Biomass pellet fuel is made of agricultural and forestry waste such as corn stalks, wheat straw, wood chips, corn cores, rice husks, etc. through wood chip pellet machine. Due to its small size, large density, convenient storage and transportation, stable combustion, long cycle, high combustion efficiency, small content of pollutants in ash slag and flue gas, it can indirectly replace traditional fuel coal-fired in many fields.

Compared with traditional energy, biomass pellet machine fuel has many differences in raw material sources, environmental impact, combustion characteristics, production and processing, and application, as follows:

1. Source of raw materials

Biomass pellet machine fuel: mainly uses agricultural and forestry waste as raw materials, such as crop straw, wood chips, rice husks, peanut husks, etc. These wastes are produced in large quantities in the agricultural and forestry production process, and the reuse of resources is achieved through the collection and processing of biomass pellet fuel.

Traditional energy: Traditional fossil energy sources such as coal, oil, natural gas, etc. were formed by ancient organisms through long geological ages. Its raw material sources are limited, and its reserves gradually decrease with mining and use, making it a non-renewable resource.

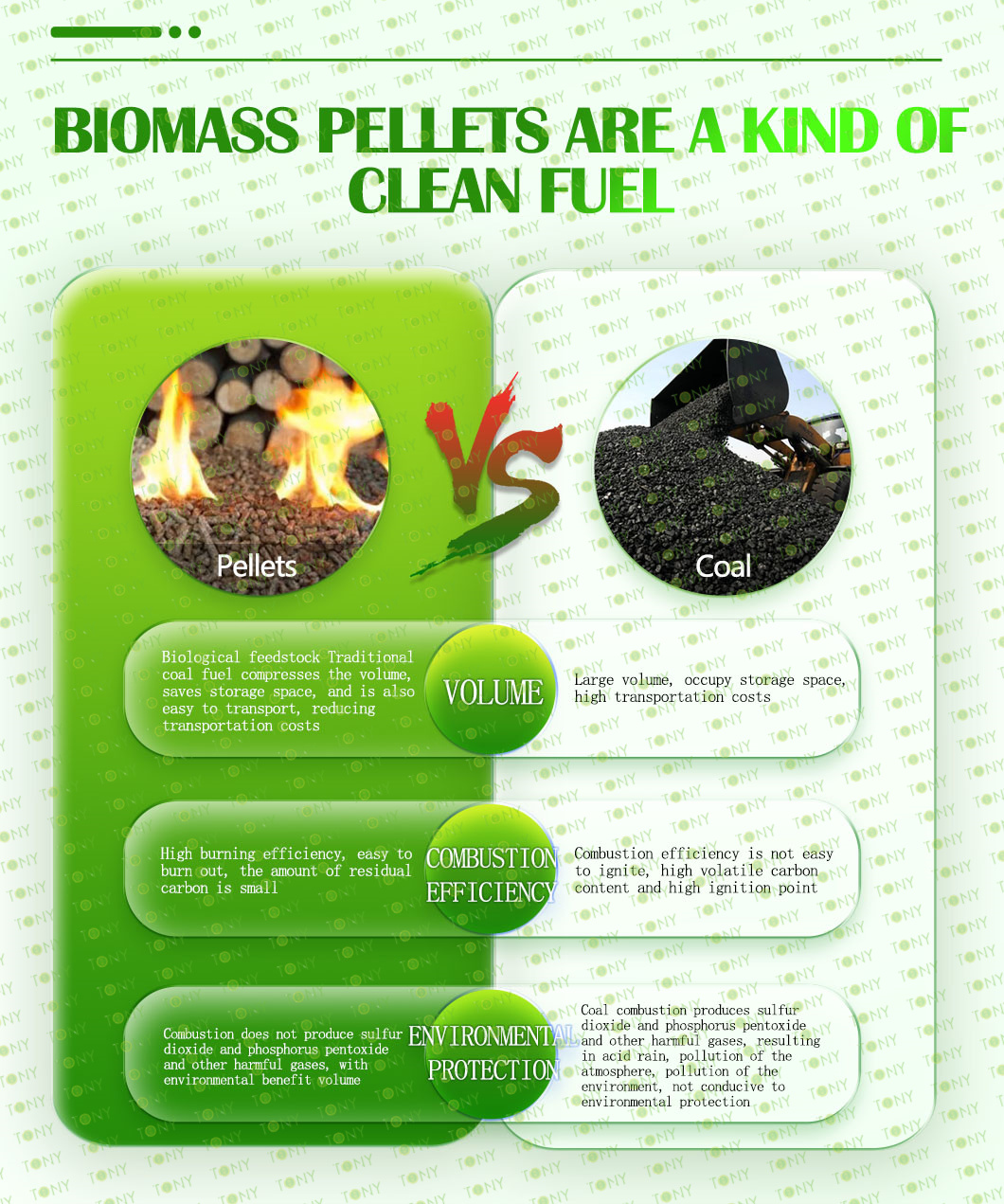

2. Environmental impact

Biomass pellet machine fuel: The carbon dioxide emissions generated during combustion are roughly equivalent to those absorbed during plant growth. From a life cycle perspective, basically achieving zero carbon dioxide emissions will help reduce greenhouse gas emissions and alleviate global climate warming. At the same time, the burned ash residue is rich in minerals such as potassium, calcium, magnesium, etc., and can be used as high-quality organic fertilizer to return to the field, which is relatively environmentally friendly.

Traditional energy: The combustion of traditional fossil energy will release pollutants such as carbon dioxide, sulfur dioxide, nitrogen oxides, etc., which is one of the important reasons for environmental problems such as acid rain and haze, and it has serious harm to the ecological environment and human health.

4. Combustion characteristics

Biomass pellet machine fuel: has high volatile components, is easy to ignite and has a fast combustion speed. However, due to its high oxygen content and relatively low calorific value, it is generally around 16-18MJ/kg, which is lower than traditional energy sources such as coal. However, through reasonable combustion equipment and technical optimization, the thermal energy needs of different application scenarios can be met.

