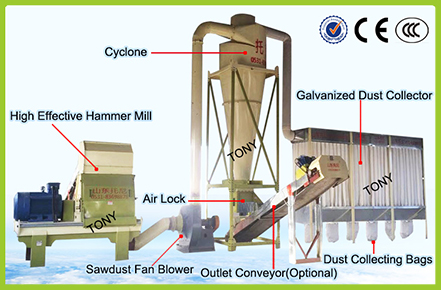

TFD series high-efficiency hammer mill is a pulverizer specially used for raw materials crushing in the biomass fuel production process. It has two series of single spindle and dual spindle, with features of high output and efficiency. It can crush wood chips, shavings, crop and plant crude fibers, roughage, etc.

TONY Effective Hammer Mil Advantages:

1.The shell adopts welded-steel plate construction, the main machine is embedded for seal, completely avoids dust spillover and maintains a clean work environment.

2.The motor and crusher are direct-connected driving with drum coupling and built-in rotors. Dead-zone free crushing and better uniform granularity.

3.Magnetic selector on the upper part can sort out magnetic metal materials and reduce machine's damage rate.

4.Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area. Wear-resisting material behind sieving slice has big wrapping angle. Hammer are independent designed with fasteners for easy assembly. The blades are enhanced for better wear-resistance and longer working life.

5. After balance calibration, rotors can work reversely.

6.Operating door has safety interlock equipment to make sure it can not be opened when the machine is running.

7.The blower's efficiency is maximized with faster pneumatic conveying and mini wind resistance. Arc side door ensures easy observation and replacement of the sieve, without disturbing wind and flying dust.

Spare Parts of Hammer Mill

1.Screen

The size specification of screen is screen diameter of 6mm-12mm, the thickness of more than 4mm.

2.Rotor Group

The motor and the hammers are directly connected by the coupling.

There is no dead angle during the crushing so the finished product is very fine.

The rotor has made the balance test and can work backward.

3.Hammer

The corners of the hammers are welded with high hardness material like carbon tungsten alloy.

The welding layer thickness is around 3mm. The lifetime is 7- 8 times by normal 65mm overall quenching hammer.

TONY Hammer Mill spare parts such as hammers and screen are made by our CNC systems, through high technical heat treatment, standing out from other suppliers is that we could ensure the parts high precision and good quality.

TONY efficiency hammer mill has received a wide range of welcome and reputation in the market with good use effects. If you are interested in our crushing machine, you can contact us