TONY Design 5-6Ton/Hour Hazelnut Husk Pellet Production Line Specification

Global Distribution Of Hazelnut Husk Resources

As an important natural resource, hazelnut husks are not only widely used in food processing, but also have great potential in the field of environmental protection and energy. Here are some key information about the global distribution of hazelnut husk resources:

Geographical Distribution

1. Turkey

Turkey is the world's largest producer of hazelnuts, providing two-thirds of the global total. Due to its abundant sunshine and abundant rain, Turkey produces hazelnuts that are full and of good quality. This makes Turkey also an important country in terms of hazelnut husk resources.

2. China

Hazelnut is also an important producer of hazelnut in China, where hazelnut plants can be found in many provinces and regions, especially in Northeast China, Shanxi, Inner Mongolia, Shandong and Henan. China is rich in hazelnut husk resources, but because the market demand is more dependent on imports, the domestic hazelnut husk resources may be mainly used for local processing and research.

3. Other Countries

In addition to Turkey and China, Italy, Spain and the United States are also major hazelnut producers. These countries are also rich in hazelnut husk resources and occupy an important share in the global hazelnut husk resources.

1. Application Field

Hazelnut husks are used as biomass pellet fuel, which is suitable for boiler combustion, factory, bathroom, hotel aluminum melting, galvanized, printing and dyeing, heating and other occasions. Its high cellulose content (about 70%) and low sulfur content make it an environmentally friendly and efficient fuel choice.

2. Environmental Protection Advantages

Hazelnut husk biomass pellets and materials not only have a wide range of applications, but are also favored for their environmental properties. Its combustion products are low, low pollution, is a high-quality renewable energy, help to reduce the dependence on fossil fuels and environmental pollution.

As a renewable, sustainable and clean energy source, hazelnut husks have shown great application potential and environmental protection value in many fields.

1.Feasibility Of Hazelnut Husk Making Biomass Pellets

As a biomass raw material, hazelnut husk can be transformed into biomass pellet fuel with high utilization value by grinding, drying, granulation and other processes. Hazelnut husk pellets, with the advantages of environmental protection and renewable energy.

2.Application Prospect Of Hazelnut Husk Making Biomass Granule

Large Farm Livestock Feed: Easy to store and transport, rich in nutrition.

Civil Heating And Living Energy: Clean, pollution-free, suitable for family use.

Industrial Boiler And Kiln Fuels: Replace coal and gas, reduce environmental pollution.

Fuel For Gasification And Thermal Power Generation: Solve the problem of shutting down small thermal power plants and promote the adjustment of energy structure.

Through the analysis of the above steps and application prospects, it can be seen that hazelnut husk biomass pellets not only have the advantages of environmental protection and renewable energy, but also have a wide range of market application value.

In recent years, hazelnuts, walnuts and other nut food because of health and delicious, by the majority of consumers love. The planting yield is also increasing year by year, and the proportion of the total fruit weight accounted for by the husk is large, which theoretically generates a large amount of nut husk waste every year. Nut husk mechanical strength is high, more acid and alkali resistance, random discard non-perishable nut husk, will form solid waste pollution. At present, many nut fruits are gradually processed and utilized, and a large number of concentrated fruit husks are discarded or burned, resulting in a great waste of resources and environmental pollution.

With the development of social economy, the problem of environmental deterioration is becoming more and more serious, and low-carbon economy has become a widely concerned topic. At the same time, the development of environmental protection and sustainable low-carbon economy is the only way for the development of human beings who are deeply affected by global warming. With the rise of energy prices and the state's attention to the agricultural ecological environment and air quality, the scale and commercialization degree of China's biomass molding fuel industry has increased year by year, and the market has developed rapidly. Vigorously develop the biomass molding fuel industry, the utilization of agricultural and forestry waste energy, can improve the ecological environment, improve the quality of life of farmers, expand the economic added value of crops. The existing biomass fuel can not meet the conditions of blast furnace or high calorific value demand, and there are problems such as point failure, long ignition time and flue gas pollution when used in small cooking stoves, and the combustion efficiency is low, so it needs to be modified to obtain high calorific value and high combustion efficiency of environmental protection biomass pellet fuel.

Hazelnut husk is a natural biomass material, a wide range of sources and renewable, its production and use process does not produce a lot of greenhouse gases and pollutants, in line with environmental requirements, help to reduce carbon emissions, more friendly to the environment. Converting hazelnut husks, which would otherwise be considered waste, into useful pellet products reduces the need for landfills and incineration, reducing the negative impact on the environment.

