Biomass pellet machine is not a single device, but continues to iterate with changes in raw material characteristics and application scenarios, further consolidating its "necessity":

1. Special pellet machine for different raw materials:

Straw raw material fibers are coarse and waxy, and need to be equipped with a high torque ring mold granulator (compression ratio 1:8-1:10);

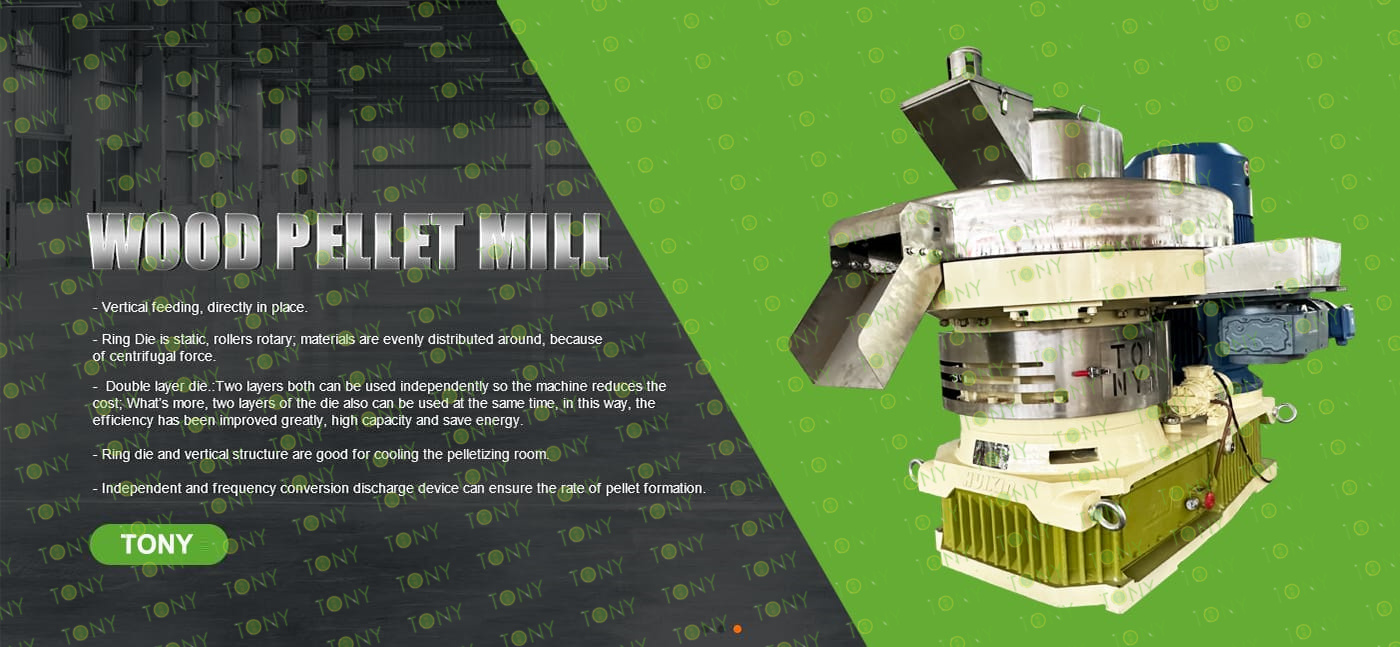

Wood chip raw materials have high lignin content, and wood pellet machine can be used (reduce energy consumption);

For organic waste such as livestock and poultry manure, organic fertilizer pellet machine need to be equipped with pretreatment equipment (dehydration, fermentation) to expand to the "biomass + organic fertilizer" coproduction scenario.

2. Intelligent and large-scale upgrades:

Modern pellet machine have achieved fully automatic production lines (raw material crushing - drying - granulation - cooling - packaging integration), and the production can reach more than 10 tons per production line, meeting the needs of large biomass power plants and heating companies; at the same time, the energy consumption and particle quality of equipment are monitored through IoT technology, further reducing operating costs.

The advantages of biomass fuel (resource circulation, environmental protection, energy substitution) can only stay at the theoretical level if it is separated from the pellet machine; and the technological progress and popularization of the pellet machine can further amplify the advantages of biomass fuel (such as reducing costs and expanding application scenarios). The relationship between biomass pellet fuel and biomass pellet machine, coupled with the multiple driving force of policies, markets and technologies, makes the development of biomass pellet machine inevitable - it is not only an iteration of equipment, but also a "infrastructure" demand for the transformation of the global energy structure and the development of the circular economy.