|

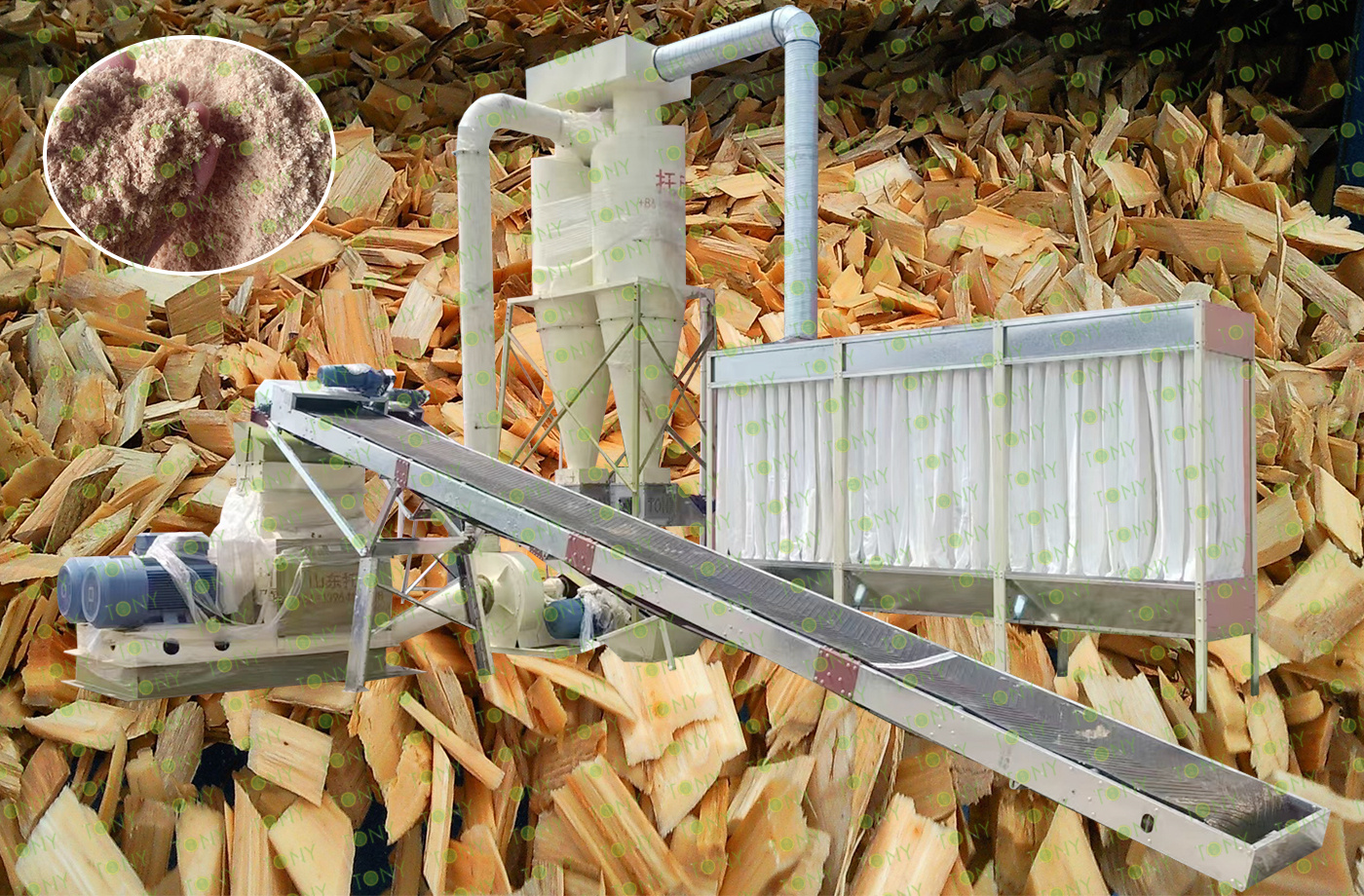

TONY TFS series Dual shaft high effective Hammer Mill machine is the most ideal grinding equipment for all kinds of wood pieces, wood shavings, grass, straw, stalk, corn, weeds, soybean and so on. it adopts water cooling structure inside, avoiding the damage to spare parts due to long time working friction .except biomass It also can crush animal feed materials such as soybean, maize, cereal and fertilizer materials from animal manure , chemical etc. which is mainly used in wood factory, fodder factory, cultivation factory, organic fertilizer factory, and so on. Besides,TONY Dual shaft high effective Hammer Mill have the characteristics of high efficiency, stability, easy movement, low noise, and low power consumption. In actual use, it is necessary to pay attention to safe operation, ensure that the equipment is in a safe state, and avoid continuous long-term use to prevent the bearing from overheating and damaging the motor. In addition, the equipment should be placed in a ventilated, dry, and clean location to ensure normal operation and a suitable environment. |

