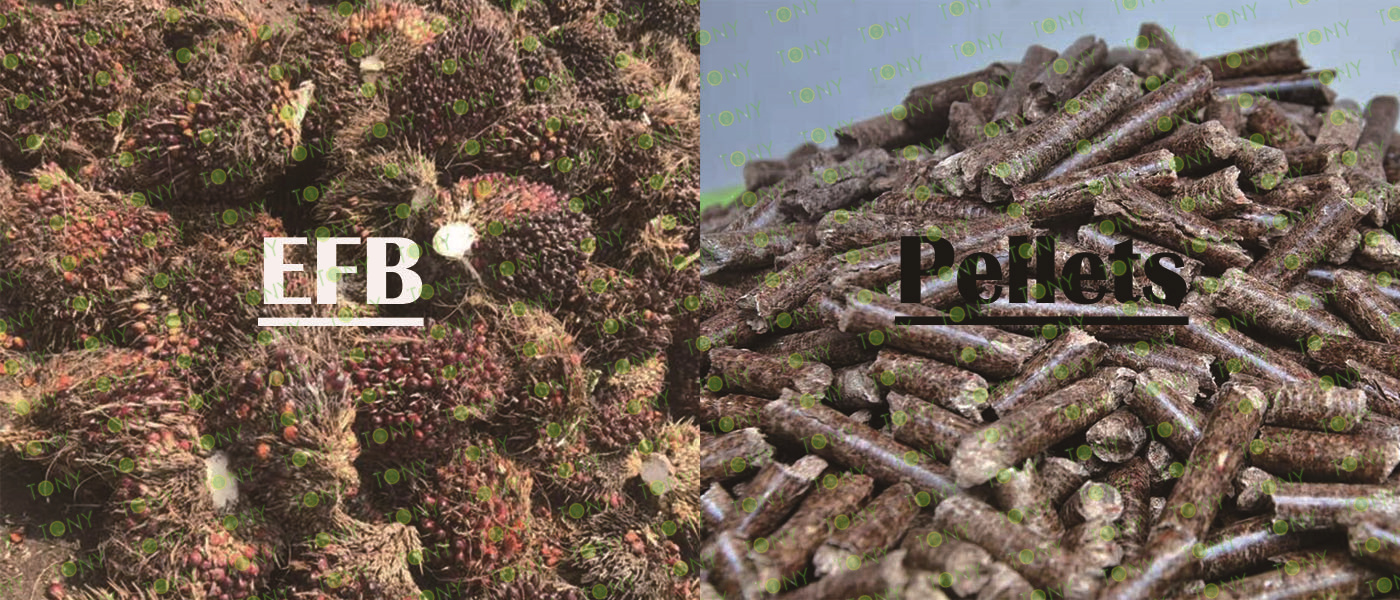

Since the EFB pellet machine was put on sale, it has received unanimous praise from industry insiders. However, some customers still don't know much about the small operation details of the EFB pellet machine equipment after purchasing it. Today, we will briefly introduce some little tips on how to improve the usage efficiency of the EFB pellet machine for you.

As we all know, biomass fuel made by biomass pellet machine uses solid waste biomass such as corn stalks, wheat straws, rice straws, peanut shells, corn cobs, cotton stalks, soybean stalks, rice husks, weeds, branches, leaves, sawdust, tree bark, EFB and other agricultural crops as raw materials. Through pretreatment and processing, it is solidified and formed into high-density pellet fuel, which is an ideal fuel to replace kerosene. It can not only save energy but also reduce emissions, bringing both economic and social benefits. It is an efficient and clean renewable energy source. However, if you want the EFB pellet machine to achieve your desired production efficiency during the usage process, you need to know more about the following aspects:

Feed the materials evenly. The advantage of this is that it can make the granulation of the pellet machine smoother and keep the machine running at a high speed.

Select the appropriate die hole diameter according to your own usage. Some users use a die hole diameter that is too small, often resulting in low output or even no output. It is hoped that when you purchase the pellet machine, you can carefully ask our factory's sales staff about what size of die hole diameter should be equipped.

Adjust the gap between the die and the pressure roller properly. Appropriate pressure can make the ripening degree and compactness of the pellets achieve very good results. There are pressure regulating screws on the biomass pellet machine. Adjust the pressure screws on both sides to be balanced and tighten them.

Keep the biomass pellet machine clean. Customers often don't pay attention to keeping the pellet machine clean during use, which will shorten the service life of the pellet machine. Therefore, pay attention to keeping the pellet machine clean. It is best to clean it regularly.

Keep the pellet machine lubricated regularly. Inject grease and add lubricants regularly. Clean the die regularly. Generally, injecting grease can improve the usage efficiency of the machine.

The above points are the little tips for improving the usage efficiency of the EFB pellet machine in production that we have summarized. Of course, if you encounter problems with the pellet machine during the actual production process of using the biomass pellet machine, there may be other reasons. This requires you to keep learning and master new technologies during the actual production process. Of course, you can also directly contact TONY to discuss various aspects of the biomass pellet machine.