The wood chip pellet industry is becoming increasingly mature, and there are some established standards. These can be called the common knowledge of pellet machines. Understanding this knowledge is of great help for you when purchasing equipment.

1. The output of the fuel pellet machine is measured in hours, such as 1.5 tons per hour.

2. The moisture content of the raw materials entering the pellet machine must be below 15%.

3. The size of the raw materials entering the pellet machine must be sawdust-like.

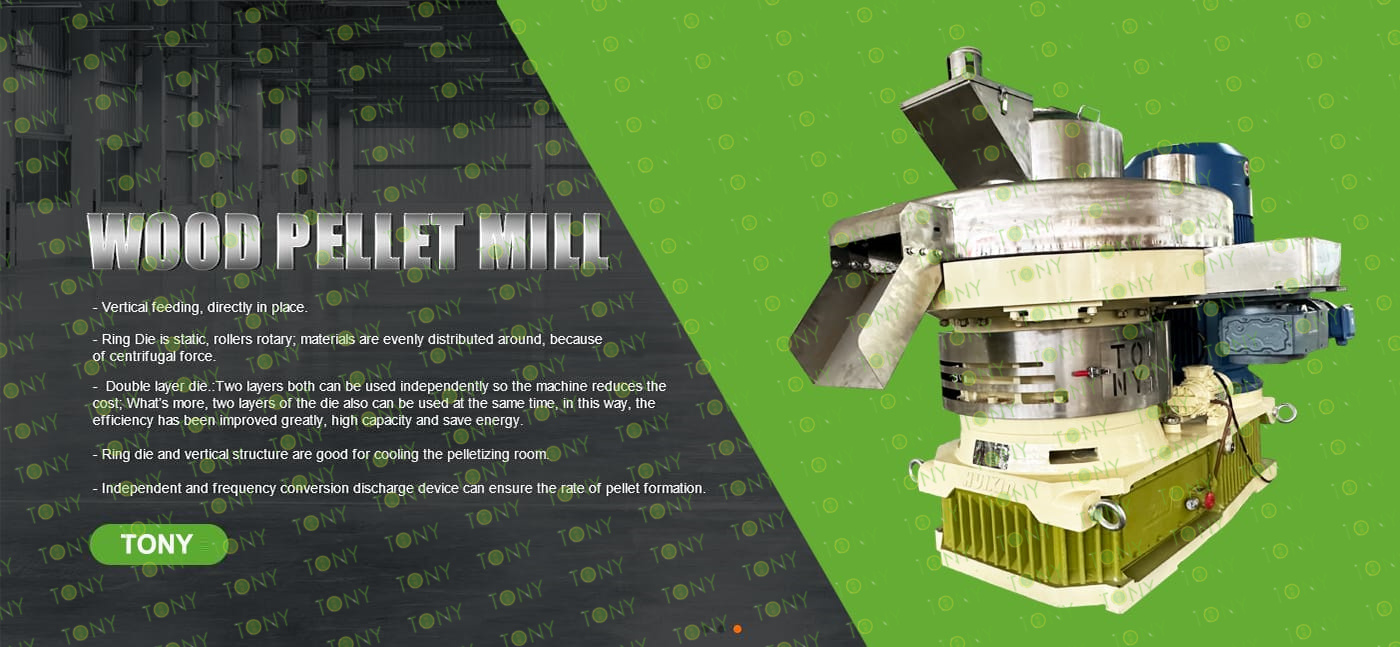

4. The main models of pellet machines are vertical ring die pellet machines, and the models vary from factory to factory.

5. To make biomass fuel pellets, only centrifugal high-efficiency pellet machines can be used, also known as vertical ring die pellet machine.

6. "The mold is oriented vertically, the feed is vertical, there is no arching, easy heat dissipation, the rotating roller rotates, the material is centrifugal, distributed evenly, two sets of lubrication, large shaft roller, double-layer mold" — These advantages are the advantages of centrifugal high-efficiency pellet machines, not the advantages of a certain manufacturer's equipment, any pellet machine has these features.

7. Wood chip pellet machines can not only be used for wood chips, but also for straw, medicinal residue, garbage, sludge, etc. They can do many kinds of things. Wood chip pellet machines can not only be used for wood chips, but also for straw, medicinal residue, garbage, sludge, etc. They can do many kinds of things.

Understanding these 7 common knowledge about granulators will help you choose the appropriate granulation equipment more easily. There are many similar common sense points, and we will update them continuously. Welcome to follow us at Shandong TONY.