1. A complete set of crushers includes crusher mainframe, fan, cylone, fan-off, bag dust collector, etc.

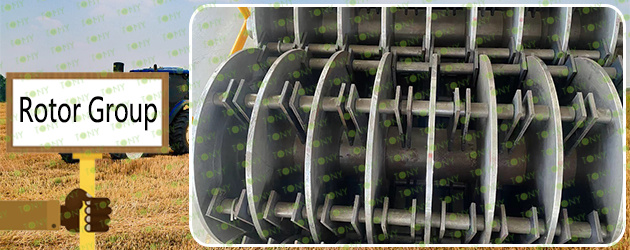

2. The main component of the crusher, the rotor, is dynamically balanced before assembly to ensure the stability of the machine during operation.

3. The base assembly platform of the crusher motor and the rotor main shaft bearing seat assembly platform are processed synchronously by large CNC machine tools at one time to ensure horizontal accuracy, thereby ensuring the smooth operation of the machine.

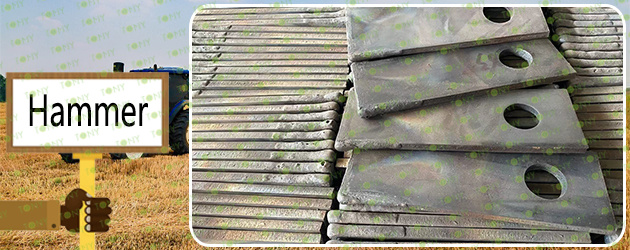

4. The hammer of the crusher's vulnerable parts is made of manganese steel, of which two corners are welded with wear-resistant alloy materials, which increases the service life of the hammer and reduces costs.

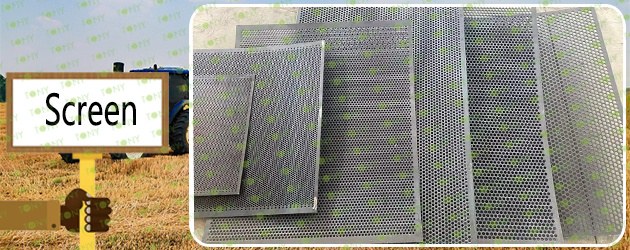

5. The operating doors on both sides of the crusher can be opened horizontally for easy maintenance and replacement of the screen.

6. The crusher screen consists of two pieces. After installation, the overall discharge angle is close to 360 degrees, the discharge area is large, and the production efficiency is high.

7. The crusher can be equipped with two shackles according to customer requirements. This installation method allows the dust-containing gas to pass through the secondary shackle filter and enter the bag filter, making the filtration more complete.

8. Our crushers have different models with different outputs. The output of a single machine ranges from 1 ton to 8 tons, which can meet a variety of needs.

9. The main factor affecting the crushing efficiency of the crusher is the moisture content of the material. The drier the material, the smaller the size of the finished product.

|

Raw material is placed into the feeding hopper, which leads to the hammer chamber where the material enters from the top and is beaten and crushed (hammered) by high speed rotating blades. Under centrifugal force the material is processed quickly due to continuous squeezing, crushing, and beating, by the hammer mill blades. Under rotor centrifugal force, fan suction force, and gravity crushed material and air is discharged through the holes in the 180 degree screen on the bottom while those that cannot get through will repeat the process until they are small enough to pass through the screen into the lower body of the hammer mill. The double-shaft high-efficiency pulverizer is designed based on the principle of mixed powder spraying. It is suitable for the pharmaceutical, food, chemical and other industries for pulverizing raw materials, auxiliary materials and granular materials. |

| Item | Function |

| Dual Shaft Hammer Mill | To crush the materials into 3-5mm sawdust |

| Blower | To help transport the sawdust into dryer |

| Cyclone | To discharge the materials and collect the dust |

| Air-Lock | To prvent the outside air from entering inside |

| Galvanized Dust Collector | To collect the dust while in the production |

The complete crusher system includes the crusher main unit, blower, fan, air lock, bag dust collector, belt conveyor pipe, electrical control cabinet and more.