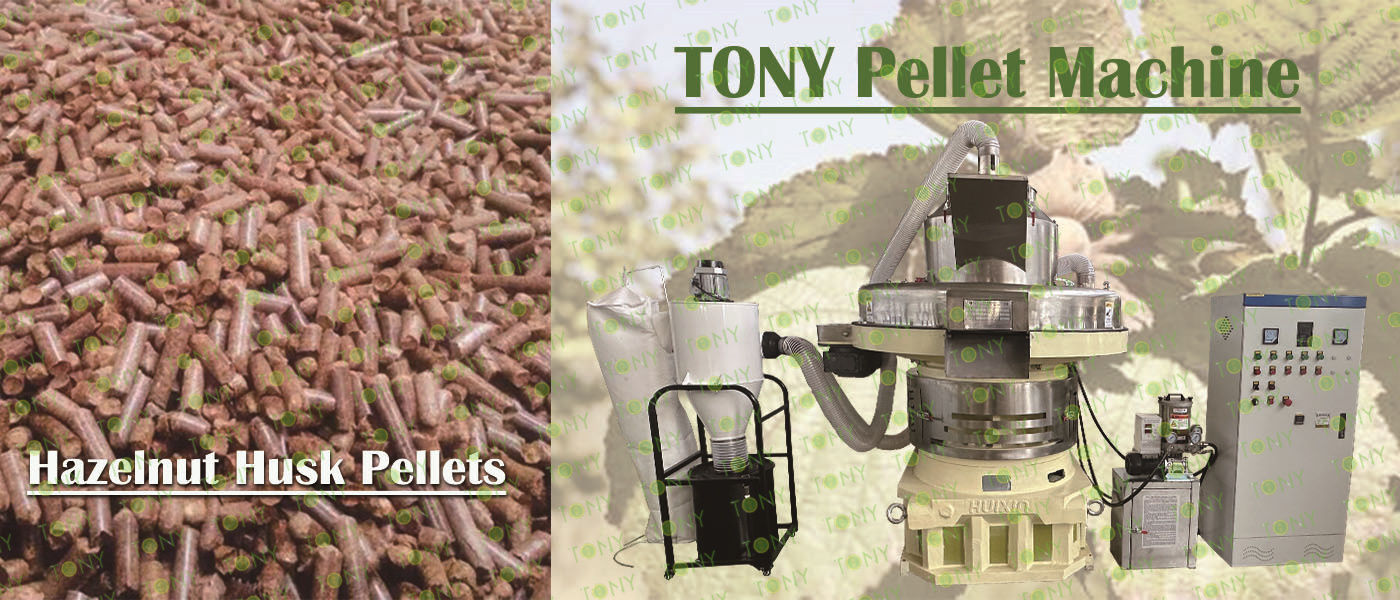

Biomass Pellet Machine is a professional equipment for the treatment of biomass fuel. After the hazelnut husk is compressed and formed, its volume is greatly reduced to make it easier to transport, storage and use, which solves the key problem of large-scale utilization of biomass, so the technology and equipment are very suitable for biomass power generation, clean energy transformation of industrial boilers, and new cooking fuels in rural areas.

During the investment process, some users will worry about the economic efficiency of the fuel raw material. Let's take a look at the economic benefits of pellet fuel machined by biomass pellets.

In the international market, the use, research and development of biomass pellet machine is earlier. At present, biomass curing molding fuel has been commercialized in Japan, the European Union, the United States and other regions, and is very popular and convenient, and can be purchased in supermarkets.

The exhaust gas emissions from the combustion of hazelnut husk particles CO2 emissions are close to zero. NO2 emission is 14mg/m3. SO2 and soot emissions are far below the standard. Therefore, biomass pellet machined biomass fuel has important environmental protection significance and energy saving significance, which lays a foundation for its market application.

At present, hazelnuts are planted in large quantities because of the popularity of users, followed by a large number of hazelnut husk resources are abandoned, the choice of hazelnut husk biomass particles, the first is to save the cost of raw materials, basically, the investment can be restored within a year, the economic benefits are very significant.

The biomass fuel processed by biomass pellet machining not only has the significance of environmental protection and energy saving, but also has good economic benefits, and therefore will be promoted.

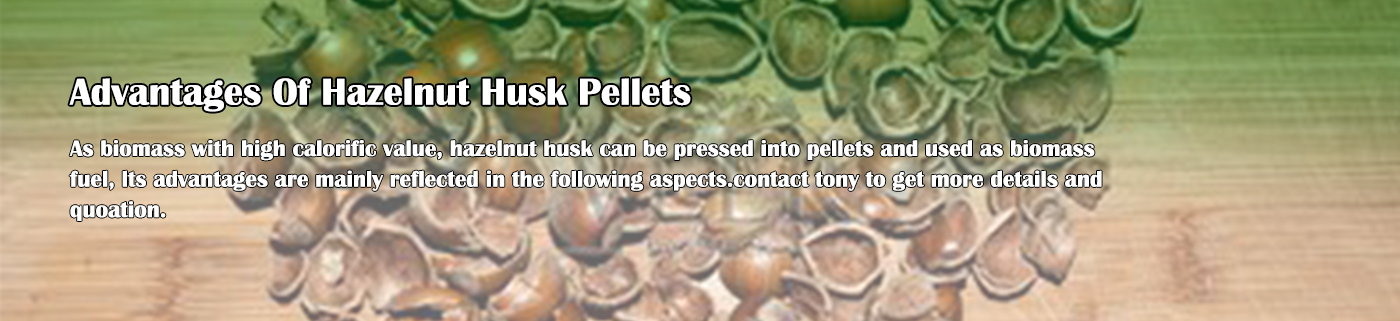

Energy:

