In winter, biomass pellet machine are the most operational in the year. Maintenance and maintenance in winter are very important for leveraging the performance of biomass pellet machine and extending the service life of biomass pellet machine. Only by reducing the maintenance frequency and shortening the maintenance time can we seize market opportunities during the peak sales season of biomass pellets and make a lot of money.

Therefore, the maintenance and maintenance of biomass pellet machine in winter is the guarantee of normal production throughout the winter. In this article, the editor will provide a detailed introduction to the seasonal maintenance of pellet machine equipment in winter to ensure that every customer can produce smoothly and efficiently during the peak season of pellet demand.

First, it is very important to replace the special lubricating grease for the fuel pellet machine in winter as soon as possible. Special lubricating greases for winter can ensure that they continue to work in low temperatures, thereby reducing the cost of using consumable parts.

Second, identify freeze-dried and dried materials to provide guarantees for the normal operation and work of the biomass pellet machine. In cold winters, the temperature often blocks and freezes the moisture inside the material due to the drop in temperature, which makes it difficult to squeeze the biomass pellet machine. At this time, using a simple method - the feel, there will inevitably be great errors. We recommend using a special wood chip moisture tester for scientific measurement.

Third, the oil in the mold is blocked from the hole. The mold is the heart of the biomass pellet machine. Regularly inspect the mold and clean the metals and impurities in the mold holes. After the work is completed or the use is discontinued for a long time, oil must be used to block the holes to prevent working materials from being left in the mold holes and cannot be taken out in the cold winter.

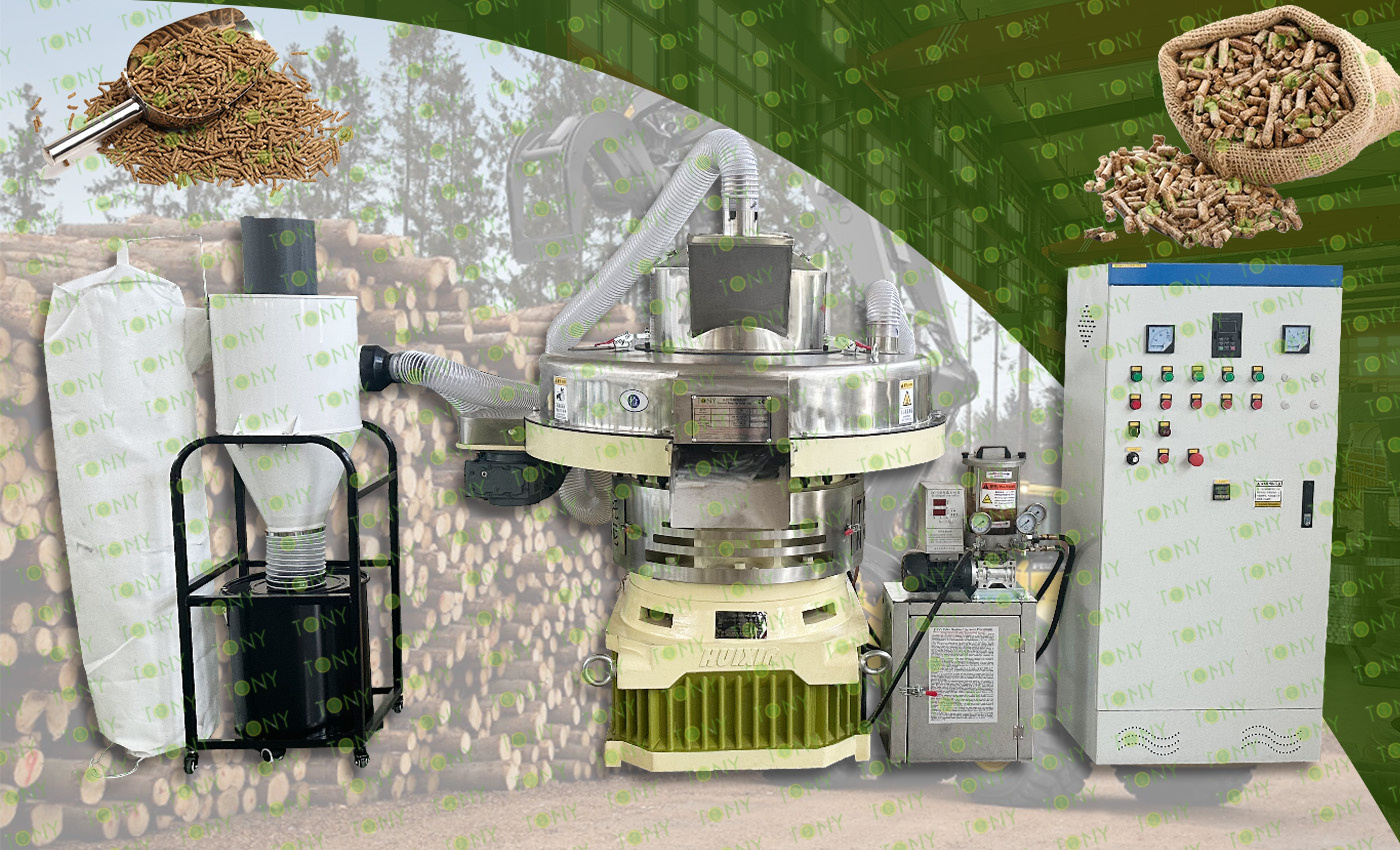

Fourth, the most important thing is to choose the biomass pellet machine produced by TONY, Zhangqiu, Jinan. Our motors and reducers are all produced by themselves. The motors are energy-saving motors and the reducers belong to the high torque series, which have significantly improved energy saving and production efficiency. The most important thing is that the TONY brand pellet machine is not afraid of the cold and can still operate continuously in extreme areas, bringing considerable economic benefits to users.

Biomass pellet machine are like cars we use every day, with three parts of use and seven parts of maintenance. Only by implementing this law can the good performance of biomass pellet machine be maximized. For more biomass pellet machine usage issues and industry information, please follow our TONY company official website, or contact us directly