|

Feed Belt Conveyor: 1. Continuously and evenly feeds materials into the crusher at a stable conveying speed. 2. The belt's elasticity and the roller's cushioning design reduce direct wear on the crusher's feed port and hammers. 3. Variable frequency speed regulation enables automated feed adjustment. 4. Belt width and dimensions can be customized according to actual production needs. 5. Made of galvanized material, the TONY conveyor is more corrosion-resistant and extends the life of the belt conveyor. |

|

Dual Shaft Hammer Mill: 1.The double-shaft high-efficiency crusher adopts a double-shaft rotating blade design, which can quickly crush larger items into small pieces, improving the crushing efficiency. 2. Widely applicable: This crusher is suitable for various types of waste items, such as metal, plastic, wood, etc., and has a wide range of applications. 3.Environmental protection and energy saving: The double-shaft high-efficiency crusher adopts a closed design, which reduces dust and noise pollution, while having low operating costs and energy saving and environmental protection. |

|

|

Blower 1.The blower on the Dual Shaft hammer mill discharges the dust generated during the industrial production process from the working area through strong suction, effectively reducing the concentration of dust in the air, thereby improving the working environment. 2. Its high efficiency is not only reflected in its strong suction, but also in its innovation and optimization in design, such as the use of high-efficiency blades, intelligent adjustment systems, etc., to ensure that the dust removal effect is guaranteed while achieving the purpose of energy saving and consumption reduction. |

|

Cyclone 1.The main purpose of the Cyclone in the high-efficiency hammer mill is to separate and collect gas and solids, especially when processing materials containing a large amount of dust, it can effectively reduce dust emissions and improve the working environment. 2.Cyclone dust collector, also known as cyclone separator, is widely used in industrial production such as food and medicine, and is particularly suitable for processing materials with coarse dust particles and high dust concentration. |

|

|

Air-Lock 1.To prvent the outside air from entering inside 2.The main purpose of the air lock on the high-efficiency pulverizer is to reduce dust, improve the working environment, and provide a stable unloading function. The air lock is usually installed under the shackle at the rear end of the pulverizer to minimize dust during the working process. 3.TONY manufacture it by factory to guarantee the quality. 4.You can confirm with TONY for spare parts price. |

|

Galvanized Dust Collector 1.High-efficiency filtration: The dust bag uses high-efficiency filtration materials, which can effectively capture and filter various dust particles. 2.Energy saving and environmental protection: The dust collector avoids secondary dust pollution by regularly removing dust accumulation, while reducing energy consumption and operating costs, and has good energy-saving and environmental protection effects. 3.Small footprint, stable operation, easy maintenance 4.TONY's galvanized material effectively prevents corrosion and extends its service life. |

|

|

Pipe 1. When a hammer mill is operating, raw materials enter the milling chamber and are impacted and crushed by the high-speed rotating hammers, generating a large amount of dust. 2. Negative pressure airflow captures dust at the dust-generating point and transports it to the dust collector. 3. Preventing Dust from Spreading into the Workshop, Maintaining a Clean Production Environment and Protecting Operator Health. 4. Reducing Dust-Induced Wear on Equipment (e.g., Overheating of Motors and Bearings Caused by Dust Accumulation). |

|

Electrical Control Cabinet 1. The electronic control system controls the mill's start and stop, monitors operating status, and provides fault protection. 2. Power Control: Starts and stops the main motor (the mill's core power source) and auxiliary motors (e.g., the feed conveyor and dust removal fan). 3. Protection: Automatically shuts off power and issues an alarm when an abnormality such as overload, short circuit, phase loss, or bearing overheating occurs, preventing equipment damage (e.g., motor burnout, hammer jamming, and shaft breakage). 4. Status Monitoring: Real-time information such as motor current, operating time, and fault codes is displayed on a meter or display, allowing operators to easily understand equipment status. |