High Calorific Value: Hazelnut husk contains a certain amount of oil and other combustible components, so that the made particles have a high calorific value, when burning can release more energy, can be used as high-quality biomass fuel, used to replace coal, wood and other traditional fuels, reduce the dependence on non-renewable energy.

High Combustion Efficiency: The structure of hazelnut husk particles is more uniform, and it can fully contact with oxygen during combustion, burning more fully, improving combustion efficiency and reducing energy waste.

Environmental Protection:

Renewable: Hazelnut husk is a natural biomass material, a wide range of sources and renewable, its production and use process does not produce a lot of greenhouse gases and pollutants, in line with environmental requirements, help reduce carbon emissions, more friendly to the environment.

Waste Utilization: Converting hazelnut husks, which would otherwise be considered waste, into useful granular products reduces the need for landfill and incineration and reduces the negative impact on the environment.

Economic Aspects:

Low Cost: As a by-product of hazelnut processing, hazelnut husks are rich in sources and low in price, and the cost of making them into pellets is relatively low and has high economic value.

Large Market Demand: As people's attention to environmental protection and renewable energy continues to increase, the demand for biomass pellet fuel and other products is also increasing, hazelnut husk particles have broad market prospects, can bring good economic benefits for enterprises.

Widely Used:

The main use of hazelnut husk particles can be used for home heating, industrial boilers, power plants and other places. The heat generated by its combustion can be used for heating, power generation, drying and other processes.

Development prospect analysis of hazelnut husk biomass pellet fuel:

Hazelnut husk biomass pellet fuel is a solid fuel compressed from hazelnut shell, which is an ideal alternative to fossil fuels due to its renewability and low carbon emissions.

1. Development Status

Technological advances: In recent years, advances in efficient compression and drying technologies, as well as the standardization of biomass energy, have improved the combustion efficiency and stability of biomass pellet fuel, making it widely used in home heating, industrial boilers and power plants

2. Market Demand:

With global concerns about climate change and the increasing need for energy diversification, the market for biomass pellet fuels is expanding rapidly.

3. Policy Support And Future Prospects

National Policy: The global government attaches great importance to the development of biomass energy, through the formulation of a series of policies to encourage the research and application of biomass energy, such as household biogas digester, wood saving stove, firewood forest, large and medium-sized biogas projects, etc., has achieved a number of excellent results.

Future Development Trend: It is expected that the biomass pellet fuel industry will maintain rapid growth in the next few years, with an average annual growth rate of more than a certain percentage.

1.The Working Principle Of Hazelnut Husk Biomass Pellet Processing Equipment

Hazelnut husk biomass pellet processing equipment is the hazelnut husk and other biomass raw materials crushing, drying, and finally compressed into granular fuel processing equipment, hazelnut husk can not directly press the particles, the need to crush the hazelnut husk into sawdust, moisture drying to 10-15%, so as to meet the conditions of the granulator, and finally made of hazelnut husk particles compact structure, good gloss, not easy to break.

2.Characteristics Of Hazelnut Husk Biomass Pellet Processing Equipment

(1) Hazelnut husk biomass pellet processing equipment has the characteristics of high efficiency and low energy consumption, which can rapidly process biomass raw materials into fuel pellets, improving production efficiency.

(2) Biomass pellet machine has a variety of specifications of the mold, according to different biomass raw materials to choose the corresponding mold for processing, improve the adaptability of processing.

(3) The processing equipment of biomass pellets has the characteristics of high automation and good safety, effectively reducing labor intensity and improving production efficiency.

(4) The quality and specifications of pellet biomass fuel processed by hazelnut husk biomass pellet processing equipment are stable and meet the requirements of production standards.

3.Application Scenarios Of Hazelnut Husk Biomass Pellet Processing Equipment.

(1) Civil Heating And Domestic Energy: Biomass particles are often used as heating and living energy for homes, apartments and other civil buildings because of their clean and pollution-free characteristics. It can not only replace traditional coal and firewood, but also serve as a reliable backup energy source.

(2) Industrial Boiler And Kiln Fuel: In the industrial field, biomass pellets can replace coal and gas and be used in industrial boilers and kilns to reduce environmental pollution and reduce operating costs. It is especially suitable for those industries that require a lot of heat energy, such as textiles, paper, and food processing.

