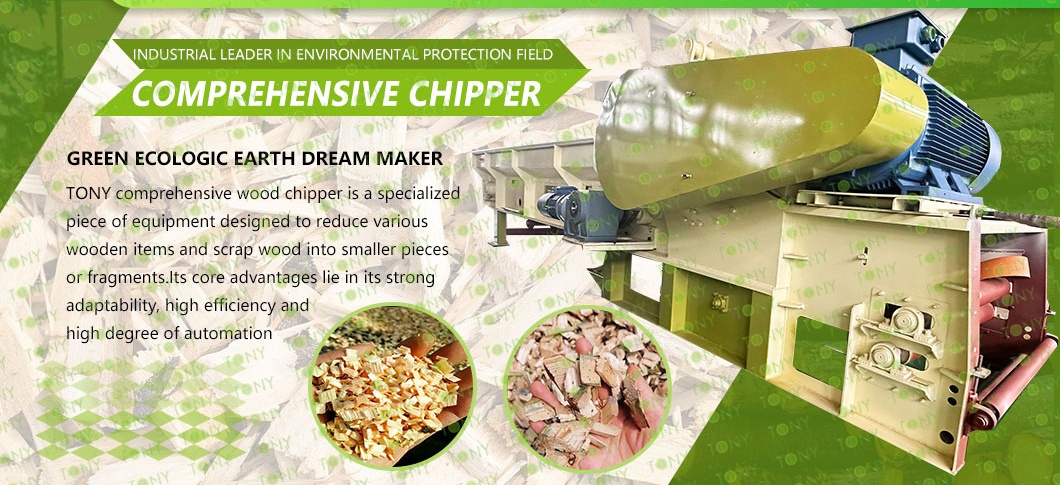

The Comprehensive chipper (also known as a multi-function crusher) is specially designed for the production of biomass pellets. It can efficiently process a variety of raw materials (such as wood chips, branches, straw, bark, bamboo chips, etc.). Through crushing and crushing, the raw materials are processed into pelletized materials with uniform particle size (usually 2-5mm), laying the foundation for subsequent drying and granulation. Its core advantage lies in its versatility and energy-saving design:

1. Applicable material scope

Wood raw materials: logs, waste wood, furniture scraps, sawdust, etc.;

Crop straw: corn stalks, wheat stalks, rice husks, cotton stalks, etc.;

Other biomass: bamboo, palm shells, sugarcane bagasse, etc.

2. Energy-saving characteristics

High-efficiency crushing structure: adopts a combination design of blade + hammer to reduce the energy consumption of repeated crushing of raw materials. The unit raw material crushing power consumption is 15%-20% lower than that of ordinary crushers (the ordinary crusher is about 8-12kWh/ton, and the integrated crusher can be reduced to 6-9kWh/ton);

Frequency motor drive: Automatically adjust the speed according to the hardness of raw materials (such as the speed of hardwood is increased and the speed of straw is lowered) to avoid the energy waste of "large horses pulling small cars";

Synchronous optimization of feeding and crushing: equipped with automatic feeding devices (such as conveyor belt + magnetic separation and decomposition), reduce manual intervention and downtime, increase the processing volume per unit time (produces 1-3 tons for small and medium-sized equipment, and can reach 5-10 tons for large equipment), and indirectly reduce unit energy consumption.

3. Value for pellet production

The particle size of the crushed raw materials can reduce the heat consumption of the subsequent dryer (uneven particle size will lead to a longer drying time and an increased energy consumption), while reducing the wear of the granulator mold and extending the equipment life.

In production industries such as wood chip pellets and biomass pellets, energy saving is the key to reducing production energy consumption and improving efficiency, and comprehensive crusher are the core energy-saving equipment for raw material pretreatment.