|

|

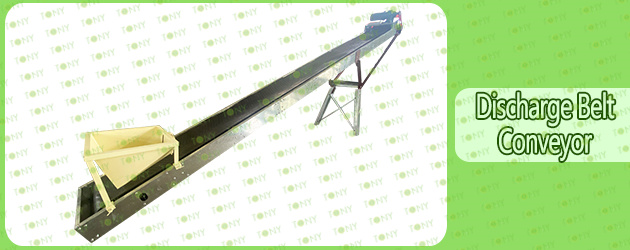

Discharge Belt Conveyor: 1. Continuously conveys crushed materials from the crusher discharge port to the next stage. 2. Prevents material accumulation and blockage at the discharge port, ensuring continuous and efficient crusher operation. 3. Equipped with variable frequency speed regulation, the conveyor speed can be adjusted based on the processing capacity of subsequent processes. 4. The belt width and size are customized according to actual production needs. 5. Tony uses galvanized material for greater corrosion resistance, extending the life of the belt conveyor. |

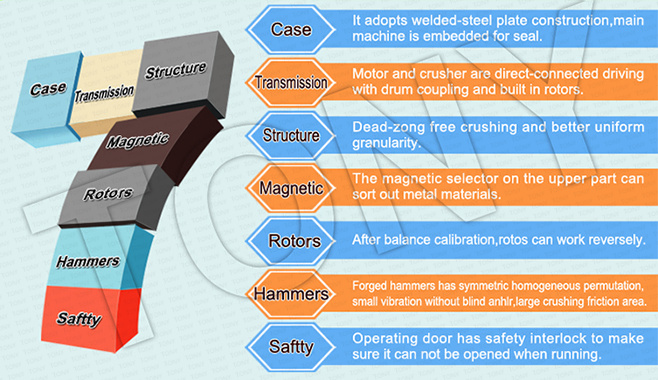

1). The shell adopts welded-steel plate construction, the main machine is embedded for seal, completely avoids dust spillover and maintains a clean work environment.

2). The motor and crusher are direct-connected driving with drum coupling and built-in rotors. Dead-zone free crushing and better uniform granularity.

3).The magnetic selector on the upper part can sort out the magnetic metal materials and reduce the machine's damage rate.

4).Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area. Wear-resisting material behind sieving slice has big wrapping angle. Hammer are independent designed with fasteners for easy assembly. The blades are enhanced for better wear-resistance and longer working life.

5).After balance calibration, rotors can work reversely.

6).The operating door has safety interlock equipment to make sure it can not be opened when the machine is running.

7).The blower's efficiency is maximized with faster pneumatic conveying and minimum wind resistance. Arc side door ensures easy observation and replacement of the sieve, without disturbing wind and flying dust.

|

TONY Dual Shaft Hammer Mill Type Models |

||||||

|

Brand |

Model |

Power(kw) |

Capacity(T/H) |

Hammer QTY |

Size:L*W*H(MM) |

Weight(T) |

|

TONY |

TFS65*75 |

55*2-75*2 |

4-5 |

144 |

3000*1900*1700 |

6.5 |

|

TONY |

TFS65*100 |

90*2-110*2 |

5-7 |

192 |

3500*2900*1700 |

7.8 |

|

Screener 1. The bottom diameter of screen is 6mm-12mm, thickness is greater than 4mm. 2. The screen is easy to install and disassemble, with high screening efficiency and convenient cleaning. 3. TONY manufacture it by factory to guarantee the quality. 4. You can confirm with TONY for spare parts price. |

|

Rotor Group 1. The motor and the hammers are directly connected by the coupling. 2. There is no dead angle during the crushing so the finished product is very fine. 3. The rotor has made the balance test and can work backward. 4. TONY manufacture it by factory to guarantee the quality. 5. You can confirm with TONY for spare parts price. |

|

|

Hammer 1. The corners of the hammers are welded with high hardness material like carbon tungsten alloy. 2. The welding layer thickness is around 3mm. 3. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer. 4. TONY manufacture it by factory to guarantee the quality. 5. You can confirm with TONY for spare parts price. |

|

The main application areas of high-efficiency hammer mill include: 1. Agriculture And Forestry: Processing of crop straw, branches, roots and other wastes, and converting them into biomass energy, organic fertilizer or feed. 2. Minerals And Metallurgy: Key equipment in ore crushing, screening and mineral processing to improve mineral processing efficiency and resource recovery rate. 3. Chemical And Building Materials: Pretreatment of raw materials and product processing, such as the production of plastics, rubber, ceramics and other materials. 4. Environmental Protection And Waste Treatment: Treatment and resource recovery of urban garbage and industrial waste to reduce environmental pollution. 5. Food And Feed Processing: Crushing agricultural products such as corn, wheat, straw, etc. into particles or powder to make feed or food raw materials. |