(3) Power Generation: Biomass particles can be used as fuel for gasification power generation and thermal power generation, which provides a feasible solution to the shutdown problem of small thermal power plants. In addition, biomass pellet power generation is also a renewable energy utilization mode, which helps to adjust the energy structure and reduce dependence on fossil fuels.

(4) Feed For Livestock In Large Farms: Some types of biomass pellets are suitable for animal feed and can be used as part of poultry and livestock feed to provide energy and nutrition.

In summary, biomass particles are a multi-functional form of renewable energy, its application is not limited to the field of energy, but also involves agriculture, industry and environmental protection and other aspects. With the advancement of technology and the promotion of environmental awareness, the potential use of biomass particles will continue to expand.

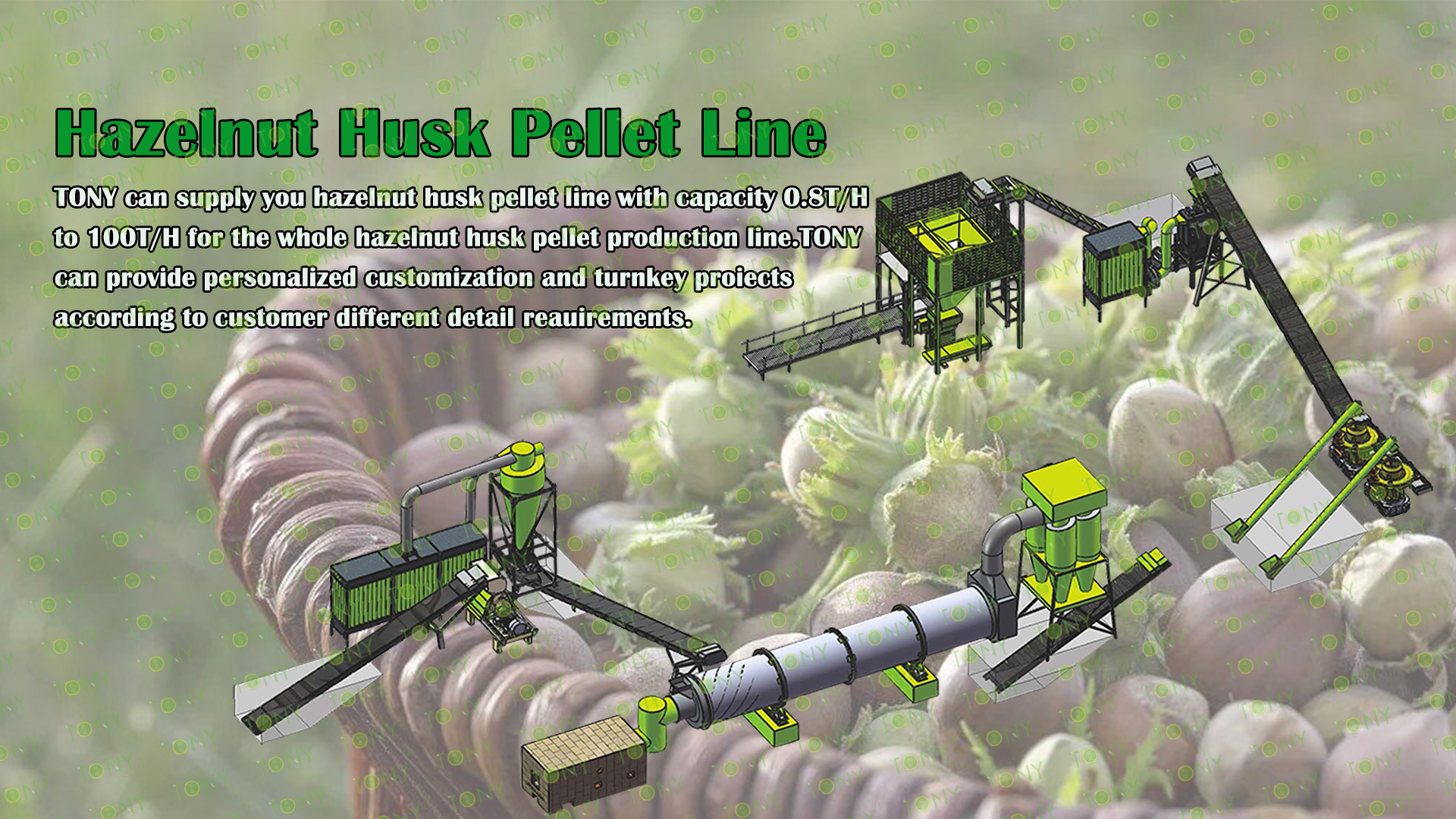

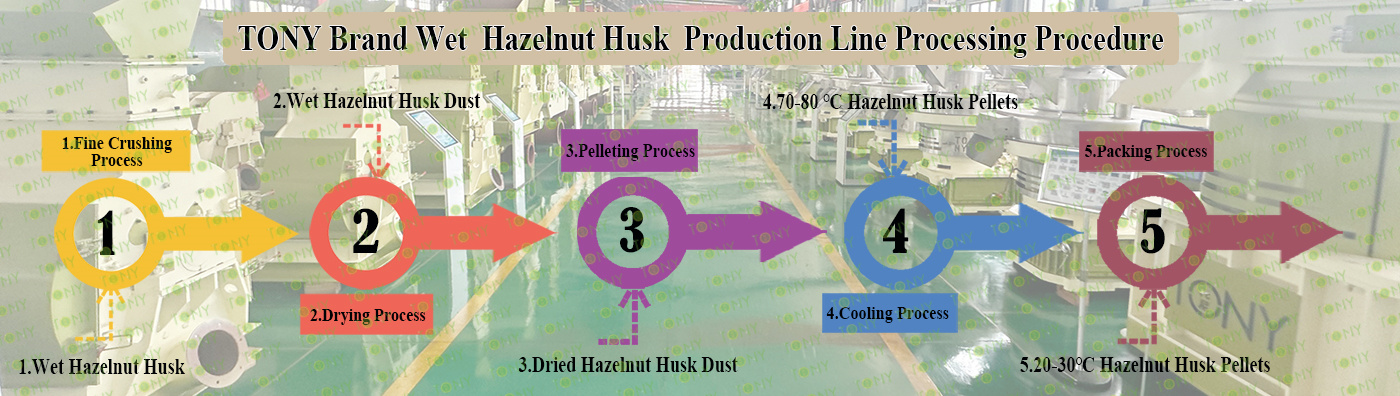

1.Project Name: Hazelnut Husk Pellet Line

2.Raw Materisl: Hazelnut Husk

3.Moisture Of Raw Material: Wet Type 40-55%

4.Capacity: 5-6Ton/Hour

5.Process: Fine Crushing Process→Drying Process→Pelleting Process→CoolingProcess→Packing Process

6.Main Machine: Hammer Mill,Rotary Drum Dryer,TONY Pellet MachineTYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

7.Total Power: About 695KW

8.Need Area: About 700-900㎡

9.Project Country: Turkey

10.Voltage: 220V,50HZ

1.Capacity: 5-6 Ton/Hour

2.Raw materials: Hazelnut husk, Peanut shell, Rice shell, Walnut core etc.

3.Moisture: Wet type ,about 40-55%.

4.Application: All kinds of husk.

Suitable customers: Green energy companies, large farms, private growers and other customers with advantages in raw materials.

5.Finished Pellets Markets: Large power plants (domestic customers, as well as Japan and South Korea, mainly South Korea more), domestic heating, industrial heating, combustion heat, heating heating, boiler room, school canteen, foundry heat source.

