw materials for making biomass pellets are abundant, such as common corn stalks, caragana, rice husks, etc., and common furniture factory scraps and bamboo shavings in southern regions. All of them can be used to make biomass pellets. There are many types of raw materials for making biomass pellets, and they can be selected according to the specific raw materials of the region. Establishing a biomass pellet fuel factory is a good choice and it is definitely feasible.

Many customers will ask, what are the basic conditions for building a pellet fuel plant? In this article, TONY responds to the most frequently asked questions by his client friends.

1. Types of raw materials: What are the raw materials?

In addition to the raw materials mentioned above, there are too many other types of raw materials. There is nothing that a biomass pellet machine cannot make if you can think of it. In addition to common agricultural straw waste and agricultural and forestry waste, there are also items such as animal manure, household garbage, and residue of traditional Chinese medicine, all of which can be processed.

2. Moisture content of raw materials

When discussing particle production, the moisture content of raw materials is a key factor that you need to carefully review. You may not know that a higher moisture content will increase the final cost of each particle, as you will need more investment to dry the material to bring the moisture content to an acceptable level. For users who are just starting to enter the industry, it is recommended that you directly obtain wood chips with appropriate moisture content. Then, you only need to purchase a biomass pellet machine to get started and make money.

3. Do you need a dryer?

Similar to the above question, raw materials with a high moisture content need to be dried. For small yields, natural moisture evaporation can be achieved through sun-drying, while for large yields, a dryer is required.

4. The initial dimensions of the raw materials.

Making pellets is not simply about feeding any shape of raw material into a pellet machine and waiting for the pellets to come out. In reality, we encounter various materials of different shapes, which could be powder, blocks, wood chips, or even entire tree trunks. Therefore, we need to first crush these raw materials into powder, which is what we often call sawdust or wood shavings. This also falls within the industry's process requirements.

5. What size of particles do you need?

The size of the particles refers to the diameter of the cross-section. The particle size processed by the particle machine ranges from φ6 to φ12mm. At present, 6mm, 8mm and 10mm are the three most commonly used sizes. However, if the customer requires other sizes, the pellet machine manufacturer can readjust the ring die to meet your requirements. The ring die is a key part of the fuel pellet machine and directly determines the final diameter of the pellets.

6. How is the electricity demand?

In China, when industrial power supply is below 380V and 50Hz, it is what we commonly refer to as three-phase electricity. The production of biomass pellets must use three-phase electricity. According to the different power conditions in foreign countries and local areas, we will provide customized services for customers

7. How many raw materials can you provide per hour/per day?

A greater supply of raw materials means that more pellets can be produced and also more investment funds. For instance, if your raw material supply is 1 ton per hour, then one pellet machine is sufficient to complete this task. However, if you have a raw material supply of 10 tons per hour, you definitely need a high-output pellet machine. Pellet machines account for a significant portion of the entire pellet factory's cost. Calculate carefully and find the correct value.

8. What is the purpose of processing particles?

You can either sell it to make a profit or use it for your own project. If you plan to sell the pellets, there are two conditions. One is to find out the pellet price in the local market and calculate the cost per ton of raw materials that you can accept, as well as the cost of production equipment that you can accept. After you understand all the information, you can set a sales price that suits your profit.

9. What are the local environmental requirements?

Dust occurs during the drying process and the production of pellets. Although dust collectors strive to minimize dust emissions as much as possible, they still need to comply with local industrial production environmental protection regulations. Additionally, as pellet fuel is known as a renewable and clean energy source, many governments in various countries encourage it by providing subsidies to energy producers.

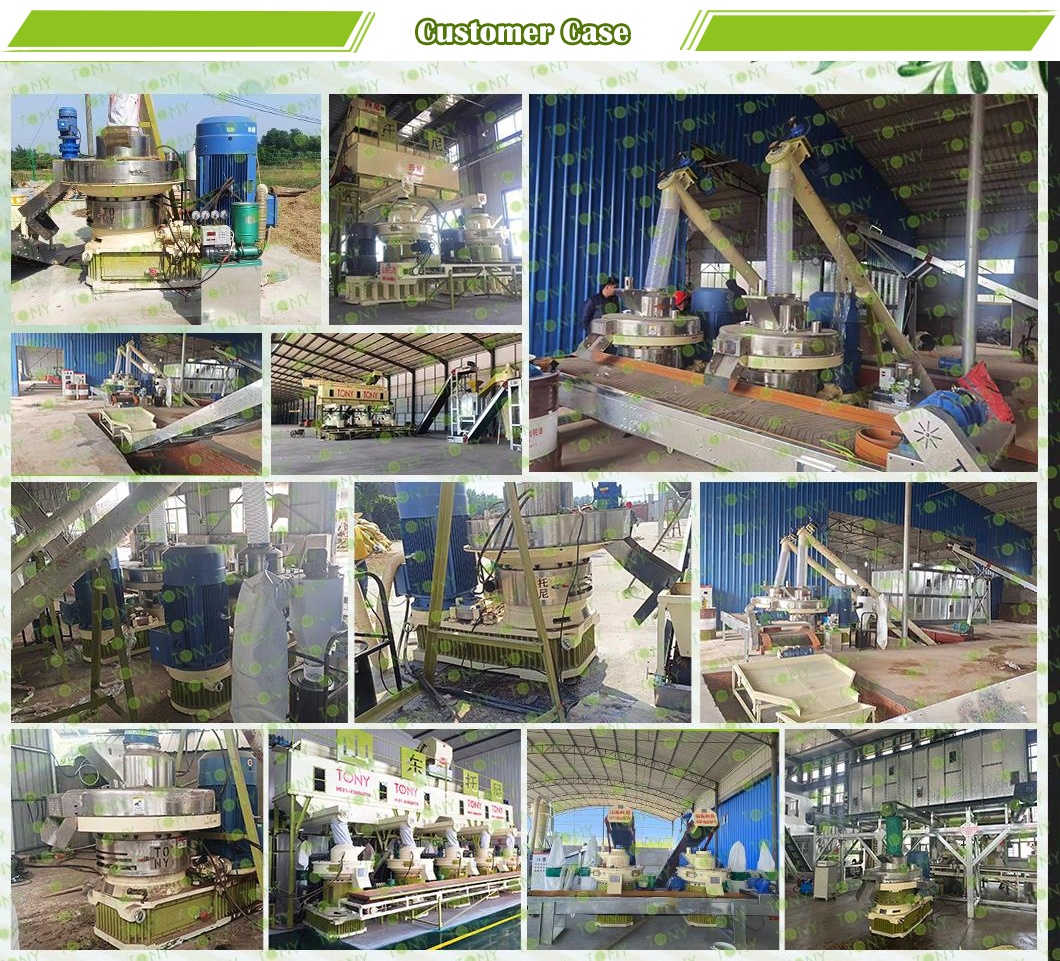

10. All the above 9 questions have clear answers. Then, which manufacturer's biomass pellet machine should be chosen?

When making biomass pellets, it is necessary to choose biomass pellet machines produced in Shandong region, especially those produced in Zhangqiu area, which are the mainstream models at present. Surely you have also learned about the brands of Shandong biomass pellet machines from your friends around you, through online channels and so on. There are many of them. Among them, it is recommended that you give priority to our TONY biomass pellet machine brand. As a large-scale physical manufacturer, you can see the processing technology and physical components of each part of ours. Hardware strength is only part of it. We have a large number of customer cases in various industries around the world for your reference. If you also want to join the biomass pellet industry, then don't hesitate!