Russia— 15-20Ton/Hour Wood Log Pellet Line

Project Brife Introduction:

|

1.Project Name:Wood Log Pellet Line

2.Raw Material: Wood Logs Without Barks

3.Moisture Of Raw Material: Wet Type 45-55%

4.Capacity:15-20Ton/Hour

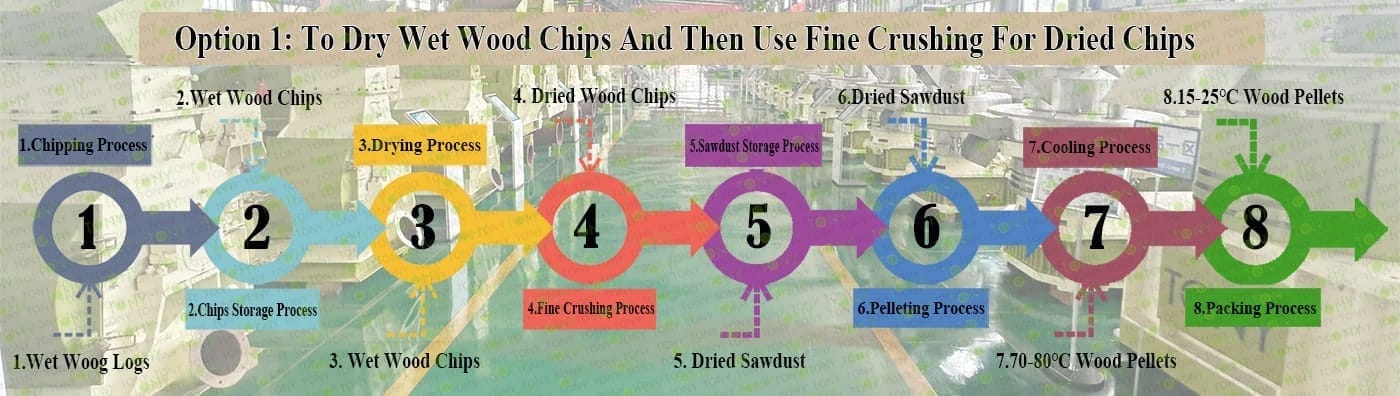

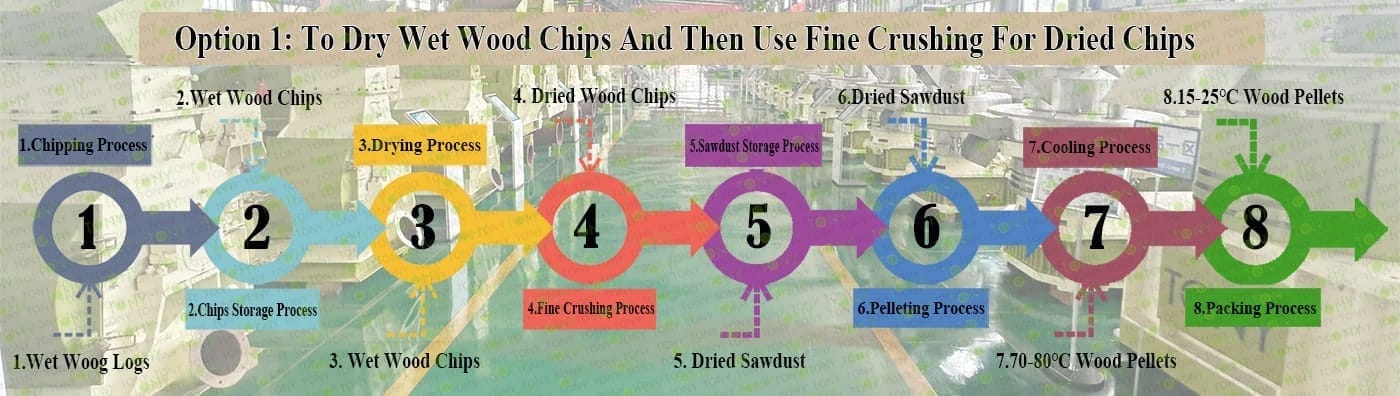

5.Process:1.Chipping Process→2.Wood Chips Storage→3.Drying Process→4.Fine Crushing Process→5.Dried Sawdust Storage→6.Pelleting Process→7.Cooling Process→8.Packing Process

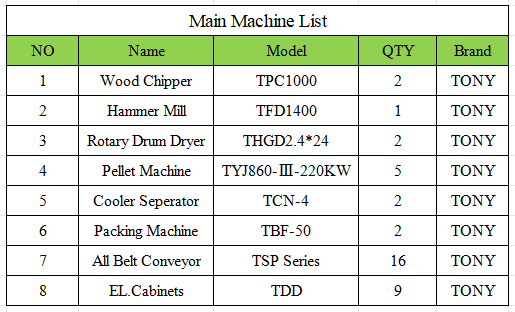

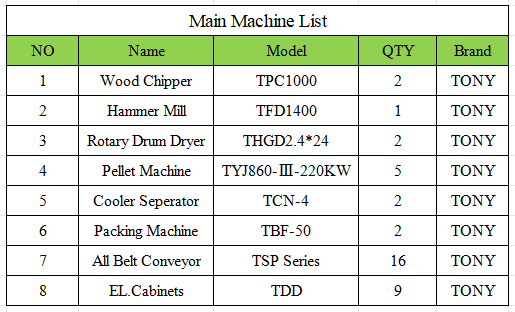

6.Main Machine: Wood Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet MachineTYJ850-III-220KW,Pellets Coller,Packing Machine And Belt Conveyors.

7.Total Power: About 1700KW

8.Need Area: About 2000-3000m㎡

9.Project Country: Russia

10.Voltage:380V,50HZ

|

Production process:

Equipment list:

|

It mainly contains the following steps and machines as following:

1.To Use TONY Wood Chipper To Grind Wood Logs φ ≤20cm Into 30-40mm Wood Chips.

2.To Use TONY Hammer Mill To Crush 30-40mm Wood Chips Into 8-14mm Sawdust.

3.To Use TONY Single Layer Rotary Drum Dryer To Dry The 45-55% Sawdust Into 10-15% Sawdust.

4.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm.

5.To Use TONY Galvanized Coller To Cool Pellets From 80-90℃ to 20-30℃.

6.To Use TONY Semi-Auto Packing Machine To Packing Pellets To 15-50KG/Bags.

You can contact TONY to get for more details information and quoation.

TONY can supply you all the products as above with competitive price and excellent quality.

|

Customer Site:

|

|

|

|

|

|