|

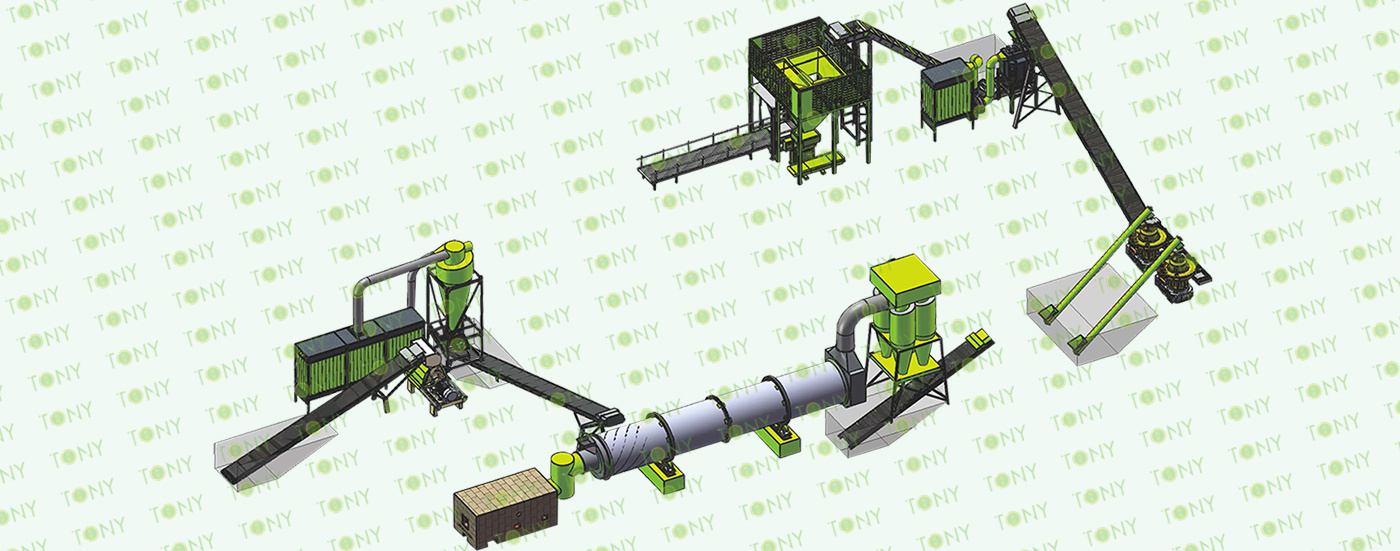

Project Brief Introduction: 1.Product: Hazelnut Husk Pellet Line. 2.Capacity: 5-6T/Hour 3.TONY Brand 5-6Ton/Hour Hazelnut Husk Pellet Line Project Process 4.Main Machine: Hammer Mill,Rotary Drum Dryer,TONY Pellet MachineTYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors Packing Machine And Belt Conveyors. 5.Total Power: About 695KW 6.Need Area: About 700-900㎡ 7.Country: Turkey |

Project Layout For Customer |

|

|

|

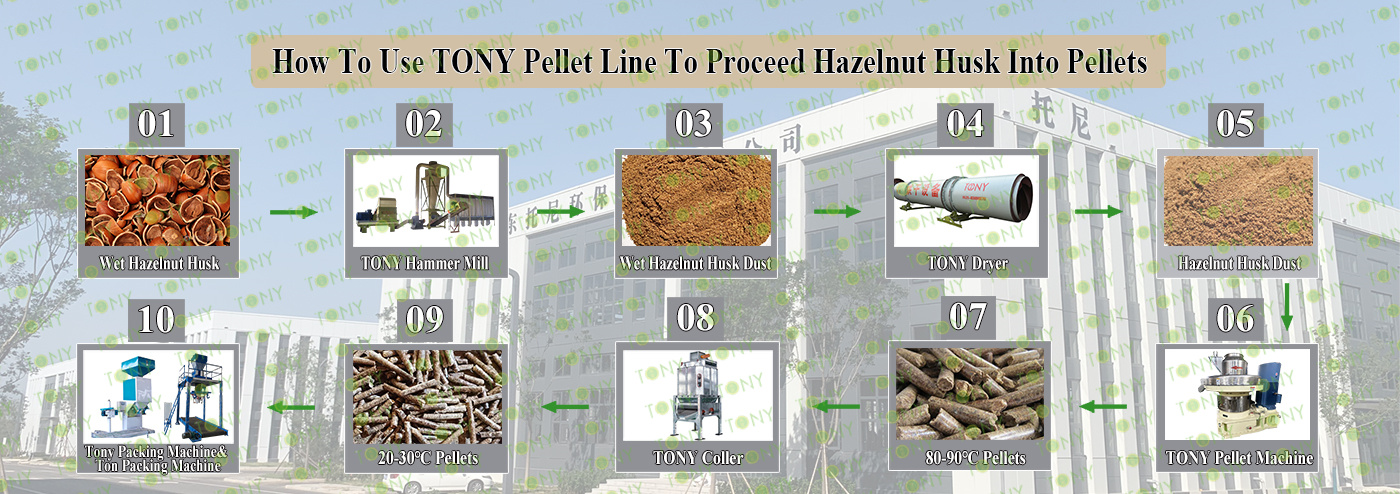

How to use TONY pellet line to proceed from Hazelnut Husk into pellets? How to use TONY pellet line to proceed from Hazelnut Husk into pellets? It mainly contains the following steps and machines as following: 1.To Use TONY Hammer Mill To Crush Hazelnut Husk Into 8-14mm Hazelnut Husk Dust. 2.To Use TONY Rotary Drum Dryer To Dry The 40-55% Hazelnut Husk Dust Into 10-15% Hazelnut Husk Dust 3.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm. 4.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ To 20-30℃. 5.To Use TONY Simple Cooling Bin To Store Cooled Hazelnut Husk Pellets 7.(1)To Use TONY Semi-Auto Packing Machine To Packing Pellets To 15-50Kg/Bags. (2)To Use TONY Ton Packing Machine To Packing Pellets To 1Ton/Bag You Can Contact TONY To Get For More Details Information And Quotation. TONY Can Supply You All The Products As Above With Competitive Price And Excellent Quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some machines can be custom made by customer according to different customer's detailed demand.Contact TONY for more details with quotation and layout.

|

|

|

|

|

High Efficient Hammer Mill |

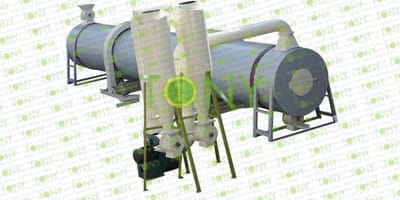

Rotary Drum Dryer |

Vertical Ring Die Pellet Machine |

Galvanised Cooler Separator |

|

1.Crush Hazelnut Husk Into 8-14mm Hazelnut Husk Dust. 2.Model: TFD75-160 3.Capacity:5-6.5Ton/Hour/Set |

