TONY rotary drum dryer is a kind of mechanical equipment specially used for the treatment of wood chips, sawdust and other wood materials, its main purpose is to remove the moisture in these materials, in order to facilitate the subsequent processing and utilization. The following is a detailed introduction to the working principle and characteristics of the rotary drum dryer:

The Working Principle Of TONY Rotary Drum Dryer :

The working principle of the rotary drum dryer is mainly based on the way of heat transfer, by heating the air or other heat sources to evaporate the water in the material. Specifically, the wood chips enter the dryer drum, under the action of the dispersion and lifting device in the drum, the material is continuously separated into fine particles, and with the rotation of the drum continues to advance, and finally the wood chips after drying are discharged from the discharge port.

Drying process

Downstream drying: After the wood chips enter the drum part of the dryer, they will first be dried downstream. Under the action of the inner sheet, the wood chips continue to exchange heat and gradually remove water.

Counter-current drying: Subsequently, the wood chips enter the middle layer for counter-current drying to further complete the drying.

Boiling fluidization: The wood chips are fluidized in the drying cylinder, and the hot air is in full contact with the material to effectively complete the drying.

TONY Rotary Drum Dryer Features:

Automatic operation: The rotary drum dryer can realize automatic operation, easy and simple operation, stable operation of the equipment, low probability of failure.

Energy saving and environmental protection: In the process of drying and treating materials, the rotary drum dryer has good environmental protection performance and can minimize the air pollution of dust and other impurities.

Compact structure: The rotary drum dryer has perfect structure configuration, small footprint, easy to build and maintain.

High efficiency and energy saving: the thermal efficiency of the cylinder self-insulation is more than 70%, which significantly improves the thermal efficiency compared with the traditional single cylinder dryer.

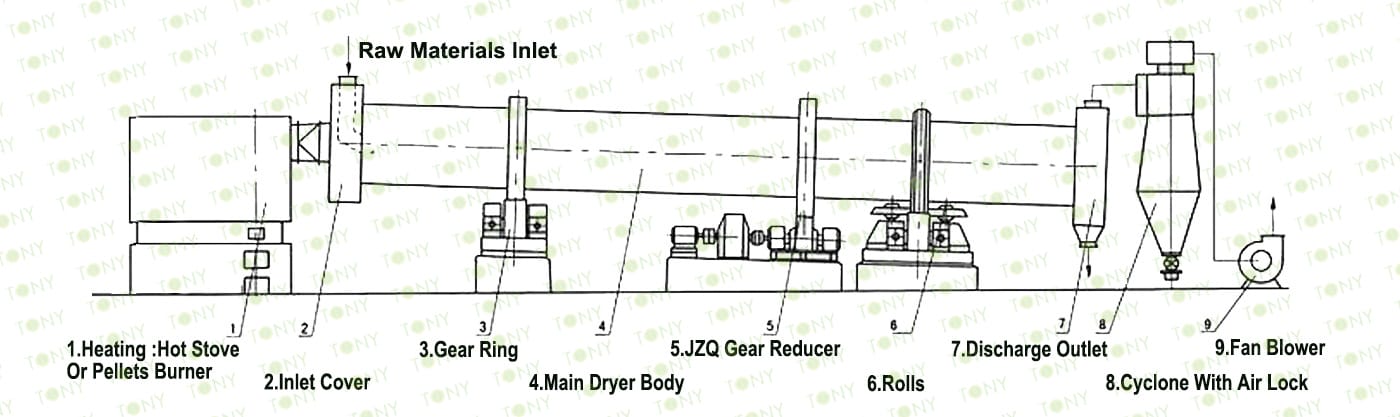

TONY Rotary Drum Dryer Components:

rotary drum dryer is mainly composed of feeding part, heating part, drying part, dust removal part, granulation part and packaging part. Each part works together to ensure a smooth drying process.

Maintenance And Maintenance Of TONY Rotary Drum Dryer

Installation requirements: The rotary drum dryer should be installed on a horizontal concrete foundation, fixed with foot bolts, and pay attention to the vertical between the main body and the level.

Daily inspection: Regularly check whether the bolts in each part are loose and whether the main engine door is fastened to keep the equipment in good condition.

Lubrication maintenance: Good lubrication has a great relationship with bearing life, and clean lubricating oil should be injected regularly.

In short, rotary drum dryer through its unique working principle and structural design, not only can effectively remove the moisture in wood chips, but also to ensure the environmental protection and efficiency of the drying process, is an indispensable important equipment in the modern wood processing industry.