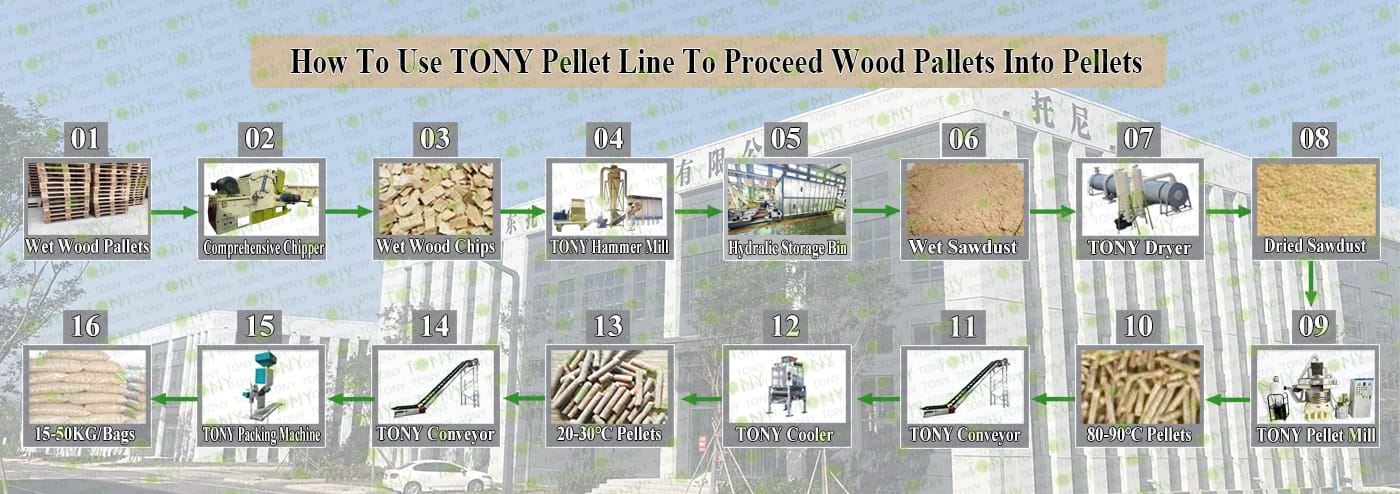

Do you know how wood chips turn into biomass combustion pellets? Today, the TONY pellet machine manufacturer will introduce to you the work flow of the wood chip pellet production line.

First, the broken wood chips are fed into the crusher through a conveyor for crushing.

The crushed materials are dried through a belt conveyor and then dried. TONY supports custom dryer models

The dried saw wood is then sent into the wood pellet machine through a conveyor for physical extrusion. Processed into high-density rod-shaped combustion pellets. Finished pellets are rod-shaped, with high density and higher calorific value than wood chips

The temperature of the newly processed finished product pellets is 70-80℃, which is not suitable for direct packaging of bags. At this time, a cooler needs to be used, which can quickly and at one time reduce the temperature of the finished pellet to the indoor temperature for easy packaging.

Then it is conveyed into the automatic weighing and baling machine through a conveyor for weighing and packing. The weighing range of semi-automatic packaging machine is 25-50kg

This is the whole process of turning wood chips into burning pellets. Do you know?