1.To Dry The 45-55% Hazelnut Husk Dust Into 10-15% Hazelnut Husk Dust. 2.Model: THGD2*24 3.Capacity: 5-6Ton/Hour/Set |

1.Model:TYJ760-Ⅲ-160KW*2 Sets 2.Capacity:2.5-3Ton/Hour/Set 3.New 304SS Type |

1.To Cool Pellets From 80-90℃ to 20-30℃ 2.Model:TLN 3.Capacity:5-6Ton/Hour |

| 图5 | 图6 | 图7 | 图8 |

|

|

|

|

|

1.To Store The Cooled Hazelnut Husk Pellets 2.Model:TJLN-100 3.Capacity:100m³ |

1.Packing Pellets To 15-50KG/Bags 2.Model:TBF-50 3.Capacity:5-6Ton/Hour |

1.Packing Pellets To 1Ton/Bag 2.Model:TBD 3.Capacity:5-6Ton/Hour |

1.Transport Hazelnut Husk,Hazelnut Husk Dust,Pellets 2.Width:60cm*7 Sets 3.Capacity:Designed With The Whole Line |

|

1.Fine Crushing Process: A.The process is mainly used to crush hazelnut husk into 8-14mm hazelnut husk dust. B.Capacity:5-6.5 tons/hour. C.TONY uses high efficiency hammer mill TFD75-160-160KW-1Set. Main parts: (1) TONY High Effective Hammer Mill. (2) 90 Hole Galvanized Dust Collector. (3) Sawdust Conveying Fan. (4) Cyclone With Airlock. (5) Electrical Cabinet. |

|

2.Wet Hazelnut Husk Dust Drying Process: A.This process is mainly used to dry the hazelnut husk dust from 55% to 10-15%. B.Capacity: 4-5Ton/Hour. C.TONY use 1 sets of 2*24m single layer rotary drum dryer for this process,this customer use biomass waste wood as buring raw material with hot stove 5.8*2*2m. TONY hot blast stove is made of firebrick pan, husk with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer. TONY Dryer use spiral tube material, which has higher heart rate and is not easy to deform. Unlike other manufacturers with iron plate splicing welding, very easy to deformation. Main Parts: (1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.) (2)TONY's Wood Waste Hot Stove. (3)Fan Blower+Cyclone With Airlock. |

|

3.Pelletizing Process: A.This process is mainly used to product pellets with φ6-8mm. B.Biggest Capacity: 2.5-3 Ton/Hour/Set. C.The customer chooses 2 sets of TONY brand Vertical Ring Die Pellet Machine TYJ760-III-160KW with capacity 5-6 Ton/Hour. Main Parts: (1) TONY's new Vertical Ring Die Pellet Machine. (2) Cyclone And Bags Dust Collectors. (3) Bearings Automatic Lubrication System. (4) Electrical Cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

|

4.Cooling Process: A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃. B.The customer chooses 1set of TONY Galvanized Cooler Separator with capacity 5-6 Ton/Hour. Main Parts: (1) TONY's new Galvanized Cooler Separator With Vibrating Screen. (2) Cyclone And Bags Dust Collectors. (3) Fan Blower. (4) Connect Pipes. |

|

5.Packing Process: A.This process is mainly used to pack pellets to 15-50KG/Bags &1 Ton/ Bag B.The customer chooses 1 set of TONY Semi-Automatic Packing Machine& 1 set of TONY brand Ton Packing Machine Main Parts: (1) TONY's new TONY Semi-Automatic Packing Machine&Ton Packing Machine. (2) Sew Machine,Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With TONY For The Price Difference. (3) Bags Transportation Conveyors. (4) Feeding Inlet Silo With 1㎥. (5) Electrical Cabinets. |

TONY Detailed Design 3D Layout With Detailed Size For 5-6Ton/Hour Hazelnut Husk Pellet Line According To Cusomer Factor Size

Advantages of Hazelnut Husk as biomass pellet fuel:

1. Regenerative Advantages Of Biomass Pellet Fuel

Biomass pellet fuel raw material sources are more extensive, it can be produced by: crop straw, forestry processing scraps and so on processing, biomass pellet fuel is different from coal, oil, natural gas and other traditional fuels non-renewable, coal, oil, natural gas is used a little less, one day will be exhausted. Biomass pellet fuel is renewable energy, as long as the earth has air, water, soil, sun, we have enough plant raw materials to use.

