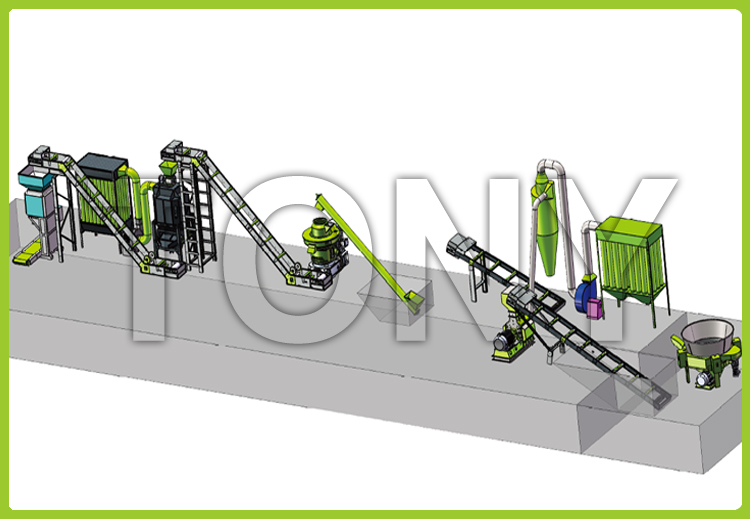

There is no doubt that biomass pellet fuel has a market prospect, and if you have enough raw materials suitable for processing pellet fuel, you can consider building a pellet processing plant, but before you make this decision, know these 10 questions:

1.What are your raw materials?

There are so many raw materials that can be made into pellets, from the common sawdust and logs, to EFB, bamboo, crop straw, grass, biomass pellets, as long as the biomass can be burned can be used to process biomass pellets. The raw material determines everything, it determines the burning value of the particles, it determines whether you need a crusher or dryer to adjust the size and water content of the material, it determines what type of pellet machine you need, and so on.

2. What is the water content of the raw material?

When talking about pellet production, the water content of the raw material is a key factor that you need to scrutinize carefully, and you may not know that a higher water content will increase the cost per pellet because you need more investment in drying equipment to dry the raw material to an acceptable level of moisture content.

3. What is the initial size of the raw material?

Making pellets is not simple, it's not just about feeding any shape of material into the granulator and waiting for the pellets to come out. In fact, we encounter a variety of materials in different shapes, they may be powders, blocks, wood chips, or even whole tree trunks, but the production of pellets needs to be done in a moderate and smooth way. That's why you can always find shredders in pellet plants, which aim to cut raw materials at uniform dimensions.

4. What size pellets do you need?

In the wood pellet industry, the size of the particle refers to the diameter of the cross-section, 6mm, 8mm and 10mm are three commonly used sizes, but if customers need other sizes, pellet manufacturers can meet your requirements by re-adjusting the ring mold, the ring mold is a key part of the biomass pellet machine, directly determine the diameter of the particle.

5.Will you need the pellets cooler?

The temperature after the pellet machine will be about 70-80℃, it is better to use pellets cooler to cool down pellets from 80℃ to 20-30'℃ for quality pellets.

6. How is your power supply?

Different areas may have different power conditions. For example, in China, the industrial power supply is below 380V, 50Hz, three-phase, while the residential conditions are below 220V, 50Hz, single-phase, this is not a big deal, but please contact the pellet machine manufacturer and make sure to provide them with the correct data so that they can do the correct power calculation for you.

7. How many ingredients can you provide per hour/day?

More raw material supply means that more pellets can be produced, and also means more investment funds, for example, if your raw material supply is 1 ton per hour, then a pellet machine is enough to complete this task, but if you have 10 tons/hour of raw material supply, you will definitely need a large volume of pellet machine, pellet machine accounts for a large part of the cost of the entire pellet factory. Calculate carefully and find the correct value.

8. What is the purpose of processing pellets?

You can either sell them for profit or use them for your own projects, if you plan to sell pellets, there are two conditions, one is to find out the price of pellets in the local market, and calculate the cost per ton of raw materials that you can accept, and the cost of production equipment that you can accept, after you know all the information, you can set a sales price that suits your profit.

Another is that in order to sell pellets, you need to buy a packaging machine to put pellets in bags, so that it is easy to transport and promote your brand.

9. Which port in your country will be used to receive the product?

If you choose a domestic supplier, they offer FOB (free on board) prices, however, if you know the information, you can also use CIF (cost, freight, insurance) prices, for those who intend to sell pellets overseas, for their own benefit, clear information about the seaports.

10. What are the local environmental requirements? What is the subsidy policy?

Dust occurs during the drying process and pellet production, and while dust collectors reduce dust emissions as much as possible, they still need to comply with local environmental regulations for industrial production, and because pellet fuel is known as a renewable and clean energy source, many governments encourage it by providing subsidies to energy producers.

The above are the "top ten" questions that TONY needs to know about the establishment of a biomass pellet processing plant. I hope it will be helpful to you. If you have any questions, please feel free to contact us