Soil Preparation And Improvement:

Nutritional Soil: Sawdust is mixed with human feces and urine for fermentation, and then mixed with soil in half and half. It can be used as potting soil for cultivating flowers and trees, making them grow luxuriantly.

Soilless cultivation: Sawdust after fermentation and decay has comprehensive nutrition and loose texture. It is a simple soilless cultivation material, especially suitable for potted asparagus fern, orchids, etc.

Soil Conditioner: Sawdust is rich in organic matter, which can improve soil structure, maintain soil moisture, and increase soil fertility and crop yield.

Biomass Energy: Sawdust can be used as a biomass fuel for power generation, heating and heating. After being compressed into granules or made into charcoal, it is a clean and renewable alternative energy source.

Animal Feed: Sawdust can be used as part of animal feed to provide certain nutrition for poultry, cattle, sheep, etc.

Other Industrial Uses:

Wood Products: Sawdust can be used to make wood boards and artificial boards, such as particleboard, fiberboard and plywood. Packaging materials: Sawdust can be used for packaging materials, such as filling materials, cushioning materials, and protective materials.

Wooden Crafts: Sawdust can be used to make some wooden crafts, such as paper pulp sculptures, wood chip paintings, etc.

Life And Environmental Protection:

Plant Warmth: In winter, sawdust can be used to keep plant roots warm and prevent plants from freezing.

Absorb Spills: Sawdust is highly absorbent and can be used to absorb spilled oil or paint.

Cleaning Floors: Wet sawdust can be used to clean concrete floors, capturing and absorbing fine dust and dirt.

Special Uses:

Making Fake Snow: Sawdust mixed with white paint and glue can be used to make fake snow covered holiday crafts.

Ground Control: Sawdust can be spread on truck paths in winter to provide traction and protect the ground.

Weed Control: Walnut sawdust can be used as a natural herbicide.

These uses of sawdust reflect its wide application and importance in many fields such as agriculture, industry, life and environmental protection.

|

1. It is used for grinding raw materials by large and medium livestock and aqua feed mills. It can also be used for grass and pharmacy fine grinding. The granular raw materials, such as corn, sorghum, wheat, beans, etc can be grinded; 2. It is derived from tear circle type hammer mill and efficiency can be improved by 45%-90% comparing to universal hammer mill; 3. It can produce qualified aqua feed under full load with 0.8\1 screen and reduce jam significantly. Both coarse and fine grinding can be realized without changing screens; 4. The right aspiration can make materials go through screen quickly, reduce temperature of grinding chamber and increase output effectively. 5.TONY's dual-shaft high-efficiency pulverizer adopts an automatic control system with overload protection and emergency stop functions to ensure safe and reliable operation. |

Q: What is a Hammer Mill?

A: A Hammer Mill is a machine that pulverizes wood chips, shavings, grains and plant fibers into sawdust.

What is raw material?

Stalk, wood chips, nut shell, straw, rice husk, banboo chips, paper, leaves, waste wood, agriculture waste, wood shavings, sawdust

Q: What is the usage?

Hammer mill is widely used in fodder factories, cultivation factories, and organic fertilizer factories. It can be used in producing Chinese medicine, chemical industry and in other areas.

Q: What is your main market?

A: South America, Eastern Europe, Southeast Asia, Africa, Oceania, Eastern Asia

Q: What is your producing time?

A: Producing time depends on that machines you ordered. Usually takes 45 days.

Q: If equipments have some quality problem, how would you deal with?

A: We will responsible for all the quality problems. We will check the machine to get the problem. If need parts, will send them to you.Q. what is your payment term?

A: T/T 40% down payment, balance to be paid before shipment.

2025 Tony Machinery - All Rights Reserved. Map