2. Storage Advantages Of Biomass Pellet Fuel

Biomass raw materials after the biomass pellet machine compression molding, its volume is greatly reduced to make it easier to transport, storage and use, to solve the key problems of large-scale utilization of biomass, so biomass pellet fuel is very suitable for biomass power generation, industrial boiler clean energy transformation, rural new cooking fuel.

3. Environmental Advantages Of Biomass Pellet Fuel

The diameter of biomass pellet fuel is generally 8~10 mm, the length is 4~5 times its diameter, the crushing rate is less than 1.5%~2.0%, the dry base water content is less than 10%~15%, the ash content is less than 1.5%, the sulfur content and nitrogen content are less than 0.07%, and the carbon content is less than 0.5%. The environmental emissions of biomass pellet fuel meet the emission standards of gas-fired boilers.

4. Cost Advantage Of Biomass Pellet Combustion

Biomass pellet fuel is the use of all kinds of waste, after processing, not only to solve the pollution of waste to the environment, but also to replace coal, for combustion in the boiler. In the biomass pellet fuel dedicated combustion equipment, the fuel utilization rate is comparable to that of coal, which is one-third of the cost of gas-fired boilers and one-fourth of the cost of electric boilers. In terms of replacing high-cost energy sources such as gas, biomass pellet fuel has inherent advantages.

Adjusting energy structure and using biomass energy is an inevitable choice. Biomass raw materials after the biomass pellet machine compression molding, its volume is greatly reduced to make it easier to transport, storage and use, to solve the key problems of large-scale utilization of biomass, so biomass pellet fuel is very suitable for biomass power generation, industrial boiler clean energy transformation, rural new cooking fuel. The promotion of biomass pellet fuel has greatly exploited the environmental protection and cost advantages of biomass fuel, coupled with the support and promotion of national policies, and the development of biomass pellet fuel has been thriving in recent years.

Biomass pellet fuel is the inevitable trend of fuel development.

Biomass fuel is mostly hazelnut husk, rice husk, peanut husk, corncob, oil tea husk, cottonseed husk and "three leftovers" after processing block environmental protection new energy.

According to the classification standards of biomass particles in Sweden and the EU, if the classification value in the middle is taken as an example, biomass particles can be roughly described as the following characteristics: The diameter of biomass particles is generally 6 to 8 mm, the length is 4 to 5 times its diameter, the crushing rate is less than 1.5 percent to 2.0 percent, the dry base water content is less than 10 percent to 15 percent, the ash content is less than 1.5 percent, the sulfur content and chlorine content are less than 0.07 percent, and the nitrogen content is less than 0.5 percent. If additives are used, they should be agricultural and forestry products, and the type and amount used should be indicated.

The EU standard does not put forward a specific value for the calorific value of biomass pellets, but requires that sellers should be marked. Swedish standards require that the calorific value of biomass pellets should generally be 16.9 megajoules. The research and development of bioenergy technology has become one of the major hot topics in the world, and has attracted the attention of scientists and countries all over the world.

Many have developed corresponding development and research plans, such as Japan's Sunshine program, India's green energy project, and the United States' energy farms, among which the development and utilization of bioenergy occupies a considerable share. Many foreign bioenergy technologies and devices have reached the degree of commercial application, compared with other biomass energy technologies, biomass pellet fuel technology is easier to achieve large-scale production and use.

In the past two years, the utilization rate of biomass pellet fuel has begun to rise, and it has also begun to pay attention to the green fuel of biomass fuel. Some biomass particles in many regions have entered the stage of large-scale and industrialized development, and the use of biomass fuel is expected to reach popularity in the future.

1. Background Of The Project:

With the rapid development of the global economy and society, the issue of energy security is becoming more and more prominent. Vigorously developing biomass energy is an important part of the global energy strategy and the only way to achieve sustainable development of energy. In order to accelerate the development of biomass energy industry. Many countries have introduced various policies to encourage the development of biomass pellet energy, coupled with the global existing forest reserves and a large number of crop surplus products, biomass pellet fuel will have great prospects for development.

2. Which Machines Can Replace Coal With New Energy Biomass Pellet Fuel ?

This can be based on your raw material and production requirements. A complete set of biomass pellet production line processing equipment mainly includes: slicer, crusher, dryer, biomass pellet machine, cooling machine, packaging machine and so on. Taking hazelnut husks as an example, the main use of efficient shredders, dryers, biomass pellet machines, coolers and packaging machines are optional.

3. What Is The Budget For The Biomass Fuel Processing Line?

It depends on your raw materials and production requirements. Also do not want to cheap, to take into account the manufacturer's reputation, product design and quality, mold service life, is not to provide technical guidance and training and equipment installation and commissioning, and even the warranty and later supply of various parts are all aspects that you have to consider. Tony has more than 20 years of experience in the industry, serving customers worldwide, you can contact us to find out more about the Hazelnut husk pellet line.

2024 Tony Machinery - All Rights Reserved. Map