Traditional energy: The calorific value of coal is higher, generally above 20-30MJ/kg, and the calorific value of oil and natural gas is higher. They can release a large amount of heat when burned, providing strong energy support for industrial production, transportation and residents' lives. However, traditional energy requires higher temperatures and sufficient oxygen when burning, so the combustion process is relatively complicated.

5. Production and processing

Biomass pellet machine fuel: The production process is relatively simple, and agricultural and forestry waste is processed into granular form through processes such as crushing, drying, and forming. The investment in production equipment is relatively small, and can be flexibly arranged according to raw material supply and market demand. It is suitable for development in rural and remote areas, which is conducive to promoting local economic development and employment.

Traditional energy: coal mining requires large-scale mining equipment and complex mining technology, while oil and natural gas exploration, mining and refining require more advanced technology and large-scale capital investment. The production process involves multiple links, is technically difficult and has a great impact on the environment.

6. Application areas

Biomass pellet machine fuel: mainly used in heating and heating fields, such as home heating, small boiler heating, etc., it can also be used in the power generation field, and it is converted into electricity through biomass power plants. In addition, in some areas with high environmental requirements, biomass pellet fuel can also be used for fuel replacement in industrial kilns to reduce pollutant emissions.

Traditional energy: Traditional fossil energy has a wide range of applications. In addition to being used in power generation, heating, and industrial production, it is also the main energy in the field of transportation. For example, automobiles, aircraft, ships, etc. are mostly fueled by petroleum products. In the chemical field, oil and natural gas are more important raw materials, used to produce many chemical products such as plastics, rubber, and chemical fiber.

The use of clean energy such as biomass pellets can not only alleviate the pressure on energy, but also protect the environment. It also improves people's dependence on traditional energy.